oil well safety valve made in china

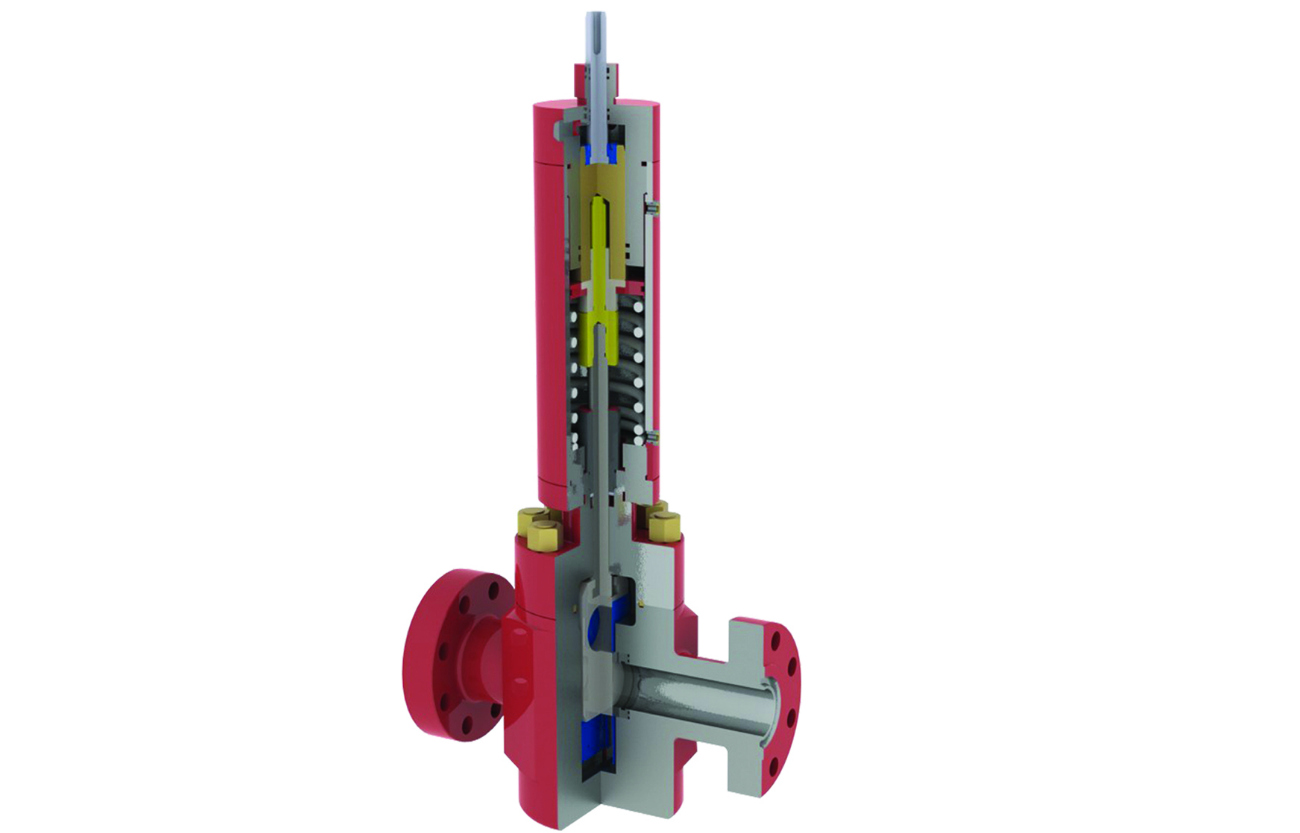

Because of different of drive source, SSV can dividedinto Hydraulic safety valve and pneumatic valve ; With thermal and high voltage explosion-proof device ; Actuators and prepare two parts of the valve, standard interface, easy replacement and maintenance .

This valve is used for power plant boilers, pressure containers, pressure and temperature reducing device and other facilities. It serves to prevent the pressure exceeding the highest allowable pres-sure value and ensure the safety of the device when working.

(1)The pressure of the disc is balanced through the lever and heavy hammer and the valve is ensured seal by moving the for ton of heavy hammer and changing the weight of heavy hammer to reach the required set pressure.

(3)At the top of valve is equipped an electromagnet to open and another to close the valve. The actions of the mechanism and the electric appliance are separate and will not affect each other.

(2)Impulse safety valve shall be installed vertically and the lever shall be kept level. The clearance from the lever to both sides of guide fork shall be even.

(4)A long distance between the leading pipe of the impulse safety valve and the inlet pipe of the main safety valve shall be kept. And the distance between the electric contact pressure meter and the inlet pipe of the main safety valve shall be no less than 5 times of the diameter of the inlet pipe, for feat that the validity of the mater and the impulse safety valve may be affected by the steam releasing process of the main safety valve.

This valve is used for power plant boilers, pressure containers, pressure and temperature reducing device and other facilities. It serves to present the pressure exceeding the highest allowable pres-sure value and ensure the safety of the device when working.

1,When the medium pressure rises to the set pressure, the in-pulse safety valve opens, and the medium in the impulse pipe enters into the piston chamber of the main safety valve from impulse pipe, forcing the piston to descend, and then the valve automatically open-s; when the impulse safety valve closes, the disc will slash automatically close.

2,The main safety valve shall be fastened upon the gallows, which sustains the back-seat force produced in the steam discharging process of the main safety valve.

3,The exhaust pipe shall contain a special gallows to prevent the force of its weight directly applying on the main safety valve. The connecting Lange At the lowest point of the exhaust pipe, water drainage shall be taken into consideration to avoid producing water hammer while discharging set between the main safety valve and exhaust pipe shall eliminate any extra stress.

Our company has been awarded such honors as High & New Tech Enterprise, Key Enterprise in National Torch Planning Project, Famous Trademark in ZheJiang Province, Famous Brand Product in ZheJiang Province, Special Valve R&D Center in ZheJiang Province, Deputy Director Member of China Valve Association, National Valve Standards Setter. We have obtained most international certificates like DNV ISO9001:2008,ISO14001:2004,OHSAS 18001:2007Certificates, Our products designed and manufactured according to API standard,Ball valve with fire safe certificates API 607,API 6Fa.as well as TUV Germany Rhine Company CE Certificate and Pressure Pipe Fittings Manufacturing License TS Safety Certificate issued by the State Bureau of Quality and Technical Supervision, and the certificates from Russian GOST-R, RTN. Our company is the approved vendor of China National Petroleum Corporation(CNPC), China National Offshore Oil Corporation(CNOOC), SINOPEC, China Aluminum Group Corporation, China National Chemical Equipment Corporation, China Gas, Beijing Gas and also the supplier of international Oil Gas company like BP,Gazprom,LUKOIL, EIL, PDO, GE Oil & Gas, SABIC, SWCC, SAUDI MA"ADEN,Ecopetrol.

WuZhou Valve is also the exclusive supplier of high pressure large-diameter fully welded ball valves designated by the National Energy Administration, National Development and Reform Commission and PetroChina, and, our products have been widely applied in Phase 2 and 3 in the project of Natural Gas Transmission from West to East China.

Our company produces 10 major series of products totaling 1,200 varieties and specifications of high temperature, high pressure, high wear resistant, and large-diameter ball valves, gate valves, butterfly valves, gate valves, globe valves, check valves, ore slurry valves, power station valves, as well as non-standard and special valves with auxiliary devices for petroleum, chemical industry, metallurgy, light industry, coal chemical industry, power station, urban construction, water supply, oil, gas and natural gas transportation, long transportation pipeline and other projects. Nominal diameter DN10~4500mm(1/2"~64"), nominal pressure 1.6MPa ~ 42Mpa(150Lb ~ 2,500Lb), working temperature -196℃ ~ 750℃. Valve materials: carbon steel, stainless steel, heat resistant alloy steel, Monel, low temperature steel, and other special types of steel. Driving modes include manual, electric, pneumatic, gear transmission, worm gear and worm transmission, pneumatic and hydraulic combined, electric and hydraulic combined, and computer programmed control system. The products sell well throughout China and are exported to USA, Europe, Africa, the Middle East, Singapore, and other places in the world. By insisting on the corporate policy of Quality First, Customer Foremost, and Credibility-based, seeking the goal of “Three Merits” of Usability, Creditability, and Reliability, and establishing the first class brand of “WuZhou”, our company will make further contributions to the economic development of China and other countries with high quality products, favorable prices and excellent services.

Product Gas Air Compressor Safety Valve Thermocouple Valves Gas Air Compressor Safety Valve Thermocouple Valves Picture Model HC-2025 HC-2026 Branding OEM/ODM Meterial Brass Technology Forged,Cutting by Numerically controlled lathe Surface treatment: Plated or pickling. Application Use for plumbing, sanitary ware, machine part and so on. Size 1/8" 1/4’ 3/8" 1/2" 3/4" 1" 1/8" 1/4’ 3/8" 1/2" 3/4" 1"

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

YKSLS series single line hydraulic control sliding sleeve is a downhole tool used for layered mining to realize oil sleeve annulus switch and flow regulation.

We"re well-known as one of the leading subsurface safety valve manufacturers in China for our competitive price and customized service. Please feel free to buy high quality subsurface safety valve in stock here from our factory.Our personnel are always in the spirit of "continuous improvement and excellence", and together with the top-quality good quality solutions, favorable selling price and superior after-sales providers, we try to acquire each customer"s rely on for .

[1] 张梦婷,张勇. 国外井下安全阀的技术现状[J]. 石油机械,2008,36(7):81-84. doi:10.16082/j.cnki.issn.10014578.2008.07.019 ZHANG Mengting, ZHANG Yong. Technical status of subsurface safety valves at abroad[J]. Journal of Petroleum Machinery, 2008, 36(7):81-84. doi:10.16082/j.cnki.issn.1001-4578.2008.07.019

[2] 周大伟,钟功祥,梁政. 国内外井下安全阀的技术现状及发展趋势[J]. 石油矿场机械, 2007, 36(3):14-16. doi:10.3969/j.issn.1001-3482.2007.03.005 ZHOU Dawei, ZHONG Gongxiang, LIANG Zheng. Study of technical state and development tendency for downhole safety valve of domestic and foreign[J]. Oil Field Equipment, 2007, 36(3):14-16. doi:10.3969/j.issn.10013482.2007.03.005

[5] Al-YATEEM K S, HANBZAZAH S M, ALSYED S M, et al. First successful rigless conversion of subsurface safety valves from tubing retrievable to wireline retrievable in Middle East[C]. SPE 159202-MS 2012. doi:10.2118/159202-MS

[6] SCHLUMBERGER. Tubing-retrievable safety & injec tion valves[EB/OL].[2016-06-15]. http://www.slb.com/services/completions/safety_valves/tubing_retrievable_valves.aspx.

[7] HALIBURTON. Subsurface safety equipment[EB/OL].[2016-06-30]. http://www.halliburton.com/public/cps/contents/Books_and_Catalogs/web/CPSCatalog/09_Subsurface_Safety_Equip. pdf.

[8] BAKER Hughes. Subsurface safety systems[EB/OL].[2016-07-08]. https://www.bakerhughes.com/products-and-services/completions/well-completions/subsurfacesafety-systems.

[9] WEATHERFORD. Optimax series safety valves[EB/OL].[2016-07-15]. http://www.weatherford.com/en/productsservices/completion-and-stimulation/upper-completions/safety-systems.

[13] TAYLOR D M. Packer & safety valve development for ultra high pressure high temperature test & production wells[C]. OTC 23627-MS, 2012. doi:10.4043/23627-MS

[14] IMBO P, GANDINI G. Electro magnetic wireline retrievable-surface controlled subsurface safety valve:A new backup for surface controlled subsurface safety valve to avoid workover[C]. Ravenna, Italy, Offshore Mediterranean Conference and Exhibition, 2011.

[15] RAUSAND M, VATN J. Reliability modeling of surface controlled subsurface safety valves[J]. Reliability Engineering & System Safety, 1998, 61(1-2):159-166. doi:10.1016/S0951-8320(97)00066-5

[17] THAI D, ORZECHOWSKI D, PINARD G. Case study:Deepwater design verification and validation testing for subsurface safety valves for HPHT environments[C]. OTC 28983-MS, 2018. doi:10.4043/28983-MS

[18] LEBOEUF G J, ADAMS S M, PITTMAN A, et al. New design in surface-controlled subsurface safety valves resolves valve problems in subsea completions in the Gulf of Mexico[C]. OTC 19620-MS, 2008. doi:10.4043/19620MS

[19] AL-YATEEM K S, HANBZAZAH S M, ALSYED S M, et al. First successful rigless conversion of subsurface safety valves from tubing retrievable to wireline retrievable in Middle East[C]. SPE 159202-MS, 2012. doi:10.2118/159202-MS

[20] CHARPENTIER T V J, BARAKA-LOKMANE S, NEVILLE A, et al. Comparison of characteristic of antiscaling coating for subsurface safety valve for use in oil and gas industry[C]. IPTC 17953-MS, 2014. doi:10.2523/IPTC-17953-MS

[21] KUMAR D, WELCH J C, XU Z. Reduction in scale buildup from sub-surface safety valve using hydrophobic material coating[C]. SPE 166218-MS, 2013. doi:10.2118/166218-MS

[22] EHTESHAM M A, TUCKER R, GILES J. Downhole safety valve for well-intervention operations:Design, testing, and successful case history[C]. SPE 142887-MS, 2011. doi:10.2118/142887-MS

[23] WAGNER A N. Capillary based surface controlled subsurface safety valve systems solution for problematic wells[C]. SPE 183837-MS, 2017. doi:10.2118/183837MS

[24] 周大伟. 井下安全阀系统设计与分析[D]. 成都:西南石油大学, 2007. ZHOU Dawei. Design and analysis of subsurface safety valves" system[D]. Chengdu:Southwest Petroleum University, 2007.

[25] 牛贵锋, 杨万有. 高温高压井下安全阀阀板优化研究[J]. 石油矿场机械, 2017, 46(2):11-16. doi:10.3969/j.issn.1001-3482.2017.02.003 NIU Guifeng, YANG Wanyou. Optimization of valve plate of high temperature and high pressure downhole safety valve[J]. Oil Field Equipment, 2017, 46(2):11-16. doi:10.3969/j.issn.1001-3482.2017.02.003

[27] 黎伟,宋伟,李乃禾,等. 滑套式井下安全阀设计及动态特性分析[J]. 中国安全生产科学技术, 2017, 13(2):159-163. doi:10.11731/j.issn.1673-193x.2017.02.028 LI Wei, SONG Wei, LI Naihe, et al. Design and dynamic characteristic analysis of sliding-sleeve subsurface safety valve[J]. Journal of Safety Science and Technology, 2017, 13(2):159-163. doi:10.11731/j.issn.1673193x.2017.02.028

[28] 李美求,阳康,周思柱,等. 自平衡井下安全阀动态平衡响应分析[J]. 液压与气动, 2017(6):70-74. doi:10.11832/j.issn.1000-4858.2017.06.014 LI Meiqiu, YANG Kang, ZHOU Sizhu, et al. Dynamic equilibrium response analysis for self-balancing subsurface safety valve[J]. Chinese Hydraulics & Pneumatics, 2017(6):70-74. doi:10.11832/j.issn.10004858.2017.06.014

[29] 李常友,孙宝全,董社霞,等. SC35-129A型井下安全阀的研制[J]. 石油机械, 2005, 33(1):43-44. doi:10.16082/j.cnki.issn.1001-4578.2005.01.014 LI Changyou, SUN Baoquan, DONG Shexia, et al. Development of model SC35-120A downhole safety valve[J]. Journal of Petroleum Machinery, 2005, 33(1):43-44. doi:10.16082/j.cnki.issn.1001-4578.2005.01.014

[31] 孔学云, 李宝龙, 齐海涛, 等. 88.9 mm油管携带式井下安全阀研制[J]. 石油矿场机械, 2016, 45(9):49-52. doi:10.3969/j.issn.1001-3482.2016.09.011 KONG Xueyun, LI Baolong, QI Haitao, et al. Research and development of 3-12 in. tubing-retrievable subsurface safety valve[J]. Oil Field Equipment, 2016, 45(9):49-52. doi:10.3969/j.issn.1001-3482.2016.09.011

[32] 吴迪. 井下安全阀液体综合试验系统的研究[D]. 长春:长春理工大学, 2011. WU Di. Research on subsurface safety valve liquid test system[D]. Changchun:Changchun University of Science and Technology, 2011.

[33] 王战友. 井下安全阀气体综合试验检测系统研究[D]. 长春:长春理工大学, 2014. WANG Zhanyou. Research on subsurface safety valve gas test system[D]. Changchun:Changchun University of Science and Technology, 2014.

[34] SHANG Chenmin, ZHANG Dongmei, ZHANG Xinming. Subsurface safety valve automation test systems design[J]. Applied Mechanics & Materials, 2014, 543-547:1188-1191. doi:10.4028/www.scientific.net/AMM.543547.1188

[36] 张福涛. 海上油井井下安全阀检测系统设计[J]. 内蒙古石油化工,2012(24):79-80. doi:10.3969/j.issn.10067981.2012.24.036 ZHANG Futao. Testing system design of offshore well subsurface safety valves[J]. Inner Mongolia Petrochemical Industry, 2012(24):79-80. doi:10.3969/j.issn.10067981.2012.24.036

[38] 廖谟圣,杨本灵. 世界石油设备发展的新特点及机遇与挑战[J]. 石油矿场机械, 2007, 36(9):1-6. doi:10.3969/j.issn.1001-3482.2007.09.001 LIAO Mosheng, YANG Benling. The opportunity and challenge to new trend in current world petroleum[J]. Oil Field Equipment, 2007, 36(9):1-6. doi:10.3969/j.issn.1001-3482.2007.09.001

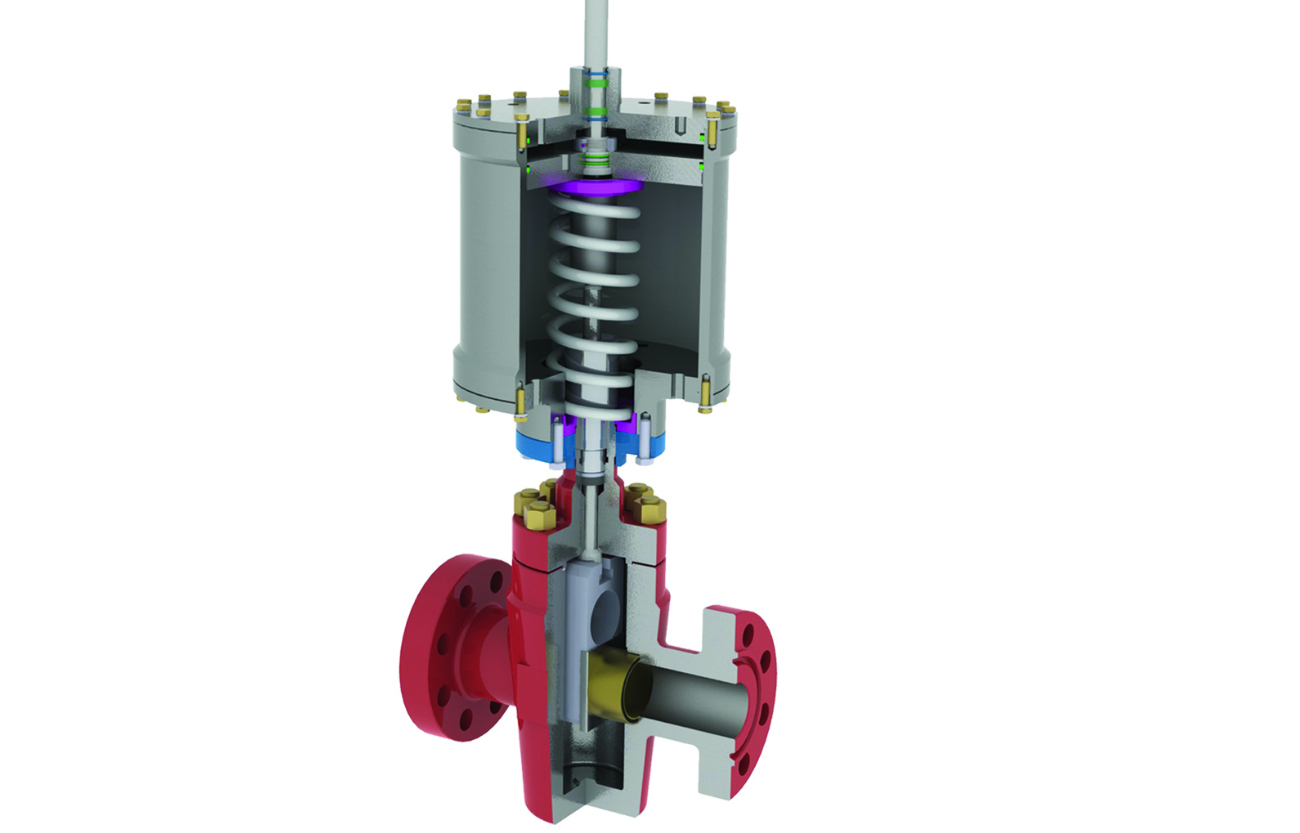

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology was developed and proved with exhaustive verification and validation of reliability, longevity, and performance. The validation methodology utilized a unique sapphire crystal bore, enabling the design team to view the seal’s dynamic and static performance in real time while simulating wellbore pressure and temperature conditions.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

Subsurface Safety Valve TRSSSV is a kind of tubing retrievable safety valve which is controlled at the surface. It directly connects to the tubing string. There is a hydraulic control line connecting to the safety valve from the ground. While a certain amount of pressure is supplied through this control line to the safety valve, the valve remains open; while the pressure is released, the safety valve will close and the tubing pass is closed at the same time.

Whether downhole or subsea, safety can be hard to achieve in the oil and gas industry. Sudden pressure spikes can ruin equipment, leading to production stoppages and worse. Protection starts at the component level, which is where Lee Pressure Relief Valvescome into play.

Our relief valves come in three main varieties. Safety relief valves are designed to be exercised for intermittent “pop-off” applications. Pressure-regulating valves are intended to operate more continuously with stable performance throughout the operating range. Thermal relief valves relieve a few droplets of fluid from a trapped volume expanding due to rising temperatures. Each type of valve plays an essential role in downhole oil tool applications, and each is manufactured to the exacting tolerances that this role requires.

Like all products from The Lee Company, pressure relief valves are small, lightweight, and incredibly durable– enough to serve out the entire lifespan of an oil tool. In addition, these products are available in a range of sizes and cracking pressures.

The world is rapidly changing. As the industries we serve face increasing pressure to reduce their carbon footprint, digitally transform processes and optimize operations, the Valves team at Baker Hughes is ready to help our customers meet those challenges. Our culture of innovation and legacy of quality make us uniquely positioned to recognize and adapt to changing industry trends. From staying abreast of new manufacturing processes and materials sciences development, to converting our facilities and processes to reduce our own carbon footprint, we are creating solutions to help customers achieve their goals.

8613371530291

8613371530291