leser safety valve distributor free sample

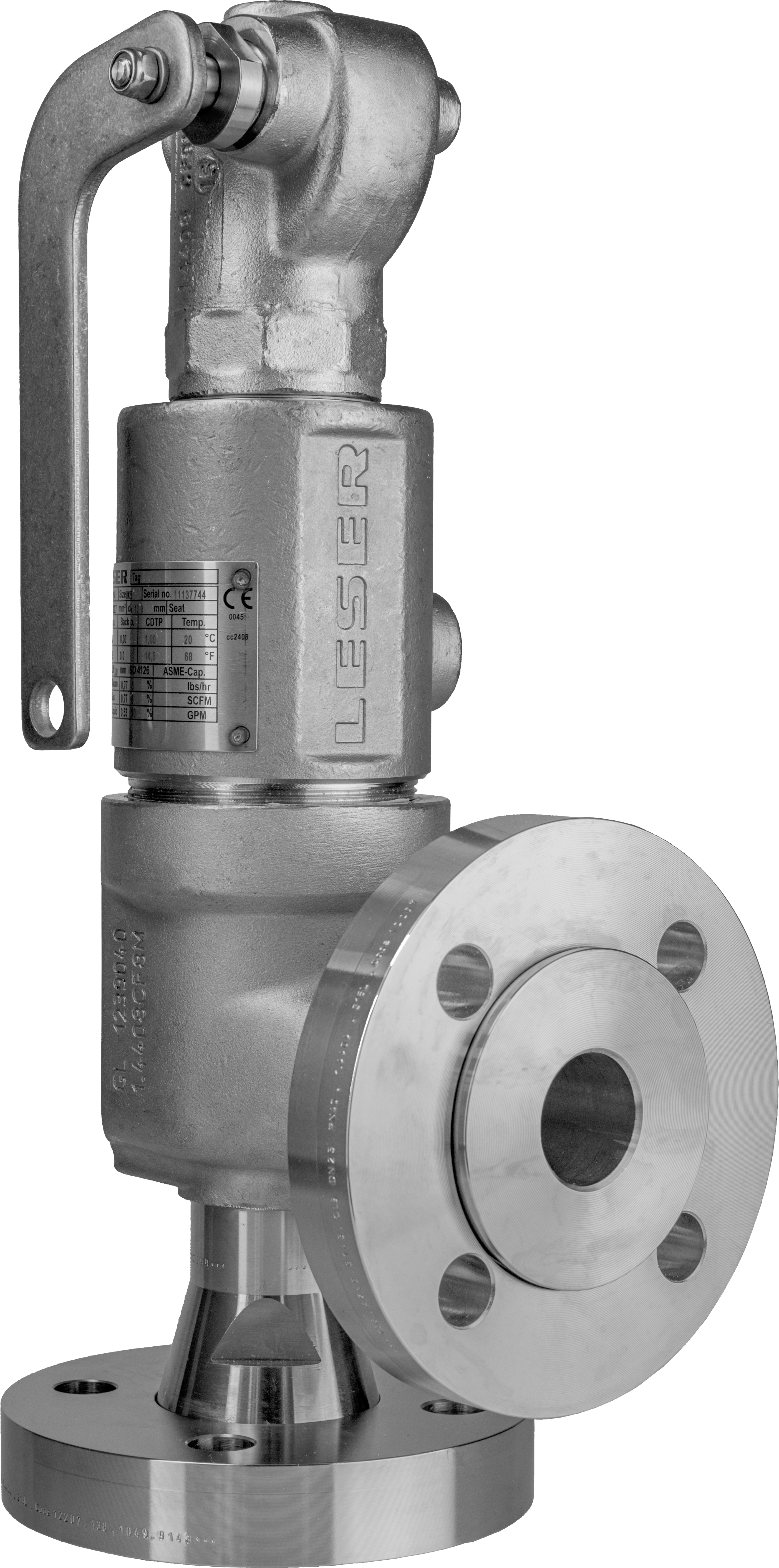

The primary purpose of a safety valve is to protect life, property and the environment. Safety valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of safety valves differs depending on the load or main type of the valve. The main types of safety valves are spring-loaded, weight-loaded and controlled safety valves.

Regardless of the type or load, safety valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

Certificates indicate the quality of the material used and the tests a safety valve has undergone during the production process at LESER. You can download the safety valve certificates that you have ordered from LESER for your valve at any time. This gives you full access to your documentation regardless of where your safety valve is installed.

Enter the combination of your customer number and the order number (LESER job number) and you will receive all the certificates from a complete order.

The worldwide LESER distribution network ensures competent technical support as well as fast and reliable deliveries. Find your local contact person for all questions regarding safety valves. For this purpose, navigate via the map.

LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide, backed by more than 200 years of tradition. LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the API, PED and ASME VIII. Major companies in the oil and gas, petrochemical, chemical, energy, technical gases, LNG/LPG etc use LESER safety valves. LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany.

VARIVENT® Safety valves were specially developed for the food, beverage, and pharmaceutical industries and meet all the relevant standards and regulations such as DIN 11866 or ASME BPE. With a low deadspace inlet area, the unique LESER HyTight assembly, and the optional pneumatic lifting device you have very good cleanability (CIP, SIP). With a large selection of aseptic connections (threaded, flanged, or clamped) the valve can be optimally fitted to different requirements.

VARIVENT® Safety valves were specially developed for the food, beverage, and pharmaceutical industries and meet all the relevant standards and regulations such as DIN 11866 or ASME BPE. With a low deadspace inlet area, the unique LESER HyTight assembly, and the optional pneumatic lifting device you have very good cleanability (CIP, SIP). With a large selection of aseptic connections (threaded, flanged, or clamped) the valve can be optimally fitted to different requirements.

Full-life safety valves open pop action so that it is possible to release high mass flow rates or quick occurring pressures. They are often used in steam or gas applications. These valves open completely even at small pressure rises and can therefore discharge the full mass flow.

Normal stroke safety valves are optimal pressure relief valves. They have got a wide proportional area so that they steadily activate during pressure relief and pressure peaks. Their long proportional phase have nearly full-life character. These similar properties can reduce big mass flows. They are also used as overflow valves and when smaller sizes of full-life safety valves are still to big.

To guarantee that all product touched surfaces can be cleaned hygienically (CIP) or sterilized (SIP) it is possible to get the valves with optional pneumatic lifting device.

Safety valves prevent tanks against overpressure for example vessels within a sterilization process or during tank filling. They protect fermentation tanks prior damages in case of unexpected disturbance.

Normal stroke safety valves are optimal pressure relief valves. They have got a wide proportional area so that they steadily activate during pressure relief and pressure peaks. Their long proportional phase have nearly full-life character. These similar properties can reduce big mass flows. They are also used as overflow valves and when smaller sizes of full-life safety valves are still to big.

Very good cleanability - this is the requirement for the design of the LESER Clean Service safety valves. These valves are equipped with the HyTight Assembly which offers optimal cleaning possibilities.

Safety valves of the VARIVENT series have got gas sealed lifting devices of the valve disk. This design makes enables the lifting of the valve disk during pipe cleaning to clean all inner parts including seat area and O-Ring. There are either manual as well as pneumatic lifting devices available.

The Safety Relief Valves series 488 were developed in close cooperation with plant owners and engineers. They reliably protect process plants from overpressure without putting hygienic requirements at risk. The whole series has been designed and officially approved according to international standards (DGR 97/23/CG, ASME, GOST, etc.).

A variant for steam, gas and liquid of each valve has been type-tested by TÜV in accordance with German regulations. They comply with the EU directive for pressure equipment and bear the CE symbol. The VARIVENT(R) Safety Valve Type 488 fulfills the special cleaning and performance abilities which are required for the food, brewery und beverage industry. It has a wide performance area so that is very good applicable for large plants.

Casting simulation software, finite element analysis and flow simulation are digital tools which, combined with practical experience gained from 1.5 million safety valves in operation, form the basis for innovative product development. Close coordination between all disciplines involved in the development process is crucial.

8613371530291

8613371530291