how does a gas safety valve work price

Most modern appliances have safety features built in, but your gas oven safety valve is arguably the most important. If an electrical appliance malfunctions, it can cause a fire, but a misfiring gas oven could potentially blow up your house. You don"t really need to know how the safety mechanism works to use your oven, but you may find that it gives you some extra peace of mind.

Broadly speaking, there are two ways a built-in safety mechanism can work. One option is that it remains "open" by default and to shut off if certain conditions are met. That"s how fuses and circuit breakers work in an electrical circuit: Ordinarily, the electricity is free to flow, but if the current grows too large, the fuse or breaker will blow and cut off the circulation of electricity.

The other option is for your safety mechanism to be "closed" by default and allow a device to operate only when the correct conditions are met. That"s how a gas oven safety valve works. Gas ordinarily is prevented from flowing, and if the valve is working correctly, it opens only when you want to light your oven.

Many gas stoves use what"s called a "hot surface igniter," a bar or element (similar to the ones on your stovetop) that gets hot enough to ignite the gas on contact. Gas oven safety valves on stoves with this type of ignition system take a couple of different approaches.

In one approach, a bimetallic strip operates the valve. It harnesses a simple scientific principle: Metals expand and contract at different rates when they"re heated and cooled. If you bond two suitable metals together in one strip, that strip will flex to a predictable degree as the temperature goes up and down. Wall-mount thermostats often use this principle, as do analog oven thermometers and the thermometer in the lid of your gas grill.

As appliance-repair website PartSelect explains, turning on your gas oven causes electricity to flow into the heating element of your hot surface igniter. As the igniter heats up, it warms a bimetallic strip inside your gas oven safety valve. When the igniter reaches its operating temperature, the bimetallic strip opens the valve and allows the gas to flow, igniting as it crosses the heated surface.

One intriguing thing about electricity is that a change in temperature can affect how well it passes through certain materials. For example, a lot of research revolves around superconductors – materials that offer very little resistance to an electrical current – but superconductors typically must be heavily chilled to work.

According to heating-equipment vendor Anglo Nordic, gas oven safety valves use a variation of that principle to operate. In these stoves, the flow of electrical current through the hot surface igniter becomes the control mechanism. The igniter"s bar is made of a material that offers less and less resistance to electricity as it heats. When it reaches the temperature required to ignite the gas, its resistance becomes low enough to trip the safety valve and open the flow of gas.

More modern ranges use an electrical igniter. When you turn on your oven, the gas begins flowing immediately, and it sends an electrical current to a piezo electric igniter. The current makes the igniter spark (like the manual igniter on your gas grill) and lights the oven"s burner. In this case, the safety valve works in the opposite way: An electronic sensor checks for the heat caused by ignition after a few seconds, and if it"s absent, it will close the valve and shut off the flow of gas.

It"s worth pointing out that not all gas ovens have a safety valve in the conventional sense. Older stoves simply use a pilot light, a small but constant flow of gas, which, in turn, feeds a small, candle-like flame. You essentially are the safety mechanism in this system: It"s up to you to check that the pilot is lit. When you turn on the gas manually, the small pilot flame ignites the main flame. It"s a mechanically simple system, which makes it durable, and for that reason, you"ll still see it used on commercial restaurant ranges, which must stand up to decades of heavy use.

Water heater gas valve replacement costs $150 to $550 on average. Hot water heater gas control valve prices are $100 to $300 for the part alone, plus $50 to $250 for labor. Replacing a water heater pressure relief valve costs $50 to $300.

Consider replacing the entire water heater if the repair estimate is over $500 or the unit is more than 10 years old. Water heater replacement costs $600 to $1,800.

Costs to replace a gas control valve depend on the brand of the valve and labor. Diagnosing a failed gas valve involves troubleshooting several more common part failures, often leading to other potential repairs.

Gas control valve prices are $100 to $300 for the part alone, depending on the brand. The gas valve controls the flow of gas to the water heater"s burner, allows the pilot light to ignite, and shuts down the gas supply if the water temperature reaches critical heat limits.

Other water heater repairs cost $150 to $700on average, depending on the problem. Troubleshooting the gas control valve involves testing several more common malfunctioning parts, including the pilot light, ignitor, thermocouple, thermostat, or pressure relief valve.

Replacing a water heater pressure relief valve costs $50 to $300.The pressure relief valve, or TPR valve, is the most important safety device in the water heater. If the pressure inside the tank gets too high, the valve opens and releases water to prevent the tank from exploding.

DIY water heater gas valve replacement costs $100 to $300for the valve and $10 to $20 for the necessary tools and supplies like a screwdriver, wrench, and Teflon tape. Replacing the valve yourself saves $50 to $250 in labor costs.

If you smell gas, immediately shut off the gas supply and contact a plumber for emergency repairs. A faulty gas control valve may cause a dangerous gas leak, fire, or explosion.

Since these are also common signs of other component failures, rule out simpler repairs first. Check the pilot light, ignitor, and thermocouple before assuming the gas valve has failed.

Water heater gas valves are not always interchangeable. Brand-specific valve styles and connections ensure gas flow to the pilot and burner matches the heater"s BTU output. Different fuel sources, like natural gas, propane, and oil-fired heaters, use different valves.

A furnace gas valve replacement costs $200 to $800 installed. A replacement is more cost-effective than a furnace gas valve repair since the increased labor costs exceed the cost of a new part.

A furnace gas valve replacement costs $200 to $800 on average. Furnace gas valve prices are $75 to $300 for the part alone or up to $600 for original manufacturer parts (OEM). Gas valve replacement labor costs $125 to $500. Furnace gas valve repair costs $75 to $200.

Furnace gas valve prices are $50 to $300 on average or up to $600 for original manufacturer parts (OEM) without installation. Gas valve prices depend on the type and brand.

A furnace gas valve repair costs $75 to $200 for diagnostics, valve cleaning, and tightening connections for minor problems. However, a faulty gas valve that needs internal repairs requires a full gas valve replacement. Only the part manufacturer can legally repair a gas valve for safety reasons.

The cost to replace a gas fireplace valve is $300 to $500 on average, including a full fireplace inspection and diagnostic tests. The total cost depends on the valve brand and fireplace accessibility.

The gas valve on a furnace opens or closes to regulate the gas flow to the pilot light and burners. A properly functioning gas valve is necessary to stop gas leaks and maintain indoor temperatures. Gas-valve designs are specific to different furnace makes and models.

If a furnace gas valve is bad, there will be no warm air coming from the furnace, or it will shut down completely. Faulty gas valves are a major safety concern. Contact an HVAC technician to test the valve and diagnose the source of the problem.

Some furnace gas valves are interchangeable between propane and natural gas models, depending on the furnace brand, location, type, and local building codes.

Replacing a furnace gas valve takes 30 to 60 minutes on average or up to 2 hours for hard-to-access locations like crawlspaces and small attics. This time includes HVAC diagnostic tests. Most technicians charge a minimum service fee regardless of the time spent.

Buy a furnace gas valve from Amazon, Walmart, or HVAC distributors and service companies for the widest selection. Buying directly from the manufacturer typically costs more but ensures an exact match.

Some people have proposed a “safety valve” to control the costs of a cap-and-trade policy to fight global warming. This post explains what a safety valve is, and why it provides only an illusion of cost management.

In a cap-and-trade program, companies can choose either to lower emissions below the cap, or buy extra allowances. Some worry that if many companies need to buy extra allowances, demand will drive up the price, placing an undue burden on businesses.

The “safety valve” or “escape hatch” is meant to address this. It specifies that when prices reach a predetermined dollar value, businesses no longer have to rely on the established supply of allowances available in the market. Instead, the federal government makes new allowances available for sale at a specified price – potentially in an unlimited quantity.

There are two problems with this approach:A safety valve destroys the cap. The hard limit on emissions is the cornerstone of a cap-and-trade policy. Without a solid cap, we can’t be sure our emissions will go down enough to avoid the worst consequences of global warming. A safety valve gives the illusion that we are controlling emissions while allowing more greenhouse gas pollution into the atmosphere.

A safety valve limits the economic opportunity of those who develop cleaner technology. Higher permit prices signal the market to invest more in innovative low-carbon technologies – happy news if you’re in the business of inventing and selling ways to cut pollution. A safety valve would sharply curtail incentive for innovation. This drives up costs in the long run, and discourages the development of the clean technology we need.

A safety valve seriously undermines the main advantages of a cap. Its ability to control costs is an illusion, it lets more pollution into the atmosphere, and discourages entrepreneurs from investing in pollution-cutting technology.

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale gas safety valve price on Alibaba.com. When you search for gas safety valve price and related items, you will be able to find many types of gas safety valve price varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of gas safety valve price that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

For example, new regulations require utilities install curbside excess flow valves for all new home construction. These regulations resulted from years of learning and experience of the potential danger of ruptured gas lines between the roadside gas pipes and a home’s gas meter. When gas utilities install curbside excess flow valves, accidental ruptures of the gas line from landscaping and excavation no longer present danger to the home and community, since the EFV will automatically stop gas from flowing.

As good as our gas service is in the United States, we continuously improve on safety for our homes, based on what we learn from past incidents, and the experience both domestically and internationally.

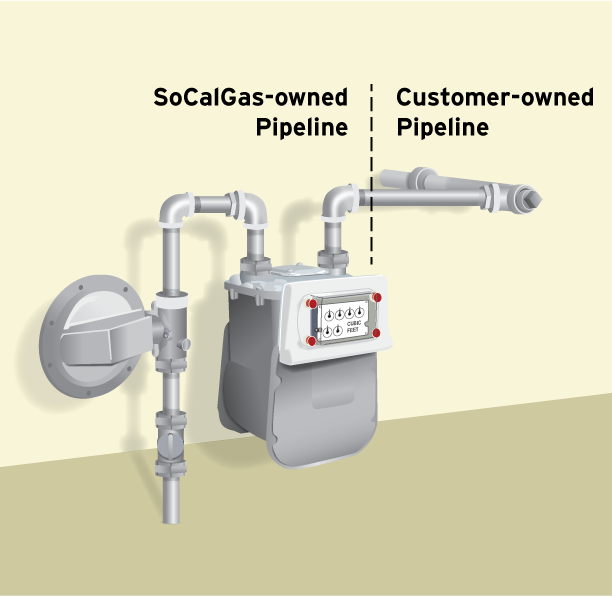

The gas utility is responsible for the integrity of the gas supply to the home up to the meter. The responsibility for the integrity and safety of the gas line after the gas meter lies with the homeowner.

Gas line ruptures can happen within the home as well, when nails or drills inadvertently compromise gas supply within the home. And many gas appliances use plastic tubing, which can corrode and deteriorate over time.

Fortunately, TECO Americas provides homeowners with the same type of technology used by gas utilities to protect their family, home, and furnishings from inside the home.

For this reason, responsible home owners install GST Excess Flow Valves, often with their gas appliance connectors, protecting them from internal gas line ruptures, or disconnections.

When the cause for the excess flow of gas is remedied, the GST EFV automatically resumes the flow of gas. The device recognizes a balance between the upstream flow rate and downstream flow rate through a small hole in the valve.

Different models of the GST EFV can be selected, depending on the pipe sizing and desired sensitivity to flow rates. Models are available that will trigger at any of the following flow rates:

The GST EFV is easily installed with previously installed gas appliances, as well as new appliances. It can also be installed in manifolds that service multiple gas appliances.

TECO Americas is introducing the GST EFV to homes throughout North America using the same patented technology that has protected homes throughout Europe and Asia for over 30 years.

As a design engineer responsible for developing and specifying boilers, dryers, furnaces, heaters, ovens and other industrial heating equipment, you face a daunting labyrinth of standards and industry regulations. Regulatory bodies sound a bit like alphabet soup, with acronyms like UL, FM, CSA, UR, AGA, ASME, ANSI, IRI, CE and NFPA tossed about. This article will help explain a common task for many thermal processing equipment specifiers: meeting the requirements of key codes — including Underwriters Laboratories (UL), Factory Mutual Insurers (FM) and the National Fire Protection Association (NFPA) — for safety valve equipment used in process heating applications.

Key to designing safety into your fuel train configurations are familiar technologies such as safety shutoff valves and vent valves as well as visual-indication mechanisms and proof-of-closure switches.

Your design skills come into play with how you take advantage of the wide range of products available. You can mix and match solenoid and safety shutoff valves — within designs from catalytic reactors to multi-zone furnaces — to create easily installed, cost-effective solutions that comply with all necessary standards. (See table.)

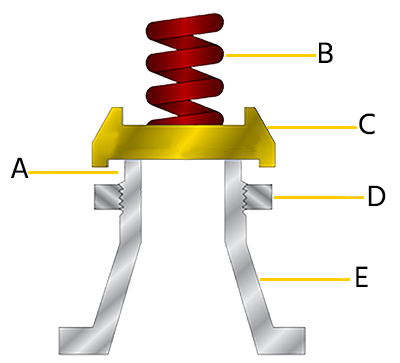

Make sure, however, that you start with a good grasp of valve element fundamentals. For example, examining a proof-of-closure (POC) switch underlines how reliably modern valves can ensure combustion safety. The POC unit provides an electrical contact interlocked with the controller safety circuit. In a typical design, the switch is located at the bottom of the valve, positioned to trace the stroke of the valve disc. When the disc seal reaches the fully closed position, it triggers the mechanism to push down on the contact, closing it and triggering the unit’s visual indicator to show open or closed status. As a result, the operator can act with full confidence in situations where it is critical that a safety valve be safely closed.

To provide ease of installation, many users prefer valves with modular capabilities. For example, to reduce mounting complexity, you can choose modular gas safety shut-off valves — combining a solenoid valve with an electrohydraulic motorized valve for a compact double-valve footprint, a slow-open feature and high flow rates. An accompanying actuator can provide on/off or high/low/off firing rates as well as visual indication and proof of closure for compliance with most industry standards.

Also, you may want to look for valves that include useful features such as pipe taps, which can facilitate accurate pressure readings and leakage testing.

Knowing your valve choices — and how they meet given codes and standards — can reduce the time required for design and production while facilitating compliance. This results in safer, more efficient and cost-effective heating process installations.

A furnace gas valve is a component of your furnace’s fuel system. The furnace gas valve opens and closes, which allows the flow of gas to the pilot light and burner(s). While the component itself if actually rather simple, a furnace gas valve is a crucial part of your HVAC system. Furnace gas valves are only seen on gas-fueled forced air furnaces or gas-powered boilers. There are also gas valves located within gas-powered hot water systems or fireplaces.

There are essentially two valves that make up your furnace’s gas valve, and they are positioned in series, or one after the other. The furnace gas valve operates by electromagnets. The primary valve -- also known as the safety valve -- supplies gas to the pilot light. The second valve -- also known as the main valve -- allows gas to flow to the burner trays.

The thermocouple (or thermopile) generates the power holds the safety valve open. Additionally, the thermocouple remains immersed in the pilot light flame. Without adequate heating of the thermocouple or thermopile, the furnace gas valve closes. As a result, this cuts off the supply of gas to the pilot light. Ultimately, the thermocouple acts as a safety mechanism that prevents gas buildup within the home.

A 24 VAC transformer (or the thermopile) powers the main valve. This valve allows gas to flow to the burner trays via a much larger tube than the pilot light valve. Additionally, the valves are installed in series with all of the other furnace safety controls. As a result, if the system detects a problem, then the circuit interrupts itself. During this process, the system shuts off power to the main furnace gas valve, while still keeping the pilot light valve open.

As the thermostat calls for heat, the furnace gas valve opens and closes. This process maintains the desired temperature within the home. Plus, this design helps regulate the pressure of gas flowing into the furnace.

There are a few types of furnace gas valve systems: gas chain, consisting of a manual valve, solenoid valve, and pilot safety; and a combination gas valve. A gas chain valve system requires the homeowner to manually turn a valve handle in order to open or close the flow of gas to the furnace. A solenoid valve opens only when the furnace calls for heat. As a result, gas only flows if all the other valves in the system are open. Plus, the pilot safety valve only stays open if the thermocouple or thermopile heats to a certain temperature by the pilot flame. It can be manually overridden in order to relight the pilot light, but otherwise operates via electromagnets as described above.

The combination gas valve gained popularity in the 1960s and performs all the functions of the gas chain in one package. It contains a valve knob or handle, regulator, thermocouple, electric terminals, and a solenoid valve. As technology has progressed, combination gas valves have fallen out of regular use, with their job now being performed by electronic ignition controls or integrated furnace controls (IFCs).

If you think your furnace gas valve is not working, there are a couple of steps you can take to troubleshoot the problem and narrow down the root cause.

Check to see if the pilot light is on. If not, follow the manufacturer’s instructions for relighting the pilot light. It may take a few seconds after relighting the pilot light for the main valve to have enough power to stay open.

Check to see if the thermocouple or thermopile is generating enough voltage to keep the safety valve open. If not, you can replace it. Also check to ensure the other safety mechanisms within the circuit are receiving adequate voltage. If this doesn’t fix the problem, you will need to replace the entire furnace gas valve.

If you need to replace the gas valve in your furnace, costs will vary depending on the make and model, as well as your location as labor costs differ depending on region and even season.

Although many homeowners troubleshoot heating issues, the best option remains consultation with a qualified HVAC professional if your furnace isn’t operating properly. They are experts who can get your heat back up and running quickly and safely.

When you’re working with gas, safety should be the name of the game. It’s extremely easy to cause a lot of damage, both to yourself and your establishment, when you’re not showing that invisible little devil the respect it deserves. Fortunately, modern-day gas safety valves have been tested and outfitted around the world, and these bad boys are essential pieces to any efficiently-working system. That said, when your gas safety valves are a little worse for wear, making a repair or finding a replacement is a no-brainer. That’s why keeping an extra in your repair kit or tool closet is a smart move, and we’ve got the gas safety valves you need!

1. The FMDA safety valve is the only type with the thermocouple permanently attached to it. This means the thermocouple cannot be replaced; the entire safety valve must be replaced if the thermocouple fails. The easiest way to identify an FMDA type safety is a ½” diameter red button on the bottom of the valve. You must know the gas pipe size and if the pilot tube is an “in and out” or an “out only.” An “in and out” safety valve has two threaded holes at the top of the part, one for gas for the pilot to come in and one for gas to go out. An “out only” safety valve has just one threaded hole to connect gas for the pilot to.

2. The BASO safety valve can vary in design depending on the piece of equipment it is on, so it is important to know the brand name, model and serial number of the piece of equipment to get the correct safety valve the first time. The easiest way to identify a BASO valve is by the 15/16” diameter red pilot button. The thermocouple is separate from the safety.

3. The TS type safety valve is the only one that can be rebuilt. It is similar to the FMDA and BASO types in that it has “in and out” or “out only” pilot tubing, so you must know what is in your equipment. A rebuilt kit is available in both and it is not necessary to replace the body unless it is damaged. The body has no moving parts in it. The easiest way to identify the TS safety is by the 5/8” diameter red button. The thermocouple is also separate from this safety, similar to the BASO.

If the wire leads are screwed to the top terminal block, and two tubes are coming out of the top of the valve, it is the tubing type combination safety valve.

While it"s possible to manually shut off your natural gas, the following specialized valves are available that can automatically shut off your service in case of an emergency:

Earthquake natural gas shut-off valve (also known as a seismic natural gas shut-off valve) automatically shuts off your natural gas service when an earthquake of a sufficient magnitude occurs at your home.

An excess-flow valve (EFV) automatically closes and restricts the flow of natural gas in the event an underground pipe is damaged or if there is a significant increase in the flow of natural gas to the meter.

If you want to have an earthquake natural gas shut-off installed, or are required to have one by your insurance company or the local Department of Building and Safety, the valve must be installed on your house line.

If installation requires natural gas service closure, you"ll need to contact us to shut off the service and restore service when installation is completed. Natural gas service shut off and restoration of service orders can be scheduled by contacting us at 1-800-427-2200.

Under the regulations of the California Public Utilities Commission (CPUC), General Order 112-E, only SoCalGas® or its certified contractors are authorized to operate the natural gas service shut-off valve.

When you hire a qualified professional to install your earthquake valve, you"ll need to make sure that the valve is installed on your house line, not on SoCalGas" facilities. SoCalGas" facilities include all of the pipe fittings installed and maintained by SoCalGas, up to and including the last elbow or tee connecting to your house line. See the diagram below for to see where your house line starts.

All unauthorized valve installations found on SoCalGas" facilities will be removed. In addition, earthquake valves are not permitted in utility curb meter vaults.

If an earthquake or other significant event causes your earthquake shut-off or excess-flow valve to close, you can follow the manufacturer"s instructions for resetting the valve so that natural gas flows again. However, we recommend that you contact a qualified professional or SoCalGas to reset the valve, and to perform a safety check of your natural gas appliances before they are placed back in operation to verify that no natural gas leaks exist, and to re-light your pilot lights.

Remember that following a major emergency it may take many days or even weeks before someone can come to your location. (SoCalGas charges a fee to reset valves and re-light pilot lights when your earthquake shut-off valve has closed due to a non-earthquake occurrence.)

Price: The cost of the valve is going to vary based on the type and size of the valve, as well as the installation requirements and the company installing it.

Choosing a valve: In order to choose the right valve size and manufacturer, contact your local Department of Building and Safety to find out their earthquake valve requirements.

Where to buy a valve: You can purchase an earthquake valve at supply retailers, licensed plumbing contractors, or directly from the valve manufacturer.

Using a contractor: You can hire a qualified professional to install the earthquake or excess-flow valve on your house line. SoCalGas will not install a valve for you.

Effective February 10, 2002, California Public Utility Commission (CPUC) Decision 01-11-068 prohibits installation of an earthquake valve on SoCalGas" facilities. In addition, SoCalGas no longer installs earthquake shut-off valves for its customers, and does not allow any customer owned equipment, including excess-flow valves, be installed on SoCalGas" facilities.

If you have an earthquake valve that was installed by SoCalGas or one of its authorized contractors on or before the February 10, 2002 cutoff date, that is located on SoCalGas" facilities, with proper documentation your installation may be allowed to remain in place. Authorized contractors are those who participated in SoCalGas" earthquake program and were trained by SoCalGas to work on their facilities.

Additional information regarding earthquake valves and natural gas service restoration after a valve activates can be found in Tariff Book, Rule 10, Section G, "Earthquake Valve Service."

An Excess Flow Valve, or EFV, is a safety device installed on natural gas distribution pipelines to automatically close and restrict the flow of natural gas in the event an underground pipe is damaged or if there is a significant increase in the flow of natural gas to the meter. These conditions are typically caused by digging or construction but can also be caused by damage to your natural gas meter by a vehicle impact.

EFV can reduce the risk of explosions, fires, and personal injury because they close or restrict any unplanned or excessive natural gas flow. Installation of an EFV will not protect a customer from household appliance malfunctions, small punctures in underground pipelines, and pipeline damage from earthquakes or flooding. It is

important to understand that an EFV does not shut off the flow of natural gas completely. Some leakage may still occur resulting in a hazardous condition.

An EFV is installed on the service pipeline that runs underground between the natural gas main (usually located in or near the street, alley or easement) and the SoCalGas® meter on the customer’s property).

The best way to prevent damage to a natural gas pipeline due to digging is to call 811, the Underground Service Alert program, at least two working days before digging. Underground Service Alert will coordinate with SoCalGas to mark the locations of buried utility-owned lines - absolutely FREE.

If you are interested in having an EFV installed on the service pipeline serving you[1], please call SoCalGas at 1-800-427-2200. SoCalGas will first check to see if your service already has an EFV installed and, if not, an estimate to install the EFV will be provided. The cost to install an EFV can vary widely depending on site specific conditions and can range from $2,500 to $5,000 or more.

If you decide to have an EFV installed, we will coordinate with you to schedule the installation (note that it is possible that natural gas service will be interrupted to install the EFV). The construction crew will dig around the natural gas line in order to install the EFV and when the job is complete natural gas service will be restored (if it was shut off). If paving or concrete needs repair that work will be scheduled at a later date.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

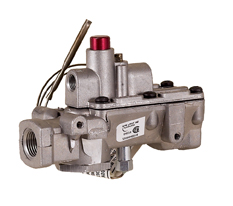

Dual gas safety valve assembly. The gas oven safety valve works with the oven igniter to provide gas to the burner. If the safety valve fails, the oven won’t heat. Since safety valves rarely fail, be sure to check more commonly defective parts before replacing the safety valve.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

In this 3-minute guide, we’ll explain how a boiler gas valve works, common gas valve problems you may encounter, as well as the potential replacement and repair costs.

A boiler gas valve controls the flow of gas to the pilot light and burner. It’s controlled by an electrical signal coming from the printed circuit board (PCB).

When you call for heat or hot water on a gas boiler, the process works like this:The PCB detects that the fan is operational, ready to expel dangerous flue gases via the flue

Not prepared to waste money on repairing a deteriorating boiler? We’d suggest heading over to Heatable. They’re focused on technology rather than salespeople, and their tiny overhead lets Heatable install Worcester boilers at competitive prices. Better still, you can get a fixed price online with no obligation to buy.

Like any mechanical component, a gas valve wears out over time. When the valve gets stuck or seized, it will either:Not open, and therefore cut off the gas supply to the burner and pilot light

As boilers vibrate, they can work wiring and connections loose. This often generates weak (or incorrect) signals and leads the PCB to think the gas valve is on or off when it isn’t.

However, the time and cost of these kits usually means replacing the valve is a better option. Your boiler care policy should cover the replacement cost, but if you’re not covered, you’ll end up spending £300 or so out-of-pocket.

When electrical faults are present, the PCB can’t be ruled out as the culprit. After all, it’s the PCB that controls these components and displays the fault code in the first place.

Taking that into account, the homeowner would have been much better off installing a new boiler with a long warranty that covers expensive repairs like this.

However, whereby replacement boiler spares can be purchased from the likes of Honeywell, this price can be reduced (they sell some gas valves for under £90).

On the flip-side, if you must go with an OEM gas valve from a brand like Worcester Bosch, the part alone could cost in excess of £150. Speak to your engineer and see if there’s a non-OEM (but high quality) gas valve, like Honeywell, that’s compatible with your boiler.

On a side note:Always ensure your Gas Safe engineer inspects all the most expensive boiler parts before replacing the valve. If 2-3 expensive parts in a boiler are worn, it makes sense to invest that cash into a new boiler, not waste money on repairing an old one.

For any severe issues, however, we rarely find that the repair costs are justified — especially if the unit is already showing signs of wear. Investing in boiler replacement is generally the wiser choice if your boiler’s repairs are mounting and it’s out of warranty.

Thanks for reading our gas valve guide. Got other boiler problems not mentioned above? Leave us a comment below, and we’ll get back to you as soon as we can.

WAGS™prevents disastrous floods and untold damage to your property, and avoids costly insurance claims. The WAGS™ valve is designed to shut off the water supply (plus gas supply for gas-fired heaters) in the event of a water leak from a water heater.

The WAGS™ valve sits in a drip pan under the water heater and is activated when leaking water accumulates to a predetermined level in the pan. Once activated, the industrial-duty, spring loaded piston in the valve shuts off the water flow, and the gas supply - if so equipped.

Pilot ignition systems use a flame sensing element to sense whether the pilot is lit and the safety valve can open. The sensing element sits right in the pilot flame.

Just exactly where the sensor sits in the pilot flame is important. (See figure 6-A) If the sensing bulb is not in the right part of the flame, or if the pilot is adjusted too low or too high, it will not get hot enough and the safety valve will not open.

When two dissimilar metals (for example, copper and steel) are bonded together electrically, and then heated, they generate a tiny electrical current between them. The voltage is very small, measured in millivolts. This is the basis for a millivolt oven ignitor system. All that"s needed is a safety valve that will sense this tiny voltage and open the valve if it is present. If the pilot is out, there is no millivoltage and the safety valve will not open. See figure 6-B.

If the burner in a millivolt system will not start, typically the problem is the gas valve. Occasionally the problem might be the pilot generator or thermostat. The thermostat in these is just a temperature-sensitive on/off switch. To test, turn it on and test for continuity.

If that doesn"t work, we have a minor dilemma in determining whether the problem is the pilot generator or the safety valve. The dilemma here is that the voltages are too small to be measured with standard equipment. VOM millivolt adaptors cost nearly as much as the pilot generator itself. And the safety valve, which is usually the problem, costs twice as much as the pilot generator. So usually you just replace either or both of them. But don"t forget they are electrical parts, which are non-returnable. What I recommend is just to replace the gas valve first; that usually will solve the problem. If not, replace the pilot generator. You just ate a gas valve, but trust me, you"d have bought one sooner or later anyway.

When installing the pilot generator, screw it into the safety valve finger tight, plus 1/4 turn. Any tighter than that and you can damage the electrical contacts on the valve.

In some systems the sensor is a liquid-filled bulb, with a capillary to the safety valve or flame switch. When the liquid inside heats up, it expands and exerts pressure on a diaphragm, which opens the valve or closes the switch.

It is important to know that these sensor bulbs do not cycle the burner on and off to maintain oven temperature. That is the thermostat"s function. It has a sensor bulb too, but it senses oven temperature, not pilot flame. The only function of these pilot sensing elements is to prevent gas flow to the burner if the bulb does not get hot enough to assure burner ignition.

In flame switch systems, hydraulic pressure from the capillary physically closes the switch, which completes an electrical circuit to the safety valve. The safety valve is electrical and operates on 110 volts. See Figure 6-D. If the pilot is out, the flame switch does not close and the 110 volt heating circuit is not complete, so the safety valve will not open.

Some of these direct-pressure (hydraulic) systems use a two-level pilot. The pilot stays at a very low level; not even high enough to activate the safety valve. This is called the constant pilot, or primary pilot. Gas for the primary pilot may come from either the thermostat or directly from the gas manifold.

When the thermostat valve is turned on, the pilot flame gets bigger, heating the sensor bulb, which activates the safety valve (hydraulically) and the burner ignites. This is called the heater pilot, or secondary pilot. Gas for the secondary pilot comes from the oven thermostat itself.

When the gas oven reaches the correct temperature setting, the thermostat drops the pilot flame back to the lower level, the safety valve closes and the burner shuts off. See figure 6-E.

The sensing bulb needs to be sitting right in the hottest part of the flame as described in section 6-2. If you don"t have a good strong pilot (secondary pilot, in two-level systems) that engulfs the pilot sensing bulb with flame, try cleaning the pilot assembly and sensor bulb as described in section 6-5. If that doesn"t work, replace the pilot assembly.

If you do have a good strong pilot that engulfs the pilot sensing bulb with flame, then odds are that the sensing element and/or whatever it is attached to are defective. If it is a flame switch, replace the flame switch. If it is a safety valve replace that.

In a two-level pilot system, remember that the main oven thermostat supplies the secondary pilot with gas. So if you cannot get a good secondary pilot the problem may be the pilot assembly, or it may be the thermostat. If you do get a good secondary pilot, you"re back to the sensing bulb and safety valve.

Spark ignition systems use a spark module to generate a pulsing, high-voltage spark to ignite the gas. The spark module is an electronic device that produces 2-4 high-voltage electrical pulses per second. These pulses are at very low amperage, measured in milliamps, so the risk of shock is virtually nil. But the voltage is high enough to jump an air gap and ignite gas. The spark ignition module is usually located either under the cooktop or inside the back of the stove. The same module is used for both the surface burner ignition and the oven burner ignition.

However, the spark is not certain enough to light the oven burner, and the gas flow is too high, to rely on the spark alone. Remember, in an oven, before the safety valve opens, you need to be assured of ignition. So the spark ignites a low-gasflow pilot, and then the safety valve opens only when the pilot is lit.

This is the same two-level pilot system described in section 6-2(b), with a few important exceptions. The constant or primary pilot does not stay lit when the oven thermostat is turned off. It does, however, stay lit the whole time the oven thermostat is turned on.

When the gas oven is turned on, a switch mounted to the oven thermostat stem signals the spark module. These are the same switches as shown in section 5-3.

The flame is positioned between the spark electrode and its target. The pilot flame actually conducts electricity. So when the pilot flame is burning, electricity from the spark electrode is drained off to ground, and sparking stops. If the pilot quits, sparking resumes.

When the thermostat calls for more heat in the oven, the heater or secondary pilot increases the size of the pilot flame, which heats the sensing bulb, which opens the safety valve and kicks on the burner.

Yup, this ol" boy"s got it all. Spark ignition, a pilot, a flame switch and TWO - count "em - TWO safety valves; one for the pilot and one for the burner. (Figure 6-H)

The operation is actually simpler than the diagram looks. When you turn on the oven thermostat, a cam on the thermostat hub closes the pilot valve switch. This opens the 110 volt pilot safety valve and energizes the spark module, igniting the pilot. As in the other spark system, the pilot flame provides a path that drains off the spark current, so the ignitor stops sparking while the pilot is lit. As long as the oven thermostat is turned on, the pilot valve switch stays closed, so the pilot valve stays open and the pilot stays lit.

When the pilot heats the pilot sensing element of the flame switch, the flame switch closes. This completes the 110 volt circuit to the oven safety valve, so the valve opens and the burner ignites.

When the oven temperature reaches the set point of the thermostat, the thermostat switch opens, breaking the circuit and closing the oven safety valve, and shutting off the burner.

Now that you know how the system works, first look to see what is not working. When the oven thermostat is on, and there isn"t a pilot flame, is the electrode sparking? Is there spark, but no primary pilot? Is the primary pilot igniting, but not the secondary? Is there sparking after the thermostat is shut off?

(The pilot may or may not light, but the main burner is not lighting) Remember that the thermostat supplies the pilot with gas in these ovens, and only when the thermostat is on. So if you don"t have a primary and secondary pilot flame, odds are the problem is the pilot orifice or oven thermostat. Try cleaning the pilot assembly and sensor bulb as described in section 6-5. If that doesn"t work, adjust the secondary flame a little higher. If that doesn"t work, replace the pilot assembly.

If you do have a good strong secondary pilot that engulfs the pilot sensing bulb with flame, then odds are that the oven safety valve (or flame switch, whichever is attached to the pilot sensing bulb in your system) is defective. Replace the defective component.

Something is wrong with the high-voltage sparking system. If you are in a hurry to use your oven, you can turn on the oven thermostat, carefully ignite the primary pilot with a match and use the oven for now; but remember that the minute you turn off the thermostat, the pilot goes out.

Are the cooktop ignitors sparking? If so, the spark module is probably OK. What typically goes wrong with the sparking system is that the rotary switch on the valve stops working. Test continuity as described in section 5-3(a). If that isn"t the problem, check the electrode for damage and proper adjustment. The spark target (the nearest metal to the electrode) should be about 1/8″ to 3/16″ away from it, (about the thickness of 2-3 dimes) and directly across the primary pilot orifice. Replace or adjust the electrode as appropriate. When replacing, make sure you get the right kind of electrode (there are several) and do not cut the electrode lead; follow it all the way back to the spark module and plug the new lead into the proper spark module terminal.

Usually the ignition switch has gotten some moisture in it and it is shorting. To test, pull the lead off the switch and see if the sparking stops. If so, the switch is bad. Replace it.

Remember that these switches are on 110 volt circuits. If you get too fast and loose with pulling these leads off to test them, you might zap yourself.

EFVs are designed to minimize or stop the flow of natural gas in the event of a service line break. For example, if an excavator accidentally digs up the natural gas service line and severs the line, the EFV is designed to automatically minimize or stop the flow of natural gas reducing the risk of property damage or a natural gas-related safety event like a leak or fire.

Until recently, federal law did not require excess flow valves to be installed on newly-constructed or replaced service lines. As such, if a customer wants an EFV installed on their service line, the installation is performed at the customer’s expense.

EFVs will not work properly on all natural gas service lines, for reasons such as high gas flow, low pressure, or other factors. Therefore, not all customers qualify for an EFV. If you request an EFV, but your service line cannot accommodate it, we will let you know.

We work diligently to promote pipeline safety in a variety of ways, including through inspection programs, public education, pipeline markers, facility mapping, surveys, patrolling, pressure monitoring, odorization, and liaison with public officials. EFVs are an additional means of promoting safety, however, regardless of whether a customer elects to have an EFV installed, we will continue to work to protect the safety of our customers and the communities we serve in the same manner you have come to expect.

8613371530291

8613371530291