floor jack safety valve adjustment pricelist

An overload valve of a floor jack primarily exists so that the jack does not exceed the weight limit of the hydraulic press, which might cause it to break down. Overload valves stop the press from lifting further up if the weight limit is crossed.

The floor jack overload valve adjustment process is very straightforward and only requires you to follow a set of simple steps. However, if you’re trying to adjust the overload valve, chances are that your floor jack is having some trouble holding pressure. In that case, we have some solutions for that as well.

An overload valve is a safety measure to protect the hydraulic press from unwanted damage due to excessive pressure. It works by loosening the connection between the jack handle and the hydraulic press.

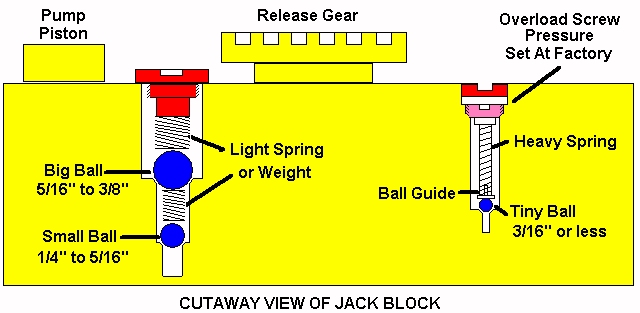

When we’re talking about adjusting the overload valve, we’re mainly changing the max weight capacity of the floor jack. To do that, you just need the right screwdriver. It varies from model to model, some use Philips heads while others use binding heads.

Once you’ve got the right screwdriver, find the location of the safety valve. There will be a shield on top of it that you’ll have to remove with the screwdriver. Spot the screws and turn them counterclockwise to release the shield.

After you’ve done that, the valve should be exposed to you. There are mainly two types of valves used on floor jacks. The handle valve and the screw valve. Handle valves have a handle, while screw valves have a hole for the screw to go through.

For a handle valve, you just have to hold on to the handle and rotate it to adjust the weight overload on the floor jack. Rotate it clockwise to increase the maximum weight capacity and counterclockwise to decrease it.

These valves are typically very sensitive so a small turn could drastically change the output. So, try it in small amounts and figure out the correct amount for you.

For a screw valve, you will need a corresponding screwdriver. Typically it is the same as the shield’s screws, but according to your model, it could be different.

Safety Note: Before attempting to put pressure after adjustments, check the instruction manual of the floor jack for the maximum supported weight capacity. Normally, the valve will be set to 90% of that max capacity. So, you can at best increase it to 100%. Going beyond that will be very risky as it can damage both the floor jack and your vehicle.

This is a very common issue for which people consider adjusting the overload valve. A loose valve can indeed cause your floor jack to suffer such problems. However, that’s not the only cause.

The hydraulic press will fail to operate if the oil levels are above or below the given margins. Also, if the oil is of low quality, it might cause friction which can also prevent it from working properly. To maintain the proper hydraulic level, you should fill your jack with oil correctly and safely.

To know exactly what types of fluid are used in a floor jack, check out this article where we have explained and recommended the hydraulic fluid to use in your jack.

Hydraulics work by using highly pressurized compressed air. After long-term use, some of that air can leak into other parts of the machine causing havoc. The air mostly gets trapped in the oil chamber. To remove air from the floor jack, you just need to bleed it.

The final most obvious consideration would be that the floor jack is damaged. In most cases, it’s the hydraulic press. Repairing a broken floor jack is not worth the effort and the money. You’re better off getting a new floor jack.

Keep in mind that the overload valve is a safety measurement. So, a floor jack overload valve adjustment should only be done under your own circumstances. To be on the safe side, never exceed the given weight limit of your floor jack.

The RFJ-3TP is a versatile lifting machine designed to meet a variety of everyday duties. Capable of handling a full 6,000 lb. load, this trusty floor jack is made out of heavy gauge steel to ensure maximum durability under tremendous pressure. As with every Ranger floor jack, the RFJ-3TP exceeds all ANSI standards in performance and safety

The ruggedly crafted RJF-3TQP is a versatile quick-lifter with a 3-Ton lifting capacity. Heavy steel construction and sealed hydraulics guarantee maximum durability, while the built-in safety overload valve protects personnel and equipment. Plus, with the exclusive "Quick-Pump" feature, this jack rises to the chassis challenge with only a single pump of the handle. The RJF-3TQP represents the ultimate in jacking speed and convenience

The Ranger model RFJ-3000AL Aluminum Quick Jack is made of the strongest aircraft alloy aluminum available. Not only does it weigh in at a feather-light 39 lbs., but it gets any racecar or hotrod a full 15" off the ground in just a few pumps of its knurled aluminum handle. With a low 3-1/2" profile front-roller, the RFJ-3000AL is perfect for working on ground-hugging, low ground-clearance performance vehicles.

The RFJ-3T is a professional grade garage floor jack that sports a 6,000-lb. maximum lifting capacity and flanged side plates for extra strength where you need it most. Double-sealed hydraulics and a sturdy steel construction help to protect your investment, while the clever universal-joint release system and roller cam plunger assembly make operation a breeze.

The RFJ-6HD 3-Ton "Low Rider" Garage Floor Jack is a true heavy lifter. With a 3-ton lifting capacity, "Quick-Pump" design, durable heavy steel construction and emergency overload system for safety, the RFJ-6HD is the jack to wheel out when working under a hefty ground-hugger.

Whether you need a tool for roadside tire changes or you plan to work on your car’s undercarriage, investing in one of the best car jacks is a good idea. The standard scissor jack or lift jack included in most tire replacement kits can get the job done, but they’re difficult to use and often less safe than alternatives.

If you perform any kind of at-home car repairs or tune-ups, you’ll want to invest in a quality floor jack. These recommendations are a good place to start your search. We’ve made an effort to suggest car jacks with various clearances, ton capacity, and price points.

The Torin Blackjack is a low-profile floor jack that is made with heavy-duty steel. A built-in safety overload system prevents lifting beyond load capacity. We like this floor jack because it is very easy to use, rolls nicely on its casters, and is simple to assemble.

While the instructions included with the Blackjack are practically useless, it isn’t too difficult to figure out how to assemble and operate this floor jack. The handle has a comfortable grip, and the low-profile jack easily slid under our test vehicle.

The release valve is integrated into the handle, which you twist when it’s time to lower the pump’s hydraulics. Among the car jacks that we tested, the Blackjack stood out as the strongest, lifting our vehicle with the least effort on our part.

Those who like the Blackjack appreciate its heavy-duty construction and low-profile design. Many are impressed with the value given the relatively low cost of this car jack. It is easy to maneuver with a long handle.

Some people received the Blackjack with parts missing or with broken swivel casters. While this isn’t common, there are multiple complaints on Amazon about this specific issue. There are also reports that customer service is slow and difficult to contact.

This low-cost, low-profile floor jack has a lifting range up to 14.0 inches. It has a 3.5-inch clearance, making it suitable for low-riding vehicles. A built-in safety valve prevents over-pumping and overloading this car jack. We like it for the price and ease of operation.

The F-767 is not as ruggedly built as the Torin Blackjack. However, it is made from alloy steel construction and is generally easy to use. The lever design offers an easy way to raise your vehicle, and this device is ultra low profile (just under 4.0 inches).

Users with low-riding cars especially seem to appreciate this car jack, which is able to neatly slide under such vehicles. The majority of reviews are comments from those who were happy to report that the jack works as advertised with no issues.

There are reviewers who say that they were shipped jacks with missing parts. This appears to be rare, but it can be very annoying if it happens to you. Some also say that it is a little short, and would prefer a jack able to raise their car higher.

The Blackhawk B6350 is a beefy car jack with a weight limit of 3.5 tons for larger vehicles. This steel floor jack has a lifting range of 5.5 to 22.0 inches and built-in safety valves for overload protection. It features an extra-long handle for greater leverage and is the most powerful car jack that we tested.

Operating this hydraulic jack is similar to the other floor jacks that we tested – insert the handle, tighten the release valve, and pump. The included instructions are easy to follow. Generally, we were impressed with the construction and material quality of this car jack. The handle is very long which makes operation easier, and it is covered in a comfortable foam. It has a fast lift speed and is made of high-quality materials.

Though quite heavy, this jack isn’t difficult to maneuver on its wheels. It does take two people to lift, however. This is the least portable jack we tested.

Most are impressed with the high load weight offered by this relatively inexpensive car jack. According to customer reviews, this is a long-lasting jack.

Some have reported poor welds on the handle, which broke for a handful of customers. Aside from that item, the jack is well-constructed. It may ship low on hydraulic fluid (and need to be topped off), but most are satisfied with a jack that can lift 3.5-ton vehicles at this price. The Blackhawk seems to be an especially popular jack for DIY mechanics.

This tiny bottle jack has a 10.0-ton lift capacity (6.0-, 8.0-, 12.0-, 30.0-, and 50.0-ton versions are also available). It can lift vehicles up to 18.13 inches and comes with a one-year warranty. This bottle jack’s small size makes it highly portable, but the design means that it won’t fit under vehicles with low clearance. It did not fit under our first test vehicle (a sedan), so we tested it on an SUV with a higher chassis.

The Big Red hydraulic bottle jack is easy to carry and position, weighing only around 10.7 pounds in total. When first using this jack you must follow the instructions to remove excess air and possibly top up the hydraulic fluid.

The lever is shorter than with floor jacks and doesn’t include a comfortable handle. It also fits together awkwardly – one part slides into the pinched end of the other, and rests that way, somewhat wobbly.

Besides positioning, this jack is harder to use than the standard floor jack, but still not difficult. It has a very high load capacity (10.0 tons) and easily raised the test vehicle.

Many write that this is an excellent option for high-clearance, heavy vehicles. It has a high weight capacity and its portability makes it a popular choice for changing spares. Be sure that it is stored upright, however, as bottle jacks can leak fluid otherwise.

Some have complained about receiving jacks that leak fluid. In the worst case, a few people got packages wet with hydraulic fluid. It’s annoying to need to clean and maintain your new product, but given the shipping distances, this isn’t entirely unreasonable.

The Big Red floor jack is a good low-cost option for a strong car jack. This jack has a maximum lift height of 20.88 inches. It uses a single-piston quick lift pump and is designed with a safety bypass system to prevent overloading.

This car jack comes with an extra-long saddle neck which can save you some pumping when lifting raised vehicles. The neck extension can be removed for lower-clearance vehicles. We found this car jack easy to use if not quite as well-constructed as our other top picks.

What most distinguishes the Big Red floor jack from the other jacks in this review is the neck extension. This positions the jack saddle higher to begin with, meaning less pumping to lift a car. This is helpful if you have a raised car, though is not necessary for low-profile vehicles like our test car.

This car jack is as easy to operate as any well-designed floor jack. However, the handle design doesn’t seem as sturdy or as comfortable as the Blackjack or F-767. Still, we were able to raise and lower our test vehicle with ease using this floor jack.

Happy reviewers like how this jack works, and many mention the extended saddle neck as an appreciated convenience. Several report years of reliable use from this car jack, which is easy to maneuver and pump.

There are some comments about faulty welding on the wheels. Though uncommon, more than one reviewer posted complaints about the wheels failing. Another typical criticism is that the jack lowers too quickly. Some write that when the pressure valve is released the jack falls down very quickly. We did not experience this when we tested the Big Red floor jack, but this issue may be more common with heavier vehicles.

Scissor jacks are accordion-looking contraptions found with many spare tire kits. These jacks use a screw mechanism to raise your vehicle. They are slow and can be difficult to use.

Floor jacks are large and heavy, but stable and easy to use (if more difficult to maneuver). These are the most common type of jack for a garage or workshop.

Bottle jacks are small and bottle-shaped. These often operate with a lever and are easy to use, but can’t lift as high as a floor jack. A bottle jack is a good option for a portable jack but a poor choice for a car with low clearance.

When selecting a jack, you need to pick something that will fit underneath your vehicle before you begin to lift it. Some sports cars and luxury vehicles have especially low clearances, so require a low-profile jack to elevate. When purchasing a jack, consider your vehicle’s clearance compared to the jack’s.

Also, consider a car jack’s maximum lift height. If you have an especially high vehicle like an SUV, smaller jacks may not raise high enough to hoist your car off the ground.

Any car jack is rated to lift a certain tonnage. If you’re buying a car jack to lift your vehicle for repairs, pick something with a weight rating to match the vehicle you’re trying to lift. Keep in mind that to change a tire, you’ll only need to lift half the weight of the vehicle. You should be able to find your vehicle’s weight on the door panel or owner’s manual. The typical sedan weighs around 3,000.0 pounds, while trucks can weigh around 8,000.0 pounds.

How you plan to use your car jack should determine which type of jack you get. If you want to raise your car so you can get under the body to tinker around, you’ll most likely want a floor jack. These are the most stable and provide the best lifting power.

Floor jacks can be large and heavy, so they aren’t reasonable to carry in your trunk at all times, should you get a flat. If you need a car jack for spare tires, a scissor jack or bottle jack will serve you better (keep in mind vehicle clearance if you get a bottle jack, which may not fit under your car unless you have a truck or SUV).

If you need to jack up your vehicle, a floor jack is typically the universal choice for its ability to lift vehicles higher than a bottle jack. Most vehicles also come with a scissor jack that can support the weight of your vehicle but may not be compatible with other car models.

You don’t need to be a professional mechanic to use a car jack, and many jacks are simple to operate. However, there are some steps you’ll want to consider to keep yourself and your car safe. Additionally, drivingtests.org has a detailed guide should our instructions here not suffice.

Before raising your car, you should also have jack stands and wheel chocks. Jack stands support and stabilize your car after it’s been lifted. They are a crucial safety component if you plan to work under your car while it is elevated. Any jack, especially a hydraulic jack, can fail and if that happens jack stands will prevent you from being crushed. Wheel chocks stop your car from rolling while it is elevated.

Before lifting your car from the ground with a car jack, make sure that it is on a level surface, in park, with the engine off, and the emergency brake engaged. If you have wheel chocks, place those behind your wheels.

You don’t want to place the jack just anywhere before lifting your car. If you put it in the wrong spot it can damage your trim or undercarriage. Consult your owner’s manual to find the jack points – typically a reinforced metal plate just behind each front wheel and just in front of each back wheel.

Slide the car jack under your vehicle and start lifting. If you’re using jack stands, set those up once your car has been raised and before you get to work.

Hydraulic floor jacks often need maintenance, sometimes even when new. Before using your jack, be sure to inspect the welds and bolts. Make sure there are no cracks and that every screw is fully tightened. If your car jack isn’t lifting properly it may need bleeding, a fluid top-off, or both.

New car jacks typically don’t need oil replacement for at least a year. However, if the screw or cap covering the oil chamber is loosened or damaged during shipping, your car jack could arrive low on hydraulic fluid.

To determine if your jack is low on fluid, open the oil chamber and inspect the fluid levels. Hydraulic fluid should come up to 1/8 of an inch from the top of the chamber. If you can’t see any oil, you’ll need to add more.

A floor jack like the Torin Blackjack will offer the fastest lifting speed and most stability. However, these jacks are heavy and not something you can store in your trunk for emergencies. For changing a tire, you’ll need a bottle jack like the Big Red Bottle Jack or a scissor jack.

Regardless of which car jack you have, be sure to also use safety equipment like wheel chocks and jack stands. You may not need jack stands just to change a tire, but you should certainly use them if you plan on sliding underneath a raised vehicle.

The automotive jacks in this article went through two rounds of reviews. We started by searching Amazon for top products, looking at customer ratings, Amazon superlatives, and prices. We combed through customer reviews to find a variety of jacks that are consistently rated for quality, durability, and value.

The car jacks that best met these standards were ordered by our team for testing. A team member assembled and tested each jack on a car, lifting it several inches off the ground. Each car jack was given a rating out of 5 stars based on ease of use, durability, and value.

To test each car jack, we unboxed and assembled the jacks according to the instructions (if any were included). We placed each jack under the test vehicle and lifted it several inches off the ground. Our tester was able to note the quality of materials, ease of use, and overall performance.

Based on our testing, we think that Torin, Pro-Lift, Blackhawk, and Big Red are all excellent brands for car jacks. Many car jacks are sold by different companies but manufactured by the same factory, so in some cases, it may be worth buying whichever is cheapest.

Never get under a car that is supported exclusively by a car jack. Even the safest car jack isn’t safe enough to hold a car on its own. While all of the car jacks we recommend (Torin Blackjack, Pro-Lift F-767 Blackhawk B6350, Big Red floor jack, and Big Red bottle jack) are excellent car jacks, you should always place your car on jack stands when working underneath.

Car jacks are reliable for lifting your vehicle, changing tires, or doing work under the chassis. However, no car jack is reliable enough that you should trust it with your life. Whenever working underneath a car be sure to support the vehicle with jack stands and not your jack’s lift arm alone.

A 3.0-ton jack can safely lift up to around 3,500.0 pounds. If the thing you’re lifting is significantly lighter than that, you may not need a 3.0-ton jack. If the thing you’re lifting weighs more than 3,500.0 pounds, you’ll need a stronger jack.

If you’re lifting a car, keep in mind you may only need to lift one side of the vehicle, so if your car weighs 7,000.0 pounds, a 3.0-ton floor jack can raise it enough to change a flat tire or perform oil changes.

A 2.0-ton floor jack can lift vehicles up to around 2,400.0 pounds. This will lift some SUVs, but the typical mid-size SUV can weigh up to 5,000.0 pounds. However, when using a jack, you’re likely only lifting one side of the vehicle, and not the entire car’s weight.

Professional mechanics generally use hydraulic jacks since they can bear the entire weight of a vehicle and allow greater access to work on a variety of issues.

The best car jack stands are best suited for specific maintenance tasks like replacing tires, changing brakes, or working on the underbelly of the vehicle. In other cases, ramps are cheaper and typically safer.

In order to learn more about the process of designing a part, group 10 took apart a Big Red car Jack. The device is designed to use hydraulic fluid and one-way valves to raise a ram rod so as to lift 4-ton vehicles in order for the user to be able to change tires. The jack is operated using a removable handle, which is pumped up and down, raising the jack, which in turn lifts the car.

After testing and dissection, we concluded that the jack was both easy to use and very compact. The jack did not take very long to achieve the desired result and required minimal energy to use. In order to get a better understanding of the jack we performed Failure Modes and Effects Analysis (FMEA), Design for Manufacture and Assembly (DFMA) and Design for Environment (DFE).

FMEA allowed the group to get a better understanding of the failure modes and the impact the failure modes had on the user. One possible failure mode is the jack could slip from under the car causing the elevated car to fall on the user.

DFE showed the group the environmental impact of the jack. EIO-LCA (Economic Input Output-Life Cycle Analysis) was used to see the greenhouse gas emission over the lifetime of the product in the various sectors of the US economy. It was concluded that the production of the hydraulic fluid had the largest percentage of Carbon.

The main stakeholder for this product is the consumer. The consumer is the main person operating the device and is the one who will suffer the most if it fails. Cost, reliability and safety are a few of the needs the consumer has from the product. However, the consumer isn’t the only group that this product has an impact on. Retailers, manufacturers, and Shippers/transporters also have interactions with the product.

The Big Red Hydraulic Bottle Jack can be operated with everything in the packaging. It does not need any additional fluid, or an electrical source. The eight-pound jack can lift vehicles weighing up to 4 tons simply by moving a handle up and down. Once the vehicle is lifted the jack can maintain the car at the required height to change a tire. To compensate for different size cars, a worm screw is attached at the top tat can extend upwards to assist in the lifting of cars that are taller.

When the group tested the jack, without using the instruction, we found the jack very confusing. However, once we read the instructions and tried operating it, we discovered that the jack was in fact very easy to use. Although it was easy to use, there were some problems with the jack. It had trouble getting under smaller cars, which is understandable since it is designed for 4-ton cars. Also pumping the handle was challenging since the user had to kneel on the ground and lift the handle once it was lowered to pump it repeatedly. The release screw was also difficult to rotate by hand. However, with the handle bar inserted, the task became easier, but still challenging.

One of our group members gave the jack without instructions to another Carnegie Mellon student and had them jack up their car. Without help, the person also struggled initially using the jack, but ultimately decided that the jack was very compact and easy to use.

After doing research and self evaluations on the jack, the group has concluded that the item is very compact and light for a jack. The group also concluded that its size makes it very easy to store in a car and the design makes the jack very easy to use. Since there aren’t very many exposed moving parts and there is not combustion, the jack is fairly safe. Its steel design also makes it very robust and hard to damage. Some of the corrections the group would make is possible widening the base to prevent tipping as well as improving the handle to prevent it from getting lost. Also allowing the jack to work for a larger variety of cars cold be another improvement.

The following is an exploded view of the hydraulic jack. The parts each number corresponds to are listed below the picture and in the Bill of Materials section.

The following is a list of the 31 parts that make up the hydraulic bottle jack. Most pieces are made of steel, that has been shopped in some way, usually on a mill or a lathe. The non steel parts are either rubber or plastic and are purchased or injection molded. The table can be sorted by Part Number, Quantity, Weight, Material, and Manufacturing Process.

The jack is made up of a series of concentric cylinders each of which is pressurized and holds differing amounts of hydraulic fluid. When the handle is inserted into the pump mechanism and moved up and down, fluid is pumped from a reservoir in the outer cylinder into the space in the bottom of the inner chamber, pushing the ramrod shell upward. This fluid is kept inside the inner cylinder by a high-pressure valve located in the base of the jack, consisting of a check valve and a debris filter to keep unwanted solids from breaking the seal created by the ball bearing. The jack can be released by loosening the valve screw at the jack’s base, thus allowing the fluid to return to the outer cylinder until the valve screw is tightened again. This release of fluid will then lower the ramrod shell, lowering the car and allowing the jack to be removed. The ramrod also has a section that can be unscrewed, providing extra length to the mechanism.

Chanshu Tongrun Auto, the company that manufactures this particular product, produced roughly 10 million car jacks in 2010 [1]. As a result, the jack is made with two primary design goals: sufficient strength to lift 4 tons of material off the ground and simple, easily mass-produced parts.

Nearly all of the parts in the hydraulic bottle jack are either machined from steel stock or purchased from other suppliers, with the exception of the cast steel base and end cap. Most of the machined steel tubes appear to have been turned on a lathe in a job shop, but given Changshu Tongrun"s incredibly high output, they were probably made in some sort of automated process.

Standardize ComponentsBearings, connector pins, O-rings and washers appear to all be purchased in bulk, and can probably all be used for the different jacks that Chanshu Tongrun producesEnsure most parts are made of similar diameter pipe to the same parts used in other size jacks, to make part purchasing easier

After considering all of our system components, we identified eight major areas where our product could fail. Most of the major areas are made up of external components of the product, parts which the user interacts with while he/she operates the system: the handle assembly, the pump structure, the base, the extended screw, the alligator clips, and the valve screw. Unless the product is dissected, the remaining areas cannot easily be reached.

Even though the probability of failure of the internal components is low, their severity and detection of failure are very high. If these parts needed to be replaced it would be extremely difficult for the user to take the system apart. We recommend a design that makes these parts more accessible. That way elements such as the hydraulic liquid and parts can be changed when needed. This will allow the user to maintain the jack which will guarantee safety and durability.

BaseTips OverCar falls causing injury to the user and/or damage to the vehicle.10The jack is not properly placed under vehicle. The user does not place car supports after lifting. An uneven surface does not provide stability.4Position jack under a flat surface of the car, place supports, don"t work on uneven ground.9360Change the shape of the base, more surface area. Make a multifunctional package to use as support for base.

Valve ScrewRemoved, LeaksLoss of hydraulic fluid. Balls bearings can fall out of place.9User unscrews the valve all the way out.6The manual instructs user on how to close and open valve.5270Place a stopper in the inside to prevent user from turning the valve further once opened.

Extender ScrewPlaced on an uneven surfaceCar may slip and screw bend8Jack is not properly placed under vehicle.4Position screw surface area under a flat area of the vehicle.8224The shape of the contact area could be altered.

Handle AssemblyInner and/or outer handle bends.Cannot properly pump the car jack.7Misuse or damage by customer.4Do not overload the material. Store it in a safe place8224Design a rigid handle with a high Young"s Modulus to resist deformation.

The inner and outer handles separate.Pumping the car jack becomes difficult and can lead to injury.3The user pulls while pumping which causes separation.7While pumping make sure the outer handle does not slip out of place.5105Design a handle assembly that locks the inner and outer handle.

O-ringsWear leads to breakageLoss of hydraulic liquid10Wear2If the jack has not been used for a while or has been used for years, test that it works before lifting a vehicle.10200Change system so it"s easier for the customer to notice and maintain.

One of the components bends.Cannot properly pump the car jack.7Misuse or damage by customer.3Limit the force applied to these components.8168Use a rigid material to resist deformation. As a customer prevent damage by using the product appropriately.

This section discusses the major sources of greenhouse gas (GHG) emissions associated with this product, shown in detail in the table below. The largest source of GHG emissions from this product is the use of hydraulic fluid in the jack. This fluid is a petroleum product and is therefore made up of a large percentage of carbon. If congress were to pass a tax on CO2 emissions, the cost of the hydraulic fluid would be likely to increase, therefore increasing the initial cost and cost to maintain the jack. Cost of manufacturing the jack itself would also increase, but not so significantly as that of the fluid. That being said, overall the cost of both the jack and an initial fill of fluid is unlikely to increase by more than a dollar, so it wouldn"t have a major impact on the sales of the jack. It is important to note that there are also GHG emissions associated with disposing of the jack. Because the fuel is petroleum based, it will release CO and CO2 into the environment as it decomposes. Recycling the jack would be a better option because you could safely dispose of the fuel and reuse the steel. Additionally, GHG emissions from the hydraulic fluid could be cut down by using a more environmentally friendly fluid such as a vegetable oil based product[3] or by choosing a fluid that does not need to be replaced so often.

Another area where GHG emissions can be reduced is in the manufacturing of the jack. Already many parts of the jack are manufactured by processes with relatively low energy intensity. Most notable are the parts made by stamping and bending sheet metal, which are processes requiring relatively low energy input. The manufacturing of many other parts of the jack, such as its inner cylinders, seem to have been produced by an automated lathe machine. These processes can be designed to reduce energy usage by minimizing machinery necessary for their production.

Assumptions*30 year lifetime*Jack is frequently used and maintained *Replaced oil every 2 years [4] *Oil costs $5 for 32oz [5]*Oil is petroleum based and therefore 85% carbon [6] *all of the carbon ends up as CO2*assumed it costs $360/ton of recycled steel [7]

It’s big, it’s red, and it lifts your vehicle in a matter of minutes. The Torin Big Red Car Jack is a simple scissor jack that’s compact enough to fit under your seats and strong enough to lift a compact SUV for an emergency tire change.

We chose the Torin Big Red Car Jack as the best portable car jack lift because it’s suitable for most vehicles, costs less than a tank of gas, and weighs less than a bag of groceries. A simple car jack like this and an emergency roadside kit can get you out of a spot of roadside trouble.

While the Big Red jack does require manual cranking, its oversized base adds stability, making it a little safer to work with when you need to change a tire or work on your vehicle.

The Torin Big Red Car Jack is storable, affordable, and powerful. It fits the price and durability needs for most drivers, making it our pick for the best portable car jack.

Like all scissor jacks, the Big Red jack fits under your vehicle and lifts as you crank the tension rod. Its extra-wide base and heavy-duty steel construction keep the jack and your vehicle stable while you work.

This car jack is suitable for vehicles of most heights, so it will work with your low-profile sports car or compact SUV. Its weight capacity is 3,000 pounds, so we don’t recommend it for heavy-duty trucks and large SUVs.

The Pro-Lift is a floor jack, so it’s best for garages and paved surfaces. It’s made of heavy-duty steel, includes a lever for lifting, and has a safety valve to prevent overloading the jack.

We focused on the six-ton jack because it covers most passenger vehicles, even those with trailers on them. This Torin bottle jack is small enough to fit in your truck, toolbox, or under the seat without rearranging anything. And it costs just under $20.

This Powerbuilt jack can lift 6,000 pounds 17 inches off the ground (21 inches, if you raise it manually first), but it’s best for specialty vehicles.

Specially designed for Jeeps and off-roading vehicles, it has an extra-wide base for better support on uneven ground. It also has a safety valve to prevent slipping while you’re working on your rig.

For roadside maintenance, look for scissor lifts with extra-wide bases and floor jacks that can withstand unpaved surfaces (if you go off-road). Jacks you’ll use in your garage don’t have to be as portable and work better with jack stands or ramps for extra support.

Whether you rock a low rider or sit high up, you’ll need a portable car jack that can reach your vehicle and raise it high enough for you to start working.

Most jacks can lift your vehicle a little over a foot off the ground. That’s enough room to change a tire, but not enough for you to slip under the car.

It depends on your car’s weight. It’s best to find jacks that can lift a little more than what your car weighs. If your car weighs 2,500 pounds, a two-ton jack would be suitable.

Floor and trolley jacks are similar but have a few key differences. Floor jacks and trolley jacks both lie flat and roll under your vehicle. They’re also both better for garages and serious maintenance.

Trolley jacks are generally heavier lifters and less portable. Floor jacks cost less and are easier to set up, making them useful for roadside help for larger vehicles.

No. Look for a jack that’s strong enough to support your car. A two-ton jack is generally enough for a small car or sedan but not enough for a heavy-duty truck.

We wanted to find a portable car jack that works best for the most people. We considered factors like price, weight capacity, lift height, and the portability of the jack itself. So while the Torin Big Red Car Jack doesn’t lift the most weight, it checks the most boxes for the most drivers.

To find the best portable car jacks, we checked firsthand customer reviews to hear about real experiences with each product. The products with the highest ratings and most reviews made our list.

We also watched instructional videos about roadside emergencies, car jacks, and how to find the right fit for your car. Read our full methodology to learn how we wrote this and other articles on SafeWise.

As a renter, pet-owner, and woman living alone, Katie McEntire takes safety seriously. She’s tested devices like pet cameras, home security systems, and GPS trackers in her own home and devices in the name of safety. In addition to testing, writing, and reviewing for SafeWise, she also makes videos for the site’s YouTube channel.

... & soft rubber pad on the saddle plateTurning handle for easy release of loadLow profile construction Low noise & smooth to floor tiles due to oil and acid resistant plastic wheelsThis product is not marketed yet in North ...

Air hydraulic jacks designed for heavy, intensive and professional applications. Easy to use, they present a hand-operated dead man’s control for optimum safety while lifting and lowering.

UGJ trolley jacks feature polyamide swivel castors for smooth and quiet operations. All models are fitted with a foot pedal for fast approach to the load. In addition all models are fitted with a safety valve and stroke ...

The DP LIFT jacks line offers its customers an easy and safe usage, both for automotive and industrial applications. The jacks consist of a highly resistant diaphragm and internal telescopic guide. They ...

raise at all, then the Ball Valve may be obstructed by debris.Open the Release Valve and keep it open.Raise the Saddle lift arm manually to full height. Now lower the

Sorry sir but not this one, please check out the Omega 26030 3 ton aluminum jack owners manual. This is exactly the same as mine. I know my pic is lousy, The only slight difference is mine has a screw instead of a clip per pic. And that"s the only difference, the rest is exactly the same including, YES 2 balls on the overload.

I should of mentioned the one I found first. Then just pure luck would have it I remember reading you recommending Hein Werner and Omega would be good jacks to purchase. So I was looking at the Omega aluminum jacks because I must have Speedy or Magic lift along with a light unit. And the plugger release knob for the handle is a must. I could not believe it when I saw the parts break down that showed 2 balls on the overload, and the same exact diagram that my Craftsman 50239 uses. I saw this all the time as a ASE mechanic, mid production changes that drove us bonkers. Now retired I dabble. But mark my words, 2 balls on this unit. Proof is how every lifting test passes.

8613371530291

8613371530291