laser safety valve brands

Well-known companies worldwide rely on LESER safety valves. With its sole focus on overpressure protection, the safety valve specialist LESER is one of the international market leaders.

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

LESER safety valves are used by leading petrochemical, industrial gas, machine building, oil and gas production, chemical, food and pharmaceutical companies. LESER offers spring-loaded and pilot-operated safety valves for all industrial applications according to PED and ASME VIII as well as application-based solutions for special requirements. The LESER product range offers the right product for almost every application.

LESER safety valves are developed and manufactured in Germany. The LESER product range offers the right product for almost every application. Multiple options and special materials complete the range as a well as client-specific solutions.

Attractive Pricing - As the largest safety relief valve manufacturer in Europe (and #3 worldwide), LESER has the ability to produce high-quality products in a cost-efficient manner through large batch sizes and full automation of production; this allows LESER to pass on cost savings to the customer.

With almost 200 years of history, LESER has manufactured its safety valves to reflect state-of-the-art design and developed a product range to provide solutions for all sectors of industry. Customer satisfaction is the impetus behind LESER’s progress. LESER defines its products based on 7 pillars of achievement; rapid availability, product range, global network, quality, reliability, price and sustainability.

LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide, backed by more than 200 years of tradition. LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the API, PED and ASME VIII. Major companies in the oil and gas, petrochemical, chemical, energy, technical gases, LNG/LPG etc use LESER safety valves. LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

... -start valve with Series MX2 air treatment units without the need for additional connection interfaces. The soft-start valve is positioned upstream of the safety valves, ...

Two hands safety valve, which allows a safety use of two hands pneumatic controls (for example two push-button 3/2 N.C. to a certain distance) excluding false signals in case of push-button ...

The SI2 safety valve prevents the allowed operating pressure from being exceeded by more than 10%. If, after opening, the adjusted response pressure falls ...

... stainless steel full-lift clean service safety valve designed to AD Merkblatt A2 and TRD 421 standards and suitable for pure steam, vapour and inert gases.

Insert style flow control valves are comprised of a precision orifice in parallel with a check valve, combined into a single component. Each is designed for easy installation into metal housings using ...

Press-in style flow control valves are comprised of a precision flow orifice in parallel with a check valve, combined into a single component. Each part is designed for easy installation into plastic ...

If you have been searching for a safety release valve that you can use to reduce short-term pressure surges successfully and diminish the effects of gas leaks, this is the product for you. With a pe of ...

... have been type tested as well. These pressure regulators have safety valves which will slam shut in the event of emergencies, such as the gas reaching too high a pressure level. The valve ...

This product has hydraulically actuated class A gas safety valves to EN 161 used for automatic shut-off. It shuts off when unstimulated for gas and air, or even biologically produced methane. It has AISi ...

The S 104 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

... Pressure Safety Valve + Rupture Disk is protected and may be utilized autonomously as essential security gadgets or in conjunction. There are 3 possible combinations. The first combinations ...

Excavator pipe-rupture valves prevent uncontrolled cylinder movement in the event that a pipe or hose bursts. The ESV valve fulfills all of the requirements of the ISO 8643 and EN 474-5 standards for ...

Material: Body- CF8M; Valve Seat- CF8M Métal Seat, PTFE Soft Seat available Orifice Size: fc"(15mm), 3/4M(20mm), l"(25mm), l1/4,’(32mm)I ltë”(40mm), ...

The Safety valves from ATOS are designed to guarantee protection for application on various devices, especially those that monitor spool position. They are also recommended for hydraulic ...

With more than 800 employees LESER is the No. 1 manufacturer of safety valves in Europe as well as a leading player in its industry worldwide. LESER safety valves are developed in Hamburg for the international market and produced in the modern plant in Hohenwestedt. Leading companies in industries like chemical, petrochemical, industrial gas, oil and gas production, mechanical engineering as well as food and pharmaceutical industry rely on LESER safety valves.

A safety valve is an important part of any engineering system or industrial installation working with media under high pressure, it is the safety of the operating personnel, the exclusion of equipment destruction and emergency situations.

Conveniently, the safety valve supplier can service, adjust or reset the pressure, and can repair and replace parts if necessary. LESER safety valves are known all over the world and are widely used in industry and heating. To provide customers with more options for service safety valves, OPEKS Energosystems, the official distributor of LESER, uses a proprietary set of LESER equipment and tools to set up and maintain valves at its own production facilities.

Setting the required response pressure of the safety valve consists of the following main steps:Fastening the safety valve using a standard mount in a tuning stand. Preparing to set up.

Valve assembly. Checking the tightness of the valve in the closed position, at a pressure less than the design one to prevent leakage of the working medium. Valve seat polishing, other work if necessary.

Setting up safety valves at the OPEKS production facility allows us to provide a shorter delivery time, shorten the period of service work, provide more opportunities and better service to our customers. Also, the company"s warehouse regularly maintains new valves for water, gases of different diameters with a response pressure, which is most often found in inquiries.

Cooperation with OPEKS Energosystems, which supplies and maintains LESER safety valves, as well as manufactures heat exchange equipment, modular units, steam condensate systems and other heat and power equipment, favorably stands out for its great opportunities for our Clients.

Project: Gas mixing panel Gas: Oxygen Pressure Safety Valve Size: G3/8” or ½” + Material: Brass or Equivalent suitable oxygen service + Set pressure: 170 bar + Working pressure: 150 bar + Q’ty: 1 Pc - Document request: + Detail drawing with a material component + Certification oxygen cleaned + Certificate type approval for Oxygen

In 1885 the company developed its first safety valve for the protection of steam boilers. Even at that early date, LESER products were working for the safety of man and the environment. Since the 1970"s LESER has specialized only in safety valves.

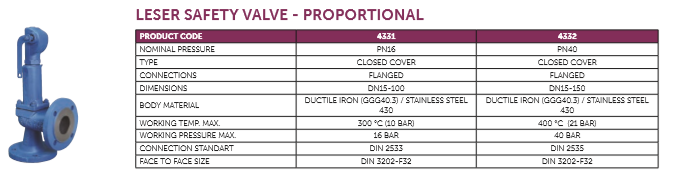

Being a quality centric company, we are engaged in offering a superior quality Leser Type Safety Valve. It is used in particular for vapors and gases, in applications where the maximum mass flow has to be discharged rapidly. Also, it is used for handling small and medium mass flows. They have the advantage of low weight and compact dimensions.

Corresponding with the constantly increasing demands of our national and international clients, we are occupied in providing excellent quality array of Safety Valve. We manufacture UK, USA, Germany, Italy, Korea, Spain.

Established in the year 2013at Bengaluru, Karnataka, we “RS Industries”are Sole Proprietorship (Individual)based company, involved as the manufacturer of Material Handling Trolley, Material Handling Lift, Safety Water Pipe, Metal Flangeand many more. With the help of our skilled workforce and well-developed facility, we offer quality bound products to our clients.

8613371530291

8613371530291