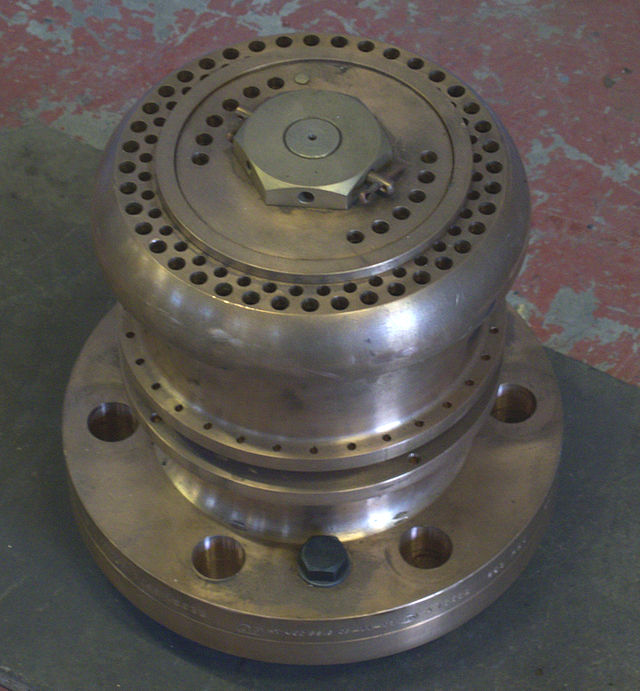

locomotive safety valve supplier

Kunkle Relief Valve OverviewWhen it comes to industrial and commercial safety and relief valve products, Kunkle’s valve’s catalog is second to none in steam, air, gas, and liquid applications.

Kunkle relief valves range in size from ¼” NPT to 6” flange and are suitable in cryogenic and high temperatures up to 800°F environments at vacuum to 7,500 psig pressure. Kunkle Valve’s code certifications meet several global and national board standards, including ASME Section I, Section IV, and Section VIII, PED, CRN, TU and Chinese, as well as non-code requirements.

Relief Valves for Steam ServiceSteam supplies heat for industrial and chemical processes and also is used to heat buildings, supply mechanical energy, and drive mechanical equipment. Steam moves from the boiler to the end point, then heats by direct heating or indirect heating through a heat exchanger. Kunkle steam relief valves are critical to protecting equipment such as boilers, steam lines, and pressure valves, from being over-pressurized.

Relief Valves for Air ServiceKunkle designs valves for air service, for example for air compressors in mechanical shops and small factories where either low-pressure or high-pressure air is required. NASVI stocks Kunkle relief valves for air service in iron, steel and bronze for a variety of uses.

Relief Valves for Liquid ServiceKunkle also makes valves for liquid service, which provide bypass relief in a variety of applications and liquid types.

More About KunkleKunkle Valve is a renowned pressure relief valve manufacturer. Erastus B. Kunkle invented the safety valve to prevent overpressure in locomotive engines. Kunkle patented it in 1875. Since that time, Kunkle has earned its reputation for high-quality valves, and other equipment manufacturers ship their products with Kunkle’s valves pre-installed.

NASVI has stocked Kunkle safety relief valves since we opened in 1975, so we are confident when we call ourselves Kunkle safety valve experts. Every day we fulfill orders for our customers looking for Kunkle relief valves for steam, air, gas, and liquid applications.

Only 5 items in stock!Add to cart[{"id":36223632769190,"title":"5\/16\" x 32","option1":"5\/16\" x 32","option2":null,"option3":null,"sku":"5055735517458","requires_shipping":true,"taxable":true,"featured_image":null,"available":true,"name":"Safety valves - 5\/16\" x 32","public_title":"5\/16\" x 32","options":["5\/16\" x 32"],"price":2450,"weight":35,"compare_at_price":null,"inventory_management":"shopify","barcode":"5055735517458","requires_selling_plan":false,"selling_plan_allocations":[]},{"id":36223632801958,"title":"5\/16\" x 40 TPI","option1":"5\/16\" x 40 TPI","option2":null,"option3":null,"sku":"5055735519216","requires_shipping":true,"taxable":true,"featured_image":null,"available":true,"name":"Safety valves - 5\/16\" x 40 TPI","public_title":"5\/16\" x 40 TPI","options":["5\/16\" x 40 TPI"],"price":2400,"weight":35,"compare_at_price":null,"inventory_management":"shopify","barcode":"5055735519216","requires_selling_plan":false,"selling_plan_allocations":[]},{"id":36223632703654,"title":"3\/8\" x 32","option1":"3\/8\" x 32","option2":null,"option3":null,"sku":"5055735502003","requires_shipping":true,"taxable":true,"featured_image":null,"available":true,"name":"Safety valves - 3\/8\" x 32","public_title":"3\/8\" x 32","options":["3\/8\" x 32"],"price":2399,"weight":30,"compare_at_price":null,"inventory_management":"shopify","barcode":"5055735502003","requires_selling_plan":false,"selling_plan_allocations":[]},{"id":36223632736422,"title":"1\/4\" x 40","option1":"1\/4\" x 40","option2":null,"option3":null,"sku":"5055735517441","requires_shipping":true,"taxable":true,"featured_image":null,"available":true,"name":"Safety valves - 1\/4\" x 40","public_title":"1\/4\" x 40","options":["1\/4\" x 40"],"price":2350,"weight":25,"compare_at_price":null,"inventory_management":"shopify","barcode":"5055735517441","requires_selling_plan":false,"selling_plan_allocations":[]},{"id":36223632670886,"title":"1\/2\" x 26","option1":"1\/2\" x 26","option2":null,"option3":null,"sku":"5055735501990","requires_shipping":true,"taxable":true,"featured_image":null,"available":true,"name":"Safety valves - 1\/2\" x 26","public_title":"1\/2\" x 26","options":["1\/2\" x 26"],"price":2750,"weight":35,"compare_at_price":null,"inventory_management":"shopify","barcode":"5055735501990","requires_selling_plan":false,"selling_plan_allocations":[]}]

... -start valve with Series MX2 air treatment units without the need for additional connection interfaces. The soft-start valve is positioned upstream of the safety valves, ...

Two hands safety valve, which allows a safety use of two hands pneumatic controls (for example two push-button 3/2 N.C. to a certain distance) excluding false signals in case of push-button ...

The SI2 safety valve prevents the allowed operating pressure from being exceeded by more than 10%. If, after opening, the adjusted response pressure falls ...

... stainless steel full-lift clean service safety valve designed to AD Merkblatt A2 and TRD 421 standards and suitable for pure steam, vapour and inert gases.

Insert style flow control valves are comprised of a precision orifice in parallel with a check valve, combined into a single component. Each is designed for easy installation into metal housings using ...

Press-in style flow control valves are comprised of a precision flow orifice in parallel with a check valve, combined into a single component. Each part is designed for easy installation into plastic ...

If you have been searching for a safety release valve that you can use to reduce short-term pressure surges successfully and diminish the effects of gas leaks, this is the product for you. With a pe of ...

... have been type tested as well. These pressure regulators have safety valves which will slam shut in the event of emergencies, such as the gas reaching too high a pressure level. The valve ...

This product has hydraulically actuated class A gas safety valves to EN 161 used for automatic shut-off. It shuts off when unstimulated for gas and air, or even biologically produced methane. It has AISi ...

The S 104 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

... Pressure Safety Valve + Rupture Disk is protected and may be utilized autonomously as essential security gadgets or in conjunction. There are 3 possible combinations. The first combinations ...

Excavator pipe-rupture valves prevent uncontrolled cylinder movement in the event that a pipe or hose bursts. The ESV valve fulfills all of the requirements of the ISO 8643 and EN 474-5 standards for ...

Material: Body- CF8M; Valve Seat- CF8M Métal Seat, PTFE Soft Seat available Orifice Size: fc"(15mm), 3/4M(20mm), l"(25mm), l1/4,’(32mm)I ltë”(40mm), ...

The Safety valves from ATOS are designed to guarantee protection for application on various devices, especially those that monitor spool position. They are also recommended for hydraulic ...

Gun metalSimplex 0-6-0 freelance locomotive in 5" gauge. Designed by Martin Evans for 5" gauge this locomotive has proved a first class performer on club tracks. Described in Model Engineer Vol 133-134

Model Steam Engines are our speciality and we have a wide range of products in stock for your locomotive needs, whether you are a keen collector or are you are building your first model train.

Kunkle delivers quality products from cryogenic to high temperature and vacuum to high pressure Steam, Air, Gas, and Liquid applications. Kunkle Valve provides code certifications that meet various global standards such as ASME, PED, CRN, TU and Chinese as well as non-code requirements.

Crosby pressure relief valves have maintained leadership in overpressure protection for over 140 years. The direct spring-operated safety and pressure relief valves are among the world’s most widely used for oil and gas production and refining, petrochemical and chemical processing, and conventional and nuclear power. Crosby pressure relief valves maintain the industry’s most extensive and capable flow facilities for testing in air, steam, and water.

As soon as mankind was able to boil water to create steam, the necessity of the safety device became evident. As long as 2000 years ago, the Chinese were using cauldrons with hinged lids to allow (relatively) safer production of steam. At the beginning of the 14th century, chemists used conical plugs and later, compressed springs to act as safety devices on pressurised vessels.

Early in the 19th century, boiler explosions on ships and locomotives frequently resulted from faulty safety devices, which led to the development of the first safety relief valves.

In 1848, Charles Retchie invented the accumulation chamber, which increases the compression surface within the safety valve allowing it to open rapidly within a narrow overpressure margin.

Today, most steam users are compelled by local health and safety regulations to ensure that their plant and processes incorporate safety devices and precautions, which ensure that dangerous conditions are prevented.

The principle type of device used to prevent overpressure in plant is the safety or safety relief valve. The safety valve operates by releasing a volume of fluid from within the plant when a predetermined maximum pressure is reached, thereby reducing the excess pressure in a safe manner. As the safety valve may be the only remaining device to prevent catastrophic failure under overpressure conditions, it is important that any such device is capable of operating at all times and under all possible conditions.

Safety valves should be installed wherever the maximum allowable working pressure (MAWP) of a system or pressure-containing vessel is likely to be exceeded. In steam systems, safety valves are typically used for boiler overpressure protection and other applications such as downstream of pressure reducing controls. Although their primary role is for safety, safety valves are also used in process operations to prevent product damage due to excess pressure. Pressure excess can be generated in a number of different situations, including:

The terms ‘safety valve’ and ‘safety relief valve’ are generic terms to describe many varieties of pressure relief devices that are designed to prevent excessive internal fluid pressure build-up. A wide range of different valves is available for many different applications and performance criteria.

In most national standards, specific definitions are given for the terms associated with safety and safety relief valves. There are several notable differences between the terminology used in the USA and Europe. One of the most important differences is that a valve referred to as a ‘safety valve’ in Europe is referred to as a ‘safety relief valve’ or ‘pressure relief valve’ in the USA. In addition, the term ‘safety valve’ in the USA generally refers specifically to the full-lift type of safety valve used in Europe.

Pressure relief valve- A spring-loaded pressure relief valve which is designed to open to relieve excess pressure and to reclose and prevent the further flow of fluid after normal conditions have been restored. It is characterised by a rapid-opening ‘pop’ action or by opening in a manner generally proportional to the increase in pressure over the opening pressure. It may be used for either compressible or incompressible fluids, depending on design, adjustment, or application.

Safety valves are primarily used with compressible gases and in particular for steam and air services. However, they can also be used for process type applications where they may be needed to protect the plant or to prevent spoilage of the product being processed.

Relief valve - A pressure relief device actuated by inlet static pressure having a gradual lift generally proportional to the increase in pressure over opening pressure.

Relief valves are commonly used in liquid systems, especially for lower capacities and thermal expansion duty. They can also be used on pumped systems as pressure overspill devices.

Safety relief valve - A pressure relief valve characterised by rapid opening or pop action, or by opening in proportion to the increase in pressure over the opening pressure, depending on the application, and which may be used either for liquid or compressible fluid.

In general, the safety relief valve will perform as a safety valve when used in a compressible gas system, but it will open in proportion to the overpressure when used in liquid systems, as would a relief valve.

Safety valve- A valve which automatically, without the assistance of any energy other than that of the fluid concerned, discharges a quantity of the fluid so as to prevent a predetermined safe pressure being exceeded, and which is designed to re-close and prevent further flow of fluid after normal pressure conditions of service have been restored.

Rail Associates Enterprises, multi-decade experience in the Production of WABCO E-1 SAFETY VALVE Manufacturer in India. Rail ASSO is Leading WABCO E-1 SAFETY VALVE Supplier in India and Overseas Companies. (Operationalized in 1995) is one of the oldest such units in India Who is Exporting WABCO E-1 Inter Cooler Safety Valve in India, We are supplying WABCO E-1 Inter Cooler Safety Valve in India. The Rail ASSO specializes in the sale of WABCO E-1 Inter Cooler Safety Valve distribution in India.

Modern “code” safety relief valves are not designed to operate continuously, as required in locomotive service. Locomotive style valves are designed for locomotive service. Our Consolidated type pressure relief valves are made to the original Consolidated design, and have the same reliability and durability as the originals. Consolidated did not recertify its locomotive style safety valves in the 1950s due to the lack of demand resulting from the demise of the steam locomotive. Though our pressure relief valves are identical to the original design, they are not National Board certified safety valves, as it is not economically feasible to have National Board recertify the design due to the small quantities required by steam locomotives today. If your jurisdiction requires a “code” safety valve, a practical solution is to install a “code” valve set at MAWP, as the “high pop,” and a Strasburg Rail Road pressure relief valve, set at 5 PSI below MAWP, as the “low pop.” This avoids lifting and wearing out the “code” safety valve.

One of the charms of steam locomotives is their individuality, but the downside of that lack of standardization is the tremendous number and variety of spare parts. The Strasburg Rail Road helps to solve that problem with our selection of flexible staybolt caps and sleeves. All are made of material certified to ASME specifications, and to the same dimensions as the old “standard” sizes. By consulting the thumbnail drawings below, it should be easy to match what we offer to your needs.

Boiler work on steam locomotives often means replacing staybolts. The Strasburg Rail Road stocks mill runs of certified, easy to drive SA-675 Grade 50 staybolt stock that we offer for sale as plain bar stock, or made to order in the form of rough or finished rigid, flexible or crown staybolts. We forge oversized heads on flexible and crown bolts, and our CNC lathes make getting your order ofcustom made bolts an easy and economical process. Thread, head and relief size and profile, bolt length and depth of telltale hole can all be customized to your specification.

The J-1 Safety Valve installed vertically in the main reservoir system vents pressure at a predetermined setting to atmosphere in order to prevent excessive main reservoir pressure buildup.its used railway.

8613371530291

8613371530291