gas cylinder regulator safety valve manufacturer

Distributor of gas valves including natural gas valves, gas compressor valves, gas cylinder valves & 2-way sub-miniature diaphragm isolation valves. Types include modular design valves & 4-port floating seal direct acting valves. Modular design valves are available orifice sizes ranging from 1/32 in. to 3/16 in. with operating pressures ranging from 15 psig to 400 psig. 4-port floating seal direct acting valves are available in orifice sizes of 1/16 in. with gas pressure ratings of 124 psig, liquid pressure ratings of 100 psig & power ratings of 10 kW & 15 kW. Applications for 2-way sub-miniature diaphragm isolation valves include analytical instrumentation, mass spectography & gas chromatography. JIT delivery available.

Lintgen, Luxembourg 10 August 2021 – Rotarex SRG a business unit of Rotarex SA announced that the entire Cryotec range including the Refrigerant Valves and Components is taken over and managed by Rotarex SRG in Gladenbach, Germany.

SRG Schulz + Rackow Gastechnik has a long history and experience of more than 85 years in the design and manufacturing of valves, regulators and equipment for various applications, such as Cylinder and Bulk Tank Storage, Automotive solutions, Cont...

Residual Pressure Valve (RPV) valves have been cycle tested to conform to GCE´s own stringent standards exceeding ISO 10297 and ISO 15996 to provide a Class Leading 15 year maintenance-free Service Life

Laser marked Batch and Part Numbers on the valve body, for easy identifi cation and traceability, all provide Operational Ease of Use for GCE´s customers

Evergreen Midwest Co. is dedicated to serving the manufacturing industry with the highest quality industrial valves available today. Valves, being critical machinery components, need to be built with maximum dexterity and strength. All valves available for sale on our website are manufactured by well-known & trusted brands Sherwood ValveandRego Products. After decades of industry experience, we are proudly a leading supplier of exceptional valves from these manufacturers. These include globe valves, gate valves, ball valves, pressure regulators, safety relief valves, check valves - the list goes on. We serve a complete range of these critical cylinder components for almost all subcategories of the compressed gas industry, cryogenic markets, and specialty gas markets, as well as the medical, chemical, welding, life-support, cryogenic, and semi-conductor fields.

All the valves that we sell are manufactured in the United States and follow strict and automated manufacturing and testing processes. Our valves also adhere to the necessary international industrial valve standard regulations, therefore meeting the safety levels required for a variety of applications. We are teamed up with technology experts and experienced professionals to guide users with the functioning and repair mechanisms.

WITT is a manufacturer of Pressure relief valvesor Safety relief valves for technical gases. They are designed to protect against overpressure by discharging pressurized gases and vapors from pipelines, pressure vessels and plant components. Safety relief valves (SRV) are often the last line of defense against explosion – and such an explosion could be fatal. Other common names for safety relief valves are pressure relief valve (PRV), safety valve, pressure safety valve, overpressure valve, relief valve or blow-off valve.

WITT safety valves are very precise. They are individually preset to open at a predetermined pressure within the range 0.07 to 652 Psi. Their small size and orientation-independent installation allow a wide range of connection options. WITT relief valves also stand out due to their high blow-off flow rates of up to 970m³/h. They can be used within a temperature range of -76° F to +518°F and even with very low pressures.

For maximum safety, WITT undertakes 100 % testing of each safety relief valve before it is delivered. In addition, WITT offers individual testing of eachsafety valveby the TÜV, with their certificate as proof of the correct set pressure.

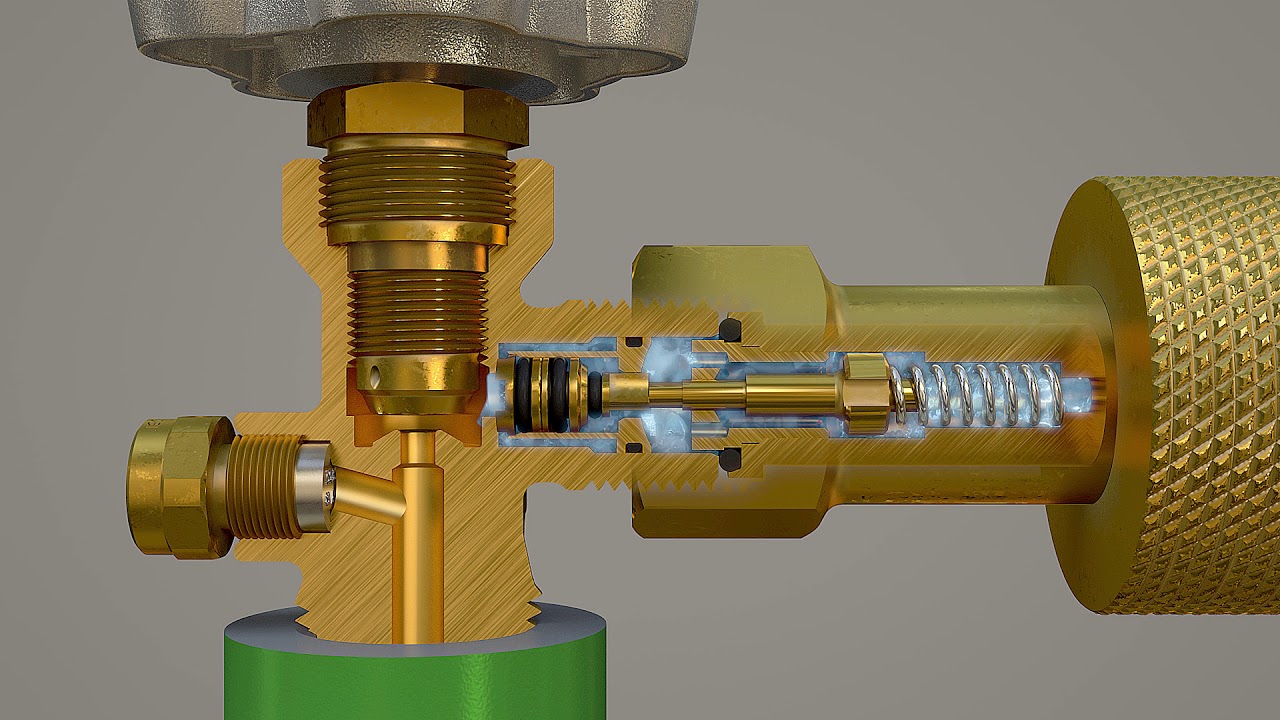

WITTsafety relief valvesare direct-acting, spring-loaded valves. When the preset opening pressure is reached, a spring-loaded element in the valve gives way and opens, and the pressure is relieved. Once the pressures are equalized, the valve closes automatically and can be reactivated any time the pressure rises again. Depending on the application and the nature of the gas, the safety relief valvescan either discharge to atmosphere, or via a connected blow-off line. The opening pressure of the safety valves is preset by WITT at the factory according to the customer’s requirements.

Safety relief valvesare used in numerous industries and industrial applications where, for example, gases pass through pipelines or where special process vessels have to be filled with gas at a certain pressure.

For most industrial applications using technical gases, brass is usually the standard material of construction of thesafety relief valvebody/housing. For the use of pressure relief valves with aggressive and corrosive gases, the housings are made of high-quality stainless steel (1.4541/AISI 321, 1.4404/AISI 316L, 1.4305/AISI 303 or 1.4571/AISI 316Ti). The use of aluminium as a housing material is also possible.

Depending on the type of gas used and individual customer requirements, various sealing materials and elastomers are available to ensure the safety of your systems under even the most difficult conditions.

WITT pressure relief valves are available with different connections. In addition to the standard versions with the usual internal or external threads, special versions with KF or CF flanges, VCR or UNF threads can also be ordered. Special adapters for connecting the safety relief valve to a blow-off line are also available.

compressed gas solutions serving blue-chip bulk and specialty gas manufacturers, distributors and storage & delivery system providers (OEMs). The Sherwood brand includes valves and accessories for all segments including industrial gases, acetylene, medical, hydrogen, refrigerant recovery, propylene, alternative energy and more.

Ensure superior pressure management with Emerson’s pressure regulating products for compressed air, natural gas, steam, fuel, propane, specialty gases, water, and other process fluids. Emerson’s suite of regulator products offers design innovation and durability even in the world’s most rugged environments. From Fisher and Tartarini direct and pilot operated regulators to TESCOM high pressure control regulators, Emerson offers the industry’s broadest portfolio of pressure control technologies, enabling dependable solutions.

Cyl-Tec, Inc.® has come to be known as a prominent leader and innovator in the compressed gas industry who really understands and fulfills what matters most to customers – on-time delivery, reliable products, and personal service. This family-owned business began in 1991 as a gas ...

The GCE Group is Europe’s leading gas equipment company. We are proud member of ESAB Corporation and our today’s extensive product portfolio service our customers in following business areas: -Cutting & Welding Technologies -Valves -Central Gas Systems -Healthcare -Homecare The GCE Group headquarter is located ...

MATAR Srl. is a high pressure gas containers player, updated to the most modern technologies. Cylinders selling, testing and refurbishing – Valves and caps – Ultra light rolls-on, modules and trailers for compressed gas transport. Family owned company, MATAR is born in 1982 as aluminium ...

Tekno Valves, established in 1971, is an ISO 9001 and TPED certified cylinder valve manufacturer of industrial, medical, and specialty gases. Our cylinder valves are tested and approved to global standards. Our integrated design and manufacturing facility in India is equipped with state-of-the-art CNC equipment ...

M/s. Vadilal Chemicals Limited is a part of Vadilal Group (Known for Vadilal Ice-Cream in worldwide) which have over 30 years of experience in specific Gas Industry. Our presence in INDIA as a leading company with 10 plant / branches. Calibration gases are traceable to ...

MSR-Electronic is a manufacturer of fixed gas warning systems with decades of experience in the field of building automation and gas measurement technology. The international company with headquarters in Germany has a wide range of methods for the detection of toxic and combustible gases. On ...

Established in 1949, with over 70 years of experience, Habonim is committed to engineering, manufacturing, and supplying superior products and providing excellent personal service to our customers. We take pride in incorporating quality, innovation, reliability, and safety into our products. We provide the best professional ...

FasTest’s high-pressure, gas filling connectors have a proven track record with over two decades of service in the field. FasTest gas quick connectors provide a simple single handed approach to filling cylinders. Under pressure, a secure, leak-tight seal is established with our patented safety locking ...

RealGaz operating on the gas sales market of Azerbaijan since 2003 year. Sales and services of industrial, technical, medical and specialty gases, as well as gas mixtures. Accredited laboratory for the analysis of all gases, which we produce at our plant and have for sale. With a higher ...

The GCE Group is Europe’s leading gas equipment company. We are proud member of ESAB Corporation and our today’s extensive product portfolio service our customers in following business areas: -Cutting & Welding Technologies -Valves -Central Gas Systems -Healthcare -Homecare The GCE Group headquarter is located ...

PTEC – the company for innovative products PTEC GmbH – a Worthington Industries company since Jan. 2021 – stands for comprehensive and reliable project supervision in mobile and stationary natural gas and hydrogen applications. We are a single source for consultation, engineering, prototyping, type approval, ...

Since 1999 we’ve been bringing our extensive knowledge, great service and an unrivalled safety record to the global valve and ancillaries market. Herose supply the top international industrial gas companies and original equipment manufacturers (OEM), and our products are used in over 100 countries. You’ll ...

ABOUT GAS INNOVATIONS Gas Innovations has become a world leading provider of high purity hydrocarbons in the refrigerant, pharmaceutical, industrial, electronics, and agricultural chemical industries. Ancillary services and products offered are technical consultation, equipment and turnkey logistics to satisfy your business needs by being strategically located at the ...

NingBo ZhengXin(ZX) pressure vessel Co., Ltd. is a leading manufacturer of high pressure gas cylinders and valves located in No.1 JinHu East Road, HuangJiaBu Town, YuYao City, China, with its sales office in Shanghai, China. Over 20 million reliable cylinders are made by ZX and in ...

SS Gas Lab Asia (SSGLA) is a leading manufacturer-exporter of carbon dioxide (CO2) generation and recovery, biogas generation and upgradation, nitrous oxide generation and dry ice process plants. SSGLA also supplies allied systems like CO2 storage tanks &transportation tankers for CO2 vaporizers, manifold systems etc. for ...

Founded in 1963, Control Devices is a leading designer and manufacturer of specialty valves and other high-quality flow control products. Control Devices’ ISO 9001:2008 certified facility boasts a dedicated and skilled work force utilizing automatic machining, assembly and final test equipment to support our production ...

Cavagna Group is a key industrial partner and enabler for the treatment, distribution, control, and metering of all types of gases. Founded in 1949 in Italy, and still run as a family business, for over 70 years Cavagna Group has been operating globally, with eleven ...

The Cavagna Group™ offers the most complete and reliable line of products in the sector, supported by a never-ending commitment to research and engineering. We design, manufacture and distribute a wide range of valves and regulators for different types of high-pressure gas applications worldwide. From ...

Dayan Gas Co. is member of Dayan Chemical Group. Dayan Gas is supplier and producer of cylinders, CNG tanks, industrial gases, pure gases, gas mixture, liquid gases, refrigerant gases and regulators. Dayan gas Co. is a private company which imports & exports industrial gases and ...

Equigas Group is dedicated to providing customers with impeccable service, high quality products, and customer minded warranties for the Americas and the Caribbean. Equigas International, Inc. is the subsidiary of the group that serves the Cryogenic & Compressed Gas, Specialty Gases, Medical Gases and LNG ...

There are various types of equipment that help make sure the high pressure gas found in many types of gas cylinders is held and dispersed at a controlled, safe level. This type of equipment includes regulators, caps and other accessories.

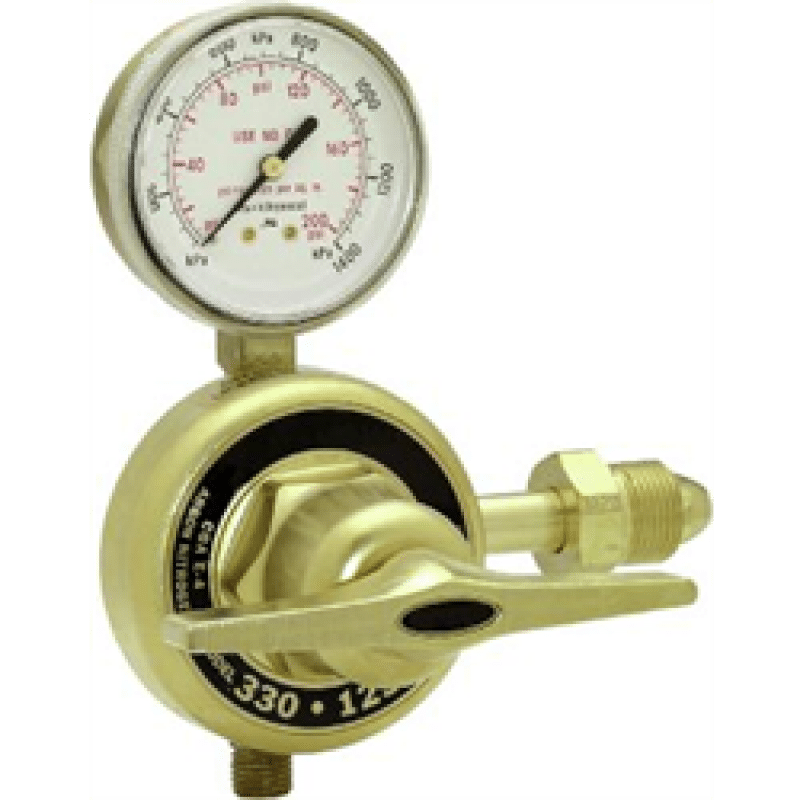

Regulators - these attach to gas cylinder valves to bring the high pressure of the cylinder contents down to a usable, safer, and consistent pressure.

Caps, valve guards, and pressure relief devices - these are all designed to make the use of gas cylinders safer, either by protecting the valve and valve stem or by preventing an unsafe increase of pressure in the cylinder.

A regulator is a device designed to regulate the delivery pressure of a gas from a compressed gas cylinder. The regulator does not handle the flow of gas or measuring the flow, unless it is also equipped with a flow meter. It only reduces the high pressure from a cylinder to a lower, more usable pressure.

Regulators should be closed before opening a valve on a compressed gas cylinder. Valves should be opened slowly. Any valves that are intended to be opened by hand, like those with a hand wheel, should not be forced with a tool to prevent putting sudden and excessive pressure on the regulator. If a hand wheel is not operating, the cylinder should be repaired.

When a cylinder is no longer in use, the regulator should not be used as the shut off mechanism. The valve should be closed, and the pressure bled from the regulator using the adjustment screw before the cylinder is stored.

Whenever possible, always stand to the side of a regulator, so that you are not directly in front of or behind the face. Regulators explode forwards or backwards, so staying out of that line is the safest place in case of an explosion. Unless the regulator has a flow meter, direct the face of the regulator upwards. Also, when adjusting the valve, do not reach over the regulator to make the adjustment, but set up the cylinder so that you have the valve between yourself and the regulator.

Grease or oil or other combustible solvents should never be used to clean a valve or regulator. These solvents can make certain compressed gases like oxygen combustible. Regulators for any combustible gas should be cleaned carefully after each use to prevent residue from acting as a combustible fuel. Regulators should also be inspected for leaks regularly using water and a non-petroleum based soap; a leaking regulator will bubble.

Only on compressed cylinders containing non-toxic gas, the valve should be “cracked” before attaching the regulator. Cracking is simply opening the valve slightly and closing it again, to blow out any dust or dirt before attaching the regulator.

Caps are exactly what they sound like, metal covers that completely enclose the valve. These are typically used during transportation of a gas cylinder or for long-term storage. They come in a variety of standard and oversized heights with several threading dimensions. Caps typically have a 1” hole for venting in the case of leaks, preventing a build-up of pressurized gas within the cap, but vented plugs can be purchased for the hole.

Valve guards are designed to provide impact protection for the valve without blocking access to it. They are typically constructed of metal or plastic and have a cage-like or cup-like appearance. Steel valve guards are sometimes designed for use as a replacement for caps, while plastic valve guards are typically designed for cylinders below a certain weight. Valve guards come in a variety of thread sizes and heights to accommodate a wide variety of gas cylinders.

A pressure relief device is designed to prevent the pressure in a cylinder from rising if exposed to a heat source. All varieties are designed to burst or melt when the cylinder pressure reaches a certain limit or a temperature threshold is reached, typically marked on the surface of the device. Devices of this type are in a disk shape or plug shape. There are also spring-loaded valves that are designed to open when the pressure reaches a certain threshold. Unlike the disks or plugs that are one-use, spring-loaded valves will typically reseat themselves when pressure has dropped back into safe limits.

Make sure to familiarize yourself with the risks associated with the use and handling of high pressure gas cylinders, as well as the equipment needed to mitigate those risks. Regulators, caps, valve guards, and pressure relief devices are all pieces of equipment that help maintain safe pressure when working with compressed gases. Understanding these types of equipment and how they’re used puts you in a better position to work with your gas cylinders safely.

Relief valves are installed downstream of a pressure reducing regulator and vent excess pressure in case the main regulator fails to close. They are also known as a downstream overpressure protection device, which is required when the internal relief valve of the upstream regulator is inadequate.

Designed to vent directly to atmosphere in outdoor installations, these “pop” style relief valves are economical for high pressures with high flows. Brass construction with a weather cap is standard.

With a variety of sizes and options available, these “pop” style relief valves can be used both outdoors & indoors. Cast iron construction is standard and a weather cap is available.

Designed for installation in stationary ASME applications such as bulk plant, skid tanks, underground and above ground containers as the primary pressure relief valve.

A back pressure regulator designed for a large variety of process applications. Used for any type of industry and ideal for liquids, air as well as gas applications.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon dioxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SKS Series globe valves short stem are designed for handling of vapor phase and cryogenic liquids through bulk tanks, trucks, trailers, ISO-containers and piping configurations. Our time tested spring loaded stem packing and superior seat design provide for long life and easy maintenance. Recommended for vapor phase and intermittent cryogenic liquid use.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon oxide, methane, ethane, ethylene, argon and LNG . Our Kold-Sea™l stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon dioxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon oxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SKS Series globe valves short stem are designed for handling of vapor phase and cryogenic liquids through bulk tanks, trucks, trailers, ISO-containers and piping configurations. Our time tested spring loaded stem packing and superior seat design provide for long life and easy maintenance. Recommended for vapor phase and intermittent cryogenic liquid use.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon dioxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon oxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SKS Series globe valves short stem are designed for handling of vapor phase and cryogenic liquids through bulk tanks, trucks, trailers, ISO-containers and piping configurations. Our time tested spring loaded stem packing and superior seat design provide for long life and easy maintenance. Recommended for vapor phase and intermittent cryogenic liquid use.

Our investment cast stainless steel is specified by leading industrial gas companies for storage tank and yard operations. Special order bonnet extensions are available for cold box applications. Valves for hydrogen use can be supplied

The RegO® Goddard 231 Series Stainless Steel globe valves are designed for handling of cryogenic liquids through bulk tanks, trailers, ASU plants and piping configurations. Compatible with oxygen, nitrogen, CO2, hydrogen, helium and argon.

The RegO® Goddard 232 Series Stainless Steel globe valves are designed for handling of cryogenic liquids through bulk tanks, trailers, ASU plants and piping configurations. Compatible with oxygen, nitrogen, CO2, helium and argon.

Ideal for use as a first stage regulator on any domestic size ASME or DOT container in propane gas installations requiring up to 1,500,000 BTU’s per hour. The regulator is factory set to reduce container pressure to an intermediate pressure of approximately 10 psig (0.69 barg).

Ideal for use as a first stage regulator on any domestic size ASME or DOT container in propane gas installations requiring up to 1,500,000 BTU’s per hour. The regulator is factory set to reduce container pressure to an intermediate pressure of approximately 10 psig (0.69 barg).

Provides accurate first stage regulation in two-stage bulk tank systems. Reduce tank pressure to an intermediate pressure of 5 to 10 PSIG. Also used to supply high pressure burners for applications like industrial furnaces or boilers. Also incorporated in multiple cylinder installations.

This kit provides the equipment necessary for checking regulator delivery pressure (low pressure) at the appliances. The basic set contains a 2424A-2 low pressure gauge and a 3 foot — 3⁄16" O.D. flexible synthetic rubber tube. Adapters are also available.

Designed for testing high pressure lines. Adapter has 0 to 300 PSIG gauge. A bleeder valve allows you to bleed down to correct pressure during pressure tests.

Designed to reduce LP-Gas and anhydrous ammonia container pressures to between 3 and 125 PSIG. Precision-built with a multi-million BTU capacity, the 1580V™ series is perfect for such big, tough jobs as crop dryers, asphalt batch mixing plants, road building "tar wagons", heat treating and other large industrial and commercial loads. It’s also ideal as a first stage regulator in large multiple operations. The AA1580V™ series is ideal for use in anhydrous ammonia applications such as blue print machines and heat treating.

Designed to reduce propane gas container pressure down to between 3 and 100 PSIG. Ideal for liquid or vapor service, they can be used in a variety of applications including salamander heaters, weed burning torches, fish cookers, tar pot heaters, and other industrial type services.

Designed to reduce LP-Gas container pressures to between 3 and 50 PSIG. Ideal for crop drying, heat treating, asphalt batch mixing and other large industrial and commercial load application utilizing high temperature LP-Gas or high temperature atmosphere under conditions up to 300ºF. Also ideal as a first stage regulator in large multiple operations.

For use in systems that require uninterrupted gas service during cylinder exchange. Especially for summer cottages, mobile homes and single appliance loads.

These inlet fittings are available for assembly into either first stage of single stage regulators. All have ¼" M. NPT connections and are machined from brass

Designed for use on portable systems with vapor or liquid including torches, heaters, lead melting burners, tar and asphalt burners, wallpaper steamers and other applications involving portable DOT cylinders. The POL inlet attaches directly to the cylinder valve and the outlet mounts to the regulator.

Designed to reduce first stage pressure of 5 to 20 PSIG down to burner pressure, normally 11" w.c. Ideal for medium commercial installations, multiple cylinder installations and normal domestic loads.

Designed to reduce first stage pressure of 5 to 20 PSIG down to burner pressure,normally 11" w.c. Ideal for larger commercial and industrial applications, multiple cylinder installations and large domestic systems.

RegO’s Dielectric second stage regulators are designed to reduce first stage pressure normally 10PSIG down to burner pressure, normally 11" w.c. and are ideal for medium commercial inst

Designed to reduce first stage pressure of 5 to 20 PSIG down to burner pressure,normally 11" w.c. Ideal for larger commercial and industrial applications, multiple cylinder installations and large domestic systems.

The LV3403B4 is designed to reduce first stage pressure of 5-20 PSIG down to burner pressure normally 11" w.c. Designed as a second stage regulator for smaller applications with flow requirements up to 450,000 BTU’s/hr, they are ideal for homes, mobile homes, and cottages.

The LV3403B66R Back Mount Regulator is designed to reduce first stage pressure of 5-10 PSIG down to burner pressure normally 11" w.c. Designed as a second stage regulator for smaller applications with flow requirements up to 450,000 BTU/hr. and are ideal for homes, mobile homes, and cottages.

The LV3403BR Back Mount Regulator is designed to reduce first stage pressure of 5-10 PSIG down to burner pressure normally 11" w.c. Designed as a second stage regulator for smaller applications with flow requirements up to 450,000 BTU/hr. and are ideal for homes, mobile homes, and cottages.

Designed to reduce first stage pressure of 10 PSIG down to 2 PSIG. A line pressure regulator is required downstream to reduce the 2 PSIG to a nominal 11" w.c.

Designed to reduce first stage pressure of 10 PSIG down to 2 PSIG. A line pressure regulator is required downstream to reduce the 2 PSIG to a nominal 11" w.c.

Designed to reduce first stage pressure of 10 PSIG down to 2 PSIG. A line pressure regulator is required downstream to reduce the 2 PSIG to a nominal 11" w.c.

Designed to reduce first stage pressure of 5 to 10 PSIG down to pressure higher than 11" water column, the actual pressure setting is specified in the table below. These regulators are designed for installations where the appliances require pressures greater than 11 inches w.c.

Designed to reduce first stage pressure of 5 to 20 PSIG down to burner pressure,normally 11" w.c. Ideal for larger commercial and industrial applications, multiple cylinder installations and large domestic systems.

Especially developed for drying barns in the tobacco industry. The LV5503G4 regulator will supply a steady and constant flow of fuel to as many as 12 to 20 burners throughout the barn.

These compact regulators are designed for smaller outdoor grills and fish cookers. It is intended for use on small portable appliances that use 100,000 BTU’s/hr. or less. It may not be used on fixed pipe systems per NFPA 58, 1995 edition.

This compact two-stage regulator is designed to reduce container pressure down to 11" w.c. delivery pressure. It is ideal for "on-site" cylinder applications, mobile homes and average domestic service including small ASME and 100 to 420 pound DOT cylinders.

The compact twin-stage regulator is designed to reduce container pressure down to 11" w.c. delivery pressure. It is ideal for "on site" container applications such as homes, mobile homes and cottages for average domestic service; including small ASME tanks and 100-420 pound DOT cylinders.

These combination automatic changeover, two stage regulators are especially suitable for homes, mobile homes, cottages, construction and other portable two cylinder installations. Empty containers may be replaced without interrupting customer’s gas service.

SPECIAL 2 PSIG DELIVERY pressure twin stage regulator is designed to reduce container pressure down to 2 PSIG. A line pressure regulator is required downstream to reduce the 2 PSIG to a nominal 11" w.c.

This dual cylinder valve was designed especially for industrial uses. It increases the cylinder’s flexibility by permitting DOT cylinders up to 100 lbs. propane capacity to be used interchangeably or simultaneously for either liquid or vapor withdrawal.

Designed specifically for vapor or liquid withdrawal service on ASME motor fuel containers. Since none of these valves have an integral pressure relief valve, they may only be used as an accessory valve on containers that have an independent pressure relief valve sufficient for that container’s capacity.

Designed specifically for vapor or liquid withdrawal service on DOT fork lift containers. Valves with 1.5 GPM closing flow are for use in small and medium size lift truck applications, while those with 2.6 GPM closing flow are for large lift trucks. Since none of these valves have an integral pressure relief valve, they may only be used as an accessory valve on containers that have an independent pressure relief valve sufficient for that cylinder’s capacity.

Equipped with excess flow valves and liquid withdrawal tubes, they are designed for liquid withdrawal of DOT cylinders up to 100 lbs. propane capacity. They are most often used with heavy BTU loads found in industrial uses.

Designed for vapor withdrawal from and protection of DOT cylinders up to 100 lbs. propylene capacity with pressure ratings such as 4B-260, 4BA-260, and 4BW-260 cylinders.

This heavy duty cylinder valve is designed for vapor withdrawal of DOT cylinders up to 100 lbs. propane capacity. It is used in domestic hookups and industrial commercial installations.

This valve is designed for vapor withdrawal from and protection of DOT cylinders up to 100 lbs. propane capacity. Ideal for cylinders used in the field by construction crews, utility repair men and plumbers.

Designed for vapor withdrawal service on ASME and DOT containers or in fuel line applications. Since none of these valves have an integral pressure relief valve, they may only be used as an accessory valve on containers that have an independent pressure relief valve sufficient for that container’s capacity.

Especially designed to bleed off liquid or vapor pressures trapped in transfer lines. When installed in the downstream boss of RegO globe and angle valves used at the end of a liquid transfer hose, the bleeder valve allows for the controlled venting of the product and indicates to the operator that the valves are closed and he can disconnect the coupling. They may also be used as a fixed liquid level gauge where the dip tube is part of the container.

Especially designed to provide a visible warning when containers are filled to the maximum permitted filling level. At the start of the filling operation, with the vent stem opened, the valve discharges vapor. When the maximum permitted filling level is reached, the valve discharges liquid. The 3165CF*, 3165CF12.0, 3165SF12.0 and TA3169F12.0 incorporate a No 54 drill orifice; the 3165DF* and 3165DF12.0 incorporate a No 72 drill orifice. They all are normally furnished with a 12" 3/16" OD dip tube.

These Multivalves® permit vapor withdrawal from ASME containers up to 50 sq. ft. surface area and DOT containers up to 420 lbs. propane capacity. They allow on-site cylinder filling without interrupting gas service.

These Multivalves® provide vapor withdrawal and filling of ASME containers. A separate pressure relief valve is required in addition to this valve. The Multibonnet® assembly is standard on this valve.

These Multivalves® are designed for use in single opening ASME containers equipped with a 2½" M. NPT riser. They can be used with underground ASME containers up to 639 sq. ft. surface area, and above ground ASME containers up to 192 sq. ft. surface area. A separate opening is required for liquid withdrawal. The Multibonnet® assembly is standard on this valve.

These Multivalves® permit liquid withdrawal from DOT cylinders with up to 100 lbs. propane capacity. They eliminate unnecessary cylinder handling when servicing high volume loads and allow on-site filling into the vapor space without interrupting gas service.

Designed for use as a primary relief valve on ASME above ground and underground containers, bulk plant installations and skid tanks. The 3131 Series may also be used as a primary or secondary relief valve on DOT cylinders, or as a hydrostatic relief valve. All working components of these relief valves are outside the container connection, so the valves must be protected from physical damage.

Designed for use as a supplementary relief valve on small ASME above ground and underground containers. They may also be used as a primary or secondary relief device on DOT cylinders, or as hydrostatic relief valves.

Designed especially for the protection of piping and shut-off valves where there is a possibility of trapping liquid LP-Gas or anhydrous ammonia. They may be installed in pipelines and hoses located

The "Pop-Action" design permits the RegO Pressure Relief Valve to open slightly to relieve moderately excessive pressure in the container. When pressure increases beyond a predetermined point, the valve is designed to "pop" open to its full discharge capacity, reducing excess pressure quickly. This is a distinct advantage over ordinary valves which open gradually over their entire range, allowing excessive pressure to develop before the relief valve is fully open. All RegO internal, semi-internal, and external relief valves incorporate this "Pop-Action" design.

The following warning information, Part Number 8545-500, is included with each shipment of pressure relief valves and relief valve manifolds to the first purchaser of the product from the factory.

Designed especially for use as a primary relief device on smaller stationary storage containers, with 2" NPT threaded couplings. These manifolds allow servicing or replacement of either of the two relief valves without evacuating the container or loss of service. The operating lever selectively closes off the entrance port to the relief valve being removed while the remaining valve provides protection for the container and its contents. The rating of each manifold is based on actual flow through the manifold and a single pressure relief valve, taking friction loss into account. It is not merely the rating of the relief valve alone.

Designed especially for use as a primary relief device on large stationary pressurized storage containers, the base is supplied with a two-inch NPT threaded container connection. These manifolds incorporate an additional relief valve, not included in the flow rating, allowing for servicing or replacement of any one of the relief valves without evacuating the container. The hand-wheel on the manifold selectively closes off the entrance port to the relief valve being removed while the remaining relief valves provide protection for the container and its contents. All manifold flow ratings are based on flow through the relief valves after one has been removed for service or replacement.

Designed especially for use as a primary relief device on large stationary pressurized storage containers with flanged openings. These manifolds incorporate an additional relief valve, not included in the flow rating, allowing for servicing or replacement of any one of the relief valves without evacuating the container. The handwheel on the manifold selectively closes off the entrance port to the relief valve being removed while the remaining relief valves provide protection for the container and its contents. All manifold flow ratings are based on flow through the relief valves after one has been removed for service or replacement.

8543 Series relief valves are designed for use as a primary relief valve in larger ASME motor fuel containers such as on buses, RV’s, trucks and construction equipment.

Designed specifically for use as a primary relief valve on forklift cylinders, the 8545AK reduces the possibility of improper functioning of the relief mechanism due to foreign material build up. All guides, springs, stem and adjusting components are located inside the cylinder - removed from the direct exposure of foreign materials and debris from the atmosphere.

Designed for use as a primary relief valve on ASME containers such as 250, 500 and 1,000 gallon tanks. Underwriters’ Laboratories lists containers systems on which these types of valves are mounted outside the hood without additional protection, if mounted near the hood and fitted with a protective cap.

Low Emission Adapter (1.18 cc at disconnect) designed to provide quick and easy filling of DOT cylinders with Type 1 connections with minimal release of product on disconnect. This adapter may be used for dispensing systems in conjunction with RegO 7901T Series Quick Acting Shut-Off Valve. Balanced, light weight design for filling into 20 # - 200 # Cylinders

Low Emission Adapter (1.18 cc at disconnect) designed to provide quick and easy filling of DOT cylinders with POL connections with minimal release of product on disconnect. This adapter may be used with dispensing systems in conjunction with RegO 7901T Series Quick Acting Shut-Off Valve. Balanced, light weight design for filling into 20 # - 200 # cylinders.

Designed to drastically reduce labor and time when continuously filling large numbers of lift truck cylinders equipped with RegO 7141M check connectors.

Designed to provide quick and easy filling of DOT cylinders with POL or Type I connections. This adapter may be used with hydraulic and electric automatic systems or with manual systems in conjunction with a RegO 7901TB Quick Acting Shut-Off Valve.

These adapters are designed with minimal flow restriction and recommended for use on the outlet of the LP-Gas delivery truck filler hose. If the controlled bleed off of the connection indicates the filler valve on the tank being filled has failed to close, the hose adapter should be left in place on the filler valve and disconnection should be made at the regular filler hose coupling. (Repair of the filler valve must be made as soon as possible). An integral check valve in these adapters helps prevent further loss of product. The standard filler valve cap should be attached to these adapters when left on the container.

The 7193T-10 Connector is designed for use on the 7193D-10 Filling Adapters. Connector allows quick connection to the Type I 15/16" M. ACME threads for operators that fill both POL and Type I valves.

Designed to vastly reduce the amount of product vented when disconnecting bobtail delivery trucks, dispensing systems and anhydrous ammonia nurse tanks. These valves provide instant, full-on flow at the flip of a handle. Shut-off is instant and the handle locks for added protection. This "top of the line" hose-end valve is a fully contained unit that does not require additional filling adapters or connectors.

The A7914A Low Emission valve is designed to reduce the amount of product vented when disconnecting bobtail and transport loading hoses. This valve provides a full-on flow when pressing the release trigger and the lifting of an easy grip handle. Lowering the handle will immediately stop flow and lock the lever in the closed position. This valve can be used with any standard 3¼" Male ACME connector, or our 6588LE and 6589LE minimum loss filler valves.

7554S Series valves provide instant shut-off and fast opening control on LP-Gas crop driers. They are also ideal for charging manifold hoses, stationary fuel transfer hoses and other applications requiring quick, positive shut-off. They are not for use with delivery truck hoses because the handle could snag on the ground and open the valve as the hose is reeled back to the truck.

Designed primarily for use on dispensing hoses to provide safe, convenient shut-off and fast opening. These valves feature a locking handle device to help prevent accidental opening of the valve.

Designed for LP-Gas fueling stations, the FN Series LP-Gas fueling nozzle provides a fast flow rate and low emission on disconnect. The FN Series fueling nozzle only allows gas to flow when it is correctly coupled, no opening is possible when misaligned.

Specifically designed to ensure positive shut-off and long, maintenance free service life in liquid or vapor service on bulk storage containers, transports, bobtails, cylinder filling plants and plant piping.

Designed for use in conjunction with our 6588LE and 6589LE low emission filler valves installed on bobtails and transports. The valves are designed to stop flow out of the container when the hand- wheel is closed. They incorporate an automatic integral back check that is designed to allow flow back into the container to prevent liquid from becoming trapped between the 6588/89LE and the closed globe/angle valve.

The following warning information, Part Number 903-500, is included with each shipment of Quick-Acting and Tank Car Valves to the first purchaser of the product from the factory.

Designed to ensure positive shut-off and long maintenance-free service life in liquid or vapor service. Ideally suited for use on cylinder charging manifolds, truck filling hoses, bulk storage containers and plant piping.

Designed especially for liquid transfer of LP-Gas from consumer bulk storage containers when used with a Chek-Lok® or equipped with an integral excess flow valve. May also be used for vapor LP-Gas service.

Designed for installation on bulk storage containers, this valve combines a pressure gauge mounting and provision for a fixed tube liquid level gauge.

Designed primarily for use as a Multipurpose valve with combination filler valve and manual shutoff valve for the outlet connection of the valve for use on LP-Gas containers.

Designed for use with RegO Excess Flow Valves to facilitate loading operations by providing equalization of pressures in the supply and storage containers. Also may be used as a spare or replacement part. These vapor equalizing valves must never be installed directly into container couplings. They must be used with the appropriate excess flow valve to comply with NFPA Pamphlet #58.

Designed to provide high flow capacity and allow more efficient tank filling than conventional designs. The unobstructed throat area reduces flow turbulence through the valve, thereby reducing pressure drop. Large flow channels and spacious side ports ensure ample capacity for the most demanding high capacity filling operations.

This back check valve is designed to provide required back flow protection for the unloading riser in the bulk plant’s transfer area. It is designed specifically for pipeline installation and is suitable for LP-Gas and anhydrous ammonia service. Product flow moves the swing check to the open position, when flow stops the spring loaded swing check closes.

This back check valve is designed to provide required back flow protection for the unloading riser in the bulk plant’s transfer area. It is designed specifically for pipeline installation and is suitable for LP-Gas and anhydrous ammonia service. Product flow moves the swing check to the open position, when flow stops the spring loaded swing check closes.

Designed to promote maximum pump efficiency, these indicators enable bulk plant operators to visually inspect liquid flow conditions. With glass on both sides of the indicator, flow can be observed from either side, even under some poor light conditions. The integral swing check also serves as a back-check valve to prevent reverse flow and product loss if the hose fails in a loading operation.

Chek-Lok® Excess Flow Valves are designed to provide a convenient means of withdrawing liquid from stationary containers prior to moving the container. The Chek-Lok® permits one transfer shut-off valve with an adapter to be used interchangeably on a number of tanks.

Designed specifically for use with RegO 7572FC and 7580FC Chek-Lok® Excess Flow Valves. The adapter’s operating handle opens and closes the equalizing stem in these older style Check-Lok® valves. This adapter is designed to eliminate the need for gas to flow from the Chek-Lok® when the adapter is installed or removed. A shutoff valve, such as a full port ball valve must be installed at the outlet of the 7580F-20.

Designed for top installation, in any position, in liquid or vapor service lines. They are intended for long lines or branch piping where tank mounted excess flow valves cannot suffice.

Designed for liquid or vapor use for filling, withdrawal and vapor equalizing in container or line applications. They are intended for long lines or branch piping where tank-mounted excess flow valves are inadequate.

Designed for mounting in threaded full or half couplings in container installations. They may be used for filling, withdrawal or vapor equalizing applications. The exceptionally low pressure drop makes them ideal for pump suction lines. If a riser pipe to the vapor space is used with these valves, the minimum inside diameter of the riser pipe must be at least two times the valve thread size in order not to restrict flow to the side inlet ports.

These valves are designed for bottom mounting in consumer storage tanks for liquid service. They may also be top mounted for vapor service. These valves are designed especially for use with RegO globe and angle valves.

Designed for container use in pressure gauge installations to minimize excess gas discharge in the event the pressure gauge is sheared. A suitable shut-off valve should be installed between this valve and the pressure gauge to allow convenient gauge

The following warning information, Part Number 903-500, is included with each shipment of Excess Flow, Check, Filler and Vapor Equalizing Valves to the first purchaser of the product from the factory.

This combined filler valve and overfill protection device is designed to provide fast filling and protection against overfilling of Vertical above ground small bulk type containers. The SF7647V Series offers good fill rates and an overfill prevention device that will stop* the flow of product into the container when the liquid level reaches 80-83% of its capacity.

The SFL7579V Series filler valve is for use on ASME containers. This combined filler valve and overfill protection device is designed to provide fast filling and protection against overfilling of vertical and horizontal above ground LPG containers. This is typically installed in the top of horizontal containers.

RegO Manual Double-Back Check filler valves that incorporate a resilient upper check and a manual shutoff feature. When filling a container from a delivery truck, this valve will allow flow into the container through the upper and lower check, when the manual lever is in the open position. When flow stops both the upper and lower checks will close; the lever is then turned to the closed position, the hose-end valve can then be removed from the filler valve.

Designed to facilitate loading operations by providing equalization of pressures in the supply and storage containers. The supplementary excess flow valve closes when the flow from the container being filled exceeds a predetermined rate.

The 7573-20 is designed for use with RegO Multivalves® that utilize a vapor equalizing port and 7573 series vapor equalizing valves. The adapter’s operating handle opens and closes the upper check stem in the vapor equalizing valve after the ACME connection is completely made up.

Designed especially for use with Internal Valves installed in DOT MC331 pressure vessels. The A3219RT provides a remote means of mechanical closure along with thermal protection, as required by DOT MC331.

Designed primarily for LP-Gas and anhydrous ammonia filling and/or withdrawal on MC331 bobtail delivery trucks, transports and stationary storage tanks with flanged pumps or piping. Installation is quick and easy, and the valve may be operated manually by cable or pneumatically. Lever available on right or left side to allow for installation without the use of an extra pulley.

These Pneumatic Actuators are designed specifically for use with the A3217 Series 3" Internal Valves. The diaphragm design provides a convenient means of opening and closing the valve from a remote location, using either air or nitrogen.

Designed primarily for LP-Gas and anhydrous ammonia service on MC331 transport pressure vessels and large stationary storage tanks. Installation is quick and easy, and it fits in most existing tank flanges. The valve may be actuated manually or pneumatically.

The A3219FPA Pneumatic Actuator is designed especially for use with the A3219FA Series Flanged Internal Valves. The diaphragm type A3219FPA provides a convenient means of opening and closing the valve from a remote location, using either air or nitrogen, on LP-Gas and NH3 transport trailers and stationary tanks.

Designed primarily for LP-Gas and anhydrous ammonia liquid withdrawal on MC331 bobtail delivery trucks, transports and large stationary storage containers with flanged connections. The valve is fully automatic, opening and closing as the pump is turned on or off.

The EA7853A 3-way quick acting valve controls the fluid exchange between three separate transfer lines. For better control, the 3-way valve is paired with an electric actuator which provides a safe, easy way to open and close the valve from a remote location.

Designed primarily for use with LP-Gas and anhydrous ammonia as a main valve on small capacity pumping systems, NH3 nurse tanks and in-line installations. It may also be installed in the vapor equalizing opening on bobtail delivery trucks. Installation is quick and easy, and it fits in both full and half couplings, as well as, in-line applications. The valve may be actuated manually by hand or cable.

Designed primarily for use with LP-Gas and anhydrous ammonia as a main valve on small capacity pumping systems, NH3 nurse tanks and in-line installations. It may also be installed in the vapor equalizing opening on bobtail delivery trucks. Installation is quick and easy, and it fits in both full and half couplings, as well as, in-line applications.

Designed primarily for use with LP-Gas and anhydrous ammonia as a main valve on pumping systems, and in-line installations. Installation is quick and easy and it fits in both full and half couplings, as well as, in-line applications.

Designed primarily for use with LP-Gas and anhydrous ammonia for liquid withdrawal; vapor transfer or vapor equalization of bobtail delivery trucks, transports, stationary storage tanks, and in-line installations. T

Designed primarily for use with LP-Gas and anhydrous ammonia for liquid withdrawal; vapor transfer or vapor equalization of bobtail delivery trucks, transports, stationary storage tanks, and in-line installations. The valve may be operated manually by cable or pneumatically.

Designed primarily for use with LP-Gas and anhydrous ammonia for liquid withdrawal; vapor transfer or vapor equalization of bobtail delivery trucks, transports, stationary storage tanks, and in-line installations.

Designed primarily for use with LP-Gas and anhydrous ammonia for liquid withdrawal; vapor transfer or vapor equalization of bobtail delivery trucks, transports, stationary storage tanks, and in-line installations.

Designed especially for liquid filling and vapor equalization of LP-Gas and anhydrous ammonia. The limited travel of the handle on the tailpiece minimizes spin-off, encouraging cautious removal to properly bleed off trapped product to ensure closure of the filler valve and hose end valve. The ACME threads are machined on a rugged steel insert which is permanently cast in the aluminum handle, providing for durability under repeated use.

These brass connectors are especially designed to join the carburetor fuel line to the service valve on lift truck cylinders. Sturdy, long lasting ACME threads allow quick, hand-tight assembly that provides for quick and simple cylinder replacement. Back checks automatically close in each connector when disconnected.

These brass connectors are especially designed to join the carburetor vapor fuel line to the service valve on industrial cylinders especially designed for and used on propane fueled lawn mowers. Sturdy long lasting ACME left hand threads provides for quick hand tight assembly that provides for quick and simple cylinder replacement.

Specifically designed to withstand the everyday abuse given to hose end valves on delivery trucks and hose end couplings on risers in bulk plants, these rugged plugs protect the coupling tip as well as prevent the entrance of dirt, dust, snow and rain. They also prevent possible gas contamination from these same sources. The heavily ribbed outer surface permits hand-tight make-up.

Rotogage® Assembly® are designed to provide an accurate determination of LP-Gas or anhydrous ammonia container contents. They mount in a standard 1" NPT coupling on large mobile or stationary containers.

Rotogage® Assembly® are designed to provide accurate determination of LP-Gas container contents. They may be end or side mounted in a standard ¾" NPT coupling on stationary or mobile containers. To guarantee accurate measurement, they should not be used on stationary containers that exceed 60" I.D. or on mobile containers, subject to vibration, with an I.D. of more than 24".

Designed especially to provide pull-away protection for LP-Gas and anhydrous ammonia transfer operations including transport and delivery truck loading and unloading, engine fuel container filling and miscellaneous cylinder filling operations. When properly fastened to the inlet end of the discharge hose, the valve is designed to stop gas escape from both upstream and downstream lines in the event of a pull-away. An excessive tension pull causes the valve to automatically separate, closing two internal back pressure checks. Only a few cubic centimeters of gas escape at the instant of separation.

Designed for installation in liquid transfer lines at LP-Gas or Anhydrous Ammonia bulk plants to provide for quick shut-off of liquid or vapor flow in the event of an accidental pull-away, line break, or hose rupture.

Designed for installation in liquid transfer lines at LP-Gas or Anhydrous Ammonia bulk plants to provide for quick shut-off of liquid or vapor flow in the event of an accidental pull-away, line break, or hose rupture.

Designed for installation in liquid transfer lines at LP-Gas or Anhydrous Ammonia bulk plants to provide for quick shut-off of liquid or vapor flow in the event of an accidental pull-away, line break, or hose rupture.

Designed for installation in liquid or vapor transfer lines at LP-Gas or Anhydrous Ammonia bulk plants to provide for quick shut-off of liquid or vapor flow in the event of an accidental pull-away, line break, or hose rupture.

Designed for installation in liquid transfer lines at LP-Gas or Anhydrous Ammonia bulk plants to provide for quick shut-off of liquid or vapor flow in the event of an accidental pull-away, line break, or hose rupture.

5 psi liquid glycerin filled ambient temperature gauge w/bleeder valve, w/bleeder valve and 90° quick adapter. Available with straight quick adapter. Sold with belt loop holster

30# Gauge is used to perform leak tests downstream of 1st stage regulators by connecting quick adapters to PrestoTap LDS2000RV installed in 1st & 2nd stage regulator taps accessing 1st stage pressure

30# Gauge is used to perform leak tests downstream of 1st stage regulators by connecting quick adapters to PrestoTap LDS2000RV installed in 1st & 2nd stage regulator taps accessing 1st stage pressure

30# Gauge is used to perform leak tests downstream of 1st stage regulators by connecting quick adapters to PrestoTap LDS2000RV installed in 1st & 2nd stage regulator taps accessing 1st stage pressure

Low cost, permanently installed fitting between tank service valve and first stage regulator providing leak test capability without the use of tools. Eliminates the need to discard pigtail to access tank pressure.

30# Gauge is used to perform leak tests downstream of 1st stage regulators by connecting quick adapters to PrestoTap LDS2000RV installed in 1st & 2nd stage regulator taps accessing 1st stage pressure

30# Gauge is used to perform leak tests downstream of 1st stage regulators by connecting quick adapters to PrestoTap LDS2000RV installed in 1st & 2nd stage regulator taps accessing 1st stage pressure

30# Gauge is used to perform leak tests downstream of 1st stage regulators by connecting quick adapters to PrestoTap LDS2000RV installed in 1st & 2nd stage regulator taps accessing 1st stage pressure

Designed especially for use in liquid motor fuel lines to trap foreign material which otherwise may damage precision components in the LP-Gas carburetion system. These filters incorporate an integral sintered metal filter element in a straight through design.

Designed to provide accurate, economical filling of LP-Gas, DOT and fork lift cylinders by weight. Filling stops automatically as the total weight of the cylinder reaches the amount pre-set on the scale. One individual can efficiently handle up to four cylinder filling operations simultaneously to maximize profits, increase efficiency and allow servicing of more customers.

These valves are high quality, "true’’ throttling valves. Unlike most so-called needle valves, both the body seat and stem are tapered to provide fine, precise control over a wide range of adjustment without stem galling.

This dual cylinder valve was designed especially for industrial uses. It increases the cylinder’s flexibility by permitting DOT cylinders up to 100 lbs. propane capacity to be used interchangeably or simultaneously for either liquid or vapor withdrawal.

Designed specifically for vapor or liquid withdrawal service on ASME motor fuel containers. Since none of these valves have an integral pressure relief valve, they may only be used as an accessory valve on containers that have an independent pressure relief valve sufficient for that container’s capacity.

Designed specifically for vapor or liquid withdrawal service on DOT fork lift containers. Valves with 1.5 GPM closing flow are for use in small and medium size lift truck applications, while those with 2.6 GPM closing flow are for large lift trucks. Since none of these valves have an integral pressure relief valve, they may only be used as an accessory valve on containers that have an independent pressure relief valve sufficient for that cylinder’s capacity.

Designed for vapor withdrawal from and protection of DOT cylinders up to 100 lbs. propylene capacity with pressure ratings such as 4B-260, 4BA-260, and 4BW-260 cylinders.

This valve is designed for vapo

8613371530291

8613371530291