how does a gas safety valve work made in china

With the strengthening of China’s environmental awareness and the change of energy structure, China’s urban gas industry has made great progress. The types of gas have developed from simple coal system to multiple gas sources. In the late 1990s, the continuous development, construction and utilization of China’s natural gas resources have promoted the development of China’s urban natural gas into a new era.

The pressure of natural gas transmission and distribution is higher than that of man-made gas, so it is very important to store and transport natural gas safely in densely populated cities and towns. If the leakage and shutdown accidents caused by improper selection or poor quality of

In order to have enough “strength” and “rigidity” — “strength” means that the valve should be able to bear the Zui high pressure of gas transmission and distribution in the pipeline, and more importantly, it must have enough “rigidity”, that is, it can keep the valve from deformation even under various external forces of the underground pipe network, which can guarantee the sealing performance of the valve:

1. Reduce the structural height of the valve as much as possible (referring to the height from the center line of the valve flow section to the valve top) to reduce the buried pipe depth;

2. The top of the valve shall be equipped with a fully closed opening and closing indicator, so that the operator can see the status of the valve at any time, which is an important condition for safe operation;

3. Full diameter design, reduce the flow resistance, facilitate to pass through the pipeline cleaner or pipeline detector, and also meet the requirements of non-stop transmission of closed hole opener to open holes on the pipeline;

4. Reliable sealing performance, cj3055-95 “test and inspection of urban gas valves” standard stipulates that: under 1.1 times of nominal rated service pressure, soft sealing valve is not allowed to have any perceived internal leakage, and under 1.1 times of nominal rated service pressure, hard sealing valve is allowed to have internal leakage less than 0.3dnmm3/s, which is relatively strict, such as: 500mm nominal diameter gas valve The internal leakage per minute shall not be more than 9 ml (the capacity of ordinary drinking cup is 200 ml) and the external leakage is not allowed;

5. The shell of the gas valve used in the underground pipe network shall be corrosion-resistant. It is recommended to use different shell materials according to the transmission medium and service pressure of the pipeline;

6. For the design of valve parts, the structure of less maintenance and no maintenance shall be considered, so as to reduce the workload of maintenance as much as possible, reduce the road closure due to valve maintenance and affect the traffic;

7. Most of the underground pipeline valves are manually opened and closed. It is required that the opening and closing torque of the valve is small, and the number of turns in the whole process should not be too many, and the air source can be cut off as soon as possible after the accident;

8. Various underground pipelines of urban roads in China are crowded and complex, so it is not suitable to excavate basement inspection wells, so direct buried valves are recommended.

1. For the transmission and distribution pipeline under medium pressure class B (0.2MPa), it is recommended to use gray cast iron valve, which has the advantages of good corrosion resistance and low price, so it is very suitable for underground pipeline;

2. For medium pressure class A (0.4MPa) or below, or even high pressure class B (0.8MPa), it is recommended to use ductile iron or cast steel for manufacturing, with emphasis on the selection of ductile iron. For example, compared with cast steel brand WCB, the mechanical property of the former is no less than that of the latter, while the corrosion resistance and casting process are better than that of the cast steel, and the price is also lower than that of the cast steel (generally about 70% of the cast steel). Therefore, the overall performance and price of the ductile iron valve are better than that of the cast steel valve. In the above pressure range, the ductile iron valve can be selected as much as possible, but especially Do not pay attention to the quality control of nodular cast iron;

3. In places with high-pressure class A (1.6Mpa) or higher, it is recommended to select cast steel valves, and WCB brand is generally used to manufacture valves below 4MPa;

PE ball valve has also come out. This series of ball valves can be directly buried and have good sealing performance. However, at present, the price of PE ball valve is relatively high, especially for ball valve larger than 100mm.

In the 1980s, China’s gas is mainly made of artificial coal. There are more impurities and “gas glue” in the artificial coal gas. The traditional single ram wedge type sluice valve can not meet the needs of the gas working condition more and more. This kind of valve generally has the problems of “not tightly closed” and the valve rod is blocked. The gas oil sealed plug valve solves the problems of not tightly closed and the valve rod is blocked. Its main technical features: hard sealing structure is adopted to make it have the function of scraping rubber; the sealing surface does not contact with gas impurities, there is no valve rod in the cavity, and there is no problem of valve rod seizing; the sealing grease and O-ring that are specially developed to resist the erosion of gas medium improve the performance of plug valve.

1. It is not the same diameter as the pipeline, but about 75% of the pipeline flow area, which increases the flow resistance and eddy current, and can not pass through the pig;

With the development of gas industry and the establishment of gas plants, special gas valves with large or even extra large nominal diameter are needed. The problem of artificial gas formation is solved one by one by using parallel double gate valve for gas, and the diameter of Zui is 1600mm.

1. In the process of opening and closing, the parallel double gate valve can scrape off the “gas glue” on the sealing surface, which solves the big problem that the gas impurities adhere to the sealing surface and affect the valve sealing;

V. the valve body adopts the specially designed “squirrel cage frame stiffener” to reduce the overall weight of the valve and enhance the strength and rigidity of the shell;

7. The gate valve of this series is equipped with a fully closed opening and closing indicator, so that the operator can clearly understand the status of the valve.

Compared with the above valves, butterfly valves are lighter, larger in diameter and lower in price. In the early 1980s, some gas companies once used butterfly valves. After about ten years of use, it is generally considered that the effect is not good.

1. The isolation width of the sealing pair of butterfly valve is too narrow, which is easy to cause the valve disc to close excessively or not in place, affecting the sealing;

3. Because the middle part of the seal fitting is rubber or polytetrafluoroethylene, it is easy to be damaged or fall off during gas flushing, and the service life is short. It is proved that butterfly valve is not suitable for gas pipeline except for special position.

Flat gate valve is a general valve which has been used in gas pipeline in recent years. Its flow resistance is small when the valve is full bore, and the seal on both sides is formed by pressing PTFE or rubber O-ring on the gate. This kind of valve can’t be completely closed or fully opened without gas in the middle cavity, which is not convenient for users to judge whether the valve is closed tightly in emergency repair. If the valve is to be completely closed without gas in the middle cavity, the opening and closing torque will increase rapidly; some factories Home made reducer, such as DN200 caliber, with an inner diameter of only 150 mm. Users should pay special attention to it. Therefore, the flat gate valve is suitable for the occasion of lower pressure level system and smaller nominal diameter.

Elastic seal gas gate valve is different from flat gate valve. The features of the valve are similar to the elastic seat structure of the fixed ball valve. The sealing seat rings on both sides of the ram are of the elastic floating structure. The sealing faces are always close together during the opening and closing process, and can compensate the wear of the sealing pair, which is suitable for the occasion of high pressure system. When the valve is fully open and fully closed, there is no gas in the valve cavity, even if the remaining gas in the valve cavity is released There is still no pressure in the cavity, so users can safely construct the pipeline downstream of the valve, which greatly reduces the working time for gas stop preparation before construction.

There are two connection forms of elastic seal gas gate valve: flange type and welding type. Flange type is the traditional connection way. The welding type can directly weld the valve and the pipeline, saving the pipe laying cost; the two kinds of valves can be directly buried, avoiding unnecessary inspection wells, and bringing convenience to the construction.

When the elastic seal gas gate valve is fully opened, it looks like a section of pipeline with the same diameter of the pipeline, with minimal flow resistance; all sealing surfaces are hidden and do not contact with the medium. For the artificial coal to gas, the “gas glue” cannot adhere to the sealing surface, and for the natural gas, the dust and gravel can not wash the parts.

In a word, the elastic sealing gas gate valve is suitable for gas pipeline, especially for underground gas pipeline. From the situation of foreign investigation, many countries use the elastic flat gate valve on the natural gas pipeline. Compared with the nominal diameter elastic flat gate valve and the ball valve, they have the function of fire prevention, and the price is about 30% lower than the ball valve, so the use effect is the same. The disadvantage of Trz series elastic seal gas gate valve is that its structure height is large, and it has 4 nominal diameters. Because it is buried underground, the height above the central axis of the pipeline is the same as that of the common gate valve, and its disadvantage is not obvious, mainly that the height of the lower half is larger than that of the common gate valve, and the buried depth is larger during construction, but generally does not affect the pipeline laying;

The emergency cut-off valve for pressure regulator is an important safety protection device in gas transmission and distribution system. The emergency cut-off valve is to install the emergency trip mechanism on the upper or side position of the stop valve. It is also connected with the regulator body as a whole, and with the filter as a whole. Its function is to shut down the air source in an emergency after the regulator fails, causing overpressure or loss of pressure, so as to ensure safety. The large use of natural gas in the city has improved the pressure level system of the pipe network. The failure of the pressure regulator will bring disastrous consequences to the city. The domestic gas industry has paid more and more attention to this. The products selected in China have not formed a certain trend. Imported, joint venture and domestic products are hard to distinguish between the good and the bad, so the selection should be cautious. RAQ series gas emergency shut-off valve is connected with the filter as a whole, with novel and compact structure and high sensitivity. It can quickly cut off the gas source of the pressure regulator at the set overpressure (300 mm / H2O) and pressure loss (180 mm / H2O) to ensure the safety of users;

In case of gas leakage or other disasters of gas boiler, gas air conditioner and gas equipment, the emergency shut-off valve shall cut off the gas source quickly to prevent the expansion of the disaster. At present, the gas emergency shut-off valve has not been popularized in China. With the strengthening of environmental protection awareness and safety awareness, as well as the development of gas industry, the gas emergency shut-off valve will certainly get people’s attention. The gas emergency shut-off valve is a valve to ensure safety. It is connected with the automatic monitoring equipment to execute the valve closing instruction. Therefore, the gas emergency shut-off valves are all electric valves. According to the existing data, there are two types of such valves, one is solenoid valve, the other is electric valve. Due to the high requirements of gas emergency shut-off valve, such as fast speed, sealing, small flow resistance, caliber specification, etc., the existing solenoid valve and electric valve have certain defects, which can not meet all the requirements. These valves are analyzed one by one as follows:

I. At present, most of the solenoid valves are imported. The speed of the solenoid valve is fast, but the flow resistance is large. The flow resistance Zui in the stop valve is large, the pressure loss is large, and the caliber is small. It is difficult to manufacture the large caliber solenoid valve. Generally, it can only be below DN150, and the price is expensive. If the large caliber solenoid valve is equipped to meet the requirements of the diameter, the technical and economic ratio index is poor. Some solenoid valves are opened by electromagnetic field. Once the power is lost, the valve will be closed even if the power is lost instantaneously, which is not in line with the actual working condition. Uncoupling solenoid valve, energized uncoupling and closing valve, has high sensitivity and fast speed, because with DC low voltage, a little interference or power supply “shaking” will cause misoperation, affecting normal life and production;

2. Electric butterfly valve, with low price, is easy to be made into large caliber, and its opening and closing speed is faster than that of gate valve, and slower than that of solenoid valve; the flow anion is smaller than that of solenoid valve, and larger than that of gate valve; its sealing performance is worse than that of solenoid valve and gate valve, and because of the small sealing isolation width, the rapid opening and closing speed impact is easy to cause insufficient or excessive opening and closing;

3. Electric gate valve, with higher price, small flow resistance and good sealing performance, but its speed is too slow to meet the requirements of emergency cut-off;

4. The ball valve has small flow resistance and good sealing performance. However, the opening and closing speed of domestic or imported electric ball valve in the market is generally within 15-30 seconds, which can not meet the fast requirements. The user’s requirements for the opening and closing speed of emergency shut-off valve are generally within 10 seconds. The electric ball valve has many advantages. It can become an ideal emergency shut-off valve only by improving the opening and closing speed.

The emergency cut-off electric ball valve integrates the advantages of the ball valve, with the opening and closing speed of 3.75 seconds, which fills in the gaps at home and abroad. In addition, it has the function of anti-static and fire prevention in the structure design. The electrical equipment can be connected with the gas leakage alarm, disaster control equipment, fan and other auxiliary equipment. The overall design conforms to the price of dbj08-65-97 technical code for urban natural gas pipeline engineering It is much lower than similar imported products. Once it came out, it was accepted by gas users and received high praise.

The compressor of gas storage and distribution station often needs to be equipped with check valve to prevent gas from flowing back into the compressor. The water check valve has been eliminated in the gas industry. The main disadvantage of the general gas check valve is that the valve plate vibrates with the reciprocating motion of the compressor, which makes a great noise when colliding with the valve body and easily damages the valve plate. The second is poor sealing.

The gas valve plays an important role in the gas industry, and the Ministry of construction attaches great importance to the normative construction of the gas valve. The industry standards of the gas valve include CJ3005-1992 general technical requirements for grey cast iron valves for urban gas, CJ3055-1995 test and inspection for valves for urban gas, CJ3056-1995 general technical regulations for ductile iron and cast steel valves for urban gas In June 2002, it also passed the industry standard of domestic manual gas valve. The formulation and promulgation of these standards standardize the valve industry, promote the progress and development of gas valves, and promote the development of gas industry; provide a reference for the research, production and use units; improve the understanding of the difference between gas valves and general valves, and ensure the safety margin of gas valves; they are welcomed by the gas industry.

1. The underground pipe network is made of medium pressure class B and below, and it is recommended to use direct buried gray cast iron parallel double gate valve;

2. The underground pipe network is of medium pressure class A and below, and it is recommended to use directly buried parallel double gate valve or elastic flat gate valve;

3. For underground pipe network under high pressure class B or under high pressure class A, it is recommended to use directly buried elastic flat gate valve and fixed ball gas ball valve;

5. For storage and distribution station or ground equipment with pressure below 0.4MPa and larger than DN500 caliber, gate valve shall be used as far as possible to reduce the price.

6. In the pressure regulator or pressure regulating station, parallel double gate valve is recommended for low pressure level (below 0.4MPa), and floating type gas ball valve can be used for gas ball valve. If the pressure level system is lower than 1.6Mpa, fixed type gas ball valve and elastic flat gate valve can be used.

7. In the pressure regulating box, if the butterfly valve must be selected due to the limited space conditions, the multi eccentric butterfly valve shall be selected, and the sealing material shall be polytetrafluoroethylene or hard seal, and it must be adjusted to the closed position accurately during commissioning.

China’s gas industry, especially the rapid development and popularization of natural gas, has driven the progress and development of gas valve manufacturing industry. With the introduction of West to east gas transmission, offshore natural gas, and Russian gas sources, new gas valves will come out to meet the needs of gas users.

(Yaang Pipe Industry is a leading manufacturer and supplier of nickel alloy and stainless steel products, including Super Duplex Stainless Steel Flanges, Stainless Steel Flanges, Stainless Steel Pipe Fittings, Stainless Steel Pipe. Yaang products are widely used in Shipbuilding, Nuclear power, Marine engineering, Petroleum, Chemical, Mining, Sewage treatment, Natural gas and Pressure vessels and other industries.)

The gas valve on your boiler controls the flow of gas to the pilot light and burner. When you demand heat or hot water, the boiler works like this: The PCB first detects the fan is operational, ready to expel dangerous flue gases via the flue.

In the open position (gas is flowing) the handle (lever) will be parallel with the pipe, when it is closed (gas not flowing) the handle (lever) will be perpendicular to the pipe. This should make it easy for you to tell if the gas is on, or off.

A thermocouple is a device made of two different metals which creates a small electrical charge when heated at one end by the gas pilot. This small charge causes an electromagnet inside the gas valve to open and allow gas to flow to the main burners.

A gas control valve can be found on any appliance that utilizes gas. These valves are vital for the operation and safety of any gas appliance. The valve does exactly what it sounds like, it controls the amount of gas flowing to create a steady flow without allowing any gas to leak.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A60 safety valve is adopted in the European type range. The flameout protection device uses the principle of magnetic attraction of the solenoid valve to ensure that the gas is automatically closed when the flame goes out unexpectedly. Widely used in Europe, Australia, Middle East, Southeast Asia and China market.

A variety of installation ways, the application is more flexibleWe can adjust and tailor-made the specifications according to the structure and functions of the cooker manufacturer. A60 safety valve has a variety of installation methods, including SPIGOT, SADDLE MOUNT, U MOUNT and FLANGE.

The A60 safety valve with CSA, CE and Australian certification meets the highest standards of air tightness, durability and working pressure and temperature in the commercial appliances industry. Cooker"s manufacturers can sell the same model to multiple markets for saving development and design costs.

The body of clamping design of on-off valve A18-X1X can be assembled with a general wrench, which is fast and convenient for assembly. Stainless steel flexible tube are produced from CSA certified raw materials with durable and reliable quality.

Manifolds and gas valves pre-assembly service to save the assembly cost of cooker"s manufacturers and increasing their production capacity. All of Alpha Brass Control"s products are high accurate and 100% air-tight tested.

Because of different of drive source, SSV can dividedinto Hydraulic safety valve and pneumatic valve ; With thermal and high voltage explosion-proof device ; Actuators and prepare two parts of the valve, standard interface, easy replacement and maintenance .

This valve is used for power plant boilers, pressure containers, pressure and temperature reducing device and other facilities. It serves to prevent the pressure exceeding the highest allowable pres-sure value and ensure the safety of the device when working.

(1)The pressure of the disc is balanced through the lever and heavy hammer and the valve is ensured seal by moving the for ton of heavy hammer and changing the weight of heavy hammer to reach the required set pressure.

(2)The sealed surface is made of Fe base stainless steel by overlaying welding. Through thermal treatment, the wear resistance and anti-erosion of disc is improved.

(3)At the top of valve is equipped an electromagnet to open and another to close the valve. The actions of the mechanism and the electric appliance are separate and will not affect each other.

(2)Impulse safety valve shall be installed vertically and the lever shall be kept level. The clearance from the lever to both sides of guide fork shall be even.

(4)A long distance between the leading pipe of the impulse safety valve and the inlet pipe of the main safety valve shall be kept. And the distance between the electric contact pressure meter and the inlet pipe of the main safety valve shall be no less than 5 times of the diameter of the inlet pipe, for feat that the validity of the mater and the impulse safety valve may be affected by the steam releasing process of the main safety valve.

This valve is used for power plant boilers, pressure containers, pressure and temperature reducing device and other facilities. It serves to present the pressure exceeding the highest allowable pres-sure value and ensure the safety of the device when working.

1,When the medium pressure rises to the set pressure, the in-pulse safety valve opens, and the medium in the impulse pipe enters into the piston chamber of the main safety valve from impulse pipe, forcing the piston to descend, and then the valve automatically open-s; when the impulse safety valve closes, the disc will slash automatically close.

2,The sealed surface is made of Fe base stainless steel by over-laying welding. Through thermal treatment, the wear resistance and anti-erosion of disc so improved.

2,The main safety valve shall be fastened upon the gallows, which sustains the back-seat force produced in the steam discharging process of the main safety valve.

3,The exhaust pipe shall contain a special gallows to prevent the force of its weight directly applying on the main safety valve. The connecting Lange At the lowest point of the exhaust pipe, water drainage shall be taken into consideration to avoid producing water hammer while discharging set between the main safety valve and exhaust pipe shall eliminate any extra stress.

A safety valve protects the system and equipment from overpressure. Overpressure develops when the pressure exceeds the system’s maximum allowable working pressure (MWAP) or the pressure under which it has been designed. Safety valves have a short opening time to discharge gases or liquids immediately. A safety valve opens when a certain pressure is reached; it opens partially at first to eliminate undesirable pressure from the system as rapidly as possible.

Safety valves are utilized to stop pressure rises that might cause malfunctions, fire risks, or explosions. Safety valves are utilized when electrical or pneumatic safety systems malfunction since they only have mechanical components. The system’s media fully activates a safety valve, keeping it operational in the case of a power failure.

Most modern appliances have safety features built in, but your gas oven safety valve is arguably the most important. If an electrical appliance malfunctions, it can cause a fire, but a misfiring gas oven could potentially blow up your house. You don"t really need to know how the safety mechanism works to use your oven, but you may find that it gives you some extra peace of mind.

Broadly speaking, there are two ways a built-in safety mechanism can work. One option is that it remains "open" by default and to shut off if certain conditions are met. That"s how fuses and circuit breakers work in an electrical circuit: Ordinarily, the electricity is free to flow, but if the current grows too large, the fuse or breaker will blow and cut off the circulation of electricity.

The other option is for your safety mechanism to be "closed" by default and allow a device to operate only when the correct conditions are met. That"s how a gas oven safety valve works. Gas ordinarily is prevented from flowing, and if the valve is working correctly, it opens only when you want to light your oven.

Many gas stoves use what"s called a "hot surface igniter," a bar or element (similar to the ones on your stovetop) that gets hot enough to ignite the gas on contact. Gas oven safety valves on stoves with this type of ignition system take a couple of different approaches.

In one approach, a bimetallic strip operates the valve. It harnesses a simple scientific principle: Metals expand and contract at different rates when they"re heated and cooled. If you bond two suitable metals together in one strip, that strip will flex to a predictable degree as the temperature goes up and down. Wall-mount thermostats often use this principle, as do analog oven thermometers and the thermometer in the lid of your gas grill.

As appliance-repair website PartSelect explains, turning on your gas oven causes electricity to flow into the heating element of your hot surface igniter. As the igniter heats up, it warms a bimetallic strip inside your gas oven safety valve. When the igniter reaches its operating temperature, the bimetallic strip opens the valve and allows the gas to flow, igniting as it crosses the heated surface.

One intriguing thing about electricity is that a change in temperature can affect how well it passes through certain materials. For example, a lot of research revolves around superconductors – materials that offer very little resistance to an electrical current – but superconductors typically must be heavily chilled to work.

According to heating-equipment vendor Anglo Nordic, gas oven safety valves use a variation of that principle to operate. In these stoves, the flow of electrical current through the hot surface igniter becomes the control mechanism. The igniter"s bar is made of a material that offers less and less resistance to electricity as it heats. When it reaches the temperature required to ignite the gas, its resistance becomes low enough to trip the safety valve and open the flow of gas.

More modern ranges use an electrical igniter. When you turn on your oven, the gas begins flowing immediately, and it sends an electrical current to a piezo electric igniter. The current makes the igniter spark (like the manual igniter on your gas grill) and lights the oven"s burner. In this case, the safety valve works in the opposite way: An electronic sensor checks for the heat caused by ignition after a few seconds, and if it"s absent, it will close the valve and shut off the flow of gas.

It"s worth pointing out that not all gas ovens have a safety valve in the conventional sense. Older stoves simply use a pilot light, a small but constant flow of gas, which, in turn, feeds a small, candle-like flame. You essentially are the safety mechanism in this system: It"s up to you to check that the pilot is lit. When you turn on the gas manually, the small pilot flame ignites the main flame. It"s a mechanically simple system, which makes it durable, and for that reason, you"ll still see it used on commercial restaurant ranges, which must stand up to decades of heavy use.

Fusible link valves are designed to automatically shut off any gas or liquid in the pipeline when the fire is present. This ensures that fires don’t spread and offers better performance than standard shut-off valves.Heat-sensitive elements will shrink and cause the fusible top work assembly to open, cut off fluid flow through a pipe, and prevent fuel leakage.

The fusible link serves as a pressure release and shutoff valve used to prevent the overpressurization of equipment and/or piping systems. It allows pressurized fluid to discharge through a pipe into the atmosphere or into another section of piping.

The fusible link can be set to melt at different temperatures depending on the type of gas or liquid that is being used, such as natural gas, propane, oil, water, etc.

Fusible links are fast-acting shutoff devices that, once activated by high temperature, release pressure rapidly to protect equipment and/or systems from damage due to overpressurization. The fusible link consists of a length of wire or ribbon of fusible metal with two small arms at either end. The fusible metal used is an alloy that has a low melting point, generally the same as or lower than the pressure-containing medium being protected against overpressurization.

A fire-safety valve with a fusible link is an important safety device in the event of a fire on naval vessels, as a fire extinguisher is not sufficient on its own to prevent the risk of explosion from overheating oil tanks.

Contact us today if you would like more information about our fire-safety valves with fusible links! We offer competitive pricing and excellent customer service! You can get fusible link valves from THINKTANK, and build your own brand.

Gas Safety ValvesThese valves automatically control main gas flow. Our automatic pilot valves shut off both the main and pilot gases. Pilot gas is tapped from the main line within the control. Gas will flow only to the pilot burner when the reset button is depressed. The manual pilot valve stop can be adjusted for maximum pilot flow.

Pilot BurnersThese “J Series” combination pilot burners are universal replacement pilot burners and are supplied in three models. Mounting brackets on all four sides of each burner permit adaptation to almost any application. We also offer pilot burner fittings (R Series) and replacement flame sensors and inlet fittings (Y Series).

BEIJING, May 6, 2019 – Guangdong Vanward New Electric Co., Ltd., a gas appliances manufacturer, and Resideo Technologies, Inc. (NYSE: REZI), a global leader in home technologies, today announced a global strategic partnership to develop and promote Resideo’s iXQ gas adaptive technology for residential applications.

The partnership, announced at ISH China & CIHE 2019 (China International Trade Fair for Heating, Ventilation, Air-Conditioning, Sanitation & Home Comfort Systems), will include collaboration on dedicated technical trainings, installation prototypes, testing and verification, and product launches. In addition, the partners will work together on two atmospheric gas valve projects – Atmix and the CVI Moduplus – and the pX42 basic full premixed wall-hung boiler project.

“We are always on the lookout for strategic partners who share our vision and can cooperate with us over the long term,” said Vinnie Schultz, Product and Solutions vice president and general manager of Residential Thermal Solutions at Resideo. “Vanward is known for excellence in R&D and innovation. Over the years, Resideo has supported Vanward in the development of residential and commercial products, including gas adaptive technologies. We believe the shared vision and goals of our companies will continue to spark new ideas and provide Chinese consumers with more choices for comfortable, energy-saving and environmentally friendly home heating systems.”

“Vanward greatly values Resideo"s robust technology and long-established expertise in the fields of combustion control and gas valves,” said Lu Yucong, president of Vanward. “The strategic cooperation with Resideo will enhance Vanward’s leading position in the heating industry. Currently, Vanward’s gas adaptive technology has made significant progress in the Chinese market. Our plans call for further collaboration in the future. We will work with Resideo to evaluate and upgrade our basic laboratory, to apply the technology to improve our product portfolio for our target market, to share global market resources, to promote collaboration between university and industry researchers, and to extend the application of the technology. In addition, the cooperation will be expanded to include technology development, training, talent development, testing and many other aspects. The two companies will work closely on R&D, the intelligent Internet of Things, and large-scale commercial products, so as to truly achieve a powerful combination of resources and capabilities, and forge strong competitive advantages for both parties."

Resideo’s iXQ technology builds on the company’s extensive experience in smart and safe combustion control and gas valves. The technology can identify if there is a flame, and the type of flame, and automatically adjust parameters for optimal combustion control. A specialized pX52 gas valve enables the high-precision control. The iXQ system requires no human intervention and can make intelligent adjustments that automatically adapt the boiler to the different types of gas qualities available in the Chinese market, maximizing combustion efficiency and system reliability.

In addition, the modular design of the gas adaptive iXQ system lets manufacturers introduce customized solutions that make development and manufacturing processes more flexible. The highly adaptable iXQ software algorithm ensures compatibility with all types of condensing gas boilers.

Vanward, a listed Chinese company (SHE: 002543) founded in August 1993, is a leading manufacturer of water heaters, kitchen appliances and water heating systems. Vanward owns seven manufacturing bases in Shunde, Zhongshan, Gaoming, Hefei, and other parts of China that together have an area of over one million square meters and annual production capacity of 15 million units. Vanward was the first to introduce multi-energy water heating systems to the Chinese market. Committed to becoming the world"s leading supplier of kitchen/bathroom appliances and water heating system solutions, Vanward provides energy-saving, environmentally friendly and comfortable hot water solutions, creating a high-quality, low-carbon life for millions of Chinese families.

Resideo is a leading global provider of critical comfort and security solutions primarily in residential environments, and distributor of low-voltage and security products. Building on a 130-year heritage, Resideo has a presence in more than 150 million homes, with 15 million systems installed in homes each year. We continue to serve more than 110,000 contractors through leading distributors, including our ADI Global Distribution business, which exports to more than 100 countries from more than 200 stocking locations around the world. Resideo is a $4.8 billion company with approximately 13,000 global employees. For more information about Resideo, please visit corporate.resideo.com.

As soon as mankind was able to boil water to create steam, the necessity of the safety device became evident. As long as 2000 years ago, the Chinese were using cauldrons with hinged lids to allow (relatively) safer production of steam. At the beginning of the 14th century, chemists used conical plugs and later, compressed springs to act as safety devices on pressurised vessels.

Early in the 19th century, boiler explosions on ships and locomotives frequently resulted from faulty safety devices, which led to the development of the first safety relief valves.

In 1848, Charles Retchie invented the accumulation chamber, which increases the compression surface within the safety valve allowing it to open rapidly within a narrow overpressure margin.

Today, most steam users are compelled by local health and safety regulations to ensure that their plant and processes incorporate safety devices and precautions, which ensure that dangerous conditions are prevented.

The principle type of device used to prevent overpressure in plant is the safety or safety relief valve. The safety valve operates by releasing a volume of fluid from within the plant when a predetermined maximum pressure is reached, thereby reducing the excess pressure in a safe manner. As the safety valve may be the only remaining device to prevent catastrophic failure under overpressure conditions, it is important that any such device is capable of operating at all times and under all possible conditions.

Safety valves should be installed wherever the maximum allowable working pressure (MAWP) of a system or pressure-containing vessel is likely to be exceeded. In steam systems, safety valves are typically used for boiler overpressure protection and other applications such as downstream of pressure reducing controls. Although their primary role is for safety, safety valves are also used in process operations to prevent product damage due to excess pressure. Pressure excess can be generated in a number of different situations, including:

The terms ‘safety valve’ and ‘safety relief valve’ are generic terms to describe many varieties of pressure relief devices that are designed to prevent excessive internal fluid pressure build-up. A wide range of different valves is available for many different applications and performance criteria.

In most national standards, specific definitions are given for the terms associated with safety and safety relief valves. There are several notable differences between the terminology used in the USA and Europe. One of the most important differences is that a valve referred to as a ‘safety valve’ in Europe is referred to as a ‘safety relief valve’ or ‘pressure relief valve’ in the USA. In addition, the term ‘safety valve’ in the USA generally refers specifically to the full-lift type of safety valve used in Europe.

Pressure relief valve- A spring-loaded pressure relief valve which is designed to open to relieve excess pressure and to reclose and prevent the further flow of fluid after normal conditions have been restored. It is characterised by a rapid-opening ‘pop’ action or by opening in a manner generally proportional to the increase in pressure over the opening pressure. It may be used for either compressible or incompressible fluids, depending on design, adjustment, or application.

Safety valves are primarily used with compressible gases and in particular for steam and air services. However, they can also be used for process type applications where they may be needed to protect the plant or to prevent spoilage of the product being processed.

Relief valve - A pressure relief device actuated by inlet static pressure having a gradual lift generally proportional to the increase in pressure over opening pressure.

Relief valves are commonly used in liquid systems, especially for lower capacities and thermal expansion duty. They can also be used on pumped systems as pressure overspill devices.

Safety relief valve - A pressure relief valve characterised by rapid opening or pop action, or by opening in proportion to the increase in pressure over the opening pressure, depending on the application, and which may be used either for liquid or compressible fluid.

In general, the safety relief valve will perform as a safety valve when used in a compressible gas system, but it will open in proportion to the overpressure when used in liquid systems, as would a relief valve.

Safety valve- A valve which automatically, without the assistance of any energy other than that of the fluid concerned, discharges a quantity of the fluid so as to prevent a predetermined safe pressure being exceeded, and which is designed to re-close and prevent further flow of fluid after normal pressure conditions of service have been restored.

They are made with high pressure resistance, and even in the form of a thermocouple gas valve. Thermocouple gas valves are suitable for compressed air, and has a high pressure resistance with high pressure pipes.

There are several types of thermocouple gas valves, including electric gas valves, reciprocating gas valves, and non-flammable thermocouple gas valves are divided into three types, including electric gas valves and reciprocating gas valves. Some types are thermocouple gas valves, also called thermocouple gas valves, including electric gas valves, reciprocating gas valves, and self-propelled gas valves.

"TRS is an exciting opportunity for an Offshore Safety Valve Technician to carry out Maintenance / Commissioning / Testing of Safety and Control Valves experience within the Oil and Gas industry to join our International Client"s Offshore project team based in Soyo, Angola.".

Our company has been awarded such honors as High & New Tech Enterprise, Key Enterprise in National Torch Planning Project, Famous Trademark in ZheJiang Province, Famous Brand Product in ZheJiang Province, Special Valve R&D Center in ZheJiang Province, Deputy Director Member of China Valve Association, National Valve Standards Setter. We have obtained most international certificates like DNV ISO9001:2008,ISO14001:2004,OHSAS 18001:2007Certificates, Our products designed and manufactured according to API standard,Ball valve with fire safe certificates API 607,API 6Fa.as well as TUV Germany Rhine Company CE Certificate and Pressure Pipe Fittings Manufacturing License TS Safety Certificate issued by the State Bureau of Quality and Technical Supervision, and the certificates from Russian GOST-R, RTN. Our company is the approved vendor of China National Petroleum Corporation(CNPC), China National Offshore Oil Corporation(CNOOC), SINOPEC, China Aluminum Group Corporation, China National Chemical Equipment Corporation, China Gas, Beijing Gas and also the supplier of international Oil Gas company like BP,Gazprom,LUKOIL, EIL, PDO, GE Oil & Gas, SABIC, SWCC, SAUDI MA"ADEN,Ecopetrol.

WuZhou Valve is also the exclusive supplier of high pressure large-diameter fully welded ball valves designated by the National Energy Administration, National Development and Reform Commission and PetroChina, and, our products have been widely applied in Phase 2 and 3 in the project of Natural Gas Transmission from West to East China.

Our company produces 10 major series of products totaling 1,200 varieties and specifications of high temperature, high pressure, high wear resistant, and large-diameter ball valves, gate valves, butterfly valves, gate valves, globe valves, check valves, ore slurry valves, power station valves, as well as non-standard and special valves with auxiliary devices for petroleum, chemical industry, metallurgy, light industry, coal chemical industry, power station, urban construction, water supply, oil, gas and natural gas transportation, long transportation pipeline and other projects. Nominal diameter DN10~4500mm(1/2"~64"), nominal pressure 1.6MPa ~ 42Mpa(150Lb ~ 2,500Lb), working temperature -196℃ ~ 750℃. Valve materials: carbon steel, stainless steel, heat resistant alloy steel, Monel, low temperature steel, and other special types of steel. Driving modes include manual, electric, pneumatic, gear transmission, worm gear and worm transmission, pneumatic and hydraulic combined, electric and hydraulic combined, and computer programmed control system. The products sell well throughout China and are exported to USA, Europe, Africa, the Middle East, Singapore, and other places in the world. By insisting on the corporate policy of Quality First, Customer Foremost, and Credibility-based, seeking the goal of “Three Merits” of Usability, Creditability, and Reliability, and establishing the first class brand of “WuZhou”, our company will make further contributions to the economic development of China and other countries with high quality products, favorable prices and excellent services.

Short Description: A41H type are used for the equipment and pipeline of the petroleum gas, air, water etc medium what the working temperature are less than 300℃. A41Y P/R type are used for the equipment and pipeline of the quality with corrode medium what the working temperature are less than 200℃. Take for extra pressure devices. Flange connecting dimensions of comply with Standard series first of JB/T79-94.

Code:A41H-16C,A41Y-16P,A41Y-16R,A41Y-16C,A41Y-16P;A41H-25C,A41Y-25P,A41Y-25R,A41Y-25,A41Y-40P;A41H-40,A41Y-40P,A41Y-40R,A41Y-40,A41Y-40P;A41H-64,A41Y-64,A41Y-64P,A41Y-64R;A41H-100,A41Y-100,A41Y-100P,A41Y-100R.(See below).

Short Description: A42Y-C type are used for the equipment and pipeline of the air, petroleum gas, liquid etc medium what the working temperature are less than 300℃.A42Y P type and A42Y R type are used for the equipment and pipeline of the quality with corrode medium what the working temperature are less than 200℃. Take for extra pressure protection devices.Flange connecting dimensions of comply with Standard series firstof JB/T……94. Comply with Standard series twice of J8/T…….94 when more than 6.4MPa.

Code:A42Y-16C,A42Y-16P,A42Y-16R,A42Y-16;KA42Y-16,DA42Y-16C(P),A42Y-25,A42Y-25P,A42Y-25R,KA42Y-25(P),DA42Y-25(P),A42Y-40,A42Y-40P,A42Y-40R,KA42Y-40,DA42Y-40(P) … …(See below).

Short Description: This safety valves are used for the equipment and pipeline of the steam, water etc.medium what the working temperature are less than 350℃. Take for extra pressure protection devices.Flange connecting dimensions of comply with Standard series one of JB/T79-94.

Short Description: A48Y type are used for the equipment and pipeline of the with steam and air etc medium what the working temperature are less than 350℃. A44Y type are used for the equipment and pipeline of the with air and petroleum gas medium what the working temperature are less than 300℃.Take for extra pressure protection devices.Flange connecting dimensions of comply with Standard series first of JB/T–94 when the pressure less than 6.4MPa, comply with Standard series second of JB/T-94 when more than 6.4MPa.

Code:A48Y-16C,A48Y-25,A48Y-40,A48Y-64,A48Y-100,A44Y-16P,A44Y-25PA44Y-40P,A44Y-64P,A44Y-100F,A44Y-16C,A44Y-25,A44Y-40,A44Y-64,A44Y-100,A44Y-16R,A44Y-25R,A44Y-40R,A44Y-64R,A44Y-100F

Short Description: These safety valve are used for the equipment and pipeline of the steam. etc.Medium what the working temperature with C Typeless than 425℃ and I type are less than 500℃ and V Type are less than 550℃. Take for extra pressure protection devices. Flange cc ecting dimensions of comply with Standard series first and second of JB/T79-94.

Code:SFA48Y-16C,SFA48Y-161,SFA48Y-16V,SFA48Y-40,SFA48Y-401,SFA48Y-40V,SFA48SH-4C,SFA48Y-64,SFA48Y-641,SFA48Y-64V,SFA48sB-64,SFA48sB-64,SFA48sB-64,SFA48Y-100,SFA48Y-1001,SFA48Y-100V,SFA48sB-100,SFA48sB-1001,SFA48sB-100V,SFA48TH-100,SFA48Y-160,SFA48sB-160,SFA48sB-1601,SFA48sB-160V

Short Description: Pilot operated safety valve, newly-structured, is mainly applied to such trades as petroleum & natural gas, chemistry, electric, metallurgy & burning gas. It is the best super-pressure protecting equipment on press equipment, container, or pipeline. It is mainly characterized by shifting direct function of spring to indirect function of guide valve. What – s more, main valve, applying for sleeve piston & double sealed

seat. Is characterized by high precision of action, good recycling function, fast turning back to seat, ability to high-pressure leaking, long working time & security, together with readjustment on line, automatic turning back to seat after leaking again and again, tight closure,operating and maintaining convenience.

Short Description: This safety valve are used for the equipment and pipeline of the steam, air etc medium what the working temperature are less than 350℃. Take for extra pressure protection devices.

Short Description: The valve of the air what the working temperature are less than 200℃, is air compressor specificity safety valve. when the pressure of equipment exceeding the allowed

value, the valve will turn on automatically and discharge the pressure entirely. when the pressure decrease to the stated value, the valve will quickly turn off automatically, in

Short Description: A27H type are used for the equipment and pipeline of water, air, steam etc.Medium what the working temperature are less than 200℃. A27Y type are used

Short Description: This safety valve are used for the equipment and pipeline of the steam, air etc medium what the working temperature are less than 350℃. Take for extra pressure protection devices.

Short Description: A27H type are used for the equipment and pipeline of water, air, steam etc.Medium what the working temperature are less than 200℃. A27Y type are used

Short Description:A28H type are used for the equipment and pipeline of the air, N2,H2 mixed gas vapour etc. medium what the working temperature are less than 200℃. A28Y-P/10R8 type are used for the equipment and pipeline of the quality with corrode medium what the working temperature are less than 200℃. Take for extra pressure protedtion devices.

Short Description:A28H type are used for the equipment and pipeline of the air, N2,H2 mixed gas vapour etc. medium what the working temperature are less than 200℃. A28Y-P/10R8 type are used for the equipment and pipeline of the quality with corrode medium what the working temperature are less than 200℃. Take for extra pressure protedtion devices.

Short Description:A28H type are used for the equipment and pipeline of the air, N2,H2 mixed gas vapour etc. medium what the working temperature are less than 200℃. A28Y-P/10R8 type are used for the equipment and pipeline of the quality with corrode medium what the working temperature are less than 200℃. Take for extra pressure protedtion devices.

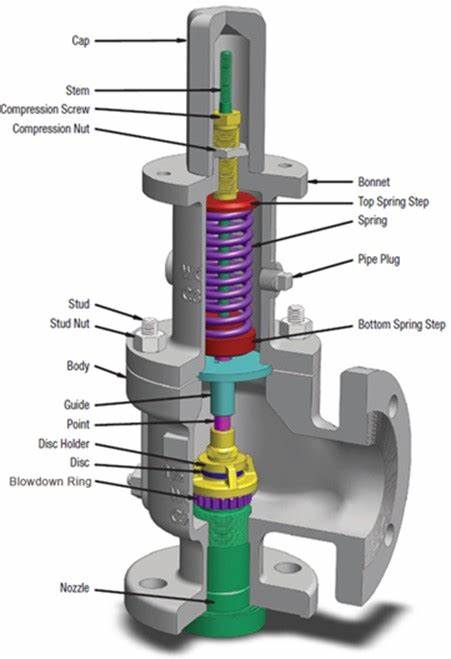

Safety valve is a special valve that the opening and closing parts are normally closed under the action of external force. When the medium pressure in the equipment or pipeline increases beyond the specified value, the medium pressure in the pipeline or equipment is prevented from exceeding the specified value by discharging the medium outside the system. Safety valve belongs to automatic valve category, which is mainly used in boiler, pressure vessel and pipeline. The control pressure does not exceed the specified value, which plays an important role in protecting personal safety and equipment operation. Note the safety valve can only be used after pressure test.

In most cases, the safety valve is the last safety defense line. If the above safety measures fail, the safety valve will take off and release pressure to prevent the pressure in the pressure equipment from exceeding the design allowable value. Safety valve is a kind of intrinsic safety protection measure. It takes off automatically by spring force and medium force, without any manual participation and external force participation, so as to prevent the safety accident caused by human misoperation. The function of the safety valve is realized through the following action process: when the system reaches the maximum allowable pressure, the safety valve can be opened accurately, and can discharge stably with the increase of the system pressure, and can discharge the rated amount of working medium under the rated discharge pressure. When the system pressure drops to a certain value, it should be closed in time, and keep the necessary sealing under the closed state Sex.

According to the different overall structure and loading mechanism, the common types of safety valve are spring loaded safety valve, balance bellows safety valve and pilot safety valve.

Spring loaded safety valve is a common safety valve, which overcomes the force produced by the medium pressure under the valve disc by the closing force of the spring. If the medium is harmless to people and the environment, such as non-toxic, non flammable and low-cost, such as air, it can be directly discharged into the atmosphere, in this case, the ordinary safety valve is used.

Balanced bellow safety valve, the effective area of the bellow is equal to the area of the sealing surface of the valve seat, which is used to counteract the effect of back pressure on the set pressure. It is suitable for the working conditions of high temperature and pressure, high back pressure or the medium can not be directly discharged into the atmosphere.

The pilot type safety valve is usually composed of a main valve with a movable unbalanced disc and an external pilot valve (piston). It drives or controls the opening and closing of the main valve by means of the medium discharged from the pilot valve. Compared with the balanced bellows type safety valve, its back pressure compensation coefficient is higher, which reduces the influence of back pressure on the action characteristics to a minimum and the discharge volume is large. For example, in the process of overpressure, the discharge of medium in the reactor is very large. If the balance bellows type safety valve is used, 16 sets are needed at most. If the pilot type safety valve is selected, 8 sets are enough, or even less. It will bring many advantages to users, such as less installation, less maintenance, less work and convenient maintenance. Of course, the technical complexity of the pilot safety valve is high, which puts forward higher requirements for the technical level of operators.

In the load spring safety valve, the valve closing pressure or spring force is applied by the coil spring under the pressure of the adjusting screw. The spring force is transferred to the disc through the stem. As long as the spring force is greater than the force generated at the inlet of the safety valve, the valve disc will seal the nozzle. The following figure shows the expanded nozzle and disc area of the relief valve at the pressure acting on the disc.

According to the preset conditions, the safety valve will open at the preset pressure. The spring force FS is applied in the closing direction, and the force FP generated by the pressure at the inlet of the safety valve is applied in the opening direction. When the pressure FS and medium force FP reach a balance, there is no force to place the valve disc on the valve seat; at this time, the safety valve will start to leak, and the sound of medium discharge can be seen or heard (the sound of medium just discharged).

Before the safety valve is obviously opened, the pressure at the valve inlet must be increased above the set pressure. Due to the flow restriction between the disc and the adjusting ring, the pressure gradually increases in this so-called mixing chamber. This pressure now acts on the expanded disc area, further increasing the pressure FP, which overcomes the additional force required to enter a compression spring. The valve will open quickly with a “bang” and in most cases it will be fully open. Overpressure refers to the pressure increase beyond the necessary set pressure of the safety valve to achieve full opening and full displacement of the valve. This overpressure is usually expressed as a percentage of the set pressure. The value is usually 10%, between 3% and 21% according to relevant specifications and applications.

In most applications, the proper size of safety valve will reduce the pressure when the vessel is discharged. The pressure of the vessel will drop at any subsequent point in time, but not later than the end of the pre-set condition. A decrease in pressure in the vessel will reduce the pressure FP. However, at set pressure, flow still acts on the expanded disc area, which opens the valve. Further pressure reduction is required before the spring force FS exceeds FP again and the relief valve begins to close again. Moreover, under the so-called reseating pressure, the disc will contact the nozzle again and the safety valve will close again. Return pressure difference refers to the difference between the set pressure of the safety valve and the return pressure, which is calculated as a percentage of the set pressure. According to the definition of relevant codes and standards, the reseating differential pressure is generally – 7% to – 10%, and it is – 4% to – 20% according to relevant codes and services (steam, gas or liquid).

API 526 safety valve series has a down regulating ring, and its set pressure is defined as the set pressure of the valve when the pressure reaches the initial discharge sound.

It is important to understand that the operating pressure of the protected equipment should be less than the reseating pressure of the safety valve. Most manufacturers and relevant codes and standards recommend that the difference between the reseating pressure and the operating pressure of 3% – 5% can achieve reasonable adjustment of the valve seat, and can again achieve good tightness of the valve seat.

Because the area of the pressure chamber is larger than the area of the main valve seat, the closing pressure is larger than the opening pressure. This allows the main valve to close tightly.

When the pressure reaches the set pressure, the pilot relief valve is activated. The medium will no longer lead to the pressure chamber (see Figure). This prevents further pressure rise in the pressure chamber.

At the same time, the pressure of the pressure chamber is discharged. Results the closing pressure of the main valve disappeared, which provided the precondition for the system overpressure to push the main valve to open.

The main valve is open. According to the design of pilot safety valve, there are two opening modes of safety valve, one is quick and thorough (quick opening action), the other is gradual and local (regulating action).

When the pressure in the pressure chamber increases, the main valve can be closed again through quick and thorough (quick opening action) or gradual local (regulating action).

Safety valve, also known as overflow valve, is a special valve that the opening and closing parts are normally closed under the action of external force. When the medium pressure in the equipment or pipeline increases beyond the specified value, the medium pressure in the pipeline or equipment is prevented from exceeding the specified value by discharging the medium outside the system. Safety valve belongs to automatic valve category, which is mainly used in boiler, pressure vessel and pipeline. The control pressure does not exceed the specified value, which plays an important role in protecting personal safety and equipment operation. Note the safety valve can only be used after pressure test.

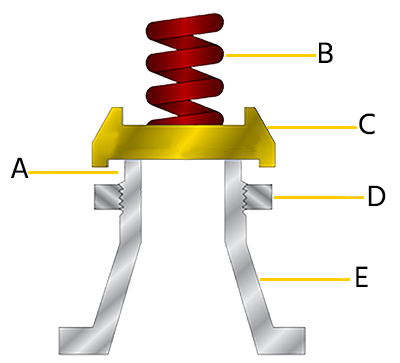

The figure shows several typical structures of the safety valve. Fig. A is a piston type safety valve with a flat valve core. The air source pressure acts on piston A. when the pressure exceeds the safety value determined by the spring force, piston a is jacked open and part of the compressed air is discharged into the atmosphere from the valve port; when the air source pressure is lower than the safety value, the spring drives the piston to move down and close the valve port.

Figure B and figure C are ba

8613371530291

8613371530291