hydrogen safety valve in stock

Double block and bleed needle hydrogen valve with full bore is used for hydrogen application up to pressure of 1550 bar Compact and easy to use High reliability High safety

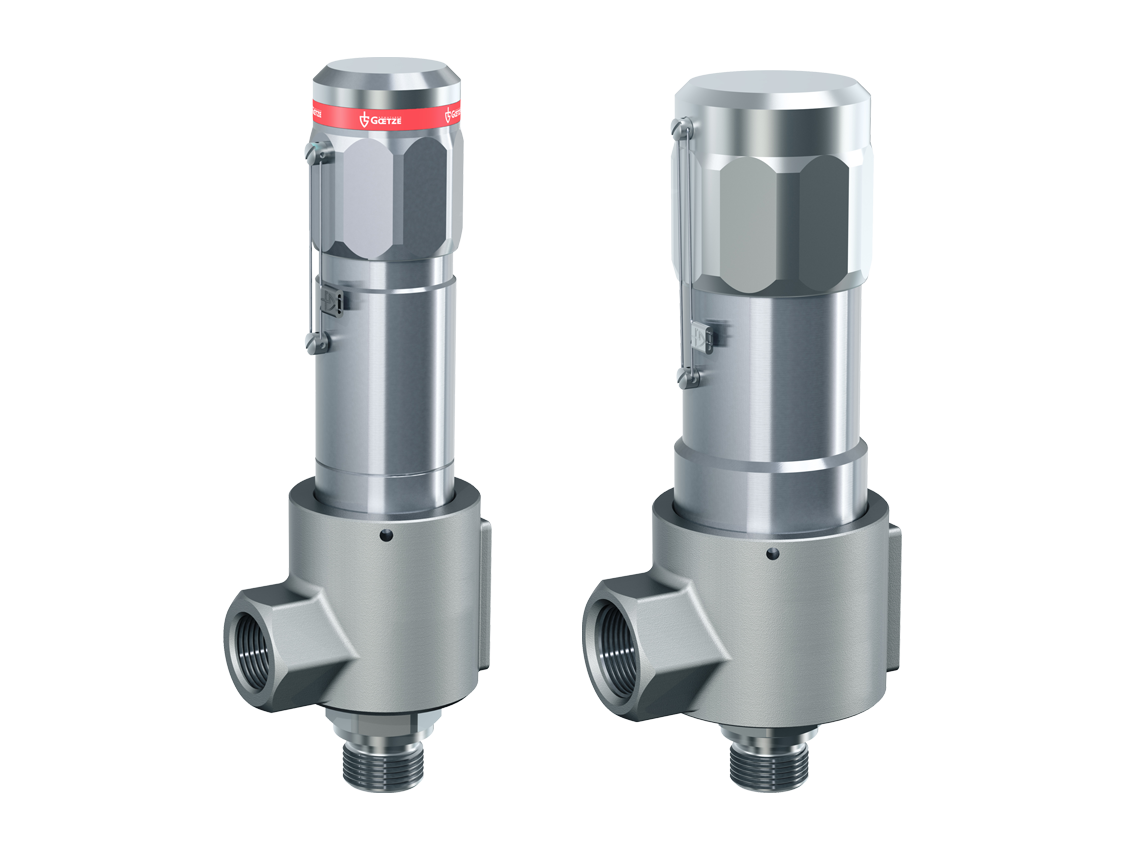

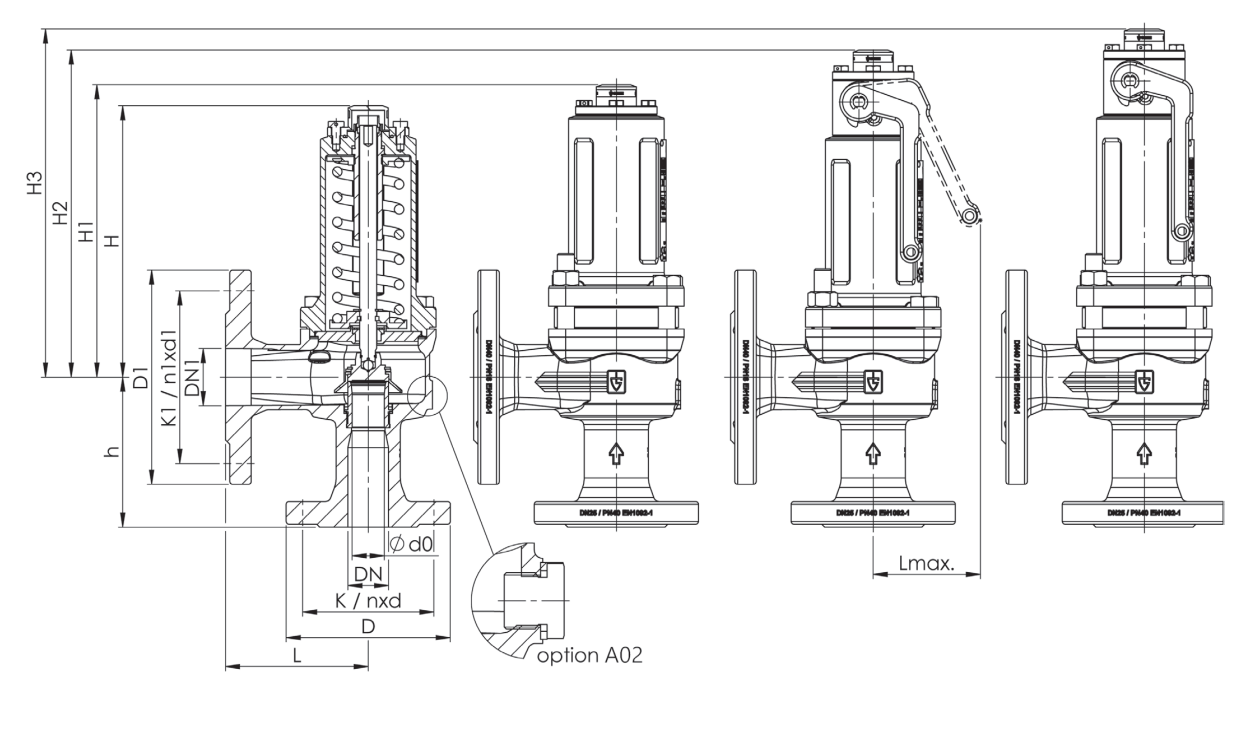

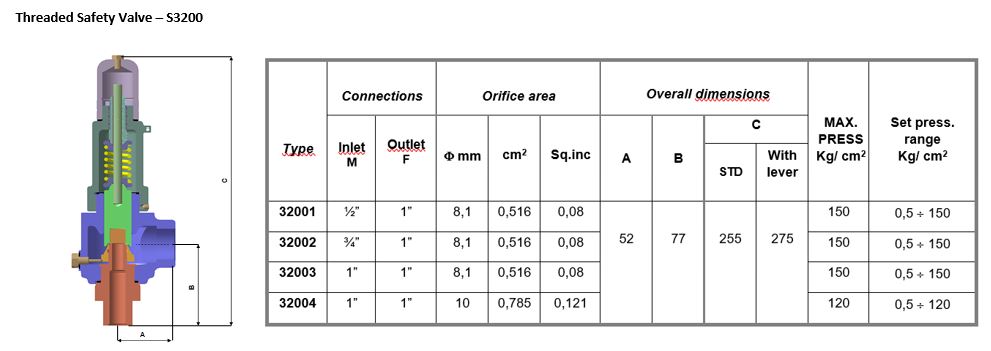

Hydrogen pressure relief valve – series 451Our safety valves is used to prevent excess pressure of the vessels in different applications and prevent the further release of gases after normal conditions have been restored.

In addition to the basic version the numerous sealing possibilities and materials, back-pressure compensating metal bellows and / or a gastight cap offer the necessary optional extras required to fulfill the highest safety requirements.

Double block and bleed needle hydrogen valve with full bore is used for hydrogen application up to pressure of 1550 bar Compact and easy to use High reliability High safety

HiP has been in the forefront of providing high pressure valves, fittings and tubing to support our customers as they incorporate hydrogen in their zero-carbon energy strategies. The ongoing build-out of the hydrogen refueling infrastructure necessary to support the fuel cell powered trucks, buses, cars, forklifts and other equipment depends on products designed and built to meet the unique challenges of hydrogen. HiP is a worldwide leader in delivering safe and reliable products to handle the high pressures and extreme temperatures associated with handling hydrogen.

Over the last ten years, HiP has produced tens of thousands of valves and fittings for hydrogen applications. As demand has continued to increase, we have committed the resources to develop a complete line of standard products for use with hydrogen, all either in stock or available with short lead-times. We have engineered our high pressure valve stems, packing and associated soft goods to meet the unique requirements of hydrogen. The standard material for all HiP valve bodies and fittings is 316 stainless steel, which is hydrogen compatible. In addition, we offer a range of special materials such as hastelloy and monel.

Designed to reduce contaminants in high-purity applications using hydrogen and methane gas, these valves have a stainless steel and brass body with a smooth finish to reduce dust collection and internal components designed to protect the seal and diaphragm from contamination. They’re often used in research sample systems, emission monitoring systems, and chromatography. Valves automatically reduce a high inlet pressure from compressed gas tanks to a lower, stable outlet pressure. All have Compressed Gas Association (CGA) numbered inlet fittings for secure connections to compressed gas tanks. Choose a valve with the same CGA number as your tank and other system components. Outlet fittings are Swagelok® for a leak-free seal around hard metal tubing in high-pressure lines. Also known as instrumentation fittings, Swagelok® fittings are compatible with Parker A-Lok, Gyrolok, Bilok, and Tylok fittings. Valves come with a gauge to monitor outlet pressure and a gauge to monitor inlet pressure from the tank.

Choose a valve with a maximum outlet pressure that’s approximately twice your application’s normal operating pressure. Your operating pressure should never exceed 75% of the valve’s maximum outlet pressure.

Single-stage valves reduce pressure in one step, which causes the outlet pressure to fluctuate slightly as you empty the tank. They’re best for applications where a constant outlet pressure isn’t critical.

Two-stage valves progressively reduce pressure over two steps for more consistent outlet pressure at all times. They’re often used in applications that require a constant outlet pressure regardless of the tank level.

Because relief valves are manufactured using different materials in a single valve, attention to the suitability of each material used in valves requires close attention. For example, some austenitic stainless-steel valves have stems that are made from martensitic stainless steel. Austenitic stainless steel is generally considered acceptable for hydrogen service, whereas martensitic stainless steel is not.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

The ullage volume (headspace) specified for a cryogenic vessel should always be respected. With the addition of heat, liquid hydrogen will expand at a rate 23 times greater than water. Overfilling a cryogenic vessel can lead to entrainment of liquid in the pressure relief system and the possibility of over pressurization.

Note that an LH2 cryogenic vessel will vent as part of normal operation whenever the rate of consumption of hydrogen by the process being supplied is less than the rate at which LH2 evaporates, or “boils off” in the vessel.

Since the PRD will cycle many times as part of the normal operation of a cryogenic vessel, it must be designed specifically for repeated cycles in a hydrogen environment.

If a liquid storage tank has been empty for a year or more, safety features such as pressure relief devices should be thoroughly checked before the tank is filled. Tanks that are warm need special filling procedures regardless of the length of inactivity.

Hydrogen pressure valve for home use are suitable for home use. They are safe and easy to use as a hydrogen water maker, safe for both use and home use.

Hydrogen pressure valve for home use can also improve blood circulation. There is also a need for hydrogen therapy at home, such as a hydrogen pressure device for skin.

Hydgen pressure valves offer a stable and stable hydrogen pressure. They do not contain any hydrogen at all at the same time, as they are not applied to water or other metals.

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

TESCOM HV-3500 Series Two Stage Pressure Reducing Regulator is a reliable, low maintenance pressure control solution. This EC79-tested solution is specially designed for use onboard industrial and commercial medium and heavy-duty hydrogen fuel cell vehicles and allows manufacturers to maximize fuel efficiency and keep their fleet on the road for a longer distance. The HV-3500 also provides consistent pressure and continuous flow in a full range of operating conditions. It is suitable for nominal inlet pressures up to 35.0 MPa and can reach flow rates above 3.2 g H2/s.

Our safety valves are designed and tested in compliance with all relevant safety standards. To ensure your system is always protected, our sealed housing spring design prevents moisture and particle contamination, maintaining the stability and accuracy of our valves over their lifetime of up to 35 years.

Based on a flexible modular system, we develop and supply control and switch valves for customer-specific requirements in mobile and stationary applications.

8613371530291

8613371530291