online safety valve testing made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

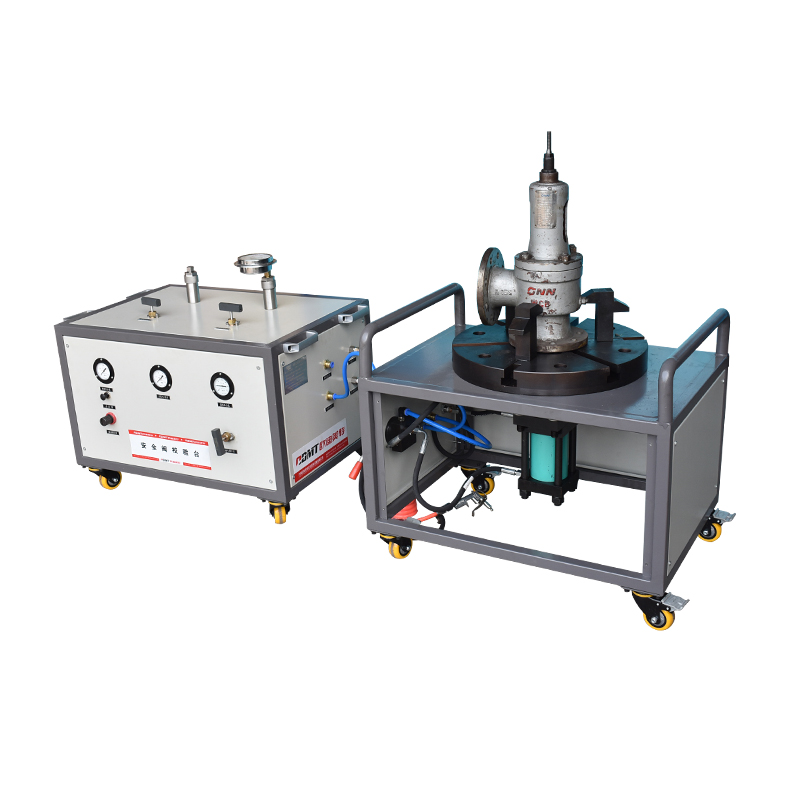

By means of claw clamping the flanges of the valves, The test bench can be equipped with air booster upon request of the user to perform the high pressure test. The safety protection devices and Data management system can be selected by users upon request. The test bench can be customized according to the user’s detailed requirements.

Our company has a certain share in the global market thanks to our excellent Conventional Slotted domed Disc, Spring valve used in Low Temperature, Safety Valve used in Low Temperature, high-quality employees, unique corporate culture and innovative teamwork spirit. Based on the creed of "sincerity-oriented, trustworthy", we have built an efficient, professional and fast service platform to continuously optimize and improve service quality. We hope to realize technological innovation and management innovation through modernization, informatization and standardization of management concepts and methods. Your needs are the driving force of our growth, your affirmation is the cornerstone of our development, we are willing to grow together with you.

Spring Safety Valve can stop valve the membrane disk by the spring pressure, when the system is overpressure, the devices will be opened, the pressure will be relief. According to the high of valve opening, it can be divided into full open and little open. Full opening, it is exhaust is huge, well spring, designed for liquid and gas. And little opening is used in liquid.

After years of hard work, our company has accumulated rich experience in the Yh-3000 Safety Valve Online Testing Machine industry, and we look forward to cooperating with you sincerely. Welcome to negotiate business. We have advanced production line equipment, strong technical force, perfect enterprise management and high-quality after-sales service to ensure quality and timely delivery. We guarantee the continuous improvement of product quality and ensure the common interests of both parties and the value of products.

SGS is pleased to announce the acquisition of a 51 percent stake in Suzhou Safety-Tech Valve Testing Co., Ltd. (Safety-Tech), headquartered in Suzhou, China.

Safety-Tech offers specialized valve maintenance, repair and overhaul (MRO) services principally to the energy, metallurgy and papermaking industries. The company holds both local and international accreditations necessary to perform MRO services. Founded in 2010 and privately owned, Safety-Tech operates principally out of Suzhou with four offices elsewhere in China. With 52 staff, the company generates revenues in excess of RMB 18 million.

“I am very pleased with this acquisition. It is in line with our strategy to develop further our industrial footprint in China,” said Frankie Ng, CEO of SGS. “It will benefit from synergies with our existing calibration, testing and non-destructive testing operations.”

SGS is the world’s leading inspection, verification, testing and certification company. SGS is recognized as the global benchmark for quality and integrity. With more than 80,000 employees, SGS operates a network of over 1,650 offices and laboratories around the world.

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

Pressure safety valves are designed to protect process piping and equipment in case of an overpressure event. TEAM Valve Solutions inspects, tests, repairs and re-certifies safety valves at 17 service centers across three continents, and in our fleet of mobile facilities, all of which are audited under the jurisdiction of relevant governing bodies.

Our solutions cover all major safety valve brands and support our customers through an inventory of spare parts and loose-assembled valves. In addition, our facilities are audited and governed by the National Board of Boiler and Pressure Vessel Inspectors. Testing, repair, and assembly are performed under license and guidelines of NBIC, and ASME Section I and VIII.

To ensure accurate in-line setpoint verification, TEAM Valve Solutions utilizes Trevitest, the pioneering system for validating safety valve performance in Conventional and Nuclear Power plants, as well as in other industrial process facilities.

For many years, ultrasound has been utilised by various vendors as an additional method to find the set point in cases the standard diagrams are hard to analyse. This can be the case when testing safety valves on liquid services.

Within an extensive benchmark test, METRUS in co operation with Sweden‘s biggest nuclear power station Ringhals AB investigated the approach to use ultrasound as an additional indication for the set point on liquid service safety valves. The result of 55 tests on different valves is that the „Ultrasound point“ is completely depending on the seat condition. This result perfectly first the fact that ultrasound will detect the start to leak point and not the set point (start to lift point).

Only on a new or freshly serviced valve, the set point will be close to the ultrasound point. Even tiniest soiling or improper maintenance will cause the ultrasound to severely „drift away“ from the true set point. Within a typical online safety valve testing scenario where a valve has not bee serviced for a year or more, it is not at all recommended to use ultrasound to identify the set point.

There are still two useful applications for ultrasound within online safety valve testing. A very simple but effective use is to compare the sound level of the valve before and after the test. Comparing those sound levels will indicate if after the test (disk lift) the valve is left in a similar condition to its previous untested state. This could be first information if the valve did properly reseat and seal after it has been lifted. White Paper – Online safety valve testing METRUS Valve Test Bench Exellence

Knowing why safety valves should be tested online and how this is done in theory, it is most helpful to get an idea of the every day questions you will have to deal with. It will enable you to imagine how online safety valve testing appears in real life.

Plant operators are often surprised when being asked by online testing engineers whether it is a problem to open a valve. Considering the definition of the set point to be the initial moment when the disk starts to lift the safety valve disk must lift to find that point in a test diagram. It very much depends on the test equipment how long and high the valve will open, but it definitely has to open. geöffnet wird.

To test a safety valve, it must be possible to lift the disk and measure the force when doing so. If a safety valve has a spindle, it is possible in 95% of all cases to test it online. Some valves might require a simple spindle modification. This depends on the valve and the adapter solution how to „connect“ the test rig. Valves that do not have a spindle at all can not be tested.

Valves installed on extremely dirty fluids like bituminous crude oil should not be tested unless they are equipped with a rupture disk to keep the seat clean. Dirt could prevent the disk from sealing properly and the valve will remain leaking after the test. It the maintenance departments decision whether to agree with slightly lifting a valve or not.

Safety valves installed in EEx areas require special equipment to operate the test rig. If such equipment is available, it is important to check the specific EEx certificate for the approved EEx class and EEx area. As of now and to our best knowledge, there is no online safety valve testing system available that has an EEx approval for the whole machine. The test rigs are approved but the power unit usually has to stay outside the EEx area or have to be protected with special temporary solutions.

A frequent question to be found in industry is „what is the highest set point and the largest nominal diameter you can test?“. According to the online testing formula of fig. 1 the set pressure is calculated from line pressure, seat area and test force. Those parameters interact. The more line pressure is to be found under the safety vales disk the less force is required to lift (test) it. A final statement can never be made as it depends on seat area, set point and line pressure, whether or not the force capacity of specific equipment will be strong enough to test a valve.

Some suppliers claim that their equipment can test „any“ safety valve. Technically speaking it means raising the line pressure will lead to a remaining test force small enough to be covered by the test equipments force capacity. As online safety valve testing should not affect the plant operation this statement is not very respectable. Usually the line pressure can not be changed significantly just to test a valve.

Thinking about the largest valves, small and medium valves are often forgotten. But those ½“ and 1“ valves built the majority of valves to be found in industry. It is a technical fact, that each measurement task requires suitable sensor ranges. Large valves require large forces and small valves usually small forces. The operational range of online safety valve test equipment is therefore not only defined by its strongest force capacity. It is a question how accurate it can deal with a variety of forces and pressures – small and large.

Online safety valve testing offers major cost saving potential. In most cases it is cheaper than workshop testing after comparing direct testing costs. This of course requires the test equipment to be efficient in handling and operation.

Safety valves need to be tested at various locations within a plant. It is common to move the test equipment a few times during a test day. Different valve types to be tested require retooling of the test rig. In every day life the equipment will be packed and unpacked several times and it will require adaptation to fit the test rig on the safety valve. Valves will be located on top of tall reactors and on difficult to reach places under or behind pipelines.

The test equipments performance is significantly defined by its mechanical performance – weight and flexibility. The time for unpacking and rigging up as well as for wiring all sensors etc. determines, how fast the individual valve test will be. And in many cases the safety valve requires adjustment. Depending on how long it takes to take the rig off the safety valve, testing and re-testing will be fast and efficient or time consuming.

Within a typical online safety valve test scenario, a valve might need to be adjusted. To adjust a valve, it requires to remove the rig (RR) adjust the valve (VA) and reinstall (RI) the rig before you can carry out the next test to see, if the adjustment was successful. This is done usually two times until a satisfying set pressure is adjusted.

The relation between handling and testing time in average test equipment is about 1/5. It becomes obvious that total test time and efficiency are significantly depending on the test rig performance – weight, portability and speed of set up / dismantling.

It may happen that safety valves stay open after the test. To make sure that such event does not affect the plant operation, a concept to remotely close the safety valve, using the test rig is absolutely necessary for safe online safety valve testing.

Testing safety valves online is not at all dangerous as long as the procedure is done properly and the system performs as it should. But there are rare scenarios in which a plant disturbance could appear, especially if a safety valve stays open or gets damaged.

Online safety valve test equipment today is either manually or electronically controlled. Electronic systems support the test process and monitor test limits, taking a lot of responsibility from the technician. TESON® e.g. automatically drives the complete lifting process, monitoring all sensor signals for pre calculated test limits. But electronic systems are sensitive to power black outs as well as to software malfunctions. To deal professionally with those, the online safety valve testing system must have an extensive safety system to guarantee the safety valve will never be blocked open or damaged – whatever might happen.

Manually controlled system are not sensitive to power black outs or system failures. They leave the full control over the test process to the technician. It is up to the technician to control the lifting force and whether or not to overload a valve. Especially with manually controlled system experience plays an important role as the safety issue is basically the human factor. Despite that even manually driven system must have some safety features to respond to hardware or hydraulic malfunction.

Considering the number of parameters to be considered and monitored during an online safety valve test, digital systems are definitely superior as the chance of malfunction and power black outs is considerably small if the systems are well designed and extensively tested. Even after intensive training and years experience it is barely possible for a technician to compete with the reliability and response time of a digital system. Considering the background of online safety valve testing it is a derived requirement of the system to be safely and correctly operated with minimum skill and experience.

When thinking of a first time investment, it is very often the purchase price that plays an important role. But if you consider the cost saving potential of online safety valve testing or the profit you could make with a service, it becomes obvious that there is more to be considered to get a real view on the cost of ownership.

Support from your supplier will be crucial for your business. If you are facing time sensitive testing sessions and your equipment gets damaged or you come across complex questions, delays of operations or loosing your customer to the competition can cause severe loss of profit. The system vendor should be able to minimize downtimes with an intelligent support strategy. This includes 24 h availability of technical support, access to most spare parts in local markets and availability of rental equipment to substitute yours during service and repair. The more a supplier is focused on the online safety valve testing business, the better resources he will offer to support your every day work.

Like all measuring equipment, online safety valve testing systems require calibration. Sensors and measuring electronic need calibration (typically every 2-3 years) to harmonize with ISO quality standards. Suppliers must be able to either offer you a calibration service or advice you where to get such service. To minimize transportation costs, the parts and modules that need calibration should be easy to isolate for shipping.

The variety of valves to be found in industry is huge. It is not at all practical to own every type of special equipment that might be required one day to test special applications. Your investment will be significantly lower if you can own core components that cover the majority of your every day online testing needs. Your supplier should offer you special extension for rent to cover the remaining applications once they are required.

We hope this white paper could draw a picture what online safety valve testing is about. If you have any further related question, please feel free to contact METRUS at any time. It will be our pleasure to support and consult you..

As soon as mankind was able to boil water to create steam, the necessity of the safety device became evident. As long as 2000 years ago, the Chinese were using cauldrons with hinged lids to allow (relatively) safer production of steam. At the beginning of the 14th century, chemists used conical plugs and later, compressed springs to act as safety devices on pressurised vessels.

Early in the 19th century, boiler explosions on ships and locomotives frequently resulted from faulty safety devices, which led to the development of the first safety relief valves.

In 1848, Charles Retchie invented the accumulation chamber, which increases the compression surface within the safety valve allowing it to open rapidly within a narrow overpressure margin.

Today, most steam users are compelled by local health and safety regulations to ensure that their plant and processes incorporate safety devices and precautions, which ensure that dangerous conditions are prevented.

The principle type of device used to prevent overpressure in plant is the safety or safety relief valve. The safety valve operates by releasing a volume of fluid from within the plant when a predetermined maximum pressure is reached, thereby reducing the excess pressure in a safe manner. As the safety valve may be the only remaining device to prevent catastrophic failure under overpressure conditions, it is important that any such device is capable of operating at all times and under all possible conditions.

Safety valves should be installed wherever the maximum allowable working pressure (MAWP) of a system or pressure-containing vessel is likely to be exceeded. In steam systems, safety valves are typically used for boiler overpressure protection and other applications such as downstream of pressure reducing controls. Although their primary role is for safety, safety valves are also used in process operations to prevent product damage due to excess pressure. Pressure excess can be generated in a number of different situations, including:

The terms ‘safety valve’ and ‘safety relief valve’ are generic terms to describe many varieties of pressure relief devices that are designed to prevent excessive internal fluid pressure build-up. A wide range of different valves is available for many different applications and performance criteria.

In most national standards, specific definitions are given for the terms associated with safety and safety relief valves. There are several notable differences between the terminology used in the USA and Europe. One of the most important differences is that a valve referred to as a ‘safety valve’ in Europe is referred to as a ‘safety relief valve’ or ‘pressure relief valve’ in the USA. In addition, the term ‘safety valve’ in the USA generally refers specifically to the full-lift type of safety valve used in Europe.

Pressure relief valve- A spring-loaded pressure relief valve which is designed to open to relieve excess pressure and to reclose and prevent the further flow of fluid after normal conditions have been restored. It is characterised by a rapid-opening ‘pop’ action or by opening in a manner generally proportional to the increase in pressure over the opening pressure. It may be used for either compressible or incompressible fluids, depending on design, adjustment, or application.

Safety valves are primarily used with compressible gases and in particular for steam and air services. However, they can also be used for process type applications where they may be needed to protect the plant or to prevent spoilage of the product being processed.

Relief valve - A pressure relief device actuated by inlet static pressure having a gradual lift generally proportional to the increase in pressure over opening pressure.

Relief valves are commonly used in liquid systems, especially for lower capacities and thermal expansion duty. They can also be used on pumped systems as pressure overspill devices.

Safety relief valve - A pressure relief valve characterised by rapid opening or pop action, or by opening in proportion to the increase in pressure over the opening pressure, depending on the application, and which may be used either for liquid or compressible fluid.

In general, the safety relief valve will perform as a safety valve when used in a compressible gas system, but it will open in proportion to the overpressure when used in liquid systems, as would a relief valve.

Safety valve- A valve which automatically, without the assistance of any energy other than that of the fluid concerned, discharges a quantity of the fluid so as to prevent a predetermined safe pressure being exceeded, and which is designed to re-close and prevent further flow of fluid after normal pressure conditions of service have been restored.

Solenoid directional valves and cartridges with inductive sensors to monitor the spool/poppet position, certified to Machine Directive 2006/42/EC. Pressure relief valves certified to PED 2014/68/EU.

The utility model is for satisfying the gas gathering and transportation device to be carried out the on-the-spot requirement that detects and debug with the safety valve performance parameter, and develops a kind of novel safety valve debugging apparatus.

The safety valve debugging apparatus, by air compressor machine, the source of the gas jar, gas-holder, the adjustment platform, switch board, the microcomputer testing management system, instrument and pipeline fittings constitute, the air compressor machine high-pressure air source is attached to the source of the gas jar by stop valve, source of the gas tank stores gases at high pressure and by control stop valve send into gas-holder, tested safety valve is installed on the adjustment platform that directly links to each other with gas-holder, switch board is concentrated installing pressure measuring instruments and pilot piping high sealing stop valve, the microcomputer testing management system is by safety valve adjustment platform, intelligent transducer, information module, computing machine, compositions such as LAN, intelligent transducer is installed on the safety valve adjustment stand of gas-holder outlet, it is characterized in that:

B, source of the gas jar, gas-holder adopt horizontal type structure respectively, and are provided with safety relief protective valve and tensimeter monitoring, in the gas-holder outlet microcomputer testing sensor contact are set;

C, adjustment platform are furnished with the above flange debugging frock of at least one cover, and the safety valve discharge flange is furnished with the noise reduction pipe fitting.

The utility model also is provided with pilot valve test gas-holder, adopts vertical installation, and gas-holder is provided with test pilot valve source of the gas control interface.

The utlity model has following advantage: 1. adopt the skid structure, innovatively the source of the gas jar, gas-holder, the adjustment platform, switch board, instrument and pipeline fittings are assembled into one on the skid base, make its compact conformation, convenient transportation, avoided on-the-spot complicated pipelines laying installation, be not subjected to any condition restriction during installation, can adapt to the field work condition of work especially, be beneficial to the online detection of oil-gas gathering and transportation system, solved at present big latus rectum, high pressure safety valve performance parameter test, the technical barrier that calibration equipment does not match is for the safety and reliability of gas gathering and transportation device provide necessary guarantee; 2. this device not only can satisfy the test of high pressure, big latus rectum safety valve performance parameter, also according to the needs of on-the-spot adjustment safety valve pilot valve, is furnished with pilot valve performance parameter test functional structure specially, be beneficial to and improve the on-the-spot test serviceability, carry out hermetic seal test detection needs for satisfying the gas gathering and transportation device with other valve type product, this device also is furnished with the gas source interface and the by-pass valve control of other valve type product of special detection, has had the characteristics and the effect of a tractor serves several purposes; 3. debugging of safety valve and management system combine with intranet, can realize the networking of safety valve testing management work, can implement management to the verification situation of safety valve in enormous quantities, comprise archives, verification and the maintenance status etc. of safety valve.Simultaneously, because database is left on the server, test data is fragile and lose, the test data personal error is little, true and reliable, from actual operating position analysis, this system can gather in real time to the force value in the checking procedure, measure set-pressure value, opening pressure value and blow pressure value exactly, the survey report of printout standard, and can also make things convenient for, promptly the every information and the data of safety valve be retrieved and inquired about, improve the automatization level of science, credibility and the management of safety valve testing process greatly.Can not only satisfy pilot operated safety valve pilot valve test and multiple universal valve performance test separately, but also have automatic recording functions such as the verification of measurement pressure, displacement, temperature and time, favourable technical application management and stroke analysis.

Use proof through the scene, this device output pressure is adjustable, the rate of rise is controlled, simple to operate, that operation detects data is accurate, can in time provide verification and report and carry out data management that performance is safe and reliable, the automaticity height.Can accurately test set-pressure, blowdown presssure and the blow pressure of PN≤16.0MPa, DN25~200mm specification safety valve, the accuracy class height, test specification is wide, and every technical performance index reaches the regulation of GB12242-1989, GB150-1998, " safe technology of pressure vessel supervision rules " standard.Satisfy the needs of national oil-gas gathering and transportation construction project, can be widely used in petroleum gas and adopt transporting operation district, collection defeated station, chemical industry metallurgical industry and safety valve testings at different levels station, market potential is big, has remarkable economic efficiency and social benefit.

8613371530291

8613371530291