hydrogen safety valve price

Hefei Sinopower Technologies Co., Ltd. develops and distributes various products in the hydrogen energy industry chain, including but not limited to hydrogen production, hydrogen storage, hydrogen supply, stacks and BOP parts, fuel cell system assemblies, fuel cell vehicles, etc.

We have an experienced professional technical research and development team, which can provide professional services from product selection and matching, system design, product customization development and technical support. We provide hydrogen fuel cell design and R&D services and finished hydrogen fuel cell products for mainstream forklift companies in China. We have experience in stack integration and packaging services and are well received by customers at home and abroad.

Hydrogen pressure valve for home use are suitable for home use. They are safe and easy to use as a hydrogen water maker, safe for both use and home use.

Hydrogen pressure valve for home use can also improve blood circulation. There is also a need for hydrogen therapy at home, such as a hydrogen pressure device for skin.

Hydgen pressure valves offer a stable and stable hydrogen pressure. They do not contain any hydrogen at all at the same time, as they are not applied to water or other metals.

Double block and bleed needle hydrogen valve with full bore is used for hydrogen application up to pressure of 1550 bar Compact and easy to use High reliability High safety

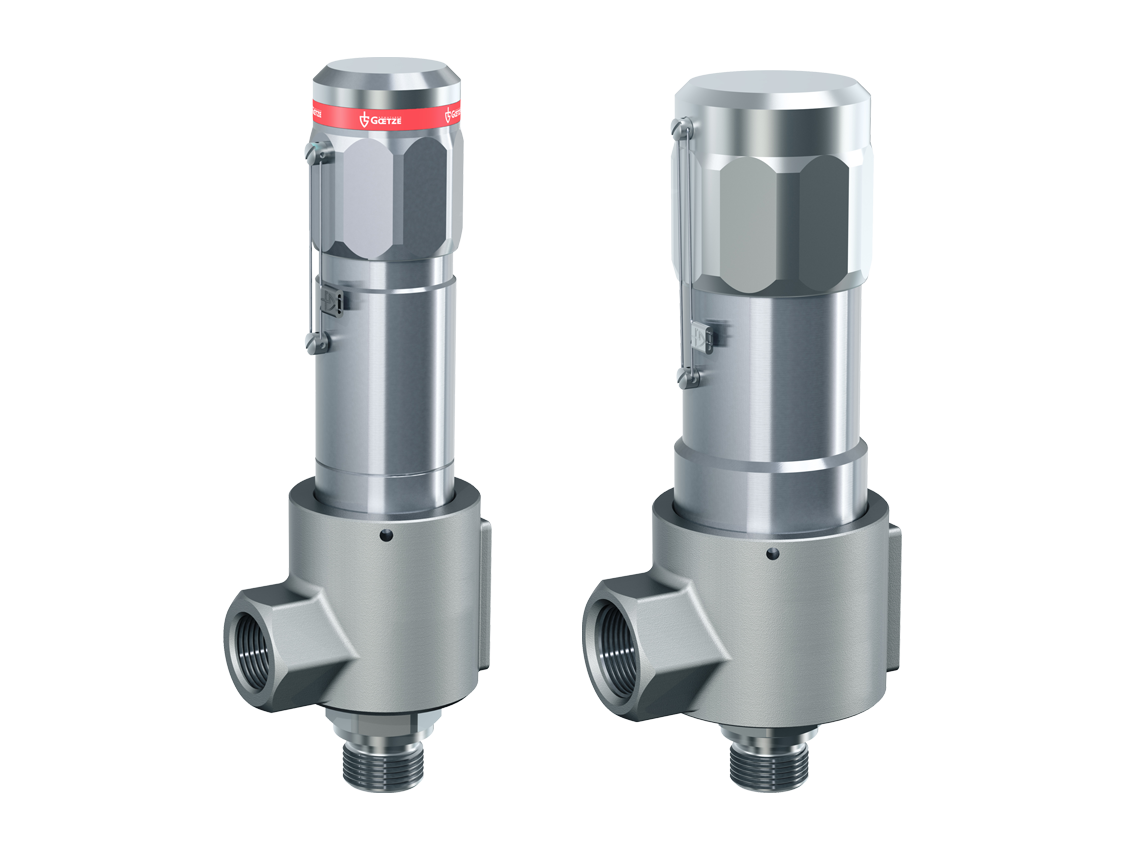

Hydrogen pressure relief valve – series 451Our safety valves is used to prevent excess pressure of the vessels in different applications and prevent the further release of gases after normal conditions have been restored.

In addition to the basic version the numerous sealing possibilities and materials, back-pressure compensating metal bellows and / or a gastight cap offer the necessary optional extras required to fulfill the highest safety requirements.

Double block and bleed needle hydrogen valve with full bore is used for hydrogen application up to pressure of 1550 bar Compact and easy to use High reliability High safety

OMB offers the complete range of high-pressure valves such as the solenoid tank valve (ERA 1) with the option of an integrated pressure regulator, the fuel receptacle, remote TPRDs and check-valves. The full range of products are developed in compliance with the major international Standards and Regulations such as EC 79/2009, HGV 3.1. HPRD-1, UL 2267 and IEC 62282.

Historically and currently, enormous amounts of hydrogen are needed for key industrial processes such as the manufacture of artificial fertilizers and steel. New H2 applications such as fuel cell vehicles would further increase future demand. To contribute to the energy transition, this hydrogen needs to be "green" instead of being derived from fossil fuels, i.e. without producing CO2 in the process.

This will require large hydrogen electrolyzers. These consist of several stacks of electrolysis cells. For safe operation, the individual stacks require protection against overpressure with safety valves.

The WITT safety valves AV 619 and AV 919 perfectly match the target pressure and temperature ranges of PEM and Solid Oxide electrolyzers. The opening pressure can be set accurately anywhere in range 5 to 500 mbar. The operating temperature can be anywhere up to 250°C.

Highly precise and reliable, the valves open when the set pressure is reached and safely protect workers and sensitive equipment from overpressure. Despite their small size, the valves allow high flow rates, making them also suitable for large installations.

The valves are available with the elastomers required for hydrogen, including EPDM or FFKM (also known as FFPM). WITT safety relief valves are oil and grease-free, can be installed in any position, and are available with various inlet and outlet connections and in different materials, including stainless steel or aluminum (AV 919). Optionally, WITT offer TÜV Certification of individual valves’ set pressures.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon dioxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SKS Series globe valves short stem are designed for handling of vapor phase and cryogenic liquids through bulk tanks, trucks, trailers, ISO-containers and piping configurations. Our time tested spring loaded stem packing and superior seat design provide for long life and easy maintenance. Recommended for vapor phase and intermittent cryogenic liquid use.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon oxide, methane, ethane, ethylene, argon and LNG . Our Kold-Sea™l stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon dioxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon oxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SKS Series globe valves short stem are designed for handling of vapor phase and cryogenic liquids through bulk tanks, trucks, trailers, ISO-containers and piping configurations. Our time tested spring loaded stem packing and superior seat design provide for long life and easy maintenance. Recommended for vapor phase and intermittent cryogenic liquid use.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon dioxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon oxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SKS Series globe valves short stem are designed for handling of vapor phase and cryogenic liquids through bulk tanks, trucks, trailers, ISO-containers and piping configurations. Our time tested spring loaded stem packing and superior seat design provide for long life and easy maintenance. Recommended for vapor phase and intermittent cryogenic liquid use.

Our investment cast stainless steel is specified by leading industrial gas companies for storage tank and yard operations. Special order bonnet extensions are available for cold box applications. Valves for hydrogen use can be supplied

The RegO® Goddard 231 Series Stainless Steel globe valves are designed for handling of cryogenic liquids through bulk tanks, trailers, ASU plants and piping configurations. Compatible with oxygen, nitrogen, CO2, hydrogen, helium and argon.

The RegO® Goddard 232 Series Stainless Steel globe valves are designed for handling of cryogenic liquids through bulk tanks, trailers, ASU plants and piping configurations. Compatible with oxygen, nitrogen, CO2, helium and argon.

HiP has been in the forefront of providing high pressure valves, fittings and tubing to support our customers as they incorporate hydrogen in their zero-carbon energy strategies. The ongoing build-out of the hydrogen refueling infrastructure necessary to support the fuel cell powered trucks, buses, cars, forklifts and other equipment depends on products designed and built to meet the unique challenges of hydrogen. HiP is a worldwide leader in delivering safe and reliable products to handle the high pressures and extreme temperatures associated with handling hydrogen.

Over the last ten years, HiP has produced tens of thousands of valves and fittings for hydrogen applications. As demand has continued to increase, we have committed the resources to develop a complete line of standard products for use with hydrogen, all either in stock or available with short lead-times. We have engineered our high pressure valve stems, packing and associated soft goods to meet the unique requirements of hydrogen. The standard material for all HiP valve bodies and fittings is 316 stainless steel, which is hydrogen compatible. In addition, we offer a range of special materials such as hastelloy and monel.

We feel immensely pleased to offer an exclusive gamut of Hydrogen Cylinder Valve. Our offered valves are manufactured by utilizing optimum quality raw material and advanced technology by our skilled professionals. In order to ensure quality, the entire range is rigorously tested on various parameters. In tune with international standard, we provide the entire range in various specifications, as per the requirement of our clients.

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon dioxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SKS Series globe valves short stem are designed for handling of vapor phase and cryogenic liquids through bulk tanks, trucks, trailers, ISO-containers and piping configurations. Our time tested spring loaded stem packing and superior seat design provide for long life and easy maintenance. Recommended for vapor phase and intermittent cryogenic liquid use.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon oxide, methane, ethane, ethylene, argon and LNG . Our Kold-Sea™l stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon dioxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon oxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SKS Series globe valves short stem are designed for handling of vapor phase and cryogenic liquids through bulk tanks, trucks, trailers, ISO-containers and piping configurations. Our time tested spring loaded stem packing and superior seat design provide for long life and easy maintenance. Recommended for vapor phase and intermittent cryogenic liquid use.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon dioxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes oxygen, nitrogen, krypton, carbon dioxide, dinitrogen monoxide, carbon oxide, methane, ethane, ethylene, argon and LNG . Our Kold-Seal™ stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shutoff and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

The SKS Series globe valves short stem are designed for handling of vapor phase and cryogenic liquids through bulk tanks, trucks, trailers, ISO-containers and piping configurations. Our time tested spring loaded stem packing and superior seat design provide for long life and easy maintenance. Recommended for vapor phase and intermittent cryogenic liquid use.

Our investment cast stainless steel is specified by leading industrial gas companies for storage tank and yard operations. Special order bonnet extensions are available for cold box applications. Valves for hydrogen use can be supplied

The RegO® Goddard 231 Series Stainless Steel globe valves are designed for handling of cryogenic liquids through bulk tanks, trailers, ASU plants and piping configurations. Compatible with oxygen, nitrogen, CO2, hydrogen, helium and argon.

The RegO® Goddard 232 Series Stainless Steel globe valves are designed for handling of cryogenic liquids through bulk tanks, trailers, ASU plants and piping configurations. Compatible with oxygen, nitrogen, CO2, helium and argon.

BRASS CYLINDER VALVE MADE BY SHERWOOD VALVE IN USA. THIS VALVE HAS A 1/2"-14 NGT INLET AND A CGA 350 OUTLET FOR CARBON MONOXIDE AND HYDROGEN SERVICE NO PRD .THE HANDWHEEL IS ALLOY. THIS VALVE IS PRIMARILY USED ON MANIFOLD SYSTEMS FOR INDUSTRIAL APPLICATIONS. PLEASE DOWNLOAD OUR TECH SHEET FOR DETAILS REGARDING MATERIALS, REPLACEMENT PARTS, ETC.

Metal hydrides are the most compact way to store hydrogen (more dense than liquid hydrogen). The internal volume of the CL-370A is less than 0.7 liters. 370 liters of hydrogen capacity is more than 500 times the size of the container!

Standard SOLID-H BL-series containers hold 18, 20, 30, 120, 220 or 740 standard liters of hydrogen gas. These are on the shelf or available on short delivery schedules.

SOLID-H CL-series containers, including CL-370 and CL-910, based on aluminum industrial gas cylinders. These two containers hold 370 and 910 liters of hydrogen respectively. The aluminum cylinders used to make the CL-series are rated for very high pressures. This makes them heavier than equivalent thin walled stainless steel BL-series containers of comparable capacity.

If you need a different capacity or special pressure-temperature specifications, just emailyour specifications. HCI has built custom metal hydride systems since 1978 with up to 300,000 liters of hydrogen capacity.

The hydrogen pressure when charging or discharging a SOLID-H™ container is something you select when you order. Four standard pressure ranges are offered; Alloy A(see Alloy A), Alloys L,M and H(see Alloys L,M,H).

Alloy A is an iron-titanium alloy that may be shipped void of hydrogen as non-hazardous material. Alloys L, M and H are rare earth-nickel alloys. After activation (activation means "charged for the 1st time") they must be shipped void of hydrogen as a flammable solid. The expense of hazardous shipping may be avoided if you order unactivated SOLID-H™ containers. HCI will send activation instructions.

Recharge your SOLID-H™ container by connecting it to a source of clean dry hydrogen gas at the pressure specified in your SOLID-H™ manual. The container will get warm to the touch. When it is cool again, recharging is complete.

Reduce the pressure to the value indicated for your alloy in the SOLID-H TM manual before disconnecting it from your hydrogen source. Failure to do so may lead to venting through the pressure relief in hot environments (pressure increases rapidly with temperature).

15,000 pounds-per-square-inch double block bleed and hand valves offer redundant protection from high pressure and superior sealing technology to avoid leaks.Emerson has launched the TESCOM™ Anderson Greenwood Instrumentation H2 Valve Series for hydrogen applications up to 15,000 pounds-per-square-inch (psi) (103.4 megapascal (MPa)). The new solution reliably isolates process pressure in high pressure gas applications such as hydrogen fueling stations and tube trailers, reducing fugitive emissions and improving safety.

As it moves from tank to pump, hydrogen is transferred at pressures of up to 15,000 psi (103.4 MPa). To protect personnel and prevent leaks, it must be effectively controlled and isolated. The Double Block Bleed (DBB) valve’s positive double block arrangement provides two layers of positive shutoff that shield maintenance staff from high pressure during instrument maintenance. Its modular design reduces the number of potential leakage points, and the reinforced sealing technology reduces the risk of fuel entering the atmosphere through the valve stem.

Among the cleanest fuels when produced using renewable resources, compressed hydrogen gas is used to power fuel cell electric vehicles (FCEVs). In 2021, 142 new hydrogen refueling stations began operating, the biggest increase in a single year, raising the total to 685 active stations worldwide. And, in January 2022, Global Market Insights Inc. predicted that the FCEV market will exceed $15 billion by 2027. To meet this growth demand, fueling station original equipment manufacturers (OEMs) must source reliable, high-performance components to ensure overall equipment effectiveness and ensure station safety.

“Given the pressures that hydrogen is subject to in these applications, it’s critical that equipment operates safely and reliably, every time. That’s why we’re committed to specifically developing components to help our customers effectively store and precisely control compressed hydrogen gas,” said Rob Lindquist, director of global marketing for TESCOM precision fluid control at Emerson.

The hand-operated, maintenance-free design of the hand valves and double block and bleed valves in the H2 Valve Series minimizes maintenance and downtime. With low operating torque and adjustment-free seal technology, these hand valves deliver a low cost of ownership in a compact solution.

For OEMs looking to safely minimize risks for operators, the H2 Valve Series provides several safety features. Each valve has a convenient QR code, allowing operators to quickly access the valve’s specs during maintenance and installation. The product also ensures that no high-pressure liquid or gas is released during maintenance. The valves are compliant to the ISO 19880-3 hydrogen fueling standard.

With this new 15,000 psi (103.4 MPa) product line, Emerson offers a comprehensive portfolio of TESCOM solutions for safe and precise operation of hydrogen fueling stations.

Valves are required in fuel cell systems to supply the gaseous fuel (generally natural gas or hydrogen) at the inlet side and to purge the condensate at the outlet side of the device. According to the initial pressure of the gas, the pressure will be reduced in several cascades.

Usually, two types of valves are embedded. On one hand the system needs on/off valves to drain condensate or to shut off the tank or the entire system. On the other hand, one proportional valve is required to dose the flow rate of gaseous fuel to the stack‘s inlet. Depending on the actual power demand, the gaseous fuel flow will be controlled through a highly dynamical proportional behavior.

One of the most important requirements for the valves are low internal and external leakage in order to ensure high level of process stability and repeatability of the system. It is hereby also important to reduce the hydrogen consumption, also while in stand-by mode.

The embedded valves have to work precisely and reliably, especially under extreme conditions such as high or low temperatures, or under extreme vibration. At the same time, the valves must comply to safety requirement during the entire expected life time.

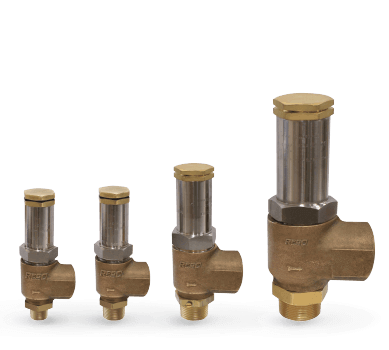

Mercer Valve Co., Inc® is committed to safely providing the highest quality pressure relief valve featuring our patented “Auto Seat Technology”® at a competitive price, delivered on time, and serviced by our trained professionals.We continue to improve our products and services, while meeting industry standards to satisfy our customer’s expectations.

Mercer Valve Company provides a Made in the USA manufactured high-quality safety relief valve. Our patented “Auto Seat Technology”® has a proven extended seat life that will allow your valve to open, close, seat and seal over and over again.

8613371530291

8613371530291