online safety valve testing brands

For many years, ultrasound has been utilised by various vendors as an additional method to find the set point in cases the standard diagrams are hard to analyse. This can be the case when testing safety valves on liquid services.

Within an extensive benchmark test, METRUS in co operation with Sweden‘s biggest nuclear power station Ringhals AB investigated the approach to use ultrasound as an additional indication for the set point on liquid service safety valves. The result of 55 tests on different valves is that the „Ultrasound point“ is completely depending on the seat condition. This result perfectly first the fact that ultrasound will detect the start to leak point and not the set point (start to lift point).

Only on a new or freshly serviced valve, the set point will be close to the ultrasound point. Even tiniest soiling or improper maintenance will cause the ultrasound to severely „drift away“ from the true set point. Within a typical online safety valve testing scenario where a valve has not bee serviced for a year or more, it is not at all recommended to use ultrasound to identify the set point.

There are still two useful applications for ultrasound within online safety valve testing. A very simple but effective use is to compare the sound level of the valve before and after the test. Comparing those sound levels will indicate if after the test (disk lift) the valve is left in a similar condition to its previous untested state. This could be first information if the valve did properly reseat and seal after it has been lifted. White Paper – Online safety valve testing METRUS Valve Test Bench Exellence

Knowing why safety valves should be tested online and how this is done in theory, it is most helpful to get an idea of the every day questions you will have to deal with. It will enable you to imagine how online safety valve testing appears in real life.

Plant operators are often surprised when being asked by online testing engineers whether it is a problem to open a valve. Considering the definition of the set point to be the initial moment when the disk starts to lift the safety valve disk must lift to find that point in a test diagram. It very much depends on the test equipment how long and high the valve will open, but it definitely has to open. geöffnet wird.

To test a safety valve, it must be possible to lift the disk and measure the force when doing so. If a safety valve has a spindle, it is possible in 95% of all cases to test it online. Some valves might require a simple spindle modification. This depends on the valve and the adapter solution how to „connect“ the test rig. Valves that do not have a spindle at all can not be tested.

Valves installed on extremely dirty fluids like bituminous crude oil should not be tested unless they are equipped with a rupture disk to keep the seat clean. Dirt could prevent the disk from sealing properly and the valve will remain leaking after the test. It the maintenance departments decision whether to agree with slightly lifting a valve or not.

Safety valves installed in EEx areas require special equipment to operate the test rig. If such equipment is available, it is important to check the specific EEx certificate for the approved EEx class and EEx area. As of now and to our best knowledge, there is no online safety valve testing system available that has an EEx approval for the whole machine. The test rigs are approved but the power unit usually has to stay outside the EEx area or have to be protected with special temporary solutions.

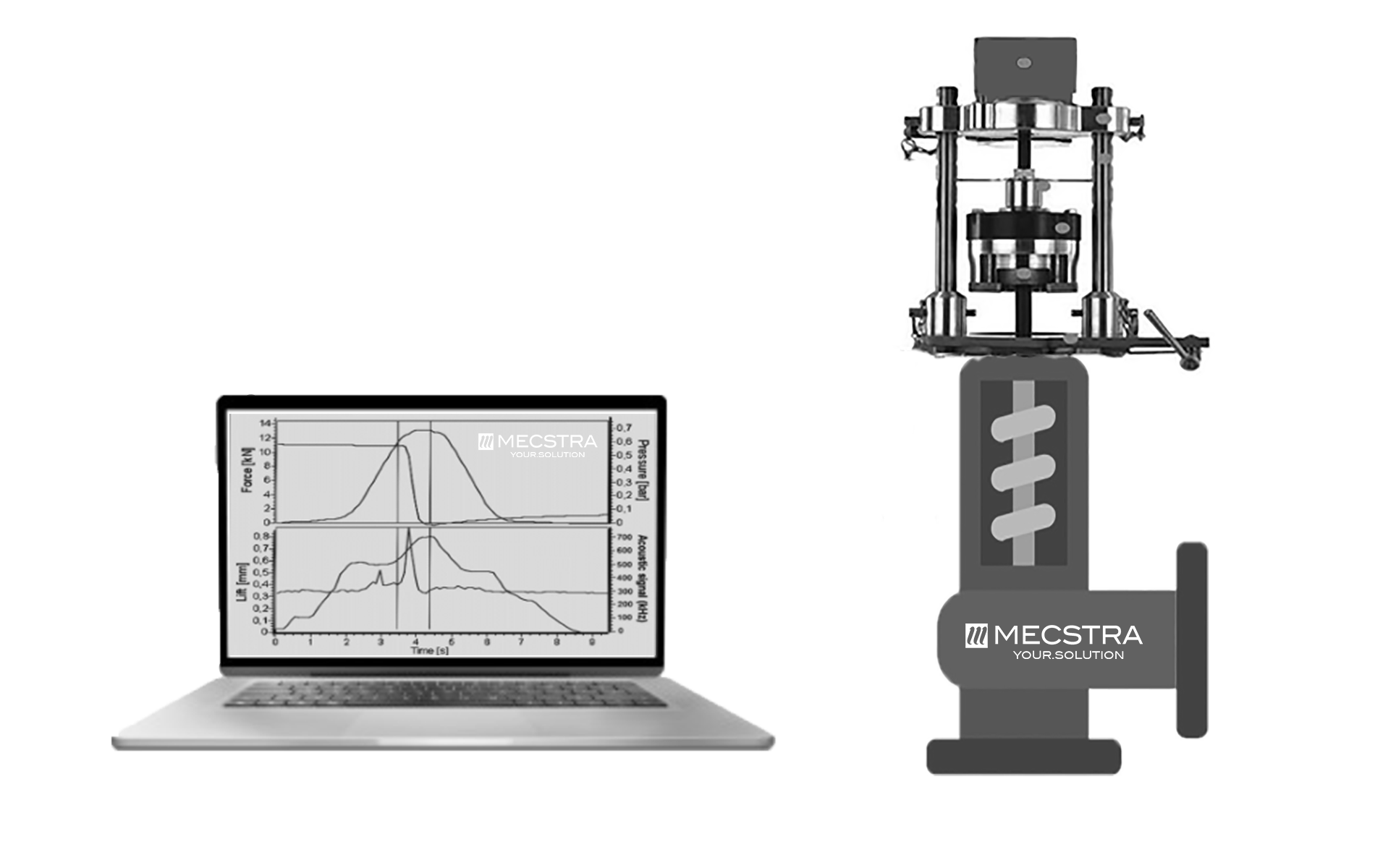

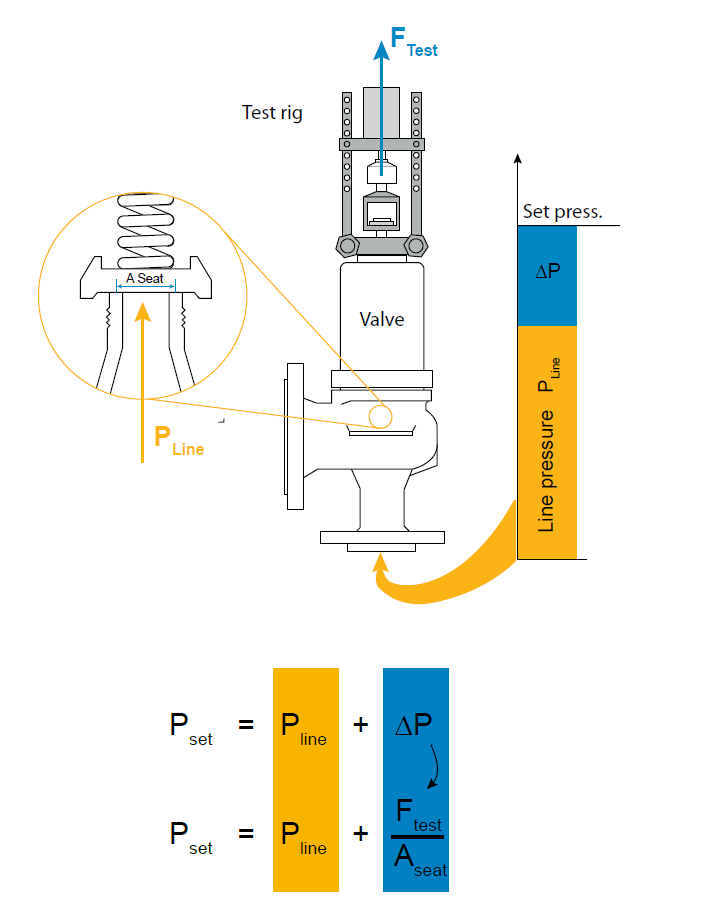

A frequent question to be found in industry is „what is the highest set point and the largest nominal diameter you can test?“. According to the online testing formula of fig. 1 the set pressure is calculated from line pressure, seat area and test force. Those parameters interact. The more line pressure is to be found under the safety vales disk the less force is required to lift (test) it. A final statement can never be made as it depends on seat area, set point and line pressure, whether or not the force capacity of specific equipment will be strong enough to test a valve.

Some suppliers claim that their equipment can test „any“ safety valve. Technically speaking it means raising the line pressure will lead to a remaining test force small enough to be covered by the test equipments force capacity. As online safety valve testing should not affect the plant operation this statement is not very respectable. Usually the line pressure can not be changed significantly just to test a valve.

Thinking about the largest valves, small and medium valves are often forgotten. But those ½“ and 1“ valves built the majority of valves to be found in industry. It is a technical fact, that each measurement task requires suitable sensor ranges. Large valves require large forces and small valves usually small forces. The operational range of online safety valve test equipment is therefore not only defined by its strongest force capacity. It is a question how accurate it can deal with a variety of forces and pressures – small and large.

Online safety valve testing offers major cost saving potential. In most cases it is cheaper than workshop testing after comparing direct testing costs. This of course requires the test equipment to be efficient in handling and operation.

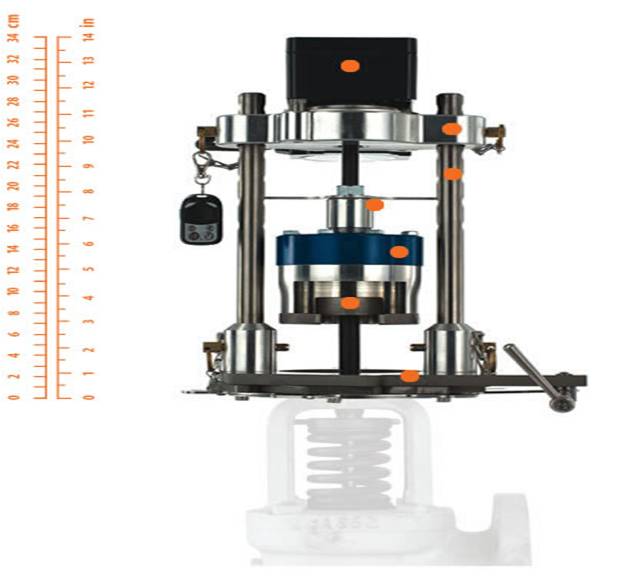

Safety valves need to be tested at various locations within a plant. It is common to move the test equipment a few times during a test day. Different valve types to be tested require retooling of the test rig. In every day life the equipment will be packed and unpacked several times and it will require adaptation to fit the test rig on the safety valve. Valves will be located on top of tall reactors and on difficult to reach places under or behind pipelines.

The test equipments performance is significantly defined by its mechanical performance – weight and flexibility. The time for unpacking and rigging up as well as for wiring all sensors etc. determines, how fast the individual valve test will be. And in many cases the safety valve requires adjustment. Depending on how long it takes to take the rig off the safety valve, testing and re-testing will be fast and efficient or time consuming.

Within a typical online safety valve test scenario, a valve might need to be adjusted. To adjust a valve, it requires to remove the rig (RR) adjust the valve (VA) and reinstall (RI) the rig before you can carry out the next test to see, if the adjustment was successful. This is done usually two times until a satisfying set pressure is adjusted.

The relation between handling and testing time in average test equipment is about 1/5. It becomes obvious that total test time and efficiency are significantly depending on the test rig performance – weight, portability and speed of set up / dismantling.

It may happen that safety valves stay open after the test. To make sure that such event does not affect the plant operation, a concept to remotely close the safety valve, using the test rig is absolutely necessary for safe online safety valve testing.

Testing safety valves online is not at all dangerous as long as the procedure is done properly and the system performs as it should. But there are rare scenarios in which a plant disturbance could appear, especially if a safety valve stays open or gets damaged.

Online safety valve test equipment today is either manually or electronically controlled. Electronic systems support the test process and monitor test limits, taking a lot of responsibility from the technician. TESON® e.g. automatically drives the complete lifting process, monitoring all sensor signals for pre calculated test limits. But electronic systems are sensitive to power black outs as well as to software malfunctions. To deal professionally with those, the online safety valve testing system must have an extensive safety system to guarantee the safety valve will never be blocked open or damaged – whatever might happen.

Manually controlled system are not sensitive to power black outs or system failures. They leave the full control over the test process to the technician. It is up to the technician to control the lifting force and whether or not to overload a valve. Especially with manually controlled system experience plays an important role as the safety issue is basically the human factor. Despite that even manually driven system must have some safety features to respond to hardware or hydraulic malfunction.

Considering the number of parameters to be considered and monitored during an online safety valve test, digital systems are definitely superior as the chance of malfunction and power black outs is considerably small if the systems are well designed and extensively tested. Even after intensive training and years experience it is barely possible for a technician to compete with the reliability and response time of a digital system. Considering the background of online safety valve testing it is a derived requirement of the system to be safely and correctly operated with minimum skill and experience.

When thinking of a first time investment, it is very often the purchase price that plays an important role. But if you consider the cost saving potential of online safety valve testing or the profit you could make with a service, it becomes obvious that there is more to be considered to get a real view on the cost of ownership.

Support from your supplier will be crucial for your business. If you are facing time sensitive testing sessions and your equipment gets damaged or you come across complex questions, delays of operations or loosing your customer to the competition can cause severe loss of profit. The system vendor should be able to minimize downtimes with an intelligent support strategy. This includes 24 h availability of technical support, access to most spare parts in local markets and availability of rental equipment to substitute yours during service and repair. The more a supplier is focused on the online safety valve testing business, the better resources he will offer to support your every day work.

Like all measuring equipment, online safety valve testing systems require calibration. Sensors and measuring electronic need calibration (typically every 2-3 years) to harmonize with ISO quality standards. Suppliers must be able to either offer you a calibration service or advice you where to get such service. To minimize transportation costs, the parts and modules that need calibration should be easy to isolate for shipping.

The variety of valves to be found in industry is huge. It is not at all practical to own every type of special equipment that might be required one day to test special applications. Your investment will be significantly lower if you can own core components that cover the majority of your every day online testing needs. Your supplier should offer you special extension for rent to cover the remaining applications once they are required.

We hope this white paper could draw a picture what online safety valve testing is about. If you have any further related question, please feel free to contact METRUS at any time. It will be our pleasure to support and consult you..

Different to a safety valve test bench test an online safety valve test (or ISVT – In Situ Valve Test) is carried out on site with the safety valve remaining in its operational position and the plant remaining in operation. Whenever a safety valve “only” requires testing and no further maintenance or overhaul, a TESON online safety valve test is the most economic approach. Those who are new to the subject kindly refer to our Online Safety valve testing white paper.

In-situ testing of safety relief valves provides generally a good alternative to bench testing and ultimate tool for annual calibration of PSVs. Ventil offers since many years an electronic relief valve tester, PreVenTest. The PreVenTest is a world-wide used auxiliary lift assist device that is widely accepted and recommended by major relief valve manufactures. PreVenTest will test all brands of pressure relief valves.

The Ventil LTC PreVenTest is a lightweight, semi-auto online relief valve tester with a small and smooth stroking hydraulic pump. The PreVenTest advanced is a larger but fully automated device with computer controlled pulling force. PreVenTest can be supplied as intrinsically safe version with ATEX and CSA certifications

PreVenTest comes with a set of accurate force / load transducers that measure the required pulling force to generate an initial lift of the valve. Further disc lift, acoustic are available and can be used for further analyses of valve performance and set pressure identification.

Reliable results can only be achieved when having accurate effective seat or pressure areas available. The PreVenTest Online Valve Test Software comes with a large database with accurate seat dimensions. The exact inlet operating pressure or line pressure must be known at time of the lift. PreVenTest features an additional connection to connect a pressure transducer. Typically achieved accuracy exceeds standard bench test results and are well within the tolerances of ASME VIII and PED

Aircraft alloy, lightweight but rugged fixture. The lift assist device is quickly installed at the valve and the time saving claw clamp feature makes connecting to the valve fast and efficient.

Safety valves are essential to the protection of lives and property. they are Installed on process equipment to release excess pressure, due to upset process operations, external fires and other hazards. failure of pressure safety valves to function properly when needed, could result in the over-pressure of vessels, exchangers, boilers or other equipment they were installed to protect, so periodic testing is crucial to ensure that valves are in a good condition, functioning properly and will provide the so important protection. But can you really be sure of the results if the test is not conducted under the stress of everyday conditions? Unsurpassed for accuracy, reliability and safety, the advanced technology of AccuTEST was developed to test the function, set pressure and general performance of your spring operated safety valves under a full load, for consistently superior, reproducible results. while in position without interrupting the process operation, The valve stays online; This means the valve is accurately tested in its process conditions.

Pressure safety valves are designed to protect process piping and equipment in case of an overpressure event. TEAM Valve Solutions inspects, tests, repairs and re-certifies safety valves at 17 service centers across three continents, and in our fleet of mobile facilities, all of which are audited under the jurisdiction of relevant governing bodies.

Our solutions cover all major safety valve brands and support our customers through an inventory of spare parts and loose-assembled valves. In addition, our facilities are audited and governed by the National Board of Boiler and Pressure Vessel Inspectors. Testing, repair, and assembly are performed under license and guidelines of NBIC, and ASME Section I and VIII.

To ensure accurate in-line setpoint verification, TEAM Valve Solutions utilizes Trevitest, the pioneering system for validating safety valve performance in Conventional and Nuclear Power plants, as well as in other industrial process facilities.

vpl has put you on the right track. The Trevitest Device is one brand of Lift Assist Device (others include KISS, EVT, PVT AVK, Hydroset, SPIVOT). SOme are manufactured by Pressure Relief Valve Companies, others by Valve Repair Shops and some are third party vendors with PRV background. A Pressure Relief Valve typically uses a spring (Force S) to hold a movable sealing member (disc) closed on a fixed sealing member (nozzle) until the system pressure (Force P) overcomes the Spring and opens the PRV to relieve an overpressure situation. The PRV works on the simple principle that IF Force S > Force P THEN the PRV remains closed (Static Force Balance Principle). However, IF Force P > Force S THEN the PRV is Open.

The problem is that most Steam Power Generating Stations, whether Fossil or Nuclear, are such high pressure and under so much demand for electricity that they do want to take the time or liability to overpressure their boilers to test Safety Valve Set Pressure. Use of the Lift Assist Device is permitted by ASME Code (both Sec. I, Power Boilers, & Sec. VIII, Pressure Vessels) to determine the Set Pressure of a PRV (Safety, Safety-Relief or Relief Valve).

The Equipment Required is a Calibrated System Pressure Gauge, a Lift Assist Device with an adapter to connect to the PRV Stem, a Calibrated Load Cell to measure the Force Applied to the PRV Stem, a calculator or PC with a program to determine the Set Pressure from the input data and most importantly, a Valve Technician who knows PRV Terminology, and is familiar with the Test Equipment.

The CALDER PROSET Pilot Valve Tester is a cost-effective way to perform the functionality of the pilot in Pressure Operated Relief Valves (PORV) with unsurpassed quality and ease of use. ROBUST, EASY TO USE, AND STATE OF THE ART Tests both modulating and snap-acting pilot...

The CALDER QUICKSET™ Safety Relief Valve Testers set a new standard for Pressure Relief Valve Testing and provide valve technicians with unrivaled performance, volume, flow, and ease of use. ROBUST, EASY TO USE, MODULAR, AND HIGHLY CONFIGURABLE The unique high flow design allows for free...

The new lineup of CALDER QUICKSET™ Safety Relief Valve Testers raises the bar with unrivaled performance and ease of use. QUICKSET™ SRV Testers are designed to match all your valve testing needs with base machines of different tonnage while offering more than 50 different configurations...

40 years ago, CALDER began manufacturing Valve Testers because founder, John Emmitte, realized that companies were not testing valves properly. Even today, many pressure relief valve testers are homemade or fabricated in a manner that does not provide the valve with enough volume, and are...

The CALDER HYDROPRO™ Universal Straight Valve Tester (USV) and Universal Flange Valve Tester (UFV) are the safest, most accurate, and most versatile advanced valve testing systems in the industry. When paired with the HYDROPRO™ Console, HYDROPRO™ valve testing systems are capable of hydrostatic tests up...

Customized to Mobilize Your Specific Valve Testing Needs! CALDER Valve Testers has been customizing valve testing systems for almost 40 years designing and creating unique solutions to meet all your valve testing challenges head-on. The CALDER Mobile Valve Workshop is no exception, offering unrivaled flexibility...

CLIMAX | CALDER invites you to visit us at the Valve World Americas Expo & Conference on October 13 – 14, 2021, at the George R Brown Convention Center in Houston, Texas, booth 1521. Valve World Americas Expo & Conference is the largest exhibition for services, equipment, and other valve needs. CLIMAX, the leading...

When safety and time are critical, look no further than CALDER for your valve testing solutions. We offer a variety of valve testing and repair machines, including the new TURN-AROUND-TESTER™ (TAT). The TURN-AROUND-TESTER™ offers the ability to put it in the back of a truck, get it on site,...

Visit us at our CALDER Valve Tester locations in Saudi Arabia and UAE. Meet the experts and get a first-hand look at the latest technology available from CALDER. See live demonstrations of the machines our customers are raving about, like the new CALDER Portable Valve...

See the CALDER TURN-AROUND-TESTER LIVE on April 28, 2021 Over 50 years ago, CLIMAX pioneered the portable machine tool industry, with state-of-the-art tools that solve the world’s toughest machining challenges. In 2013, CLIMAX acquired CALDER Testers and brought portable to the valve testing industry. The...

CLIMAX, the world’s #1 choice for portable machining, welding, and valve testing invites you to visit us in Houston on February 15 – 26, 2021. This is a great opportunity to get a first-hand look at the latest technology available from CLIMAX, BORTECH, CALDER & H&S TOOL. Meet the experts...

The CALDER HYDROPRO™ Universal Straight Valve (USV) tester is the most versatile and user-friendly tester in the industry, designed to clamp a wide variety of straight bodied valves. When paired with the HYDROPRO™ Console, the HYDROPRO™ USV is ideal for hydrostatic tests up to 9700 psi...

Congratulations to Dave Briggs and the CLIMAX | CALDER engineering team for officially receiving the Patent for the CALDER Safety Interlock System. The Safety Interlock System is designed with interlocking knobs and valve handles that will not release the clamp pressure until the internal test pressure...

CALDER Advanced Valve Testing & Repair Systems by CLIMAX is excited to announce TOMCO Industrial as an exclusive sales and service representative for all CALDER products in Canada. This new partnership with TOMCO will allow CALDER, the leading global manufacturer of valve pressure test benches...

The CALDER HYDROPRO™ Universal Straight Valve (USV) Tester is the most versatile and user-friendly tester in the industry! The USV system uses our patented Easy-Out Seal Plate™ holders which allows quick change-out of seal plates from flanged to other valve end type connections with minimal effort....

CLIMAX | CALDER invites you to visit us at the Valve World Americas Expo & Conference on June 19-20, 2019 at the George R Brown Convention Center located in Houston Texas. Valve World Americas Expo & Conference is the largest exhibition for services, equipment, and...

The CALDER TURN-AROUND-TESTER™ can efficiently perform a wide variety of pressure tests and can be easily transported for use on job sites. Valve repair shops and technicians are now taking their shop on the road. With superior quality, safety, durability, and performance, owning a CALDER TURN-AROUND-TESTER™ ...

CALDER Advanced Valve Testing Systems proudly announces the appointment of Mr. Kevin Vincent to the position of General Manager. CALDER is a subsidiary of CLIMAX Portable Machining & Welding Systems, headquartered in Newberg, Oregon. Mr. Vincent has been in commercial positions of increasing responsibility at CLIMAX for five years, serving most recently as a...

Fisher Price, CALDER Product Line Manager, focused on CALDER Advanced Valve Testers, has been working in the valve industry since 2004. Spending much of his career with Nuclear power companies, Fisher has held several roles machining, welding, testing, and repairing valves, as well as, providing expertise...

Oil & Gas News, November 2018: CLIMAX Portable Machining and Welding Systems is the world’s premier supplier of portable machining and welding equipment. Under its CALDER product line, the corporation provides the world’s most advanced line of valve testing and repair systems. CLIMAX | CALDER...

CALDER Advanced Valve Repair & Testing Systems cordially invites you to the GRAND OPENING of our new CALDER Saudi Arabia sales office, customer service center and product showroom in Dammam, Saudi Arabia. Please stop by on Monday, November 19 any time between 10:30 AM and 2:00...

Clark Turner has been in the valve industry for more than 35 years, where he’s done everything including repairing, hydrotesting, and installing line valves, as well as installing safety and relief valves in various processes. He also spent significant time as an ASME Section VIII design...

CALDER Valve Testing Systems recently introduced a new, enhanced lineup of valve testing systems that have proven to be a reliable solution for valve repair shops. The new valve testers have quickly earned a reputation as the safest, highest quality, and most durable, versatile, and productive systems...

The new CALDER TURN-AROUND-TESTER™ can efficiently perform a wide variety of pressure tests and can be easily transported for use on job sites, giving valve repair shops and technicians the opportunity to take their shop on the road. Contact us today at +1.985.974.6070 or [email protected] to...

The TURN-AROUND-TESTER™ (TAT) is the perfect solution for service teams to complete in-field testing of freshly refurbished Control and Safety Relief valves. The self-contained TURN-AROUND-TESTER™ will fit in any full-sized pickup bed with the controls positioned to ergonomically allow the operator to complete the testing even when...

Over 50 years ago, CLIMAX pioneered the portable machine tool industry, with state-of-the-art tools that solve the world’s toughest machining challenges. In 2013, CLIMAX acquired CALDER Testers, and now CLIMAX | CALDER has brought portable to the valve testing industry. The new CALDER TURN-AROUND-TESTER™ can efficiently...

We live in a world with valves, and those valves need to be repaired and tested. Today we’re asking all valve repair shops, power plants, refineries, and owners of valves: How much downtime and money could you save if you could repair and TEST your...

GOING PORTABLE WITH A WHOLE NEW TECHNOLOGY We live in a world with valves and those valves need to be repaired and tested! 51 years ago, CLIMAX disrupted traditional repair processes, introducing undeniable value by inventing the portable key mill, bringing portable machining technology directly...

CLIMAX | CALDER invite you to visit our booth (1628) at the VALVE WORLD AMERICAS EXPO, June 20 – 21, 2017 in Houston Texas. VALVE WORLD AMERICAS EXPO is the largest exhibition for services, equipment, and other valve needs. CLIMAX will showcase their valve grinding and...

The CALDER HYDROPRO™ Universal Straight Valve Tester (USV) and Universal Flange Valve Tester (UFV) are the safest, most accurate, and most versatile advanced valve testing systems in the industry. When paired with the HYDROPRO™ Console, HYDROPRO™ valve testing systems are capable of hydrostatic tests up to 9700...

The CALDER Safety Relief Valve Tester (SRV) sets a new industry standard for testing safety relief valves with unsurpassed performance and ease of use. EASY TO USE, WITH UNRIVALED QUALITY, SAFETY & CUSTOMER SUPPORT Every component in the SRV pressure circuit is designed to work...

A Dozen Questions That Can Save You Millions in Your Valve Testing Program! When purchasing a valve testing system, the top concerns have to be safety, quality, durability, performance, versatility, usability, productivity and – ultimately – total cost of ownership and return on the investment....

The Most Versatile & Cost-Effective Way to Test Straight Bodied Valves! The CALDER HYDROPRO™ Universal Straight Valve (USV) Tester is the most versatile and user-friendly tester in the industry, designed to clamp a wide variety of straight bodied valves. When paired with the HYDROPRO™ Console,...

With vastly superior quality, safety, durability, flexibility, performance and support owning a CALDER Advanced Valve Testing System is by far the most flexible and cost-effective way to manage your valve testing program, reduce your total cost of ownership and maximize your return on investment over the...

BIC Magazine, April 2017 When purchasing a valve testing system, the top concerns have to be safety, quality, durability, performance, versatility, productivity and return on investment. Ask these 12 pivotal questions when purchasing a valve tester: Is every component in the tester certified by the...

Our engineers and valve test experts asked customers what they want in the next generation of valve testers. One message was loud a clear: customers want fast, responsive, expert service and support. So we’ve built that right into the foundation of our new CALDER offering!...

CALDER engineers, in collaboration with key industry experts, spent countless hours designing this next generation of CALDER advanced valve testing systems. Not only are CALDER systems more versatile, accurate, durable and cost-effective, they’re designed with “Safety First!” in mind. Our systems maximize user protection and ensure test...

The new lineup of CALDER advanced valve testing systems, manufactured by CLIMAX, are the most flexible and versatile systems on the market. The CALDER test system can seamlessly expand and evolve with your business, giving you the lowest total cost of ownership (TCO) and the...

The HYDROPRO™ Console – The Most Versatile & Cost-Effective Way to Test Valves! The HYDROPRO™ Console is the most versatile and user-friendly tester in the industry, capable of performing a wide variety of valve tests when paired with a CALDER hydraulic clamping system or even blind...

Introducing the new CALDER Product Family The new platform of CALDER advanced valve testing systems manufactured by CLIMAX are the safest, most accurate and most versatile systems on the market, and we are pleased to announce our new line-up of valve testing equipment. HYDROPRO™ CONSOLE The...

Are you ready? On January 16th, CALDER will transform the valve testing industry, unveiling EIGHT new products! We’re going to show customers, world-wide, a whole new vision of industrial valve testing, a quantum leap in performance, safety, reliability, versatility, and cost-effectiveness. We’ve made a major investment...

Get ready – CALDER valve test systems will transform the valve testing industry starting January 16th! We’re going to show customers, worldwide, a whole new vision of industrial valve testing, a quantum leap in performance, safety, reliability, versatility, and cost-effectiveness. HOW? We have been working...

Distributor of pipe, valves, piping accessories, industrial pumps & valve automation. Fluid handling products such as steam traps, control & high performance valves, corrosion resistant piping & grooved piping systems are also available. Valves include sanitary butterfly, plug, ball, check, gate, globe, sampling & rising stem valves. Instrumentation include actuators, limit switches, instrumentation fittings, transmitter manifolds, low pressure brass fittings, quick connectors, thermometers, gauges, RTDs, thermocouples, temperature & pressure sensors, pressure & temperature regulators, fluid & gas meters & sensors, positive displacement & turbine meters, positioners, switch boxes & pneumatic cylinders. Pumps & process equipment include rotary, positive displacement, air operated double diaphragm, progressive cavity, centrifugal, vertical & horizontal, end suction & submersible pumps.

Tired of keeping track of your valve inventory’s annual certification records? We offer complete management of your safety relief valves. With an inventory of repair parts and in stock relief valves of all sizes, we can respond to any customer emergency. We offer annual certification services as well as repair of all major brands, including Kunkle, Conbraco, Consolidated, Dresser, Apollo and more.

Because of their importance, checking or calibrating valves is critical, but creating a consistent test result is difficult, as two technicians may interpret the analog test gauge differently.

Companies use pressure relief or safety valves to protect equipment from pressure spikes. Because of their importance, checking or calibrating these valves is critical, but creating a consistent test result is difficult, as two technicians may interpret the analog test gauge differently.

Crystal has a solution with its XP2i Digital Pressure Gauge. The XP2i features a special PSV mode designed to test pressure safety and relief valves. Once the valve opens, the XP2i detects the pressure drop and displays the maximum pressure that the gauge ever reached before the drop. This value remains on the display until the technician clears it. Rather than two technicians possibly reporting different values when the analog gauge spikes, with the XP2i both technicians would write the same value, even to a thousandth of a psi.

The XP2i Digital Pressure Gauge features three accuracy levels to choose from, 0.1% of reading, 0.05% of full scale, or 0.02% of full scale. They are available in ranges from vacuum to 15,000 psi and are fully temperature compensated from –10 to 50 C. All versions are ATEX, IECEx, and CSA intrinsically safe, making them ideal for the oil & gas industry and others requiring intrinsic safety. An optional datalogging upgrade allows the XP2i to collect and store up to 32,000 data points and easily download the results to a spreadsheet or protected pdf file.

Because of their importance, checking or calibrating valves is critical, but creating a consistent test result is difficult, as two technicians may interpret the analog test gauge differently.

Companies use pressure relief or safety valves to protect equipment from pressure spikes. Because of their importance, checking or calibrating these valves is critical, but creating a consistent test result is difficult, as two technicians may interpret the analog test gauge differently.

Crystal has a solution with its XP2i Digital Pressure Gauge. The XP2i features a special PSV mode designed to test pressure safety and relief valves. Once the valve opens, the XP2i detects the pressure drop and displays the maximum pressure that the gauge ever reached before the drop. This value remains on the display until the technician clears it. Rather than two technicians possibly reporting different values when the analog gauge spikes, with the XP2i both technicians would write the same value, even to a thousandth of a psi.

The XP2i Digital Pressure Gauge features three accuracy levels to choose from, 0.1% of reading, 0.05% of full scale, or 0.02% of full scale. They are available in ranges from vacuum to 15,000 psi and are fully temperature compensated from –10 to 50 C. All versions are ATEX, IECEx, and CSA intrinsically safe, making them ideal for the oil & gas industry and others requiring intrinsic safety. An optional datalogging upgrade allows the XP2i to collect and store up to 32,000 data points and easily download the results to a spreadsheet or protected pdf file.

Any valve test and repair company, no matter how big or small, is defined by the quality of service and accuracy of testing they offer. The safety valve testing equipment you use plays a big role in how quickly and how accurately you’re able to test clients’ valves and offer them the information and the service they need to do better, more efficient business.

If your company has been using the same inline pressure relief valve testing equipment for years, it’s time for an upgrade. You need pressure relief valve testing equipment that’s making use of the most advanced software and technology to make your technician’s job easier, your service better, and your business more profitable. If you’re ready to upgrade your inline safety valve testing equipment, here’s what to look for in a new system:

Your technicians are skilled, talented workers who have more knowledge about the inner workings of pressurized systems and safety valves than anyone else out there. Make sure they have the tools to do their job to the best of their ability. One-touch valve testing software takes away much of the time-consuming setup and potential for human error that comes with inline safety valve testing.

Using a computer-controlled motor, the testing software runs the pressure relief valve test automatically and with exceptionally smooth accelerations that ensure accurate and repeatable results.

High-tech systems like the AccuTEST inline safety valve testing system will graphically display the progress of the test and precisely determine the valve set point.

One-touch valve testing software, used by AccuTEST, takes the burden off of your technician. With single-touch testing and automatic setpoint calculation, this sophisticated software eliminates the potential for human error throughout the test, from automatic calibration of measurement sensors to the final results.

This is the 21st century. Your inline safety valve testing equipment should be easy to interact with and have a user-friendly interface. If you’re looking to upgrade your inline safety valve testing equipment, know that there are options out there, like the AccuTEST system, that provide intuitive software interfaces, and helpful, comprehensive data storage.

With inline safety valve testing equipment that incorporates an advanced software interface, your technicians can monitor the progress of the safety valve test on the graphical display as it happens. What’s more, the AccuTEST system sends test files directly to the system computer, where they are permanently stored for complete, simple data management. The files are then easily accessed whenever your technician needs to revisit or print out test results for a client.

While features like a visual display of the test process, and the ability to permanently store, access, and print test results sound relatively basic, they’re not incorporated in a number of inline safety valve test systems on the market today. These features offer a significant improvement to your ability to provide clients with the information they need following your valve testing service.

The more valves your technicians are able to test, the more profitable your business becomes. Many manufacturing and industrial facilities make use of a variety of different safety valves, and it’s nearly impossible to have specific testing equipment for each unique valve or valve brand. Instead, look for new inline safety valve testing equipment that offers universal testing capabilities.

Systems offering these capabilities will feature universal mounting frames designed to accommodate any variety of safety valves, and will include software that provides access to a database of a multitude of valve types and sizes from various manufacturers, to ensure your technicians have the information they need on hand, no matter what type of facility they’re working in, or what type of safety valve they’re testing.

Making the decision to switch to upgrade your inline safety valve testing equipment is a big investment. You shouldn’t have to worry about how you’re going to protect or maintain that investment. While in the past, inline safety valve testing equipment has had a reputation for poor service and exceptionally long repair turnaround times, the industry is changing. You can, and should find an inline safety valve test equipment provider that offers helpful, timely technical support.

Your business is built on properly functioning safety valve testing equipment. If something goes wrong, your provider should offer the service and support that resolves the issue as quickly as possible. AccuTEST Systems is proud to offer strong technical support for your technicians anywhere, directly from our engineers. We don’t use a third-party representative to handle service concerns — our engineers work directly with your technicians to resolve any issue they might run into out in the field or in the shop. As long as your techs can connect their AccuTEST system to the internet, our engineers can remote into their system to identify and troubleshoot any problems they’ve run into.

If you’re searching for new safety valve testing equipment for your valve test and repair shop, AccuTEST can help. At AccuTEST, we don’t believe in simply selling equipment — we develop partnerships. If you’re interested in upgrading your inline safety valve testing equipment to an option that features both advanced software and exceptional support, we’d love to talk. Our unique inline testing equipment features advanced software, accurate results, and first-class support, no matter where you are.

The EVT-Pro device simultaneously examines two critical variables of the relief device — the upward force applied to the spindle and the actual system pressure. Using sophisticated sensors, including an acoustic device, EVT-Pro testing accurately determines the pressure relief valve’s set pressure. It can also immediately sense and automatically close a relief device should it remain open during a test – a unique safety feature built into the software and hardware.

Vinson understands that complete reliability of all Pressure Relief Devices is essential to protect, not only a plant’s assets, but most importantly all personnel and the environment. Vinson offers both field and in-shop repair services, and is proud to be one of the nation’s leading National Board certified VR & TO Repair Facilities. With certifications on air/gas/liquid and steam service (Section I & VIII), Vinson provides setting, repair and testing services on all manufacturers valves up to 10,000 psi.

Without going into the acceptability or otherwise of on-line testing for non-steam applications, I hope you agree that on-line testing cannot manage some of the failures modes in any safety valve. We use the term "coverage factor" to describe the proportion of failure modes to the total managed by a given test procedure. On-line testing can never have a coverage factor of 100%.

With due respect to what EPRI or other learned bodies say, there is no reason to ban on-line testing of valves in non-steam applications to improve overhaul (and resulting Plant Shutdown) intervals. In practice, the Steam Safety Valve construction is amenable to on-line testing. Pressure Relief Valves in non-steam service do not always have designs that enable on-line testing, thus making that impossible. That, IMHO. is the main reason for not considering on-line testing in such cases.

IMHO, the availability of steam for bench-testing is not a relevant consideration. Before the advent of on-line systems, we were testing steam valves with air, for about many decades. The "cold" bench-test was followed by a "hot" or "floating" test on the boiler drum or superheater header, where the remaining safety valves were gagged and steam pressure raised to the set-pressure of the valve in question.

On dismantling, I have seen many steam valves with gumming of stems, mainly with deposits of chemicals injected into the boiler feed water. Depending exclusively on on-line testing alone for Steam Safety Valves can IMHO, be a dangerous policy.

Get a range of wholesale safety valve testing machines designed for different testing needs. For those involved in the field of digital electronics and who need to work with digital circuits and systems regularly, consider the wide range of logic analyzers that are available. Quality testing equipment will be able to help verify and debug your digital designs efficiently when required.

For owners of electronic tools and equipment supply stores, there is also a large variety of testing equipment that you might want to consider purchasing. Products that are available include vector network analyzers, circuit breaker testers, megohmmeters and even tube testers. Get safety valve testing machines from several popular and leading brands here.

8613371530291

8613371530291