gas oven safety valve troubleshooting factory

FYI, when replacing a burner valve don’t take short cuts and just replace the front portion of the valve. It may save you from future problems by replaceing the whole valve.

On the lighter side of trouble shooting issues, I recently spoke to a customer in the denver area who was positive that his 6 burner convection oven range fan was burnout and not working properly at all. After repeated phone calls back and forth with the customer and the factory numerous emails and part breakdowns, We were able to conclude that the problem was as simple as plugging in the fan for the convection oven. Sometimes it pays to check the simple solutions also!

Don’t be fearful of completing some minor repairs on your own and avoiding a costly service call. There are several fixes for your range which you can tackle yourself. Grab a “Gas Repair for the Hopeless” guide, save some money and learn how to take care of your gas equipment.

When a thermostat fails and is “Running Wild” be very careful this means the thermostat will not shuf-off and is in the WIDE open position. The thermostat controls the gas flow and when not working gas is very dangerous.

When changing out the top burner gas valves some people notice that the two pieces of the valve are held together with two small phillips head screws (on some valves, not all) DO NOT try to replace only half of the gas valve. This is a very serious safty issue and it will more than likely NOT fix your problem, leaving you with two gas valves that do not work. Do it right, and do it once!!

These are very helpful hints on troubleshooting. Since 99% of the restaurants that I work with have a range similar to this, I like to remind my customers of how to find the model and serial number of the unit, especially if I am speaking to them over the phone. It ensures that I get them the right part the first time if we can’t automatically figure it out. The model/serial number is always located on the inside of the kick plate underneath the oven door or on the unit itself once the kick plate is removed. Another helpful tip is to write this information down when you buy a new range so that you will always have it as time wears on and the information wears off.

Every restaurant owner that knows a little about fixing gas equipment should always keep a back up thermocouple or thermopile for every gas piece of equipment on the line. These items are cheap and will save you from paying next day air charges when your gas equipment goes out on Thursday night.

A little preventative maintenance never hurts either. Lubricate you burner valves with graphite grease on regular intervals. Nothing worse than a stuck, or hard to turn valve. Also a great up sell that can save your customers a service call.

I have a US Range model u60-6r24rru one side of the lower oven unit does not shut off the gas it keeps heating just by turning the Temperature knob just slightly to ON , the other oven strangely has no gas going through the Pilot line , however when I turn on the Temperature Knob I am able to lite the oven by hand although lets say when set at 350 it shuts off I guess the Thermostat is working on that unit

It sounds like your gas safety valve is defective and should be replaced as soon as possible. You’ll also need to replace the thermostat on the side that you’re having to light by hand.

Until you get this fixed, you should cut off all gas to the range, because if that safety valve is shot you face a very real danger of gas building up and possibly igniting.

Unfortunately it cannot be converted. The main reason is the lack of electrical power. Even if the range had power, there are no electronic gas valves for it.

You could put a separate sparker on each burner but it would require drilling holes into the front panel (6 of them). Then you could shut the pilot valves off and use the sparker to light each burner.

for some reason my convection oven is not working i check the plug and its plugedin. what can i check all the different relays and electrical connections with

I cook in our church camp and one of our Wolf ovens shuts off ten minutes after startup. The Pilot light also shuts off. The safety valve, thermocouple, and the thermostat have all been replaced. Do you have any suggestions?

Sounds like you may not have the thermocouple in the pilot flame far enough or when you turn it on the burner is consuming most of the gas causing the pilot flame to get too low. This would cause the thermocouple to cool and shut the safety down. The thermocouple needs to be at least three quarters of the way into the pilot flame.

I have an old Garland (can’t find the model # on the range) but the manual says G280, G30A. The oven will not light and wondering what I need to fix it and if its worth it to invest the money. Thanks for your help.

I have a maytag gas oven wall unit model cwg3100aab and when cooking it will cook for about 30 minutes and then it will give me the f3 error what can I do

The wife found an old 1952 universal gas stove, Everything worked fine when we first got it about a year ago. Now, the oven will not come on, the pilot is lit . Stove part works fine. She loves the thing!!! After reading Teddy’s problem I think mine might be the same. Approximatelyhow much will it cost to fix, is it worth it!!

The Sounds as though the thermostat may be bad. It may not be opening to allow gas to flow through. The only suggestion I can offer is to google either antique or vintage stove parts. There are a lot of sites that provide parts for the vintage units.

That’s going to be a hard one to answer. Have you checked the flue to make sure the is no grease build up in it? If it is smoking from the top of the range have you checked the tray under the top burners? Make sure you don’t have any build on the oven walls or the top of it.

Also check the burner valves to make sure the orifice is not plugged. Some burner valve orifices are adjustable so may want to make sure they are open.

My 12 year old wolf range/oven pilot won’t stay lit. have replaced the thermocouple and safety valve. won’t light unless i turn on the oven temp a little, then i can light the pilot. hold the button for 30 seconds and the oven lights. then after a few minutes, it all goes out. Any suggestions?? THANKS!

Is the pilot tube attached to the back of the oven thermostat? If so, on the front of the thermostat there is a pilot adjustment screw. Try adjusting it first if it still will not light you will have to replace the thermostat because it is not allowing the pilot gas to get through to the pilot.

Is the thermostat somewhere where I can reach it? Also, why would the oven light up and stay going for a few minutes if there’s no gas getting to the pilot? I’m going to look at it now!! thanks for the lead!

I may be repeating myself but here we go. I took over a kitchen with a propane garland 6 burner 2 oven unit that is putting out an incredible amount of soot on everything especially saute pans and stock pots. It is getting everywhere, and I am being told that its always done that. 26 years I have never seen a burners put soot/carbon on all the pots and pans. Also none of the burners will light when you turn them on even though the pilot lights are lit so I have to light with a lighter every time I want to cook something (which is very often) our cost in lighters alone is killing us. any help or suggestions would be greatly appreciated. Was gonna try and drill out holes and see if that helps but not really sure what to do. is it a oxygen gas mixture problem? again we run on propane and are at 4200 feet, however I worked in a similar restaurant at same elevation on propane and had no problems with soot, Thanks

Hi – my older commercial Wolf range oven sat for 3 months During our kitchen remodel. It was recently hooked back up to the propane and now it seems to be running too hot – black soot is insiide the oven and on the bottom of my pans.

Christie, what is the model and serial number for the range? We’ll need that info to determine what pilot valve you have, which should be located behind the manifold. Another suggestion would be to check the regulator.

Adjusted Pressure regulator down to increase WC, on occasion burners lighting blows out the pilot. Sometimes with standing pilots the burners will not ignite. I suspect too low gas pressure from municipal but need another opinion.

If you have a lot of soot you may want to clean your stove–this could explain the large flames if you’re burning lots of debris. You may also have a gas pressure issue, which is mostly controlled by the gas valve itself. Give us a call at 888-388-6372 or contact us online for more info. Thanks!

hi. I have a ?35+ yrs old commercial 8 burner. 24 in. griddle. 1 lower oven. oven has pilot. has gas. but oven burner will not ignite. only gas build up and ignite out the LP regulator! in front of oven. how can I get the oven to work properly?

I have a four burner gas stove with a double oven (one bottom traditional size, one upper 1/2 size). When all four burners are being used for cooking, and I try to use either oven, or both at the same time, the oven(s) being used shuts itself off (both will do this simultaneously), and the burners, how ever many are being used, will go out. The flame(s) quickly die(s) out, leaving me with a partially cooked meal. Meaning I get to finish dinner on the grill outside.

I am a strong believer in fixing appliances myself when possible, I’m quite handy, and follow all laws of basic common sense when it comes to safety in the home, ESPECIALLY with gas.

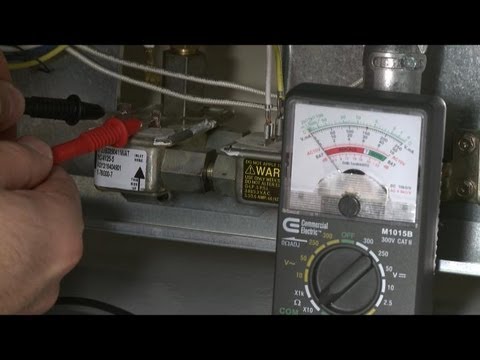

Is there some handy tool out there (hopefully not terribly expensive) that would allow me to measure, or test the stove at specific points where these are located, so that I could test each safety valve and thermostat; SO I would not have to replace them all, AS WELL as to check my work prior to returning the gas line to the stove?

Would it be safest to go ahead and just replace ALL of the safety valves and thermostats at the same time, SINCE the issue is occurring ALL throughout the stove, AT the same time?

If you’re working with a commercial unit chances are you need new burner valves. If you’re working with a residential unit then please direct these questions to the equipment manufacturers. They should have a technical assistance hotline to call.

The problem is that when the burners are on cooking something and you turn on the over when the oven starts and is heating up, the Flame on the top burners pull away from the cast iron burners about 1/2 to 1 ” and all the burners igniters start sparking.The seams to me to be some type of pressure or air mixture issue.. the repair person has replaced the Thermostat, Convection Fan, adjusted the burners and now wants to replace the spark module.

Any advise on the possible cause? This is a natural gas stove. Plugged Oven burners? I don’t understand a spark module as being the issue. Am I thinking clearly?

HELP Please!! I HAVE A HOBART GN9OS Convection oven. Its old but has worked good for years. I just recently cleaned the inside and now for some reason its not working…..I dont know if its coincidence or what?!?

Anyway, the pilots are still lit but when I go to turn it on, I get no burners kicking on. Usually there are only a few things that could be wrong, I’m handy, so I replaced the Thermostat and that didnt help…..then I replaced the gas solenoid valve, same thing……no help…..Any ideas?? Like I said, pilots are lit, just burners dont fire up. Im about to drop back and punt and call in a professional……

Patrick, the only other thing I think I would check is the wiring and making sure you have power where you’re supposed to have power. Is there power being sent to the gas valve when it’s trying to heat? Those kind of checks…

Thanks for the help! It seems that when I turn the oven on and turn the thermostat there is no power going to the gas valve solenoid as you suggested…..

I have a roper 30 in gas range. every time i go to set the oven temp as i turn the knob to raise the temp it keeps going back. Takes me several minutes to get the temp right. Could it be the thermostat?

If your gas range is not working correctly, you should check the gas pressure regulator shut-off valve. The factory default setting for the gas pressure regulator is in the "ON" position but may have been turned to the "OFF" position during handling or transportation. When the shut-off valve is on the "OFF" position, gas will flow to the cooktop burners but will not provide a gas supply to the oven.

You can check if the shut-off valve if you can slide the range out from the cabinet. If you are unable to slide the range out, we recommend consultation with a local certified technician.

Verify the pressure regulator shut-off valve is in the open position. The pressure regulator is located at the back of the range. Make sure that the shut-off valve lever is in the "On" position (see illustration below).

NOTE: If the range is hard piped, you will not be able to slide it out from the cabinet if it connected with a flexible supply line, take care not to over-extend the supply line. The main gas valve will usually be at the end of a fixed pipe and connect to the pressure regulator with a flexible supply line. Take care not to kink or pinch this flexible pipe.

If you turn on your gas oven and it doesn"t heat up, there are several possible causes, and you may be able to remedy the problem yourself, without calling a repair service.

If you are lucky, the problem may simply be that the electrical circuit supplying power to the oven has tripped a circuit breaker. Even though the oven heats with gas, it requires electrical power to operate the timer and other components, and if the circuit breaker has tripped, the oven will refuse to heat.

Since this is a gas oven, it will be connected to a circuit with a standard 15- or 20-amp breaker, not a large double-pole (usually 50-amp) breaker such as those used by electric ovens. Your oven may have its own breaker, or it may be tied into one of the small appliance or kitchen receptacle (outlet) circuits with a common breaker. If the breaker serving the oven has not tripped, the next thing to check is the gas supply and igniter.

Although rare, it is possible that your supply of natural gas or liquid propane gas has been interrupted for some reason. This usually happens when the main gas valve has been shut off to make some repair or replacement in the system and hasn"t been turned on again. Check the main gas valve, as well as any valves located on branch lines, to make sure they are in the ON position. If your oven has just been repaired or replaced, it"s also possible that the gas valve on the supply pipe hasn"t been turned back on. If the gas supply checks out to be fine, then turn to the gas igniter on the oven itself.

The problem could be that your oven igniter has simply gone bad. In normal operation, when the oven control is turned to bake, the igniter turns on and starts to glow bright orange. After the igniter gets hot, the gas valve opens and sends gas through the burner. The igniter lights the gas coming from the burner and the oven begins to heat.

If, however, the igniter doesn"t glow hot enough, the oven will not light, and you"ll likely smell a little gas. Don"t worry though; the gas valve is equipped with a safety mechanism that shuts off the gas if the igniter isn"t working properly.

To check the igniter, turn off the circuit breaker to the oven, then confirm the power is off by making sure the oven light, clock, and any other electrical functions are not working.

Remove the oven racks and the large metal plate (there may be more than one) at the bottom of the oven. This should expose the gas burner and igniter.

If the igniter looks okay, you can turn the power back, set the oven to heat, and observe the igniter at the beginning of the heating cycle. It should glow a bright orange within a few seconds. If it does not, and the gas does not ignite quickly, turn off the oven to stop the ignition function. The igniter has failed the test and will need to be replaced.

Before you can replace the igniter, you"ll have to order a replacement for the defective one. Not all igniters are the same. In fact, they are pretty much all different and have different electrical connections. The only way to get the right replacement part is to start with the oven"s model number and serial number. This may be on the back of the unit, inside the door or drawer, or even on a card or tab that slides out from behind the control panel of the oven. With your model and serial numbers in hand, you can search online for a replacement part, or call or visit a local appliance parts supplier. You can also contact the oven manufacturer online or by phone.

Shut off the power before doing any work on the oven, and be careful not to touch the igniter coil. Sometimes, these are black-colored spring-like coils; other times they are flat prong-like loops extending from the base of the igniter. The coil is very fragile, and oil from your hands getting on it can shorten the lifespan of the igniter.

Remove and replace the gas igniter, following the instructions included with the new igniter. It is an easy job, requiring only screwdrivers, a circuit tester, and a replacement igniter.

As a design engineer responsible for developing and specifying boilers, dryers, furnaces, heaters, ovens and other industrial heating equipment, you face a daunting labyrinth of standards and industry regulations. Regulatory bodies sound a bit like alphabet soup, with acronyms like UL, FM, CSA, UR, AGA, ASME, ANSI, IRI, CE and NFPA tossed about. This article will help explain a common task for many thermal processing equipment specifiers: meeting the requirements of key codes — including Underwriters Laboratories (UL), Factory Mutual Insurers (FM) and the National Fire Protection Association (NFPA) — for safety valve equipment used in process heating applications.

Key to designing safety into your fuel train configurations are familiar technologies such as safety shutoff valves and vent valves as well as visual-indication mechanisms and proof-of-closure switches.

Your design skills come into play with how you take advantage of the wide range of products available. You can mix and match solenoid and safety shutoff valves — within designs from catalytic reactors to multi-zone furnaces — to create easily installed, cost-effective solutions that comply with all necessary standards. (See table.)

Make sure, however, that you start with a good grasp of valve element fundamentals. For example, examining a proof-of-closure (POC) switch underlines how reliably modern valves can ensure combustion safety. The POC unit provides an electrical contact interlocked with the controller safety circuit. In a typical design, the switch is located at the bottom of the valve, positioned to trace the stroke of the valve disc. When the disc seal reaches the fully closed position, it triggers the mechanism to push down on the contact, closing it and triggering the unit’s visual indicator to show open or closed status. As a result, the operator can act with full confidence in situations where it is critical that a safety valve be safely closed.

To provide ease of installation, many users prefer valves with modular capabilities. For example, to reduce mounting complexity, you can choose modular gas safety shut-off valves — combining a solenoid valve with an electrohydraulic motorized valve for a compact double-valve footprint, a slow-open feature and high flow rates. An accompanying actuator can provide on/off or high/low/off firing rates as well as visual indication and proof of closure for compliance with most industry standards.

Also, you may want to look for valves that include useful features such as pipe taps, which can facilitate accurate pressure readings and leakage testing.

Knowing your valve choices — and how they meet given codes and standards — can reduce the time required for design and production while facilitating compliance. This results in safer, more efficient and cost-effective heating process installations.

Answer: No, this is not possible due to the gas being controlled by the gas safety valve. You need the ignitor to be working properly before gas is allowed out of the gas safety valve.

The ignitor is a small round or rectangular (flat oven ignitor and the round oven ignitor) device located near the burner and is wired in series with the gas safety valve. When the ignitor is cold, it has a lot of resistance, meaning it gets most of the electricity in the circuit. As the ignitor heats up, its resistance drops allowing the heat to pass to the bi-metal strip in the gas safety valve, which then allows gas to be released to the burner assembly. The gas then gets ignited by the glow-bar ignitor. The ignitor glows the whole time the burner is on, keeping the gas safety valve open. The thermostat senses when the desired temperature is reached, and cuts off electricity to the gas safety valve and ignitor.

DavesRepair.com has an article on “Gas Oven Glowbar Igniters” along with photos and some helpful tips if you plan on making this repair yourself. He also offers some helpful suggestions on the two different types of igniters: the flat oven ignitor and the round oven ignitor and how to tell which shape your gas oven takes.

8613371530291

8613371530291