oil well safety valve pricelist

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale oil well safety valve on Alibaba.com. When you search for oil well safety valve and related items, you will be able to find many types of oil well safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of oil well safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology was developed and proved with exhaustive verification and validation of reliability, longevity, and performance. The validation methodology utilized a unique sapphire crystal bore, enabling the design team to view the seal’s dynamic and static performance in real time while simulating wellbore pressure and temperature conditions.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

A premium provider of oil field equipment and service parts, Parveen Industries Pvt. Ltd is focused on high-quality manufacturing of premium-grade oil and gas field equipment that exceeds international standards. At its eight large-scale facilities, Parveen manufactures products that not only support the existing oil and gas industry but drive forward industry-wide innovation.

Subsurface safety valves (SSSVs), which are standard and often statutorily required in the oil and gas industry for upper completions, were first developed in the late 1930s. Operators sought to drill more high-pressure wells, often near populated areas or, conversely, offshore or very isolated areas, making the need for a device to protect the wells from uncontrolled flow increasingly apparent. The need was made even more urgent by the fact that the uncontrolled flow could be caused by accident or by damage to the surface equipment, which at the time was quite common.

By the 1970s three companies had established themselves as industry leaders as SSSV suppliers in the field: Otis Engineering (now Halliburton), Baker Hughes (now Baker Hughes, a GE company) and Camco Products and Services (now Schlumberger). Implementation of SSSVs grew, but it was not until the Piper Alpha incident of the late 1980s that regulations truly shifted. The explosion on Piper Alpha and resulting oil and gas fires that destroyed the platform served as the impetus for global regulatory mandates that SSSVs be deployed in offshore wells.

The watchword for the 21st century oil industry has been reliability, as offshore, deepwater workovers in many wells cost tens of millions of dollars. As such, reliability became the primary focus and mission of the engineering team at Tejas Research & Engineering as it moved to design and deliver reliable, high-performing products. In the late 2000s the energy industry and governments worldwide revisited the use of SSSV deployment requirements, which had not seen much change since the Piper Alpha incident more than two decades prior. The consensus was that when reliable SSSVs are present, a blowout and oil spill are virtually impossible. Therefore, many governments, such as the EU, now require SSSVs in all wells—even those on land.

Modern developments in SSSV design have sought to address the industry’s challenges and the issues that arise in more complex reservoirs and harsher downhole environments through additional testing and research to optimize the valves’ technical specifications. While the basic functionality of the valves has not changed for some time, the standard to which the valves are engineered and manufactured is now shifting, thanks in part to a new partnership between Tejas Research & Engineering and National Oilwell Varco (NOV). It is a partnership bolstered by Tejas’ involvement on the American Petroleum Institute’s (API) 14A standards subcommittee.

NOV has built its portfolio of completion and production products and technologies since the company’s acquisition of Trican Well Service’s completion tools division in mid-2016. As the breadth of NOV’s completions business expanded to include multistage fracturing and multizone completions, among other disciplines, it became clear that a missing link for upper completions was SSSVs. The company partnered with Tejas Research & Engineering to commercialize a line of SSSVs representing a new industry standard in design and reliability.

Tejas Research & Engineering sprang from the Camco tradition that pioneered many pivotal developments in SSSV design. The R&D and engineering for safety valve products are conducted in Tejas’ HP/HT facility in The Woodlands, Texas, where SSSVs with pressure requirements of 25,000 psi and 260 C (500 F) are designed, tested, qualified and produced.

Tejas’ model TRSV(E) SSSVs are tubing-retrievable, surface- controlled, normally closed devices installed in oil and gas wells to control tubing fl ow. Metal-to-metal seals are used in 100% of Tejas’ tubing-retrievable product line, which has products that are rated to 10,000 psig and are suitable for temperatures up to 176 C (349 F) at moderate setting depths. Higher temperature/pressure/setting depths/slimline diameters are available for custom order. The TRSSSV series are API-14A V1 certified and adaptable to any standard or premium tubing thread. The system features a large fullbore, where the inside diameter (ID) is equivalent or greater tubing than the tubing ID to which the SSSV is attached. Additionally, it has either flat flappers (2⅜ in. to 3½ in.) or curved flappers (4½ in. to 7 in.) and a single rod piston featuring nonelastomeric dynamic seals. The TRSSSV is available in either equalizing or nonequalizing trims. The valve is controlled hydraulically with a ¼-in. control line in the well’s annulus, enabling valve closure during an emergency shutdown.

The new safety valve builds upon lessons learned in valve design over Tejas Research & Engineering’s entire history. Previous valves have achieved significant milestones— including one design that has more than 8,000 valves in use without a single failure or degradation in performance. Completions have evolved since those early designs, and new valves need to withstand significantly higher temperatures, working pressures and setting depths as well as accommodate different diameters. The new valve product line meets the rigorous quality standards outlined in API Specification 14A and tested beyond the specifications in Revision 12, including Annex H, which specifically addresses the verification and validation requirements for use in HP/HT environments.

An evolution in safety valve standards means the industry can be more confident that well control incidents will not occur. As regulations continue to change and become stricter, it is imperative that safety valves maintain their rigorous quality and durability while being able to handle even more challenging well environments.

Oil and gas operations ranging from refining to distribution, are significantly reliant on pipeline systems. Infrastructure and trustworthy control systems are therefore crucial in the business. In this scenario, oil and gas valves are essential to ensure the safety of the industrial operations of pipelines.

This post will focus on explaining different types of industrial valves, their mechanism, their application in the oil and gas industry as well as API and ASME standards for oil and gas valves.

Valves regulate and steer the flow of fluids (such as gaseous and liquidized materials) by opening and closing routes or partially blocking passageways. Technically, valves are fittings, but they’re commonly treated as individual components. Whenever a valve is open, fluid flows from higher to lower pressure.

Valves used in the industry come in a variety of shapes and sizes. Different types of valves are gate valves, globe valves, ball, butterfly, and check valves as well as pressure and diaphragm valves These valves perform a variety of purposes.

Due to their widespread use in commercial construction projects and automation projects, it is expected that the demand for industrial gas valves will increase in the upcoming years. Due to technological advancements, increased industrialization and expansion of existing facilities have sparked demand and boosted the industry’s growth.

Different types of industrial valves mentioned above are used for various purposes. Some major processes that have valve applications include water and sewage treatment, mining and power generation, as well as the refining of petroleum products.

It is possible to operate a valve manually, whether it functions with a handle or lever. Alternatively, valves can be set up to operate automatically in response to a change in pressure These changes may act on a diaphragm or a piston, which in turn activates the valve.

There are more complex control systems that require an actuator, such as for regulating the flow of water through pipes depending on external input. As a result of its input and set-up, the valve may be precisely positioned and controlled to meet a variety of requirements.

There are several valves that differ in design and operation. A difference in design leads to a big change in their industrial applications. Different types of industrial valves are discussed below:

The flow of media is controlled by a gate valve that lifts and lowers the gate. The straight-through, unobstructed path of a gate valve is its distinguishing feature, resulting in minimal pressure loss across the valve.

Unlike butterfly valves, the unobstructed bore of a gate valve allows a pig to pass through during pipe cleaning procedures. Gate valves come in a variety of sizes, materials, temperature, and pressure ratings, as well as gate and bonnet styles.

In a pipeline, a globe valve controls the flow. It’s a device that allows you to control or stop the flow of liquid or gas through a pipe. This type of valve gets its name from the fact that it has an internal baffle that divides it into two halves. They are also known as throttle valves.

Although these valves have slightly higher pressure drops than other valves, they can be employed in various situations where the valve’s pressure drop is not a constraint.

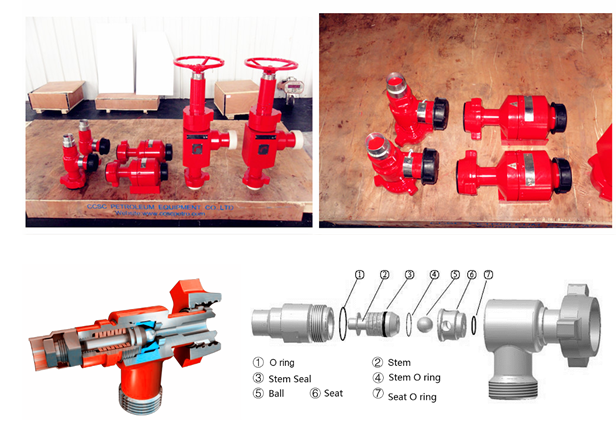

An industrial ball valve is a shut-off valve that uses a rotatable ball with a bore to control the flow of a liquid or gas. You can limit or allow the medium to flow by rotating the ball 90 degrees around its axis for a quarter revolution. While not in use for an extended period of time, they nonetheless provide a firm seal. In addition, they are more resistant to polluted media than most other valve types.

Ball valves can also be utilized as a control valve in specific variants. Because the flow rate control precision is less precise than with other types of control valves, this application is less popular.

A check valve is a unidirectional valve. It only allows one direction of fluid flow. They have two ports, one for the media inlet and one for the media output. They are known as one-way valves or non-return valves because they only allow media to flow in one direction. A check valve’s primary function is to prevent backflow in the system.

A pressure differential is required for an industrial check valve to function. To open the valve, they require more pressure on the input side than on the output side. The valve closes when the pressure on the output side is higher (or when the pressure on the input side is insufficient). The closure mechanism differs depending on the valve type. They do not require a handle, lever, actuator, or human to function properly, unlike other valves.

A pinch valve is a two-way valve that is used to control or shut off the flow of corrosive, abrasive, or granular material. Compressed air is used to open or seal the valve.

Open, the valve allows a wide variety of media to pass through its bore. Valves are designed to isolate the medium from contamination by using flexible rubber sleeves inside of them. Slurries and granular goods such as sand, cement, gravel, textile fiber, charcoal, powder, pellets, chipping, glass pieces, and so on are highly compatible with pinch valves.

These valves are affordable, and simple to operate, making them ideal for a variety of industrial applications. Get them from reliable gas valve suppliers for innovative solutions tailor-made to suit your requirements.

Butterfly valves are part of the quarter-turn valve family and function similarly to ball valves. A disc is linked to a rod to form the “butterfly.” When the rod turns the disc a quarter turn perpendicular to the flow direction, it closes. The disc is rolled back to enable flow when the valve opens.

Industrial butterfly valves are popular because of their lightweight, compact installation footprint, lower prices, rapid operation, and availability in extremely large sizes. Handles, gears, and automatic actuators can all be used to operate these valves.

To safeguard the system from overpressure, a safety valve is used. When the pressure surpasses the Maximum Allowable Working Pressure or the pressure for which the system was built, overpressure develops. When opposed to relief valves, safety valves can open quite quickly. A safety valve opens from a predetermined pressure; the valve opens slowly at first, then fully to remove the undesirable pressure from the system as rapidly as feasible.

Safety valves are used to keep pressure from rising too high, causing malfunctions, fires, or explosions. Because safety valves have no electrical or pneumatic components, they are employed when electronic or pneumatic safety mechanisms fail. Approach fully-functional production Oil valves suppliers for the best output.

A plug valve is a cone-shaped valve that rotates inside the valve body to control the flow of the fluid. One or more hollow channels are commonly positioned horizontally in plug valves to allow easy flow through the valve while it is open.

The two-port plug valve, which has an open and closed state, is the most popular. In such a valve, one route flows from inbound to outbound, while the stem and handle are located on the top of the valve. A quarter-turn valve is also used in an industrial plug valve, which is advantageous when a quick and frequent operation is required.

Industrial valves manufacturers use various materials in making different types of valves. The material is selected according to the valve’s function and application. Here are some of the common materials that industrial valves are made up of:

As a non-reactive metal, stainless steel is used in making many industrial valves. Each gauge requires a precise mix of metals such as chromium, nickel, or molybdenum. Stainless steel valves are suited for handling corrosive media such as saline marine water, acids, and halide gases as they do not corrode the body of the valve. In some cases, brass can be a good replacement for steel.

Cast steel valves are created by pouring molten steel into a mold and allowing it to solidify under controlled conditions. On the one hand, if done correctly, this procedure produces solid valves and is a practical low-cost method of production.

However, because it is prone to holes and tears where the molten steel has not formed evenly, it requires continuous monitoring and quality control. Furthermore, if the molten steel was of poor quality, the valve will be faulty as well.

Forged steel valves are made by shaping metal using extreme heat and mechanical equipment. Instead of being poured into a ready-made mold, steel is bent and shaped into the shape of the valve using tools. The benefit of this is that heat tends to harden the metal, resulting in stronger and longer-lastingindustrial valves. On the other hand, because it is constructed as a whole, the connections between various elements may be a source of leaks. Forged steel valves are likewise more expensive due to the additional labor involved.

The body of the valve is the outer casing that houses the internal pieces or trim of most or all of the valve. In commonly used valve designs, the body is usually screwed to the bonnet.

Valve bodies are often made of metal or plastic. Due to its corrosion resistance qualities, particularly against warm saltwater, duplex and super duplex valves are frequently used in seawater applications such as desalination facilities. Bonnet

On the valve body, a bonnet serves as a cover. It’s usually screwed or bolted into the valve body semi-permanently. A bonnet keeps everything together inside the valve. Users can remove the bonnet of a valve to gain access to internal parts, usually for maintenance. Many industrial valves lack bonnets; for example, plug valves are frequently devoid of bonnets. Many ball valves do not have bonnets because the valve body is assembled differently, for example by screwing the valve body together in the center. Ports

The channels that allow fluid to travel through the valve are known as ports. To control flow, the valve part or disc obstructs ports. Valves typically have two ports, but they can have as many as twenty. Almost always, the valve’s ports are connected to pipes or other components. Threadings, compression fittings, adhesive, cement, flanges, and welding are all examples of connection methods. Actuator

From outside the valve body, a handle is utilized to physically regulate the valve. Automatic valves do not have handles. However, some, such as stop-check valves, have a handle for manual overriding purposes. An actuator automatically or remotely operates a valve from outside the body. Some valves, such as check valves and relief valves, have neither a handle nor an actuator since they operate automatically from the inside. Disc

A disc, also known as a valve member, is a moveable barrier within the stationary body that restricts flow via the valve in various ways. Discs come in a variety of shapes, despite their classic disc shape. A disc can travel linearly inside a valve, rotate on the stem, or revolve on a hinge or trunnion, depending on the type of valve. A ball is a round valve part that passes through one or more routes between ports. Flow can be steered between different ports by spinning the ball. Spherical rotors with a cylindrical hole drilled as a fluid route are used in ball valves.

Plug valves use plugs, which are cylindrical or conically tapered rotors. Rotor valves can also have any round rotor shapes as long as the rotor can be spun inside the valve body. However, a ball check valve employs the ball to stop the backward flow but is not a rotor because the ball does not rotate while the valve is operated. Seat

The seat is the body’s interior surface that makes contact with the disc to create a leak-tight seal. Only when the valve is closed does the disc come into touch with the seat if it moves linearly or swings on a hinge or trunnion. The seat is always in touch with the disc in rotating discs, although the area of contact changes as the disc rotates. In relation to the body, the seat is constantly immobile. Stem

The stem transmits motion to the disc from the actuator. In some designs, the stem and the disc, as well as the stem and the handle are integrated into one piece.

The stem can transfer a linear force, a rotational torque, or a combination of these motions. The stem can be screwed into or out of the valve by rotating it in one way or the other. This allows the disc to move back and forth inside the body. To keep a seal between the stem and the bonnet, packing is frequently utilized inside an oil and gas valve. Spring

Many valves feature a spring for spring-loading, which causes the disc to default to a certain position but allows control to change it. Relief valves typically use a spring to keep the valve closed, but they also allow excessive pressure to force the valve open against the spring-loading. Normally, coil springs are employed. Zinc-plated steel and stainless steel are common spring materials. Trim

The trim of a valve refers to all of the interior components of the valve. It consists of seating and gate surface, stem, bushing, stem hole guide, and other small internal parts that normally come in contact with the service fluid.

We know that petroleum products are flammable, the oil and gas industry is particularly sensitive to temperature. Valves in petrochemical pipelines must be able to tolerate and maintain temperatures within acceptable ranges in order to meet this requirement In addition, metals expand when heated and shrink when cooled, thus the valve design must take that into account as well. For the valve to function optimally, such temperature swings should be minimized.

It is possible for high-pressure levels in the pipeline to overcome an insufficiently durable valve. When significant fluid pressure is applied to a needle valve, it may not be able to handle the force without being pushed open. Because of this, a steady valve that can handle a high pipeline pressure is required. One type of full-welded ball valve can handle high pressures while still maintaining optimal performance and low torque, for example.

Too much pressure can cause pipeline ruptures or even malfunctions in the most durable valves. As a result, an oil pipeline may require the installation of an industrial pressure relief valve. A check valve, which is pressure sensitive, maybe a useful choice in this situation. To relieve fluid pressure, it can either be opened to discharge pent-up air pressure or it can be allowed to flow media down the pipeline. In the same way, a diaphragm valve might be utilized as a throttling valve.

Crude oil is a mixture of several fuels that are separated during the refinement process. Some of the components are highly corrosive, necessitating the use of robust, non-reactive valve materials. For this type of pipeline, stainless steel valves or valves made of improved steel alloys are ideal.

Oil and gas activities require a variety of fluid flow control methods. Accordingly, a variety of valves can be used at different phases of manufacturing or distribution, depending on the intended result. Let’s take a look at some of the types of valves in the oil and gas industry.

In pipeline applications that need fast shutoffs and tight sealing, a ball valve is a rotary valve that can be relied on. A ball valve can come in a variety of shapes and sizes. Each type works well in a certain pipeline situation. Consequently, before selecting a ball valve, it’s important to evaluate the pipeline’s characteristics.

The stem and seats of a floating ball valve are all that hold it aloft. When the floating ball is moved to close the valve, fluid pressure drives it onto its seats and entirely shuts off flow. Even with high-pressure liquids flowing through a spout, opening the valve requires significant torque because pushing the ball against high fluid pressure requires a great deal of force and torque. Hence, an oil and gas pipeline with low to medium pressure should use a floating ball valve.

The ball on a trunnion ball valve, on the other hand, is mounted and does not rely on fluid pressure to hold it in position. At low torque, the mounted ball can also open and close against the force. When it comes to high-pressure applications, this is your best bet.

Oil and gas flow rates are not affected by a gate valve since it allows unfettered flow. These properties make it suited for pipelines where the flow rate must be maintained while the flow rate must be controlled.

A butterfly valve makes up for a lot of what a gate valve lacks in terms of performance. Open channels allow media to flow freely, even if they contain solid particles. Since the stem at the base of a butterfly valve holds its disc in place, it can be used in high-pressure pipelines. Its low-torque operation is also a result of these design attributes.

If you want to stop the flow of air, you can close the globe valve using a plug-like piston. When the actuator is turned, the linear valve opens and closes. It is possible to open this valve to a variety of levels due to the threading on the stem. The popularity of this sort of valve in the petrochemical industry can be traced back to this very fact. Depending on how much throttling is required, the opening size can be reduced.

Valves are designed to lower pressure by having an angled bottom that meets the piston at the base. While the fluid rushes through the raised cavity, it loses momentum. Globe valves are therefore ideal for pipeline systems that require pressure management.

A pressure-sensitive valve like a check valve is suitable for channeling separated petroleum products. The valve opens when the inlet pressure is greater than the outlet pressure. There is, however, a restriction on media that flows backward. A check valve is a one-way valve that prevents media from flowing backward.

As a linear valve, a plug valve has a piston that is larger in diameter than a globe valve. In spite of the fact that it isn’t the best choice for throttling, it can nevertheless hold its own in a pipeline with The plug’s larger surface area allowing the pressure to be spread and dissipated along with the plug while still maintaining fluid flow regulation.

Actuators are used to control the plug, which can be either manually or automatically operated. This allows thick petroleum products to flow unhindered. For unrefined oil products, such as those used in biogas generation, a plug valve can be recommended.

When the American Petroleum Institute (API) was founded in 1919 as a standards-setting body, they were a pioneer in bringing together subject matter experts from a variety of industries to develop, maintain, and distribute industry’s consensus standards. There are more than 700 API standards that focus on improving operational safety, environmental conditions, and sustainability in the valve industry. These standards have been implemented globally.

It is ensured that API standards are not just recognized for their technical rigor but also for their third-party accreditation, which makes them easier to accept by state and federal regulators as well as increased international regulators.

For almost 90 years, the American Petroleum Institute (API) has set and maintained standards for the global oil and natural gas sector and continues to do so today. This has enabled the sector to constantly create great products, provide important services, and assure fairness in the marketplace for businesses and consumers alike, thanks to their efforts and contributions. As a result, industry processes are more secure, quality is assured, and expenses may be kept down, waste is reduced, and confusion is minimized. In addition, they speed up the adoption of new products, allowing them to reach the market faster and avoiding the need to reinvent the wheel every time a new product is made.

When this standard was revised in 1988, it included threaded-end and weld-end valves to the list of acceptable valves. An ASME B16.34-compliant valve should meet the following conditions: ASME/ASTM material criteria are met for valves’ chemical composition and strength.

Industrial valves are an integral part of the oil and gas industry. This article discussed various types of industrial valves, their functions, and their components. It is evident that they are essential for oil product safety and quality. However, it will be intriguing to see how industrial valve companies will innovate in the future and how modern technology may be incorporated into valves.

If you have been searching for a safety release valve that you can use to reduce short-term pressure surges successfully and diminish the effects of gas leaks, this is the product for ...

... regulators have safety valves which will slam shut in the event of emergencies, such as the gas reaching too high a pressure level. The valve works to protect any fittings ...

This product has hydraulically actuated class A gas safety valves to EN 161 used for automatic shut-off. It shuts off when unstimulated for gas and air, ...

The S 104 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

... Pressure Safety Valve + Rupture Disk is protected and may be utilized autonomously as essential security gadgets or in conjunction. There are 3 possible combinations. The first combinations ...

It"s a Safety valve in according with Directives ATEX 20K/34/EU. Technical Norm Fire Prevention 41/256 31/10/2019. d.P.R. 10/520 19/03/1955 and subsequent amendments.

130 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

V651 Series safety relief valves are produced as safety and relief type. Safety valves are pressure relief elements used to evacuate excessive pressure ...

PVS type slam shut valves are pilot-operated relief valves in which the opening and the closing of the main plug is controlled by a pilot device which is very ...

This range of spring loaded conventional and balanced safety relief valves is specifically designed for overpressure protection of unfired pressure vessel (ASME Section VIII application). ...

The EMERSON BM7 SERIES is a disk slam-shut valve characterized as automatic isolating elements, which are suitable for installation as safety devices in regulating stations. This device has a high operation ...

... control and regulate the gas, air flow to burners and other combustion devices. HMV is a unique safety valve that can be supplied for the requiremen of handling higher ...

Type 50 is a safety valve for universal use. It can be used for nearly any industrial application, e.g. in shipping and pipeline construction, the chemical and petrochemical industries, ...

The RIEGER Safety valve Type SH prevents excessive pressure in steam and gaseous media in plant components and tanks. The set pressure is generally higher than the operating pressure of the system.

... sewage, gas, glycol, diathermic oil, industrial water, steam and other natural and aggressive media, depending on theresistance of materials usedfor the construction ofthe valve.

Baird Valve and Regulator L.L.C., the original manufacturer of the Back Pressure Regulator, offers a full line of 1”, 2” and 3” liquid and gas relief valves as well as a large stock of pump parts, cages, ball and seat testing machines and a variety of other oilfield related items.

Subsea Ball Valves are designed for the extreme pressures and harsh environments commonly found in the offshore oil and gas industry. HiP offers the industry’s broadest line of subsea ball valves for 10, 15 and 20,000 psi.

As the last line of defense in protecting life, property, and the environment, subsurface safety valves (SSSVs) are arguably the most critical downhole-completion component. When held to the highest standard of integrity, SSSVs help to assure that wells deliver their full production potential.

With more than 10,000 years of cumulative service life and zero failures, Optimax series safety valves have proven reliable in the field. Photo from Weatherford.

Over the years, SSSVs have evolved dramatically in both form and substance to meet the industry’s need for enhanced performance in increasingly challenging fields. Flapper-closure mechanisms have replaced the ball valves of 50 years ago, and have seen further enhancements from flat flappers to streamlined super-curved flappers that enable the same internal diameter, or production area, with a smaller outer diameter. Instead of concentric pistons, modern SSSVs use highly efficient rod pistons with modern non-elastomeric seals designed to last for more than 25 years.

As operators have continued to move into deeper, hotter, and more pressurized reservoirs, safety valve design has kept pace with higher setting-depth, temperature, and pressure capabilities. With ongoing improvements in valve designs, customers have gained the confidence to routinely install tubing-retrieval safety valves (TRSVs) as the primary safety barrier in new wells, with wireline-retrievable safety valves (WRSVs) serving as a contingency in the event of a failure.

While safety valve capabilities have vastly improved, SSSV reliability remains a concern for operators. With a heightened focus on health, safety, and environmental risks—in addition to the challenge posed by low commodity prices—operators need to know that the safety valves installed thousands of feet below the ocean floor will provide a long-term, high-integrity barrier against production losses, expensive interventions, and the need for abandonment.

Applying its decades of experience as an international provider of advanced downhole tools, Weatherford developed a broad platform of modern SSSV solutions. All Weatherford SSSVs are engineered for reliability, with an emphasis on hydraulics, and validated under a robust program that includes more than 3000 rigorous test cycles. The resulting valves are durable and reliable, which helps customers to avoid the production losses and intervention expenses associated with valve failures.

The Weatherford Optimax series includes TRSVs and WRSVs with advanced features that directly address the historic failure points of SSSVs. Rod-piston, flapper-style TRSVs eliminate sleeves, plugs, and other failure-prone mechanisms. The valves are actuated hydraulically via a single control line. The rod-piston assemblies feature non-elastomeric, dynamic seals to mitigate fluid-compatibility and explosive-decompression issues; glide bearings to centralize the piston in the borehole and help maintain sealing under eccentric loads; and metal-to-metal piston-stop seals to provide maximum sealing when the valve is fully open or fully closed. Additionally, Optimax series valves include through-the-flapper self-equalizing systems, which enable technicians to safely match pressures above and below a closed flapper, thereby eliminating the cost of rerouting gas from a nearby well or bringing in pressurization equipment

To date, Weatherford has installed more than 7000 SSSVs worldwide. Of those, nearly 5000 are TRSVs that have provided more than 10,000 years of cumulative service life with zero failures attributable to design or quality issues. No Optimax TRSV has ever failed; however, as a contingency, a Weatherford WRSV can be deployed on slickline to land inside a damaged TRSV. An insert safety valve effectively bypasses the TRSV and helps to restore production at a fraction of the cost of replacement workover.

In deepwater reservoirs, where the cost of failure is especially high, operators can use a new SSSV qualified in May and rated for setting at depths up to 6000ft (1829m). A new high-pressure, high-temperature (HPHT) SSSV also meets API V1 standards and was introduced in response to the industry’s push into harsh, HPHT environments. Finally, the new 7in SuperSlim SSSV for large-bore, high-rate gas-well applications was qualified in September and has been installed in a well in Latin America. Several additional installations are planned for early next year in the Asia-Pacific region.

Industry standards are a starting point for operators looking to ensure that equipment will survive the challenging operational conditions encountered during a 25-plus-year well life. Accordingly, all Weatherford TRSVs and WRSVs are slam tested at rates beyond industry standards: at least 100ft/s (30.5m/s) for TRSVs and 150ft/s (45.7m/s) for WRSVs.

To reassure operators that wells could be closed in during blowout conditions, Weatherford performs special high-velocity slam-closure tests. One such test was conducted on a 7in TRSV. The valve was successfully slam tested at 460ft/s (140m/s)—which is equivalent to a production rate of more than 480 MMscf/d (13.59MM cm/d)—making it one of the highest gas-slam-rated valves on the market.

Increasingly harsh and risky reservoirs, deeper waters, and growing well complexity call for state-of-the-art tools and technologies that deliver high performance and reliability. When it comes to SSSVs, a focus on reliability is paramount. Rigorous testing and validation, along with the implementation of modern designs and features that help address historic failure points, are essential for preventing production losses and protecting crews, equipment, and the environment.

8613371530291

8613371530291