how does a gas safety valve work for sale

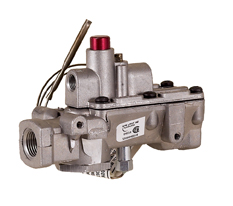

This White Rodgers Safety Valve offers 100% shut off of both the pilot and the main gas burner if the pilot light is extinguished or is not sufficiently combusting. It is thermocouple-operated and does not require electricity to operate. It features a three-position control knob: Off, Pilot, and On.

This unit comes with the pilot light with 6" of ¼” aluminum tubing and a 6’ long thermocouple. This can be used with all domestic heating gases delivered up to 0.5 psi max. It offers two different gas inlets for your choice of a side inlet or bottom inlet and also includes the plug to seal the inlet opposite your choice. The inlets and outlet of the valve are ½” F NPT. Included are two bushings to reduce the inlet and outlet to 3/8” F NPT.

Most modern appliances have safety features built in, but your gas oven safety valve is arguably the most important. If an electrical appliance malfunctions, it can cause a fire, but a misfiring gas oven could potentially blow up your house. You don"t really need to know how the safety mechanism works to use your oven, but you may find that it gives you some extra peace of mind.

Broadly speaking, there are two ways a built-in safety mechanism can work. One option is that it remains "open" by default and to shut off if certain conditions are met. That"s how fuses and circuit breakers work in an electrical circuit: Ordinarily, the electricity is free to flow, but if the current grows too large, the fuse or breaker will blow and cut off the circulation of electricity.

The other option is for your safety mechanism to be "closed" by default and allow a device to operate only when the correct conditions are met. That"s how a gas oven safety valve works. Gas ordinarily is prevented from flowing, and if the valve is working correctly, it opens only when you want to light your oven.

Many gas stoves use what"s called a "hot surface igniter," a bar or element (similar to the ones on your stovetop) that gets hot enough to ignite the gas on contact. Gas oven safety valves on stoves with this type of ignition system take a couple of different approaches.

In one approach, a bimetallic strip operates the valve. It harnesses a simple scientific principle: Metals expand and contract at different rates when they"re heated and cooled. If you bond two suitable metals together in one strip, that strip will flex to a predictable degree as the temperature goes up and down. Wall-mount thermostats often use this principle, as do analog oven thermometers and the thermometer in the lid of your gas grill.

As appliance-repair website PartSelect explains, turning on your gas oven causes electricity to flow into the heating element of your hot surface igniter. As the igniter heats up, it warms a bimetallic strip inside your gas oven safety valve. When the igniter reaches its operating temperature, the bimetallic strip opens the valve and allows the gas to flow, igniting as it crosses the heated surface.

One intriguing thing about electricity is that a change in temperature can affect how well it passes through certain materials. For example, a lot of research revolves around superconductors – materials that offer very little resistance to an electrical current – but superconductors typically must be heavily chilled to work.

According to heating-equipment vendor Anglo Nordic, gas oven safety valves use a variation of that principle to operate. In these stoves, the flow of electrical current through the hot surface igniter becomes the control mechanism. The igniter"s bar is made of a material that offers less and less resistance to electricity as it heats. When it reaches the temperature required to ignite the gas, its resistance becomes low enough to trip the safety valve and open the flow of gas.

More modern ranges use an electrical igniter. When you turn on your oven, the gas begins flowing immediately, and it sends an electrical current to a piezo electric igniter. The current makes the igniter spark (like the manual igniter on your gas grill) and lights the oven"s burner. In this case, the safety valve works in the opposite way: An electronic sensor checks for the heat caused by ignition after a few seconds, and if it"s absent, it will close the valve and shut off the flow of gas.

It"s worth pointing out that not all gas ovens have a safety valve in the conventional sense. Older stoves simply use a pilot light, a small but constant flow of gas, which, in turn, feeds a small, candle-like flame. You essentially are the safety mechanism in this system: It"s up to you to check that the pilot is lit. When you turn on the gas manually, the small pilot flame ignites the main flame. It"s a mechanically simple system, which makes it durable, and for that reason, you"ll still see it used on commercial restaurant ranges, which must stand up to decades of heavy use.

A furnace gas valve is a component of your furnace’s fuel system. The furnace gas valve opens and closes, which allows the flow of gas to the pilot light and burner(s). While the component itself if actually rather simple, a furnace gas valve is a crucial part of your HVAC system. Furnace gas valves are only seen on gas-fueled forced air furnaces or gas-powered boilers. There are also gas valves located within gas-powered hot water systems or fireplaces.

There are essentially two valves that make up your furnace’s gas valve, and they are positioned in series, or one after the other. The furnace gas valve operates by electromagnets. The primary valve -- also known as the safety valve -- supplies gas to the pilot light. The second valve -- also known as the main valve -- allows gas to flow to the burner trays.

The thermocouple (or thermopile) generates the power holds the safety valve open. Additionally, the thermocouple remains immersed in the pilot light flame. Without adequate heating of the thermocouple or thermopile, the furnace gas valve closes. As a result, this cuts off the supply of gas to the pilot light. Ultimately, the thermocouple acts as a safety mechanism that prevents gas buildup within the home.

A 24 VAC transformer (or the thermopile) powers the main valve. This valve allows gas to flow to the burner trays via a much larger tube than the pilot light valve. Additionally, the valves are installed in series with all of the other furnace safety controls. As a result, if the system detects a problem, then the circuit interrupts itself. During this process, the system shuts off power to the main furnace gas valve, while still keeping the pilot light valve open.

As the thermostat calls for heat, the furnace gas valve opens and closes. This process maintains the desired temperature within the home. Plus, this design helps regulate the pressure of gas flowing into the furnace.

There are a few types of furnace gas valve systems: gas chain, consisting of a manual valve, solenoid valve, and pilot safety; and a combination gas valve. A gas chain valve system requires the homeowner to manually turn a valve handle in order to open or close the flow of gas to the furnace. A solenoid valve opens only when the furnace calls for heat. As a result, gas only flows if all the other valves in the system are open. Plus, the pilot safety valve only stays open if the thermocouple or thermopile heats to a certain temperature by the pilot flame. It can be manually overridden in order to relight the pilot light, but otherwise operates via electromagnets as described above.

The combination gas valve gained popularity in the 1960s and performs all the functions of the gas chain in one package. It contains a valve knob or handle, regulator, thermocouple, electric terminals, and a solenoid valve. As technology has progressed, combination gas valves have fallen out of regular use, with their job now being performed by electronic ignition controls or integrated furnace controls (IFCs).

If you think your furnace gas valve is not working, there are a couple of steps you can take to troubleshoot the problem and narrow down the root cause.

Check to see if the pilot light is on. If not, follow the manufacturer’s instructions for relighting the pilot light. It may take a few seconds after relighting the pilot light for the main valve to have enough power to stay open.

Check to see if the thermocouple or thermopile is generating enough voltage to keep the safety valve open. If not, you can replace it. Also check to ensure the other safety mechanisms within the circuit are receiving adequate voltage. If this doesn’t fix the problem, you will need to replace the entire furnace gas valve.

If you need to replace the gas valve in your furnace, costs will vary depending on the make and model, as well as your location as labor costs differ depending on region and even season.

Although many homeowners troubleshoot heating issues, the best option remains consultation with a qualified HVAC professional if your furnace isn’t operating properly. They are experts who can get your heat back up and running quickly and safely.

As a design engineer responsible for developing and specifying boilers, dryers, furnaces, heaters, ovens and other industrial heating equipment, you face a daunting labyrinth of standards and industry regulations. Regulatory bodies sound a bit like alphabet soup, with acronyms like UL, FM, CSA, UR, AGA, ASME, ANSI, IRI, CE and NFPA tossed about. This article will help explain a common task for many thermal processing equipment specifiers: meeting the requirements of key codes — including Underwriters Laboratories (UL), Factory Mutual Insurers (FM) and the National Fire Protection Association (NFPA) — for safety valve equipment used in process heating applications.

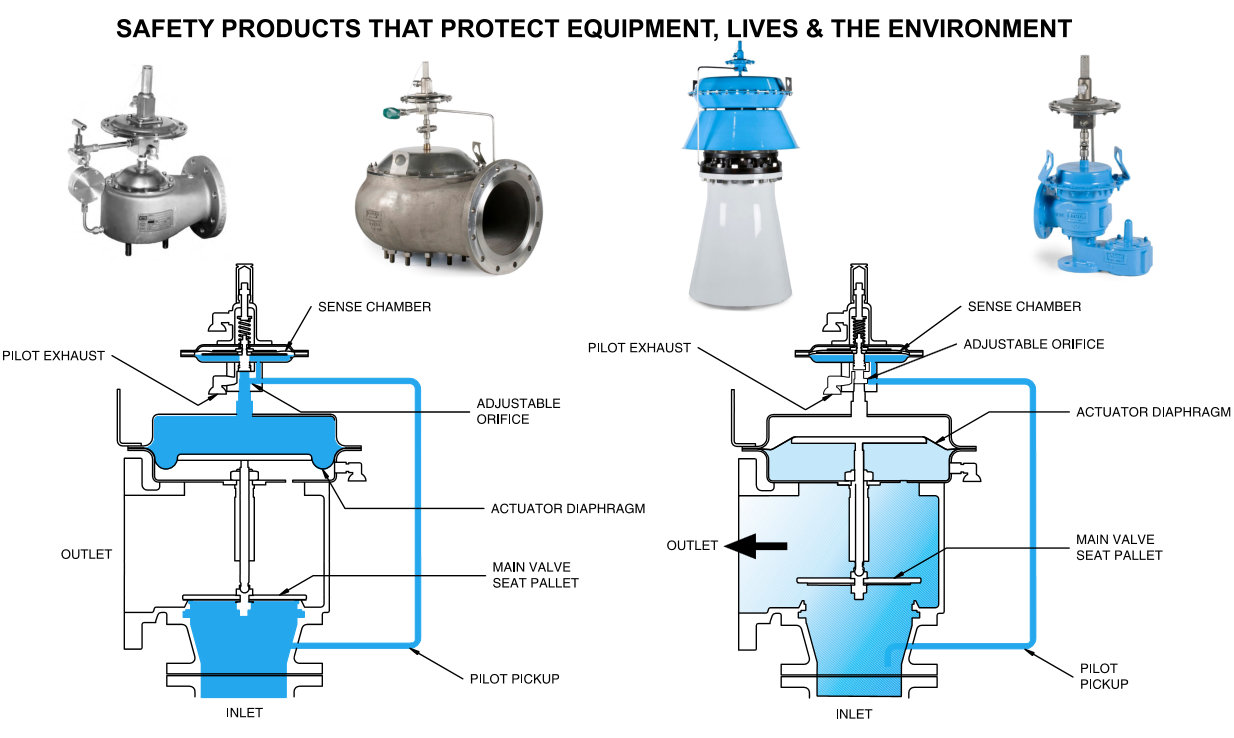

Key to designing safety into your fuel train configurations are familiar technologies such as safety shutoff valves and vent valves as well as visual-indication mechanisms and proof-of-closure switches.

Your design skills come into play with how you take advantage of the wide range of products available. You can mix and match solenoid and safety shutoff valves — within designs from catalytic reactors to multi-zone furnaces — to create easily installed, cost-effective solutions that comply with all necessary standards. (See table.)

Make sure, however, that you start with a good grasp of valve element fundamentals. For example, examining a proof-of-closure (POC) switch underlines how reliably modern valves can ensure combustion safety. The POC unit provides an electrical contact interlocked with the controller safety circuit. In a typical design, the switch is located at the bottom of the valve, positioned to trace the stroke of the valve disc. When the disc seal reaches the fully closed position, it triggers the mechanism to push down on the contact, closing it and triggering the unit’s visual indicator to show open or closed status. As a result, the operator can act with full confidence in situations where it is critical that a safety valve be safely closed.

To provide ease of installation, many users prefer valves with modular capabilities. For example, to reduce mounting complexity, you can choose modular gas safety shut-off valves — combining a solenoid valve with an electrohydraulic motorized valve for a compact double-valve footprint, a slow-open feature and high flow rates. An accompanying actuator can provide on/off or high/low/off firing rates as well as visual indication and proof of closure for compliance with most industry standards.

Also, you may want to look for valves that include useful features such as pipe taps, which can facilitate accurate pressure readings and leakage testing.

Knowing your valve choices — and how they meet given codes and standards — can reduce the time required for design and production while facilitating compliance. This results in safer, more efficient and cost-effective heating process installations.

For example, new regulations require utilities install curbside excess flow valves for all new home construction. These regulations resulted from years of learning and experience of the potential danger of ruptured gas lines between the roadside gas pipes and a home’s gas meter. When gas utilities install curbside excess flow valves, accidental ruptures of the gas line from landscaping and excavation no longer present danger to the home and community, since the EFV will automatically stop gas from flowing.

As good as our gas service is in the United States, we continuously improve on safety for our homes, based on what we learn from past incidents, and the experience both domestically and internationally.

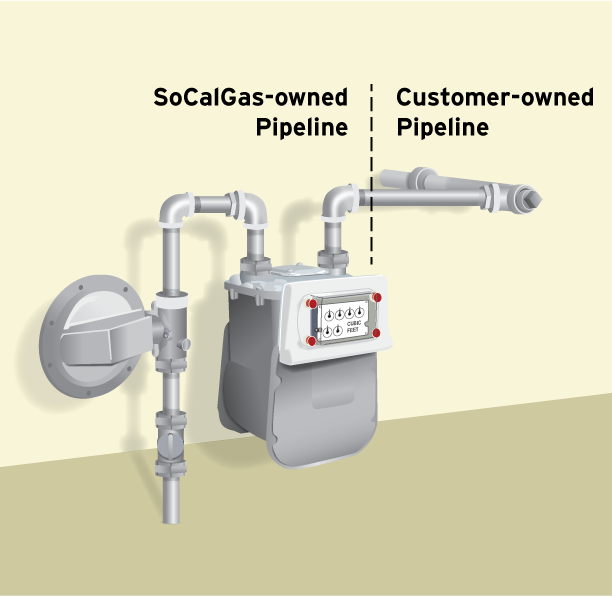

The gas utility is responsible for the integrity of the gas supply to the home up to the meter. The responsibility for the integrity and safety of the gas line after the gas meter lies with the homeowner.

Gas line ruptures can happen within the home as well, when nails or drills inadvertently compromise gas supply within the home. And many gas appliances use plastic tubing, which can corrode and deteriorate over time.

Fortunately, TECO Americas provides homeowners with the same type of technology used by gas utilities to protect their family, home, and furnishings from inside the home.

For this reason, responsible home owners install GST Excess Flow Valves, often with their gas appliance connectors, protecting them from internal gas line ruptures, or disconnections.

When the cause for the excess flow of gas is remedied, the GST EFV automatically resumes the flow of gas. The device recognizes a balance between the upstream flow rate and downstream flow rate through a small hole in the valve.

Different models of the GST EFV can be selected, depending on the pipe sizing and desired sensitivity to flow rates. Models are available that will trigger at any of the following flow rates:

The GST EFV is easily installed with previously installed gas appliances, as well as new appliances. It can also be installed in manifolds that service multiple gas appliances.

TECO Americas is introducing the GST EFV to homes throughout North America using the same patented technology that has protected homes throughout Europe and Asia for over 30 years.

When you’re working with gas, safety should be the name of the game. It’s extremely easy to cause a lot of damage, both to yourself and your establishment, when you’re not showing that invisible little devil the respect it deserves. Fortunately, modern-day gas safety valves have been tested and outfitted around the world, and these bad boys are essential pieces to any efficiently-working system. That said, when your gas safety valves are a little worse for wear, making a repair or finding a replacement is a no-brainer. That’s why keeping an extra in your repair kit or tool closet is a smart move, and we’ve got the gas safety valves you need!

The functional standard conforms in all aspects to CSA, Delta C, CE, Gas Mark and JIA for international high quality standard, which complies with low pressure 1/2PSI gas appliances.

100% in-house quality assurance inspection with all gas valve for leakage testing procedures in strict conformance to safety regulations requirements for high precision and reliability.

Some people have proposed a “safety valve” to control the costs of a cap-and-trade policy to fight global warming. This post explains what a safety valve is, and why it provides only an illusion of cost management.

In a cap-and-trade program, companies can choose either to lower emissions below the cap, or buy extra allowances. Some worry that if many companies need to buy extra allowances, demand will drive up the price, placing an undue burden on businesses.

The “safety valve” or “escape hatch” is meant to address this. It specifies that when prices reach a predetermined dollar value, businesses no longer have to rely on the established supply of allowances available in the market. Instead, the federal government makes new allowances available for sale at a specified price – potentially in an unlimited quantity.

There are two problems with this approach:A safety valve destroys the cap. The hard limit on emissions is the cornerstone of a cap-and-trade policy. Without a solid cap, we can’t be sure our emissions will go down enough to avoid the worst consequences of global warming. A safety valve gives the illusion that we are controlling emissions while allowing more greenhouse gas pollution into the atmosphere.

A safety valve limits the economic opportunity of those who develop cleaner technology. Higher permit prices signal the market to invest more in innovative low-carbon technologies – happy news if you’re in the business of inventing and selling ways to cut pollution. A safety valve would sharply curtail incentive for innovation. This drives up costs in the long run, and discourages the development of the clean technology we need.

A safety valve seriously undermines the main advantages of a cap. Its ability to control costs is an illusion, it lets more pollution into the atmosphere, and discourages entrepreneurs from investing in pollution-cutting technology.

I bought a 2007 Chrysler Town and Country minivan new and have never had any issues when pumping gas until recently. It takes forever to put gas in it now. It doesn"t matter how slow I try to go, it keeps kicking off. Can you advise me on what to do? It does have 198,000 miles on it. – Mitchell

As you pump gasoline into your vehicle, the existing air in the tank must exit the system as it is displaced by the fuel. When it doesn"t exit properly, it is forced up the filler tube and the shut-off safety valve in the gas pump will be activated repeatedly.

Common corresponding repairs for your Town and Country are to clean or replace the charcoal canister vent filter, replace the fuel tank vent hose and possibly the complete fuel filler neck.

Lou Trottier is owner-operator of All About Imports in Mississauga. Have a question about maintenance and repair? E-mail globedrive@globeandmail.com, placing "Lou"s Garage" in the subject area.

Shopping for a new car? Check out the new Globe Drive Build and Price Tool to see the latest discounts, rebates and rates on new cars, trucks and SUVs. Click here to get your price.

Toyota’s Mirai hydrogen fuel cell cars will make their Canadian debut in Quebec this year. Provincial Energy Minister Pierre Moreau says two stations to produce and supply the fuel will open in the fall.

Seismic shut-off valves are a simple, but effective way to ensure you never experience a gas fire after an earthquake. They are designed for earthquakes, accidents and any event of impact. We have installed thousands of automatic gas shut off valves to the manufacture’s specification to ensure safe, trouble free use.

The seismic valves work on a simple, consistent and accurate principle. A sensor moves when the valve is subjected to a 5.4 magnitude or larger earthquake, releasing the valve float which blocks the line and prevents gas going in to the building. The valve is then manually reset once a safety inspection has been done and you’re sure there are no leaks in the building.

Each valve is tested and certified before leaving the factory to meet approval from the State Board of Architect and LA Counties stringent requirements. They are tested to ASCE 25-97, State of California 12-23-1 & ANSI Z21.70-1981 Standards for Seismic Gas Valves.

Some cities and counties in California have regulations that require the installation of automatic gas shut-off devices, which may include excess flow gas shut-off valves and/or seismic gas shut-off valves. Regulations vary, but generally apply to new building construction, or significant alterations or additions to existing buildings.

If a customer installs an automatic gas shut-off valve, it should be one that is certified by the State of California and it should be installed by a licensed plumbing contractor in accordance to the manufacturers instructions.PG&Edoes not install or service seismic actuated or excess flow gas shut-off valves, or recommend specific contractors for customer applications.

Non-emergency shut-offs will occur if the automatic gas shut-off is not installed according to manufacturer’s specifications. For example, the impact of heavy vehicles can trigger a non-emergency shut-off. They operate on movement and shut off the supply of gas to a building, when triggered by a 5.4 magnitude or larger Earthquake.

While it"s possible to manually shut off your natural gas, the following specialized valves are available that can automatically shut off your service in case of an emergency:

Earthquake natural gas shut-off valve (also known as a seismic natural gas shut-off valve) automatically shuts off your natural gas service when an earthquake of a sufficient magnitude occurs at your home.

An excess-flow valve (EFV) automatically closes and restricts the flow of natural gas in the event an underground pipe is damaged or if there is a significant increase in the flow of natural gas to the meter.

If you want to have an earthquake natural gas shut-off installed, or are required to have one by your insurance company or the local Department of Building and Safety, the valve must be installed on your house line.

If installation requires natural gas service closure, you"ll need to contact us to shut off the service and restore service when installation is completed. Natural gas service shut off and restoration of service orders can be scheduled by contacting us at 1-800-427-2200.

Under the regulations of the California Public Utilities Commission (CPUC), General Order 112-E, only SoCalGas® or its certified contractors are authorized to operate the natural gas service shut-off valve.

When you hire a qualified professional to install your earthquake valve, you"ll need to make sure that the valve is installed on your house line, not on SoCalGas" facilities. SoCalGas" facilities include all of the pipe fittings installed and maintained by SoCalGas, up to and including the last elbow or tee connecting to your house line. See the diagram below for to see where your house line starts.

All unauthorized valve installations found on SoCalGas" facilities will be removed. In addition, earthquake valves are not permitted in utility curb meter vaults.

If an earthquake or other significant event causes your earthquake shut-off or excess-flow valve to close, you can follow the manufacturer"s instructions for resetting the valve so that natural gas flows again. However, we recommend that you contact a qualified professional or SoCalGas to reset the valve, and to perform a safety check of your natural gas appliances before they are placed back in operation to verify that no natural gas leaks exist, and to re-light your pilot lights.

Remember that following a major emergency it may take many days or even weeks before someone can come to your location. (SoCalGas charges a fee to reset valves and re-light pilot lights when your earthquake shut-off valve has closed due to a non-earthquake occurrence.)

Price: The cost of the valve is going to vary based on the type and size of the valve, as well as the installation requirements and the company installing it.

Choosing a valve: In order to choose the right valve size and manufacturer, contact your local Department of Building and Safety to find out their earthquake valve requirements.

Where to buy a valve: You can purchase an earthquake valve at supply retailers, licensed plumbing contractors, or directly from the valve manufacturer.

Using a contractor: You can hire a qualified professional to install the earthquake or excess-flow valve on your house line. SoCalGas will not install a valve for you.

Effective February 10, 2002, California Public Utility Commission (CPUC) Decision 01-11-068 prohibits installation of an earthquake valve on SoCalGas" facilities. In addition, SoCalGas no longer installs earthquake shut-off valves for its customers, and does not allow any customer owned equipment, including excess-flow valves, be installed on SoCalGas" facilities.

If you have an earthquake valve that was installed by SoCalGas or one of its authorized contractors on or before the February 10, 2002 cutoff date, that is located on SoCalGas" facilities, with proper documentation your installation may be allowed to remain in place. Authorized contractors are those who participated in SoCalGas" earthquake program and were trained by SoCalGas to work on their facilities.

Additional information regarding earthquake valves and natural gas service restoration after a valve activates can be found in Tariff Book, Rule 10, Section G, "Earthquake Valve Service."

An Excess Flow Valve, or EFV, is a safety device installed on natural gas distribution pipelines to automatically close and restrict the flow of natural gas in the event an underground pipe is damaged or if there is a significant increase in the flow of natural gas to the meter. These conditions are typically caused by digging or construction but can also be caused by damage to your natural gas meter by a vehicle impact.

EFV can reduce the risk of explosions, fires, and personal injury because they close or restrict any unplanned or excessive natural gas flow. Installation of an EFV will not protect a customer from household appliance malfunctions, small punctures in underground pipelines, and pipeline damage from earthquakes or flooding. It is

important to understand that an EFV does not shut off the flow of natural gas completely. Some leakage may still occur resulting in a hazardous condition.

An EFV is installed on the service pipeline that runs underground between the natural gas main (usually located in or near the street, alley or easement) and the SoCalGas® meter on the customer’s property).

The best way to prevent damage to a natural gas pipeline due to digging is to call 811, the Underground Service Alert program, at least two working days before digging. Underground Service Alert will coordinate with SoCalGas to mark the locations of buried utility-owned lines - absolutely FREE.

If you are interested in having an EFV installed on the service pipeline serving you[1], please call SoCalGas at 1-800-427-2200. SoCalGas will first check to see if your service already has an EFV installed and, if not, an estimate to install the EFV will be provided. The cost to install an EFV can vary widely depending on site specific conditions and can range from $2,500 to $5,000 or more.

If you decide to have an EFV installed, we will coordinate with you to schedule the installation (note that it is possible that natural gas service will be interrupted to install the EFV). The construction crew will dig around the natural gas line in order to install the EFV and when the job is complete natural gas service will be restored (if it was shut off). If paving or concrete needs repair that work will be scheduled at a later date.

The Robertshaw® TS Series Thermomagnetic Safety Valve is a control used to cut off the flow of gas to the burner in the event of a pilot outage. The magnet assembly is energized by voltage generated by a thermocouple that is heated by the pilot flame. When this flame is extinguished, the thermocouple voltage decreases until a spring overcomes the magnetic force and closes off both the pilot and main gas. This control can be used for commercial and residential ovens, infrared heaters, chicken and pig brooders, recreational vehicle gas appliances and many more applications requiring automatic safety valves.

NOTE: Once you have shut off the gas at the meter, do not try to turn it back on yourself. If the gas service shutoff valve is closed, PG&E or another qualified professional should perform a safety inspection before the gas service is restored and appliance pilots are relit.

PG&E crews will need to gain access to properties. Every gas meter must be inspected and gas crews must ensure that no gas is flowing on the customer"s property. Turning gas off at every meter is a necessary first step.

As reminder, PG&E employees always carry their identification and are always willing to show it to you. Customers should always ask to see valid identification before allowing anyone claiming to be a PG&E representative inside their home. If a person claiming to be a PG&E employee has identification and you still feel uncomfortable, call PG&E’s customer service line at 1-800-743-5000 to verify PG&E"s presence in the community.

It is important to know which appliances in your home run on gas. The most common gas appliances are stove top ranges, ovens, water heaters and furnaces.

Many older gas appliances and most water heaters have a small, continuously burning gas flame—the pilot light—that ignites the main burner. Some newer models have electronic igniters.

If the pilot light is out, shut the gas off at the appliance’s gas shutoff valve. Always wait five minutes to let gas disperse before trying to relight an appliance pilot light.

Follow the appliance manufacturer"s instructions to relight a pilot light. Often, basic relight instructions are located inside the main burner compartment door. If you cannot relight the pilot light yourself, call PG&E or another qualified professional for assistance.

Most gas appliances have a gas shutoff valve located near the appliance that lets you turn off the gas to that appliance only. In some cases, turning off the gas at the appliance"s shutoff valve will suffice if there is a gas leak or the appliance needs to be replaced or serviced. You should have an appliance gas shutoff valve installed at each gas appliance so that you can turn off the gas to that appliance only, instead of shutting off all gas at the main gas service shutoff valve.

When lighting the burners, light the match before you turn on the gas. If the flame goes out, turn off the burner and let the gas disperse before relighting.

Clean away any grease, oil or debris from the area to prevent a grease fire. In the event of a grease fire, never add water. Use baking soda or, if the fire is in a pan, use a lid to smother the flame. Stock your kitchen with a fire extinguisher.

If your water heater is elevated, make sure the platform is sturdy enough to withstand the weight of the water heater if it moves during an earthquake.

Do not use anything that could be a source of ignition, including cell phones, flashlights, light switches, matches or vehicles, until you are a safe distance away.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

Dual gas safety valve assembly. The gas oven safety valve works with the oven igniter to provide gas to the burner. If the safety valve fails, the oven won’t heat. Since safety valves rarely fail, be sure to check more commonly defective parts before replacing the safety valve.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

8613371530291

8613371530291