oil well safety valve quotation

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale oil well safety valve on Alibaba.com. When you search for oil well safety valve and related items, you will be able to find many types of oil well safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of oil well safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

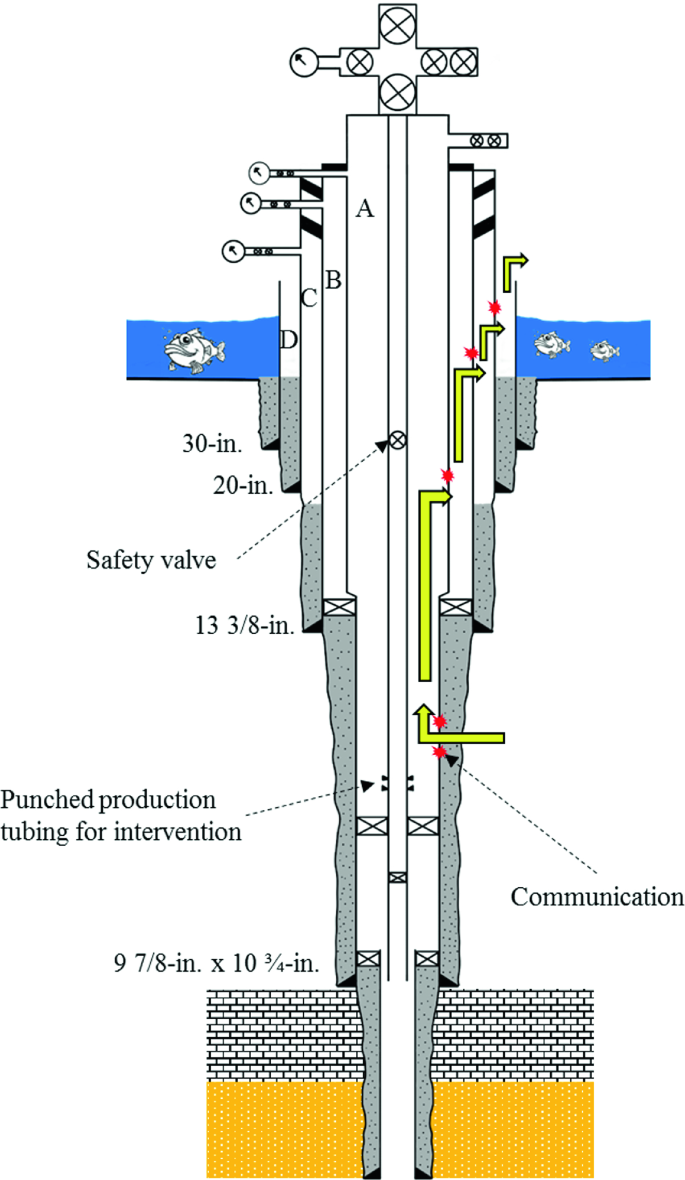

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology was developed and proved with exhaustive verification and validation of reliability, longevity, and performance. The validation methodology utilized a unique sapphire crystal bore, enabling the design team to view the seal’s dynamic and static performance in real time while simulating wellbore pressure and temperature conditions.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

The Sanjack wellhead surface safety valve is a reverse acting gate valve with hydraulically actuated compressed piston actuator mounted on it. The surface safety valve (SSV) is designed to be a fail-safe and fail-close gate valve.

SSV is mostly used on high pressure wellhead and X-mas tree, H2S wellhead and X-mas tree, offshore wellhead and X-mas tree and etc. as a master valve and/or wing valve.

The RV10 safety relief valve is well-suited for overpressure protection of production equipment, including compressors, scrubbers, separators, pipelines or anywhere overpressure protection may be required.

A safety valve is a valve that acts as the protector of your equipment. Safety valves can prevent damage to your pressure vessels and even prevent explosions at your facility when installed in pressure vessels.

A safety valve is a type of valve that automatically actuates when the pressure of the inlet side of the valve increases to a predetermined pressure, to open the valve disc and discharge the fluid. The safety valve system is designed to be a fail-safe so that a wellbore can be isolated in the event of any system failure or damage to the surface production-control facilities.

In most cases, it is mandatory to have a means of closure for all wells capable of natural flow to the surface. The installation of a subsurface safety valve (SSSV) will provide this emergency closure capability. Safety systems may be operated on a fail-safe principle from a control panel located on the surface that was custom-built by PHC.

The SCSSV is controlled by a ¼” stainless steel control line that is attached to the outside of the well tubing string and installed when the production tubing is installed. Depending on the wellhead pressure, it may be necessary to keep as much as 10,000 psi on the control line to keep the valve open. PHC control panels feature the proven Haskel pump line that generates the required hydraulic pressure for optimal valve control.

PHC constructs custom SCSSV control panels for our broad customer base and recently we built three well control panels to be sent out for a large project overseas. Below are the custom features we included on these custom panels.

A safety valve is a valve that acts as the protector of your equipment. Safety valves can prevent damage to your pressure vessels and even prevent explosions at your facility when installed in pressure vessels.

A safety valve is a type of valve that automatically actuates when the pressure of the inlet side of the valve increases to a predetermined pressure, to open the valve disc and discharge the fluid. The safety valve system is designed to be a fail-safe so that a wellbore can be isolated in the event of any system failure or damage to the surface production-control facilities.

In most cases, it is mandatory to have a means of closure for all wells capable of natural flow to the surface. The installation of a subsurface safety valve (SSSV) will provide this emergency closure capability. Safety systems may be operated on a fail-safe principle from a control panel located on the surface that was custom-built by PHC.

The SCSSV is controlled by a ¼” stainless steel control line that is attached to the outside of the well tubing string and installed when the production tubing is installed. Depending on the wellhead pressure, it may be necessary to keep as much as 10,000 psi on the control line to keep the valve open. PHC control panels feature the proven Haskel pump line that generates the required hydraulic pressure for optimal valve control.

PHC constructs custom SCSSV control panels for our broad customer base and recently we built three well control panels to be sent out for a large project overseas. Below are the custom features we included on these custom panels.

Production sustainability from oil and gas wells could be an uphill task when there is a need to constantly monitor Subsurface safety valves for optimal functionality. It"s always a standard practice that surface safety valves are tested on specific periods safe enough to ensure well"s safety is not compromised. Surface controlled subsurface safety valves are also tested with same objective.

Many Production Engineers are ignorant of the fact that the subsurface safety valve affect well productivity through drop in hydrostatic pressure across valve for Surface Controlled Subsurface Safety Valve (SCSSV) and the Sub-Surface Controlled Subsurface Safety Valves (SSCSV) additionally causes drop in fluid flow across valves in the process of sensing fluid velocity across valve.

In this Paper, A case by case analysis was performed on the various sub-surface safety valves for producing wells with the view of minimizing friction to flow of well fluids which affects performance which in turn minimizes production restriction. Efficiency of different type of subsurface safety valves where evaluated and compared and business cases where made on the most attractive option.

Periodic testing or inspection of valves was analyzed, and best routine testing time proffered with reasons to wells performance. The advantages and disadvantage of different valve options were also discussed to recommend a workable valve option for Uninterrupted well flow. Flow assurance and flow stability considerations were also made to ensure no unwanted valve closure occurs.

A Stable and uninterrupted production was realized for five wells using this analytical method and the total productivity increase was about 1,200 BOPD for the five wells. Addressed wax blockage valve/sticky flapper problems to enable the SCSSV four wells function. The SSCSV of the last well caused flow assurance challenges which was addressed by surface choke bean optimization.

As long ago as 1936, accelerated drilling of high pressure oil and gas wells in inland waters near town sites and other dangerous or isolated places required a device to protect wells from uncontrolled flow caused by accident or other damage to surface equipment. To meet this need, many types of safety valves were built and tried, most of them being of the velocity-operated type. These valves were designed to operate by increased velocity, or by the pressure differential across the valve caused by the increased velocity of flow, or by a drop in pressure to a predetermined value, caused by the rupture of some part of the well equipment on the surface. The velocity operated valve is subjected to inherent variables of flowing wells which made it difficult for average operating people to calculate and set the closing rate accurately.

While the velocity-operated valve is suitable for flowing wells producing at reduced rates, it is less suitable in areas where large volumes of flow are permitted. In wells produced at rates at or close to their potential, it is hard to predetermine spring settings to guarantee closure in an emergency.

With the rapid extension of the offshore fields into the shipping lanes of such areas as Lake Maracaibo and the Gulf of Mexico, it became apparent that a safety device should be developed which would not have the disadvantages of the velocity-operated valve.

In Venezuela, work was started on a surface controlled subsurface safety valve which would not be dependent upon the velocity off low to close the valve. As a result of this effort} the ball valve came into being. It is used in many of the oil wells in Lake Maracaibo, Venezuela.

Competitive pricing and deliveries | Products are plug-n-play | Three-year warranty on all products | Custom sizes available | High performance | Low maintenance & little-to-no repairs | Manufactured in the US | Well-stocked inventory

Due to the continued escalation of raw materials as well as additional COVID-related costs, Flow Safe is announcing a list price increase effective Aug. 2, 2021. The increase will be between 8% and 10% depending on the product line.

MCM Oil Tools Surface Safety Valve Unit is a “failsafe-closed” or “failsafe-open” hydraulically actuated gate valve used in well testing in offshore and land operations.

With their first order, the US company started replacing 200 safety valves with LESER safety valves, making LESER their main supplier after successfully prequalifying us in 2017. In December 2017, LESER was already invited to provide a quotation for 200 valves to replace the existing safety valves currently installed on an FPSO off the coast of Nigeria. LESER received the first order for a batch of 50 safety valves and spares in May 2018. The scope for full replacement is a period of two years.

The initial discussions with the FPSO’s project management and maintenance teams switched from an early CAPEX view to a more holistic OPEX assessment rather quickly. LESER was able to show that this constitutes a major difference between safety valve suppliers. The approach was to compare a 10-year operational period with spares for the existing major global brand safety valves and LESER replacement valves with spares. The market-typical definitions for 2 years and 5 years of operational spare parts were taken as a basis for the calculation.

The result showed that LESER’s package was slightly more expensive. Not surprising - it did include the investment for 200 replacement safety valves after all. However, the pricing was close and showed the big difference in required spare parts for LESER-designed valves (e.g. straight alignment spindle design) and LESER’s spare part pricing in comparison to other major safety valve manufacturers.

If you want to look at the life-cycle costs of safety valves, using the total cost of ownership concept is a good way to do it. Some of the costs of ownership for safety valves that needed to be considered in this project were:

Transaction costs: The costs associated with the purchase process itself. This includes time spent waiting for quotes as well as reviewing and revising them.

In the quotation phase, LESER suggested using smaller valves in some cases. Other tools helped us to quickly generate a SPIR (Spare Parts Interchangeability Record) for the operational spare parts stock and to identify suitable replacement valves. As a result, LESER’s sales team could promptly reply to the customer’s feedback (often on the same day) - a big advantage when one is dealing with the manufacturer directly.

However, cost was not the only reason for switching to LESER, LESER’s commitment to the customer in terms of short delivery times for new valves and spare parts was also a factor. Because both parties tried to agree on standardized solutions during the technical discussions, LESER was able to offer 8-week delivery for the full project and four weeks for smaller packages of valves and spares. This short delivery time for the project, together with the general spare parts availability within days, fully convinced the US oil and gas major to go with LESER and replace its installed base of safety valves.

For help with the assessment of the total cost of ownership and the potential value added through new safety valves in your existing plant, contact LESER: aftermarket@leser.com.

8613371530291

8613371530291