herose safety valve for sale

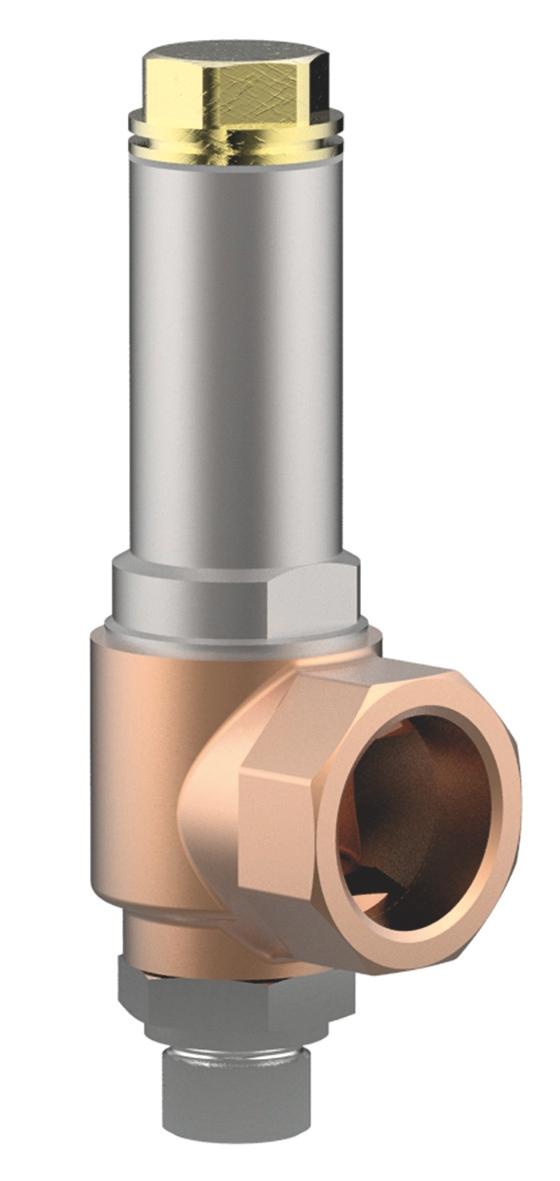

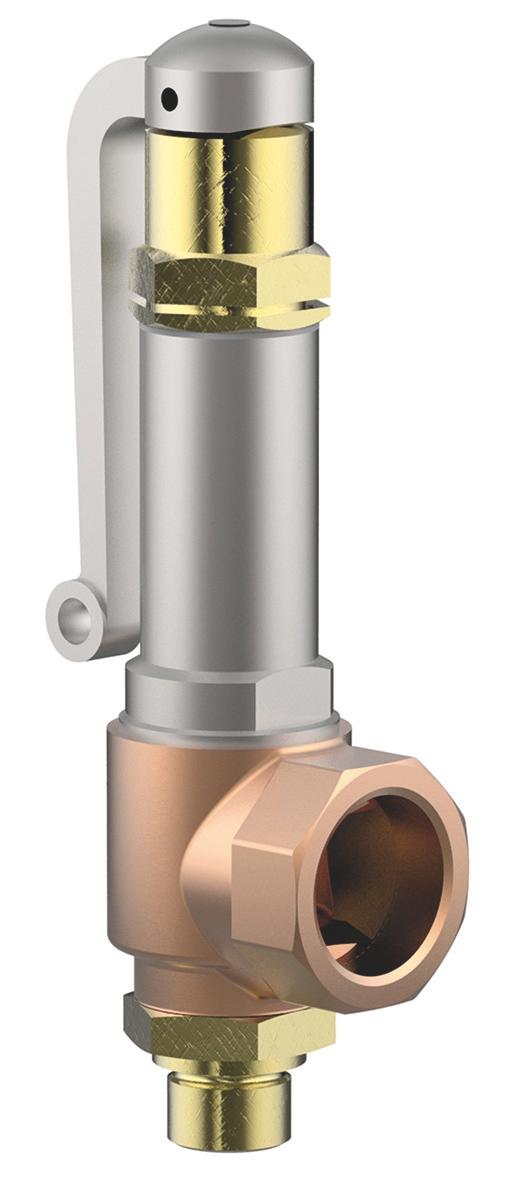

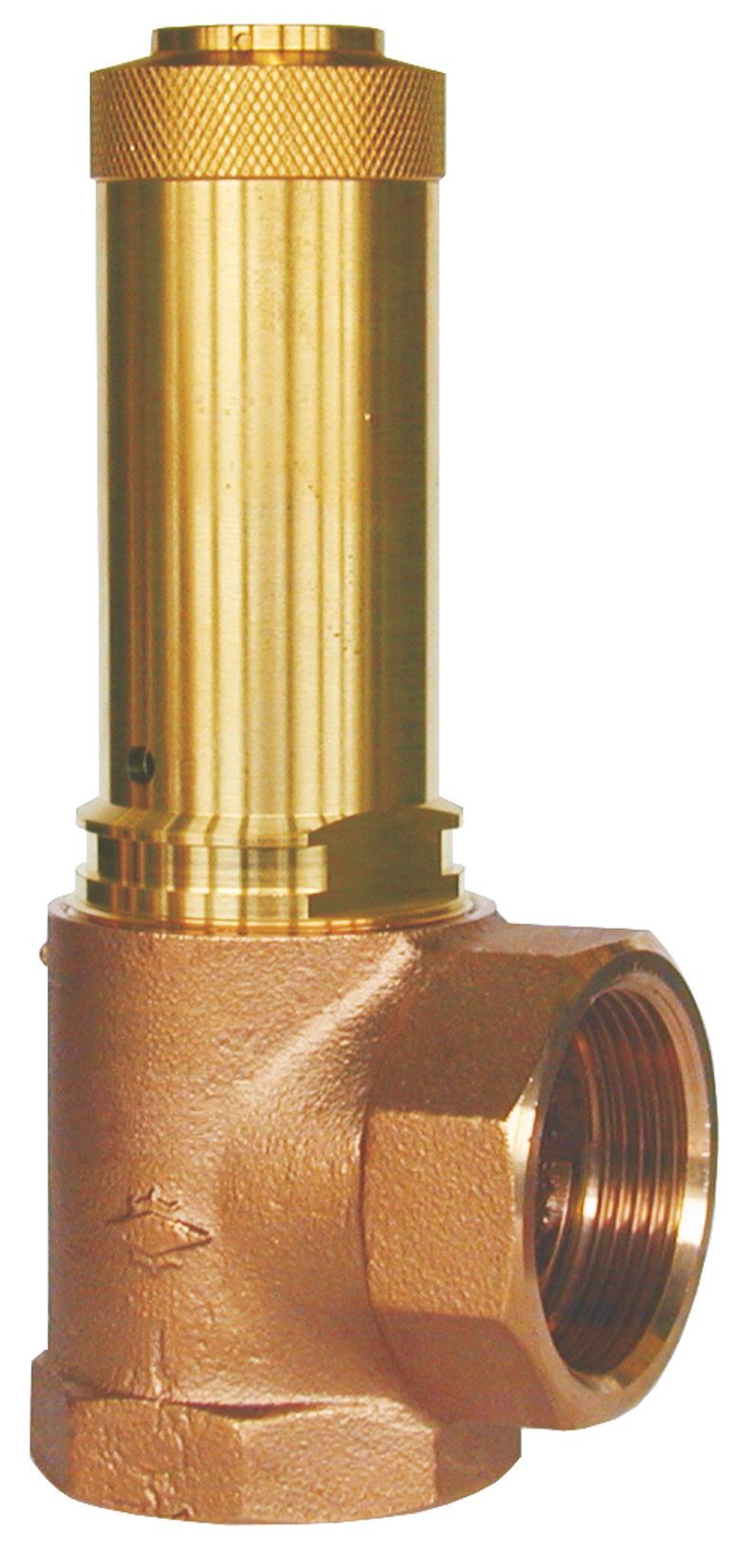

Valves for industrial applicationsIn order to prevent the uncontrolled rise in pressure in pressure vessels or pressurized pipelines, a safety valve is inserted. The safety valve is designed so that it opens at a given maximum pressure, thereby relieving the line or the container. Safety valves find their use in almost all areas of the pressure vessel and pipeline construction. In cryogenics as a spring-loaded safety valve for example.

HEROSE cryogenic safety valves are certified to global certifications for CN, TR CU and ASME. Thus they can be used worldwide, regardless of where the system is installed later. Cryogenic safety valves are available in sizes from DN6 to DN50 and secure pressures up to 550 bar, at operating temperatures of -270°C to +400°C. The safety valves are manufactured primarily in stainless steel but also in bronze and brass.

Please find the cryogenic safety valves in the product choice below. You can combine different product characteristicsto find your cryogenic safety valve better.

The HEROSE Type 06-217 is provided as a safety device for protection against excessive pressure in stationary and moveable gas cylinders and pressure vessels.

Welcome, and Thank You for visiting the leading supplier of cryogenic valves and industrial gas valves. We sell cryogenic and high pressure valves from only the highest quality manufacturers, like Herose valves. At Ratermann Manufacturing, we pride ourselves at not only shipping your valve products fast and at the most competitive price, but being the information authority in the industry. Our support staff will assist you in ordering exactly what you need to match the specifications of your gas applications.

HEROSE is the leading manufacturer worldwide of valves for cryogenic applications and services. Based on 140 years of experience in the development and manufacture of valves, we strive to provide customers with technical solutions over and above industry standards.

Our cryogenic safety valves are installed for protection against overpressure in tank containers and pipelines used for the storage, distribution and transport of liquefied gases — such as oxygen, nitrogen, argon, carbon dioxide, helium, hydrogen, etc. — at temperatures as low as -270°C (-454°F). A bellow-sealed option is available.

A major global gas company successfully subjected our cryogenic safety valves to an endurance test of 144,000 opening and closing cycles, and have subsequently been using our valves with trouble-free operation in over 35,000 installations for almost ten years.

Our diverter valves have been tested by a well-known cryogenic bulk vessel manufacturer. These tests reported a valve life expectancy of over 150 years.

HEROSE’s product range of LNG valves included bronze valves which are TUV-certified according to EN 12567, as well as stainless-steel valves which are additionally fire-safe approved according to EN ISO 10497.

This approval ensures that our fire-safe LNG valves remain tightly shut off, protecting plant and personnel when fires occur. HEROSE’s fire-safe LNG valves have been installed in critical applications worldwide.

Our product range of industrial safety valves covers the fields of gases, vapours, fluids and refrigerants. A special development is the industrial safety valve for pneumatically drained silo vehicles. Like other valves in the HEROSE range, this industrial safety valve is resistant to extreme vibration and environmental conditions.

As an environmentally aware company, we strive to ensure excellent sealing characteristics in all our industrial safety valves, minimising emissions to the atmosphere.

HEROSE offers the full package of cryogenic globe valves, control valves, check valves and emergency-closure valves, as well as diverter ball valves and change-over valves. All types are available in bronze or stainless steel, either for manual operation or as an actuated design.

More recently, we have introduced a complete range of stainless-steel gate valves, which takes HEROSE’s quality and design capabilities into new applications, such as cryogenic road tankers.

HEROSE is extending its range of products for cryogenic technology with ball valves. Especially for CO2 tanks and ISO containers for offshore use, or any other application where a rapid opening and closing of the valve is required, these cryogenic ball valves are an optimum supplement to the HEROSE product range.

HEROSE offers a range of pneumatic actuated cryogenic control valves. These valves are working with a linear or equal percentage control characteristic and are approved for air gases, vapours and cryogenic liquefied gases including LNG.

HEROSE’s success is ensured by our highly qualified staff. Our engineers are committed to the ongoing development of our valves to find tailor-made solutions for our customer base when existing products fail to meet their application requirements.

Our customers benefit from our TÜV approved quality systems according to the latest editions of DIN EN ISO 9001, PED 97 / 23 / EG, AD 2000 and TPED 99 / 36 / EG. The high-quality design of the HEROSE range is verified by the fact product complaints have only been made against less than 0.03% of the total valves we have manufactured. The company’s primary target is customer satisfaction.

HEROSE is one of Europe’s leading manufacturers of valves for industrial applications, providing safety for the handling of technical gases, steams and liquids.

For over 145 years HEROSE has developed valves for cryogenic technology and pressure vessel construction. Producing more than 400,000 valves per year, they are one of the most experienced suppliers in the sector with products being used throughout the world.

HEROSE provides safety around the world for the handling of technical gases, steams and liquids. With 140 years experience in the development, manufacture and sale of valves with a high level of innovation and modern production with certified quality management

Established in the year 2010 at Razak Garden, Arumbakkam, Chennai, Tamil Nadu,we “Dlco Cryo Gases Private Limited” are a Private Limited Company engaged as the foremost Wholesale Trader Of Safety Valves,Overflow Valves,etc.Our products are high in demand due to their premium quality and affordable prices. Furthermore, we ensure to timely deliver these products to our clients, through this we have gained a huge clients base in the market. We are Providing Gas Filling Station Installation Services, etc to Our Clients.

As of December, the Velaro RUS high speed train now connects St. Petersburg with the Urals. This train, which is built by Siemens, uses HEROSE valves. Two of the eight trains ordered have already been delivered and are now undergoing a rigorous testing programme in Russia

Each train of the Velaro series consists of ten coaches. The braking systems of these trains are each supplied with air via two compressors. These air supply systems each include two HEROSE safety valves. Volker Maass, HEROSE Deputy Sales Manager: “The braking systems of the Velaro are built for Siemens by Knorr-Bremse in Munich. At the end of 2007, this customer enquired whether we could develop and supply the necessary valves.”

HEROSE was able to do this. Volker Maass: “On the basis of the 06217 valve, which has been used for many years by the Deutsche Bahn, we developed the Type 06219 for the Velaro.” The essential difference between these valves is that the further development can withstand temperatures down to minus 55 degrees – an essential requirement for use in Russia. What exactly were the requirements? “In order to ensure the sealing and precise trigger pressure even under extreme climatic conditions, we had to redesign the plates of the safety valve and to adapt the sealing material,” say Volker Maass.

In order to test these requirements, HEROSE set up a climatic chamber in Bad Oldesloe. The new valve passed all tests, both in the cold chamber in Bad Oldesloe and in a comparable (but much larger) facility in Munich. Karl Hering, Air Supply Product Manager for Knorr-Bremse: “In this chamber we tested the functioning of the entire compressor assembly.” Knorr-Bremse developed an oil-free compressor for the Russian market, which in contrast to oil lubricated compressors can be cold-started.

HEROSE is confident that the development of this extreme cold-resistant 06219 valve will open up new markets. Volker Maass: “Railways in Scandinavian countries or in Canada also have similar climatic conditions to Russia.”

8613371530291

8613371530291