leser safety valve distributor brands

LESER China offers technical advice and customer support for safety valves in China directly from the manufacturer. The wholly-owned subsidiary covers all areas of a safety valve manufacturer with production (machining, assembly, storage and inspection), order processing, logistics, safety valve consulting, project management, after-sales service and marketing.

LESER sales offices in Tianjin, Beijing and Shanghai as well as sales service in Shenzhen, Xi"an and Wuhan ensure regional customer proximity. LESER partner Sinobright Pesch serves major customers and the province of Xinjiang.

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

Well-known companies worldwide rely on LESER safety valves. With its sole focus on overpressure protection, the safety valve specialist LESER is one of the international market leaders.

The worldwide LESER distribution network ensures competent technical support as well as fast and reliable deliveries. Find your local contact person for all questions regarding safety valves. For this purpose, navigate via the map.

LESER US supplies representatives, distributors, and end customers in North America. This subsidiary provides on-site manufacturer expertise for all your commercial and technical needs. LESER US stocks 7 million USD worth of safety valves and spare parts at its location in Charlotte, North Carolina. This allows LESER US to deliver safety valves and spare parts from the regional warehouse within one week or, in emergencies, on the same day.

LESER safety valves are used by leading petrochemical, industrial gas, machine building, oil and gas production, chemical, food and pharmaceutical companies. LESER offers spring-loaded and pilot-operated safety valves for all industrial applications according to PED and ASME VIII as well as application-based solutions for special requirements. The LESER product range offers the right product for almost every application.

LESER safety valves are developed and manufactured in Germany. The LESER product range offers the right product for almost every application. Multiple options and special materials complete the range as a well as client-specific solutions.

Attractive Pricing - As the largest safety relief valve manufacturer in Europe (and #3 worldwide), LESER has the ability to produce high-quality products in a cost-efficient manner through large batch sizes and full automation of production; this allows LESER to pass on cost savings to the customer.

LESER Authorized Repair Centre (LARC) Network - More than 30 LARCs in North America provide the end-user with access to authorized, reliable, and convenient local support for the repair of their installed base.

We are currently seeking self motivated, talented individuals with a minimum of 5 years experience in valve applications. If you meet this brief we would be interested to hear from you. Send your CV to sales@valvedistributors.com.au

With almost 200 years of history, LESER has manufactured its safety valves to reflect state-of-the-art design and developed a product range to provide solutions for all sectors of industry. Customer satisfaction is the impetus behind LESER’s progress. LESER defines its products based on 7 pillars of achievement; rapid availability, product range, global network, quality, reliability, price and sustainability.

LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide, backed by more than 200 years of tradition. LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the API, PED and ASME VIII. Major companies in the oil and gas, petrochemical, chemical, energy, technical gases, LNG/LPG etc use LESER safety valves. LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany.

Since the 1980"s LESER has been the number one supplier for safety valves in the world and strengthens this position each year. LESER currently has 7 different locations worldwide and continiues to expand its international presence in an effort to supports its growing customer base.

High performance relief valves, compact relief valves, high efficiency relief valves, modulate action relief valves, clean service relief valves, critical service relief valves.

LESER uses modern technologies to manufacture safety valves precisely and in high quality. Their safety valves are produced at the Hohenwestedt plant, which is, with a capacity of 130,000 valves per year, the largest production site for safety valves in Europe. In addition, LESER manufactures in Paithan/India and Tianjin/China for the respective local markets.

Prefabrication and assembly are largely carried out on automated production lines. Through this process, LESER ensures the consistently high quality standard of the products, regardless of whether it is a series component or an individual production of your choice.

The Leser safety valve is a product safety valve. This safety valve product line is manufactured by the manufacturer Leser, a very famous safety valve manufacturer in Germany. The manufacturer of Leser, specializes in only one product, which is a safety valve.

German Leser safety valves are widely used in a variety of industries. This Leser safety valve product is applied to a number of industries such as: in the petroleum, chemical, pharmaceutical, energy, food production, shipbuilding, heating industries...

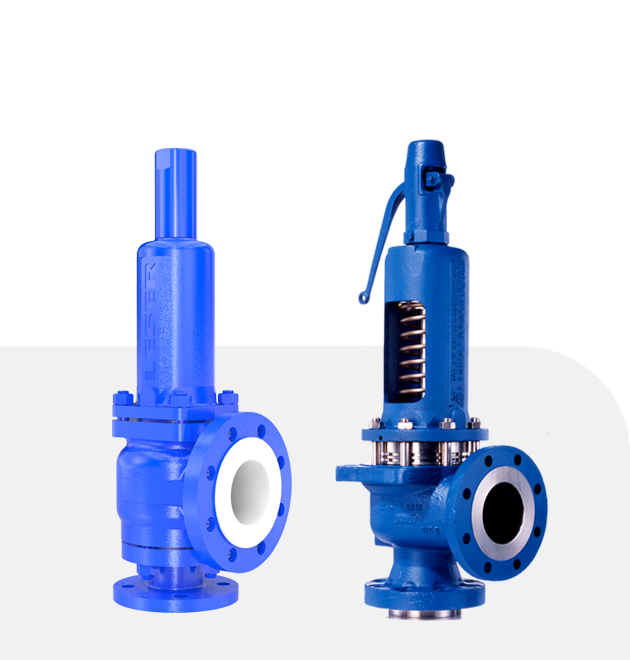

Leser full valves are produced in a variety of lines and models, with each type, each line will have separate applications. Each line, model will have a different design and structure, and different materials.

Safety valve company Leser is a German manufacturer of safety valves Leser. Safety valve company Leser is the largest safety valve manufacturer in Germany, the largest in Europe, in addition to being one of the world"s leading safety valve manufacturers.

Leser products are manufactured according to different standards, depending on the local supply, Leser"s products will be produced according to different standards. , China for these two markets.

First of all, let"s find out what is a safety valve? Safety valve is a safety device used as a safety device for the working system. The safety valve is not responsible for regulating pressure, it only has the function of releasing pressure in an overpressure situation.

Safety valves are used to ensure the safety of the system, people and the environment. The safety valve is designed to release excess pressure from the system until the pressure returns to normal and in the normal state the safety valve is closed.

Why is there a safety valve symbol? When installing a system, it is necessary to first create a drawing to build up the overall diagram of the system. In the system will install many different equipment, machines, valves. Therefore, each device will be designated with a unique symbol to identify the correct equipment and installation. So what is the symbol of the safety valve, you can observe through the image

The Leser API safety valve product has the ability to work in extreme temperature and pressure conditions, the ability to work in high and low temperatures is very good, the temperature range of this product line it is -268 degrees Celsius to 538 degrees Celsius and the working pressure of the valve can be up to 0,12 bar to 413bar.

This product line is a series of pilot valve operated safety valves. This series of products are used with high capacity applications, this safety valve has the highest discharge capacity in its class.

This valve is as its name suggests, highest discharge capacity, operating pressure up to 96% of set pressure, back pressure up to 90% of set pressure.

Designed with sizes from DN25 to DN200, made from alloy steel materials, WCB, CF8M, SA 352 LCB, etc. The working conditions of this pressure relief valve line are from -48 degrees Celsius to -200 degrees Celsius. 2,5 degrees Celsius, pressure from 426bar to XNUMXbar.

This safety valve product line features a compact design, this safety valve product is often applied to compact applications, with sizes from DN15 to DN40 and a variety of connections, flanges and threads.

Low pressure safety valve products are applied to low pressure dynamic applications, the working pressure level of this product line can only work to the highest pressure of 160bar.

Microbiological safety valve is a pressure reducing valve product line that is applied from the microbiological stainless steel material line with a smooth surface to ensure food safety and hygiene, this safety valve product is often applied to various applications. food, beverages and pharmaceuticals.

Microbiological safety valve products have the following types: 481, 483, 484, 485, 488. Different types with different designs, sizes and capacities, so the application with each type will be different.

This safety valve is manufactured with PTFE liner, PTFE liner design, as known PTFE material has good high temperature working ability, plus good corrosion resistance, thus helping to produce This safety valve product can perfectly be installed in the system with corrosive nature.

With more than 800 employees LESER is the No. 1 manufacturer of safety valves in Europe as well as a leading player in its industry worldwide. LESER safety valves are developed in Hamburg for the international market and produced in the modern plant in Hohenwestedt. Leading companies in industries like chemical, petrochemical, industrial gas, oil and gas production, mechanical engineering as well as food and pharmaceutical industry rely on LESER safety valves.

Since 2012 LESER has been supported by FE China for the purchasing of precision casting. Thereby FE carries out following tasks locally:selection of suitable precision casting suppliers as well as on-site visits together with LESER representatives

Early 2015 the Director Procurement & Quality Management of FE has visited the main plant of LESER in Hohenwestedt and has been trained for several days, in particular about the main criteria of quality control. The purchasing of precision casting by LESER in China is developing positively and the numbers of products and sizes are increasing.

W&O, a global supplier to the marine and upstream oil and gas markets for pipe, valves and fittings, valve automation and engineered solutions, has partnered with LESER in an exclusive distribution agreement to bring its safety relief valves to the United States maritime industry. This marks W&O’s first exclusive distribution agreement with a direct original equipment manufacturer of safety relief valves in the company’s 40-year history.

“W&O is excited to announce this partnership with LESER, and to do so at one of the industry’s marquee events, the International WorkBoat Show,” said Michael Hume, president and CEO of W&O. “The LESER safety relief valves are German engineered and manufactured, and will be an excellent addition to the tank venting solutions we currently bring to our customers. This partnership is a natural fit for W&O, as LESER is equally committed to meeting customer needs, providing the highest quality product and engineering solutions to fit specific applications.”

According o the companies, the partnership mean short delivery times due to high stock of raw material and finished goods at the Charlotte, N.C. LESER facility, a variety of solutions from eight product groups and 40 safety relief valve types and customer support offered by both companies.

LESER safety relief valves are optimized to feature a simplified design with fewer components, resulting in less down time, fewer spare parts and lower maintenance costs. Product highlights include a single trim for all mediums, bellows shield (which extend the life-cycle of the bellows), and the ability to be shipped and installed horizontally. The valves are application specific for various industries including maritime, oil & gas, LNG/LPG, and petrochemical, just to name a few. LESER valves are manufactured to meet USCG, ASME, PED, ABS, API, DNV, Bureau Veritas, Lloyd’s Register and RINA standards in both ANSI and DIN connections.

"Since its inception in Hamburg, Germany in 1818, LESER has supported the European maritime industry with valves and fittings for various applications. Now, partnered with W&O, LESER is able to expand its reach into the North American market,” said Steve Usina, president of LESER US.

LESER offer spring loaded and pilot operated safety valves for all industrial applications according to the European Pressure Equipment Directive 2014/68/EU (CE-mark) and ASME VIII Division 1 (UV-Stamp).

Major global companies in chemicals, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding as well as heating and air conditioning industries use LESER safety valves.

LESER safety valves are used by leading companies in industries such as chemical, petrochemical, industrial gases, oil and gas production, and machine building, as well as the food and pharmaceutical industry.

LESER offers spring-loaded and pilot-operated safety valves for all industrial applications according to PED and ASME VIII as well as application-based solutions for special requirements.

LESER safety valves are developed for the international market at our headquarters in Hamburg / Germany and manufactured at our modern factory in Hohenwestedt / Germany. In addition, LESER India produces safety valves for the local market.

LESER India is one of the leading manufacturing companies for safety valves in India. The state of the art manufacturing facility is located in Paithan, Aurangabad. The sales and marketing organization headquartered in Mumbai offers powerful and competent service.

The company was established in 1987 as a joint venture between Fainger Engineering, India, and LESER GmbH & Co. KG, Germany to manufacture safety valves with a proven design and technology. Since 2010, the company is a 100% subsidiary of LESER with now more than 1050 employees.

Our modern manufacturing and testing facilities ensure high quality safety valves and a large central stock guarantees short delivery times for valves and spare parts. To date, the more than 3,00,000 LESER India safety valves installed underline the trust the customers have in LESER India.Our safety valves are being used by customers across all major industries like oil & gas, petrochemicals, chemicals, pharmaceuticals, and Original Equipment Manufacturers (OEMs).

8613371530291

8613371530291