oil well safety valve for sale

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale oil well safety valve on Alibaba.com. When you search for oil well safety valve and related items, you will be able to find many types of oil well safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of oil well safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology was developed and proved with exhaustive verification and validation of reliability, longevity, and performance. The validation methodology utilized a unique sapphire crystal bore, enabling the design team to view the seal’s dynamic and static performance in real time while simulating wellbore pressure and temperature conditions.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

Halliburton provides proven, high-performance tubing-retrievable and wireline-retrievable subsurface safety valves (SSSV) designed to reliably shut-in (fail safe) if a catastrophic event occurs, allowing operators to maintain safe operations.

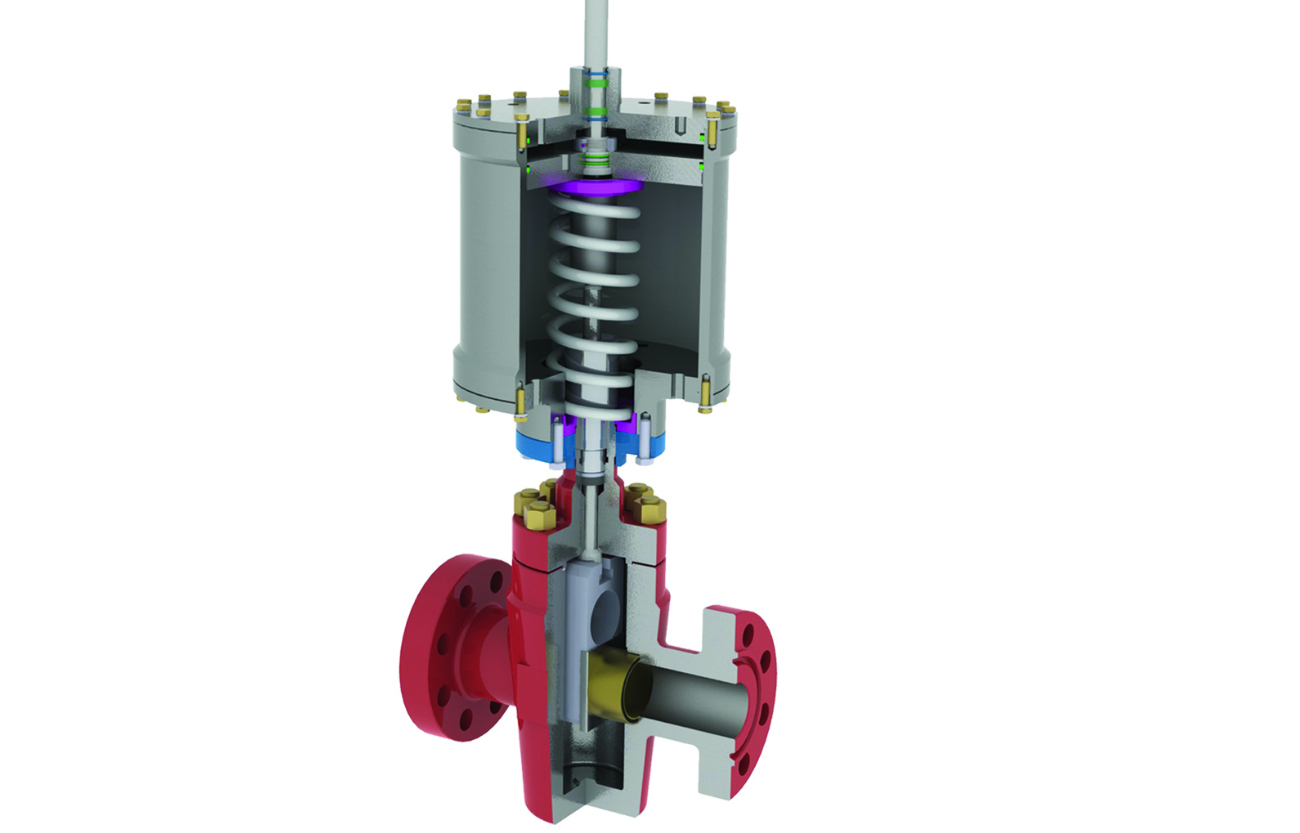

DAC Worldwide’s Pneumatic Surface Safety Valve Cutaway (295-719P) depicts a sectioned full-size valve sample, which allows for effective classroom training in the operation, construction, and maintenance of a pneumatically-operated gate-type surface safety valve. Commonly used in oil & gas production operations, this safety valve is frequently found on wellhead assemblies, production manifolds, and in pipeline applications. A key component in ESD systems, these safety-related wellhead components ensure system shutdown in emergency circumstances.

Through carefully-planned sectioning and color-coding, the complete internal configuration of the surface safety valve is exposed and showcased. Seal features and hardware locations have been retained, allowing for “hands-on” training in disassembly and maintenance.

This Pneumatic Surface Safety Valve Cutaway provides a realistic introduction to its components, and their fit-up. The common pump components are industrial-grade, mimicking what students might encounter on-the-job in the petroleum industry. The cutaways are procured from industrial surplus, and common brands and models are chose for industrial relevancy.

To make the learning process even more productive, the Pneumatic Surface Safety Valve Cutaway’s internal surfaces, seats, body, and closure devices use contrasting colors to easily differentiate between the components. Replacement hardware has also been installed, where required, to ensure the equipment has long-lasting capabilities. Finally, the cutaway has been cleaned, primed, and painted using a high-durability urethane coating to stand up to frequent student use.

The Pneumatic Surface Safety Valve Cutaway is only one of DAC Worldwide’s expansive petroleum training cutaways, including the Angled Disc Butterfly Valve Cutaway (#295-712), the BOP Cutaway (#295-716), the Oilfield Pressure Gauge Cutaway (#295-721), the Extended Wellhead Assembly Cutaway (#295-795E), and more!

Maintaining safe operating conditions can be challenging in deep-set or deepwater, high-pressure/high-temperature (HP/HT) wells. The REACH™ subsurface safety valve from Baker Hughes provides an answer, with fail-safe operation in a wide range of deep-set completions that require low operating pressures due to control system limitations.

REACH safety valves are designed to provide reliable sealing in deep, HP/HT wells. They can be set up to 20,000 ft (6,096 m) below sea level and withstand temperatures up to 400°F (205°C) and pressures up to 20,000 psi (1,379 bar).

REACH safety valves are V1 validated and have undergone the stringent prototype testing per API SPEC 14A, Specification for Subsurface Safety Valve Equipment, Twelfth Edition. Our safety valve specialists have continuously modified the design to accommodate the new V1 validation specifications while progressively exceeding the requirements set forth by API.

REACH valves rely on field-proven, heavy-sprung closure technology to ensure fail-safe-closed operation. Because tubing pressure is isolated from the control system, the valve can open at much lower operating pressures, reducing the cost of umbilicals in some applications.

The valve’s unique activation system requires lower valve operating pressures than previous safety valve designs by eliminating the need to overcome tubing pressure, making the valve ideal for applications with opening pressure limitations including: subsea completions, high-pressure wells, and fields where the rig site and other control facilities may have supply pressure limitations.

REACH valves incorporate several proven features from other safety valve designs, including flapper closure technology, RBT housing thread technology, dynamic seal technology, and debris exclusion geometries—all of which help deliver integrated functionality and dependability.

To ensure long term reliability, the valve is also offered with a reinforced dynamic seal configuration, upgraded dynamic seal materials, internal alignment enhancements, and an enhanced scraper ring to minimize debris. Because the REACH valve does not utilize gas springs, the operating seals and gland do not experience pressure reversals, making them ideal for your critical deepwater HP/HT applications

Maintaining fluid control and well protection is critical in your shallow depth well operations. The SelecT™ subsurface safety valve from Baker Hughes addresses the unique challenges that shallow set safety valves (typically <1,000 ft) endure.

The tubing-retrievable SelecT valve includes an ultra-strong power spring that delivers the high closing forces needed to reliably and consistently close the valve in the presence of paraffin and other produced solids.

The SelecT is engineered to avoid failures due to wireline damage during downhole interventions. The valve’s advanced flapper design prevents damage and ensures that all seal surfaces are protected from wireline contact—even during accidental closure of the valve during wireline operations.

Ensure greater seal integrity with the SelecT valve’s patented advances that include thru-the-flapper self-equalizing system. And the radial punch control fluid communication system eliminates accidental communication associated with linear shifting sleeves.

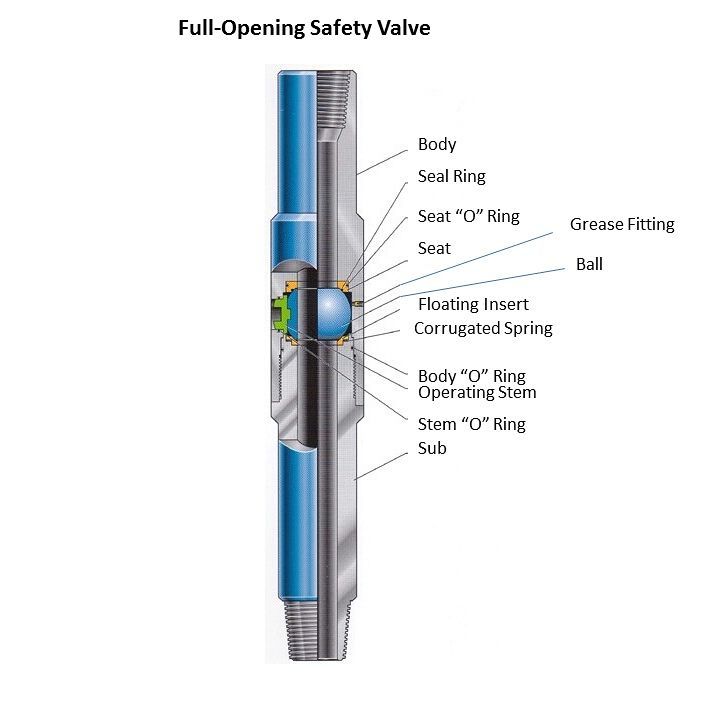

We design, test and manufacture downhole safety valves that are tubing run and surface controlled, as well as wireline run. Our range of tubing retrievable surface controlled subsurface safety valves suits 2-3/8” to 7” tubing sizes, in both standard and slim designs. It is a compact design using a concentric piston mechanism and a flapper system. Minimum metal-to-metal body connections are used to eliminate potential leak paths. All our valves include a nickel alloy flapper/flapper seat to ensure long term reliability of the valves in protecting surface facilities from uncontrolled flow from producing wells.

All our safety valves come with an exercise and lock-out facility. With a landing nipple profile in the top sub a wireline retrievable safety valve can be installed within the tubing run valve bore after lock-out allowing the well to continue to produce.

A full range of accessories is available for the downhole safety valves including exercise/lock-out tools, separation sleeves and nipple protection sleeves.

Whether downhole or subsea, safety can be hard to achieve in the oil and gas industry. Sudden pressure spikes can ruin equipment, leading to production stoppages and worse. Protection starts at the component level, which is where Lee Pressure Relief Valvescome into play.

Our relief valves come in three main varieties. Safety relief valves are designed to be exercised for intermittent “pop-off” applications. Pressure-regulating valves are intended to operate more continuously with stable performance throughout the operating range. Thermal relief valves relieve a few droplets of fluid from a trapped volume expanding due to rising temperatures. Each type of valve plays an essential role in downhole oil tool applications, and each is manufactured to the exacting tolerances that this role requires.

Like all products from The Lee Company, pressure relief valves are small, lightweight, and incredibly durable– enough to serve out the entire lifespan of an oil tool. In addition, these products are available in a range of sizes and cracking pressures.

A premium provider of oil field equipment and service parts, Parveen Industries Pvt. Ltd is focused on high-quality manufacturing of premium-grade oil and gas field equipment that exceeds international standards. At its eight large-scale facilities, Parveen manufactures products that not only support the existing oil and gas industry but drive forward industry-wide innovation.

The Super Safety Valve is the BOP safety valve applied fortesting operations from jack-up or land rigs. It canrapidly closes the test string in an emergency, serves as a fail safe safety Valve for well testing. And during the well testing, the Super Safety valve is featured with capablity to cut the wireline and 1.5-inch coiled tubing, if the super safety valve is equipped with a cutter ball, by using a nitrogen dome charge or applying balance line pressure, the safety valve has capability of cutting coiled tubing in OD 2 inch and 0.125 inch wall thickness,

The Super Safety Valve is designed with a chemical injection port and controlled by two hydraulic lines The SSV is operated to close by spring force, but the tool has a nitrogen charge chamber to quicken the closing time, which make the super safety valve has the ability to cut wireline and coiled tubing without the addition of balance line pressure.

Techcore Oil Tools expertise in design and manufacture of the Drill Stem Testing Tools and other downhole tools for more than Ten years, the professional Reserch and Development (R&D) department improves the advanced technology in design of the Drill stem testing tools for well testing service.

The drill stem testing tools are applied in cased hole, open hole and slim hole, the main DST tool string includes RTTS packer, circulating valve, safety joint, select tester valve, omni valve, hydraulic jar, shock absorber, RD safety circulating valve, high pressure retrievable packer with bypass, IPO valve, tubing string test valve, and so on

Other DST string tools: hydraulic jar, vertical shock absorber, radial shock absorber, RD safety circulating valve, high pressure retrievable packer with bypass, CHAMP packer, IPO valve, sleeve type drain valve, rupture disk sampler, super safety valve with control panel, BOP safety valve for downhole operation and so on.

ISO 10432:2004 provides the minimum acceptable requirements for subsurface safety valves (SSSVs). It covers subsurface safety valves including all components that establish tolerances and/or clearances which may affect performance or interchangeability of the SSSVs. It includes repair operations and the interface connections to the flow control or other equipment, but does not cover the connections to the well conduit.

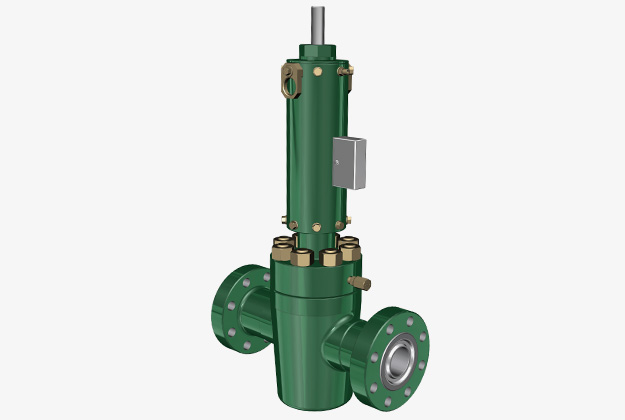

SSV is a leading global provider of wellhead and flow line actuators and other safety products serving both the offshore and onshore markets. The Business has a premier reputation with more than 60 years of operating history. SSV has operated as part of Halliburton’s completions segment.

Halliburton provides various products and services to the energy industry for the exploration, development, and production of oil and natural gas worldwide. It operates in two segments, Completion and Production, and Drilling and Evaluation. Its services comprise fluid services, drilling services, drill bits, wireline and perforating services, testing and subsea services, software and asset solutions, and integrated project management and consulting services. The company serves independent, integrated, and national oil companies. Halliburton Company was founded in 1919 and is headquartered in Houston, Texas

NOV is a leading worldwide provider in the design, manufacture and sale of equipment and components used in oil and gas drilling, completion and production operations, and the provision of oilfield services to the upstream oil and gas industry. The company operates through four reporting segments: Rig Systems, Rig Aftermarket, Wellbore Technologies and Completion & Production Solutions. NOV was founded in 1841 and is headquartered in Houston, T exas.

PPHB is an independent investment banking firm providing financial advisory services exclusively to clients in the oilfield equipment and service industry.

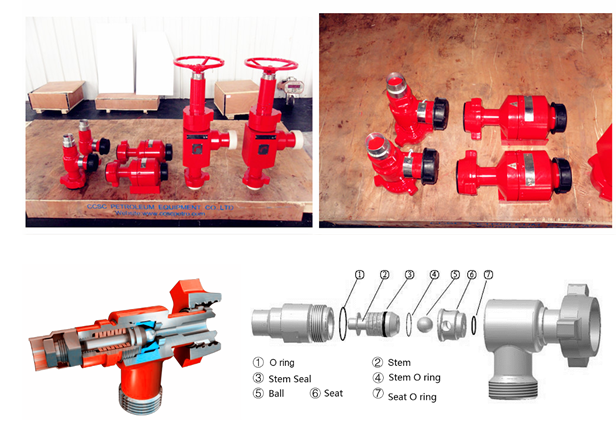

TIW is the original designer and manufacturer of ball type Safety and Kelly valves. Our strict adherence to API specifications as well as our own quality requirements ensures TIW valves are the highest quality valves in the market.

TIW Class I & Class II Kelly Valves may be utilized as a Drill Stem Safety Valve or as an Upper or Lower Kelly Cock and is designed to hold pressure from both directions.

TIW Kelly Valve Design and Quality System are certified by API.TIW Safety and Kelly Valves are also offered for H2S service, meeting all NACE standards. Standard Pressure rating is 10,000 PSI Test with higher pressure ratings available.

8613371530291

8613371530291