laser safety valve made in china

LESER China in Tianjin produces locally for the Chinese market with the same quality as in Germany. The localized safety valves cover 90% of China"s industrial demand. LESER sales offices and partner network ensure regional proximity to customers throughout China.

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

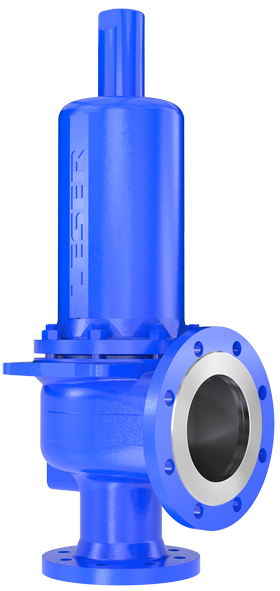

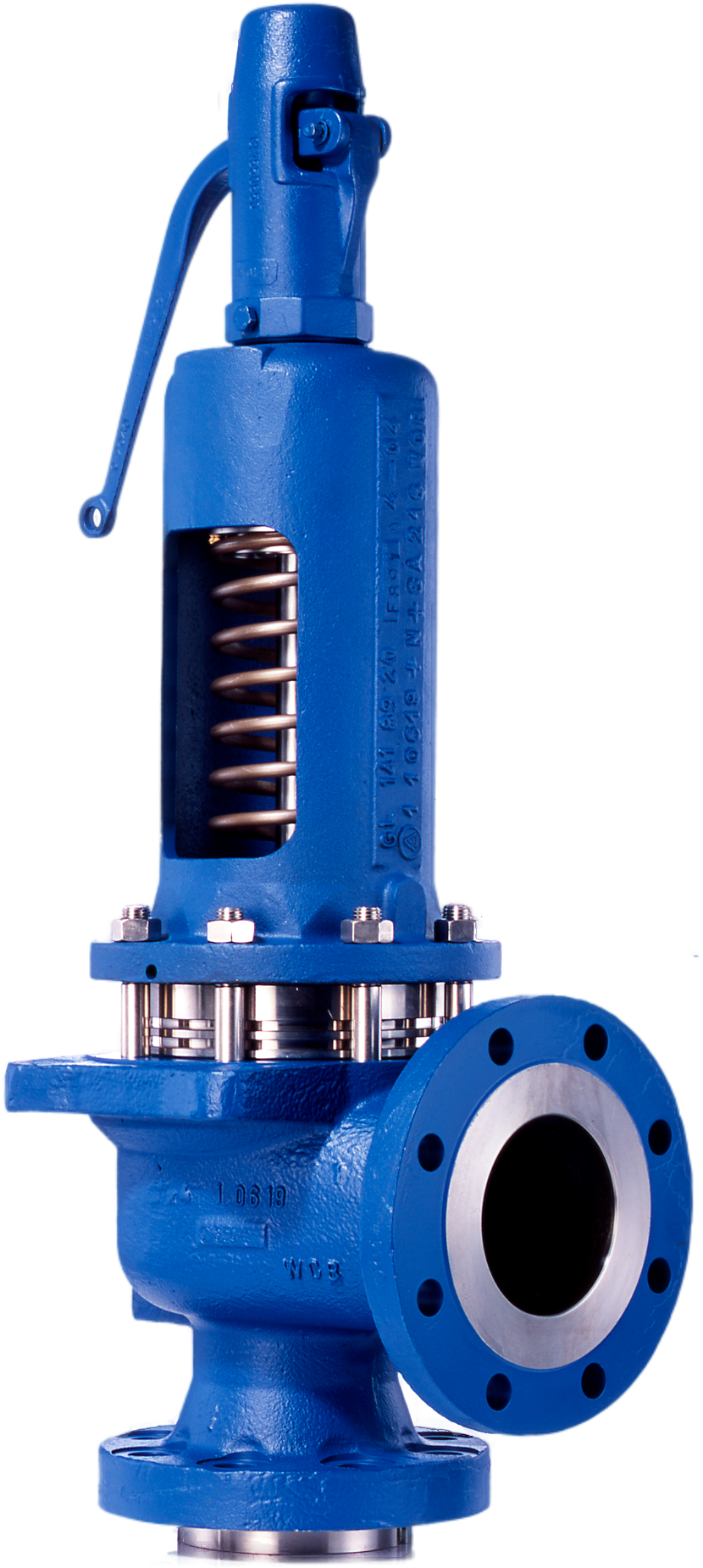

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

W&O, a global supplier to the marine and upstream oil and gas markets for pipe, valves and fittings, valve automation, and engineered solutions, has partnered with LESER in an exclusive distribution agreement to bring its safety relief valves to the United States maritime industry. This marks W&O’s first exclusive distribution agreement with a direct original equipment manufacturer of safety relief valves in the company’s 40-year history.

“W&O is excited to announce this partnership with LESER, and to do so at one of the industry’s marquee events, the International WorkBoat Show”, said Michael Hume, president and CEO of W&O. “The LESER safety relief valves are German-engineered and manufactured, and will be an excellent addition to the tank venting solutions we currently bring to our customers. This partnership is a natural fit for W&O, as LESER is equally committed to meeting customer needs, providing the highest quality product and engineering solutions to fit specific applications.”

The W&O and LESER partnership will prove very beneficial to customers for numerous reasons, including: short delivery times due to high stock of raw material and finished goods at the Charlotte, North Carolina, LESER facility, a variety of solutions from eight product groups and 40 safety relief valve types, and customer support offered by both companies.

The Leser Flanged Safety Relied Valve Series in accordance to API 526 are designed to meet all applications which require API. These valves open rapidly with an overpressure of max. 10% to full design lift and have a maximum blowdown of 7% for steam/gas service and 20% for liquid service. Service for protection of processes and equipment.

With almost 200 years of history, LESER has manufactured its safety valves to reflect state-of-the-art design and developed a product range to provide solutions for all sectors of industry. Customer satisfaction is the impetus behind LESER’s progress. LESER defines its products based on 7 pillars of achievement; rapid availability, product range, global network, quality, reliability, price and sustainability.

LESER uses modern technologies to manufacture safety valves precisely and in high quality. Their safety valves are produced at the Hohenwestedt plant, which is, with a capacity of 130,000 valves per year, the largest production site for safety valves in Europe. In addition, LESER manufactures in Paithan/India and Tianjin/China for the respective local markets.

Safety with superiorityHEROSE provides safety around the world for the handling of technical gases, steams and liquids. With 140 years experience in the development, manufacture and sale of valves with a high level of innovation and modern production with certified quality management, our company is one of the world"s leading manufacturers and suppliers of

We specialise in developing and manufacturing individual solutions required by the market right up to the production stage. We have developed, e.g. an innovative valve generation for use in extreme temperatures between -270° C and +400° C, special valves for air separation and valves for the liquefaction of natural gas (LNG).

Qualified specialist personnel produce our goods using state-of-the-art CNC machines, degrease them with systems designed in-house and create the appropriate markings with laser-controlled engraving machines.

Foundry master Theodor Rose set up the valve factory Th. Rose KG in Altona. He started production of valves for ship construction and building technology

Construction of the new production facilities in Bad Oldesloe covering 3500 square meters. Continuing more than 130 years of tradition, quality valves are still manufactured here

8613371530291

8613371530291