hydrogen safety valve brands

In our huge range of valves, there are valves and regulators for hydrogen. We have the knowledge to help you find the right way towards a green transformation. We have valves that are recognized as good in hydrogen applications, many of which have been in operation since the 80s.

Most of our standard valves are available for hydrogen. For regulation, there are ETfor higher flows and type EZfor lower flows, for example Quench valves. To minimize external leakage, there is Fisher"s Enviroseal Duplex H2 packbox which is specially developed for hydrogen applications. For shut-off, there is the triple eccentric metal sealing damper valve Vanessa which is leak tested with helium. The helium molecule is smaller than the hydrogen molecule, which ensures that the valves that are delivered meet their tightness requirements even for hydrogen applications.

A pressure relief valve prevents a predefined pressure from being exceeded. When the pressure is exceeded, the valve opens and the excess pressure is released and the medium is discharged. The pressure relief valve is activated without auxiliary energy and is triggered purely by the medium.

A pressure relief valve is used to protect a system as a last safety instance. In the case of systems requiring approval or systems that fall under the European Pressure Equipment Directive, for example, corresponding tests and approvals are required for the valves.

Even though each series differs in the field of safety valves, the main components of each valve are similar. The optimal design of the component geometry is ensured by flow simulations and elaborate function tests.

When at rest and installed on the system in normal operation, the force of the pressure spring is greater than the medium force, whereby the valve is closed and seals to the outside.

On the one hand, hydrogen is a colourless, odourless and completely non-toxic gas; on the other hand, it is highly volatile, highly flammable and has a high flame velocity. With hydrogen as a medium, the challenge is to produce, transport, store and use the gas safely, depending on the application and environment. These characteristics of hydrogen pose specific challenges for the design and construction of a hydrogen pressure relief valve.

As the last mechanically acting component in the safety chain, the pressure relief device for hydrogen systems is an important and indispensable part of the process. This applies in particular to the materials and seals used, as well as to the manufacturing process of the hydrogen valve, and the corresponding approvals.

A hydrogen pressure relief valve can be used to safeguard a hydrogen circuit, a hydrogen pressure pipe, or a high pressure hydrogen tank. The final safety chain function of such a high pressure hydrogen relief device is particularly relevant on a compressed hydrogen tank, which needs to maintain safe pressure levels even while the hydrogen system is not in operation, or left unattended.

Oil- and grease-free production, a hydrogen purity of > 5.0 (> 99.999 %), production according to a special production process for technical gases is explicitly recommended.

Which approvals for pressure relief valves are necessary in the field of hydrogen applications?Only use component-tested pressure relief valves to protect your hydrogen pressure systems.Sound technical advice from the valve manufacturer of the high pressure hydrogen relief device is essential in any case. Only then can your specific conditions be taken into account and the hydrogen pressure relief valve can be correctly designed according to the conditions prevailing on site.

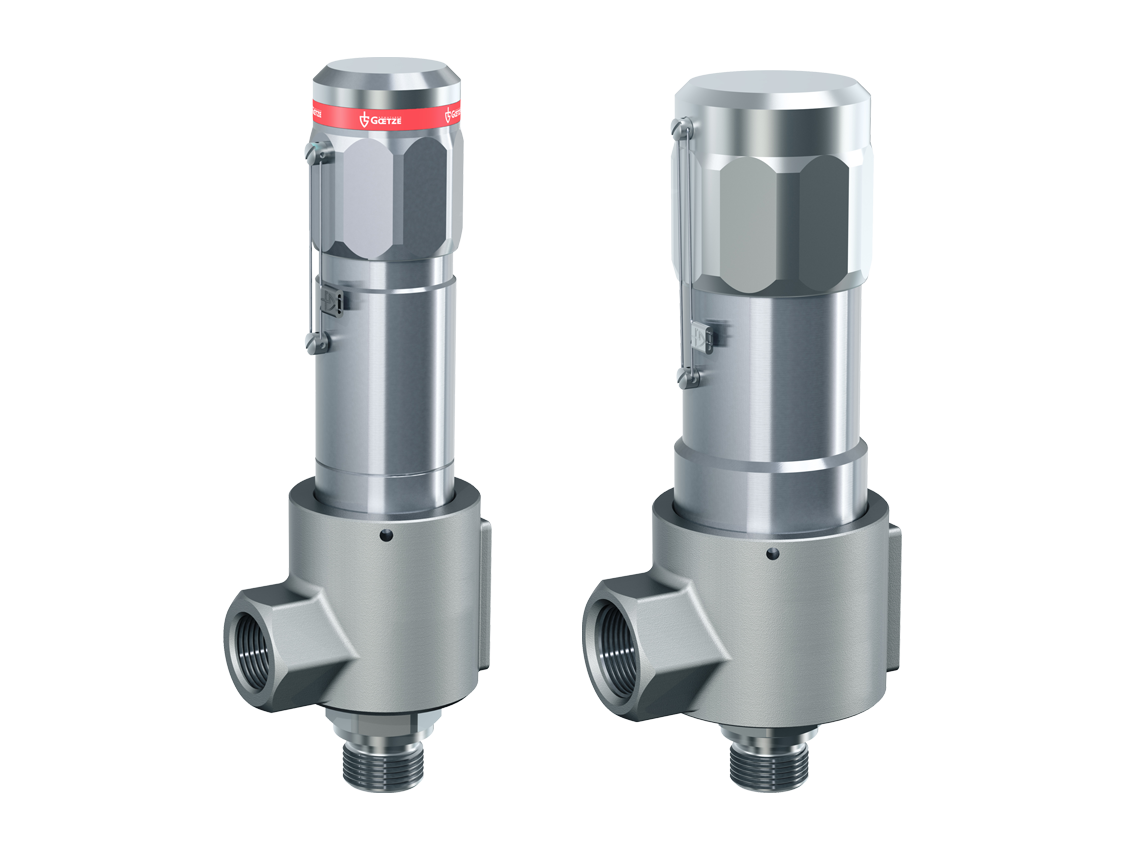

For over 70 years, Goetze KG Armaturen has been manufacturing sophisticated high-performance valves and fittings for media under pressure: liquids, air, gases and vapours. The family-owned company, which is based in Ludwigsburg, has made themselves a reputation worldwide with their high level of quality “Made in Germany”. Goetze is your partner regarding safety (valves). We assure the handling of hydrogen from the retrieval to the application – either in the electric part of the process or at the hydrogen filling station for vehicles. We protect filling processes, which are under high pressure or the storage of liquid hydrogen in tanks.

OMB offers the complete range of high-pressure valves such as the solenoid tank valve (ERA 1) with the option of an integrated pressure regulator, the fuel receptacle, remote TPRDs and check-valves. The full range of products are developed in compliance with the major international Standards and Regulations such as EC 79/2009, HGV 3.1. HPRD-1, UL 2267 and IEC 62282.

Historically and currently, enormous amounts of hydrogen are needed for key industrial processes such as the manufacture of artificial fertilizers and steel. New H2 applications such as fuel cell vehicles would further increase future demand. To contribute to the energy transition, this hydrogen needs to be "green" instead of being derived from fossil fuels, i.e. without producing CO2 in the process.

This will require large hydrogen electrolyzers. These consist of several stacks of electrolysis cells. For safe operation, the individual stacks require protection against overpressure with safety valves.

The WITT safety valves AV 619 and AV 919 perfectly match the target pressure and temperature ranges of PEM and Solid Oxide electrolyzers. The opening pressure can be set accurately anywhere in range 5 to 500 mbar. The operating temperature can be anywhere up to 250°C.

Highly precise and reliable, the valves open when the set pressure is reached and safely protect workers and sensitive equipment from overpressure. Despite their small size, the valves allow high flow rates, making them also suitable for large installations.

The valves are available with the elastomers required for hydrogen, including EPDM or FFKM (also known as FFPM). WITT safety relief valves are oil and grease-free, can be installed in any position, and are available with various inlet and outlet connections and in different materials, including stainless steel or aluminum (AV 919). Optionally, WITT offer TÜV Certification of individual valves’ set pressures.

WITT is a manufacturer of Pressure relief valvesor Safety relief valves for technical gases. They are designed to protect against overpressure by discharging pressurized gases and vapors from pipelines, pressure vessels and plant components. Safety relief valves (SRV) are often the last line of defense against explosion – and such an explosion could be fatal. Other common names for safety relief valves are pressure relief valve (PRV), safety valve, pressure safety valve, overpressure valve, relief valve or blow-off valve.

WITT safety valves are very precise. They are individually preset to open at a predetermined pressure within the range 0.07 to 652 Psi. Their small size and orientation-independent installation allow a wide range of connection options. WITT relief valves also stand out due to their high blow-off flow rates of up to 970m³/h. They can be used within a temperature range of -76° F to +518°F and even with very low pressures.

For maximum safety, WITT undertakes 100 % testing of each safety relief valve before it is delivered. In addition, WITT offers individual testing of eachsafety valveby the TÜV, with their certificate as proof of the correct set pressure.

WITTsafety relief valvesare direct-acting, spring-loaded valves. When the preset opening pressure is reached, a spring-loaded element in the valve gives way and opens, and the pressure is relieved. Once the pressures are equalized, the valve closes automatically and can be reactivated any time the pressure rises again. Depending on the application and the nature of the gas, the safety relief valvescan either discharge to atmosphere, or via a connected blow-off line. The opening pressure of the safety valves is preset by WITT at the factory according to the customer’s requirements.

Safety relief valvesare used in numerous industries and industrial applications where, for example, gases pass through pipelines or where special process vessels have to be filled with gas at a certain pressure.

These include, among other things:Pipeline, plant and container constructionIndustrial furnace constructionInsulators and reactors (e.g. “glovebox” systems)hydrogen-powered vehiclesAdditive manufacturing (3D printer)

For most industrial applications using technical gases, brass is usually the standard material of construction of thesafety relief valvebody/housing. For the use of pressure relief valves with aggressive and corrosive gases, the housings are made of high-quality stainless steel (1.4541/AISI 321, 1.4404/AISI 316L, 1.4305/AISI 303 or 1.4571/AISI 316Ti). The use of aluminium as a housing material is also possible.

Depending on the type of gas used and individual customer requirements, various sealing materials and elastomers are available to ensure the safety of your systems under even the most difficult conditions.

WITT pressure relief valves are available with different connections. In addition to the standard versions with the usual internal or external threads, special versions with KF or CF flanges, VCR or UNF threads can also be ordered. Special adapters for connecting the safety relief valve to a blow-off line are also available.

The Acme Model CV delivers precise performance, long life, and exceptional reliability ensuring your process or facility’s operation and safety while minimizing downtime.

In addition to our standard designs, Acme offers valves for specialized applications including fire control, lift check, high purity, and ultra high purity models.

Our High Purity (HP) Valve is available in ½” through 2″. Similar to the Model CV but fabricated with butt weld connections instead of socket weld connections, the HP valve eliminates the small areas in the socket where particles may become trapped.

Our ½” and 1″ Fire Control Valves are bellows sealed with extra long stems and pneumatic actuators. Acme Lift Check Valves are available in ½” through 2″ sizes and are intended for jacketed pipe.

Available in ½” through 2″ tube sizes, our Ultra High Purity (UHP) Valve is built entirely from machined parts. All connections are butt welded and all stainless steel parts are electropolished to an internal surface finish of 7RA average/14RA maximum. A lift check version is also available.

The VSV73 Vacuum Seal-Off Valve and PRV74 Pressure Relief Valve provide rugged, safe and reliable vacuum closure and pressure relief in vacuum insulated applications such as storage or transport containers, transfer lines and pipes.

Built-in the United States from a patented design by North America’s leading cryogenic valve manufacturer, the Acme Model CV exceeds industry standards for reliability and performance and has been field-proven across industry applications by many of the world’s leading companies, health systems, and manufacturers.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

CPC-Cryolab was founded in Florida to support the Space Program and the world’s first commercial size liquid hydrogen plant. The plant was built in Palm Beach County and CPC designed and manufactured all of the valves, filters, piping and transfer connections used in the facility.

In 2000, CIRCOR acquired the Rockwood-Swendeman line of cryogenic safety relief valves from Rockwood Systems of Portland, Maine. This industry valued line of SRV’s helped to further compliment the growing product line CPC-Cryolab has to offer.

At CPC-Cryolab, we strive to provide quality products and solutions to support the ever-growing cryogenic market. We are known as the world leading manufacturer of liquid hydrogen and liquid helium cryogenic components and equipment. We pride ourselves with the largest and most diverse family of products supporting the hydrogen and helium markets with; vacuum jacketed filters, valves, hoses, piping systems, manifolds and transfer connections available in the industry.

Operating as a manufacturer specializing in safety valves for high-pressure gas, Takei Company Limited provides high-quality products to the Japanese market and to clients in numerous countries around the world.

As a manufacturer specializing in safety valves for high-pressure gas, we believe that our philosophy is understood and embraced by everyone in a way that accounts for the recognition of and confidence placed today in our high level of production technologies and warmly extended after-purchase services.

ARKEMA is operating its plant in a non-stop mode requiring a high level of availability of the equipments as utilities devices as compressed air tanks. To allow high availability of its plant, ARKEMA decided to go for LESER’s new Changeover Valves.

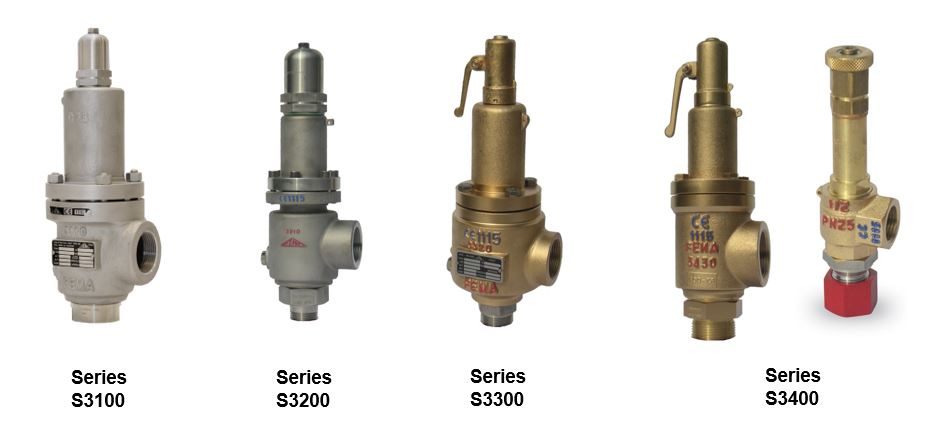

The LESER Change-over Valve Type 330 and 320 offers the solution for safe and efficient system availability 24 / 7. It is easy to operate and, in combination with safety valves, provides permanent protection for a permanently running system.

With the help of flow tests and CFD simulations (Computational Fluid Dynamics), a flow-optimized design with minimal pressure loss was developed. Each configuration of these change-over valves has a specified resistance coefficient that enables reliable and precise calculation of the inlet loss. Due to their durable construction, these change-over valves are maintenance-free and lavishly tested. They are the economical solution because an optimal selection can be made for every application.

ARKEMA is one of the leading hydrogen peroxide producers in the world. Hydrogen peroxide (H2O2) is used in different concentrations as example for food packaging sterilization. The plant in Shanghai was established in 2000, and expanded in 2008.

Through innovative organic development and strategic acquisition, we have built a broad portfolio of ASME and API valves that services the demands of global drilling, production, pipeline, storage, transmission, and critical service applications.

8613371530291

8613371530291