non rotation vs rotation resistant wire rope quotation

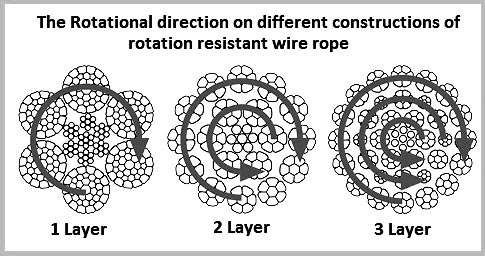

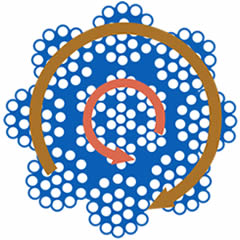

Rotation resistant wire rope refers to a series of steel ropes which minimizes the tendency to spin or rotation under load. These wire ropes boast special design - the outer layer is twisted in the reverse direction of inner layers for counteracting torsional forces generated from multi-layers of strands.

To achieve the resistance against the spin and rotation, all wire ropes are composed of at least two layers of strands. In general, more layers a rotation resistant wire rope has, more resistance it will boast. For example, 2-layer ropes is much easier to spin and rotate than 3-layer ones. Meanwhile, if one end of free rotation is allowed, 2-layer rope can only develop 55% to 75% of its breaking strength comparing with 95% to 100% of 3-layer ropes.

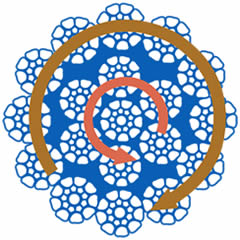

The 3-layer rope with more outer strands is capable to distribute more radial pressure onto inner layers and ideal for larger mobile such as all tower cranes.

Wire ropes with 8 to 10 strands & 2-layer constructions without reversely twisted inner strands have very similar appearance to rotation resistant wire ropes, but they are not.

Rotation resistant wire ropes are considered to be less stable needing to be handled and installed with great care. They must be taken to avoid high loads with small diameter sheaves.

The characteristic of these wire ropes are that the outer layer is twisted in the opposite direction of their inner layers. The sometimes confusing issue is that many 8-, 9- and 10 strand constructions are 2-layer types but their inner strands are NOT twisted in the opposite direction and therefore these rope are NOT spin-resistant; plus, for the untrained eye these ropes look very much alike their spin-resistant variants. These and regular 6-strand ropes will spin violently and unlay themselves when loaded when one rope end is allowed to spin freely. They may also develop a significant drop in breaking strength and an even larger drop in their fatigue life characteristic (Torsion Fatigue).

To achieve any degree of resisting the tendency of a rope to spin and unlay under load all such rope types (other than 4-strand ones) are constructed with 2 or more layers of opposite twisted strands (see picture on right).

2-layer ropes (MULTI, COMPAC 18) have a larger tendency to rotate than 3-layer ones (e.g. Class 34 x 7, COMPAC® 35). Furthermore, 2-layer spin-resistant and rotation resistant ropes will develop only about 55% to 75% of their breaking strength when one end is allowed to rotate freely. This number increases to between 95% to 100% for 3-layer (e.g. COMPAC® 35) non-rotating ropes.

Another important issue is that 2-layer rotation resistant and 2-layer spin-resistant rope types have shown to break up from the inside. The 8 (e.g. 8×25 spin-resistant) or 12 outer strands (19×7, 19×19, COMPAC®18) are not able to evenly distribute the radial forces and because of the inherent internal strand cross overs (which make the rope spin- or rotation resistant) the resultant severe notching stresses cause the rope core to break up premature (unless the core is plastic coated, e.g. Python® Multi). Unexpected and sudden rope failures may be the result. Moreover, 2-layer spin-resistant or rotation resistant ropes satisfy only low to moderate rotational resistance demands.

3-layer rope constructions (e.g. COMPAC® 35) have many more outer strands which can much better distribute the radial pressures onto the reverse lay inner strands. These ropes should be selected for larger mobile- and ALL tower cranes.

Rope Services Direct supplies a variety of anti-spin non rotating wire rope (also called rotation resistant wire-rope). All standard rope wirehas a tendency to develop torque and therefore prone to rotation, whereas non-rotating wire ropes are designed so that the wire-rope outer rotational force naturally counteracts the inner strands rotational force. This is in the event that a rope is subjected to a load.

Rope elongation and rotation occurs on standard ropes when loaded, which can therefore spin the load, quite possibly out of control, which can be dangerous. When the rope rotates in this way the strands will begin to unravel. This causes the rope to lose strength and will undoubtedly fail, which could be catastrophic. It is for these reasons that non rotating wire rope is commonly used for many types of lifting applications including main hoist rope, whip rope,crane rope, off-shore and deck rope and more.

Non rotating wire rope or rotation resistant wire rope has a different construction to standard. as wires and strands are not laid in the same direction like they would be on standard rope. Inner and outer strands of wires are laid in opposite directions. For example the inner may be constructed in left hand lay whilst the outer layer is in right hand lay. The nature of this construction means that torsional forces on the inner and outer wires/strands will counteract each other and therefore minimising the risk of unraveling.

It is worth noting that the number of strand layers will have an effect of the resistance of rotation. A 2 layer rope has less resistance than a 3 layer rope. Therefore the more layers the rope has the greater rotation resistance it will have.

These types of ropes can be classified as spin resistant, rotation resistant or non rotation resistant. Classed on the basis of the number of rotations a certain length of rope does when a force of 20% of the MBF is applied; with 1 turn or less the rope will be classified as non rotating; with rotations between 1 & 4 the rope is classed as low rotation and for rotations between 4 & 10 the rope will be classified as spin resistant, any higher and the rope is NOT rotation resistant at all.

Correct usage and care with handling will prolong the working life. This is due to the friction on the inner wires caused by the strand crossover’s which will eventually cause the inner wires to break up. This is more apparent on non rotating wire rope with two layers. Ropes with 3 or more strand layers will distribute the radial pressures more evenly. Which will reduce friction and stress on the inner wires.

Regular,thorough inspectionsof non rotating rope are essential due to the fact that it is the inner strands that often break first and broken internal wires often go unnoticed as they are difficult to see.Rope Services Direct offer inspectionson all rope with certification issued on completion.

Holding both ends of the rope will prevent unraveling. Correctly fitted terminations will help to prevent damage. Kinking and unraveling may occur and they can also have an effect on the rotational balance if not fitted correctly.

Rotation resistant ropes are known to provide the best and most economical services for specific applications. When the correct ropes are selected and appropriately used, they are unmatched in the lifting market. Elephant hoists greatly benefit from rotation resistant wires.

Rotation resistance is created when wires are laid in a contra-helical position. These ropes are different from standard construction types because rotation resistant ropes are required to meet a different and higher set of service requirements. The modes of wear and failure for these ropes vary more than standard constructions. Special operational needs make specific limitations and special handling necessary. These are not encouraged with standard constructions.

Testing on ropes that are resistant to rotation commonly shows that the total length of service for these ropes is shorter than that of standard construction ropes. The tests show that there is a need for separate guidelines for the use, inspection, retirement, and application of resistant ropes.

Using a swivel at the load hook for rotation resistant ropes results in unpredictable service life. This type of practice can potentially lead to unbalanced loading between outer and inner layers of strands. This typically results in core failure. Any significant changes in diameter found in a small length of operating rope should be retired and replaced. Make sure to use appropriate rigging supplies for all crane wire rope applications.

For more information on the benefits of rotation resistant ropes, you should not hesitate to give our team a call. Do not forget to ask about our V rope options.

Widely used for hoisting unguided loads with a single part of rope. Typical applications are hoisting ropes on Derricks, boom cranes, shaft sinking hoists and freely suspended mine hoists. Both 19 X 7 and 8 X 19 are bright, right regular lay wire ropes.

Inner strands are left lang lay; outer strands are right regular lay; the natural rotation tendency of one layer is counter balanced by the other. Not recommended for multiple part lifting.

Inner and outer strands are laid in opposing directions to counter rotation. Although less rotation resistant, 8 X 19 has a higher strength factor. Acceptable for multiple part lifting.

Actual operating loads may vary. NEVER exceed the recommended design factor of 20% of catalogue strength. Wire Rope must have the strength required to handle the maximum load plus a design factor. The design factor is the ratio of the breaking strength of the rope to the maximum working load.

We understand that there are many factors that go into choosing the correct sling, wire rope, rigging hardware or lifting device for a lift! Let our sales team help!

Main and auxiliary hoist line for mobile and for all types of construction tower cranes which require a high strength rotation resistant rope construction.

The large number of outer strands distribute the pressures introduced by sheaves and drum more evenly onto the core minimizing the danger of unexpected rope failures because of undetected core deterioration.

Aside from this safety issue PYTHON® COMPAC 35 satisfies the high-strength requirements of late model tower and mobile cranes which can NOT be met with neither 19 x 7 nor 19 x 19 style ropes.

Our company is the major in offering Rotation Resistant Wire Rope to the clients. Rotation Resistant Wire Rope is manufactured using superior grade galvanized iron and latest technologies for ensuring its quality. Our product is known for its excellent tensile strength, corrosion resistance, finest finish and superb performance.

YES, Compac 35® ropes can be used with a swivel at the end. In fact, we suggest you use a swivel during installation and the ‘break in’ period to get the rope settled. After the break in period you can lock the swivel to stabilize the rope.

When properly used Compac 35® is stable against block twisting. Fleet angles, small sheaves, small line spacing, low block weight will negatively impact this characteristic.

Main and auxiliary hoist line for European type mobile cranes as well as all types of construction tower cranes which require a high strength rotation resistant rope construction. Excellent rotation resistant properties make this rope the preferred choice for all single and multiple line reeving applications.

This rope is constructed from 16 outer die-drawn strands over 12 inner die-drawn strands. The compacted Lang Lay strands reduce interlocking while spooling onto multiple layer drums as well as inter strand and inter layer nicking. Improved abrasion resistance because of increased wire surface contacting the sheave.

This rope is suited to be used on tower cranes as well as European made mobile crane models. The large number of outer strands distribute the pressures introduced by sheaves and drum more evenly onto the core minimizing the danger of unexpected rope failures because of undetected core deterioration.

Aside from this safety issue PYTHON® COMPAC 35 satisfies the high-strength requirements of late model tower and mobile cranes which can NOT be met with either 19×9 or 19×19 style ropes.

Note: The maximum CAPACITY, WORKING LOAD LIMIT (WLL),or LINE PULL of the rope usually is 1/5 of the below stated values. For specific information consult the standards applicable to your rope application.

Recommended to be used on tower, European type mobile and offshore cranes. Available in left and right hand lang’s lay construction. Recommended if you require a rope for single line hoisting applications.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.

For industries that use wire rope, it’s frustrating and potentially dangerous if the rope spins or rotates. Unless using non-rotating steel wire rope, it can take longer than necessary to complete a job. At Murphy Industrial Products, Inc., we have a perfect solution. Our line of non-spin wire rope is reliable, safe, and cost-effective.

We manufacture our non-rotating wire rope in compliance with the Federal Specification RR-W-410E. That means our 35x7 wire rope meets or even exceeds industry standards. In addition, the non-spin wire rope we manufacture meets the performance requirements of both API-9A and A.S.T.M. A1023/1023M Wire Rope. So, it is rated as a top-of-the-line rope for general purposes.

One advantage of buying non-rotating steel wire rope manufactured by Murphy Industrial Products is that we keep a broad range of products in stock. If you need to have a product delivered quickly, we can accommodate. In fact, if you place an order for non-spin wire rope before 3:30 p.m. C.S.T., Monday through Friday, we can ship it out to you that same day at no extra charge.

The non-rotating wire ropes we produce are of the highest quality possible. They are ideal for building cranes, mobile cranes, offshore cranes, and main hoists. Our non-spin wire ropes can handle a range of minimum breaking loads, from 5.1 tons to 138 tons.

The most important factor in selecting the right wire rope for the job in hand is deciding whether a rope type is to be rotation resistant or non-rotation resistant. This point needs to be considered very carefully as using the wrong rope type can have serious consequences, for example, shortened service life, changes in the rope structure, unintentional rope breaks.

Rotation resistant ropes must be used for the lifting of an unguided load on a single fall,the lifting of an unguided load on several falls at a great lifting height

Non-rotation resistant ropesmust be used for the lifting of a guided load,the lifting of unguided loads on several falls at low lifting heights,the lifting of loads with right-handed and lefthanded ropes operating in pairs, Non-rotation resistant ropes must not be used with a swivel.

The characteristic of these wire ropesare that the outer layer is twisted in the opposite direction of their inner layers. The sometimes confusing issue is that many 8-, 9- and 10 strand constructions are 2-layer types but their inner strands are NOT twisted in the opposite direction and therefore these rope are NOT spin-resistant; plus, for the untrained eye these ropes look very much alike their spin-resistant variants. These and regular 6-strand ropes will spin violently and unlay themselves when loaded when one rope end is allowed to spin freely. They may also develop a significant drop in breaking strength and an even larger drop in their fatigue life characteristic (Torsion Fatigue).

To achieve any degree of resisting the tendency of a rope to spin and unlay under load all such rope types (other than 4-strand ones) are constructed with 2 or more layers of opposite twisted strands (see picture on right).

2-layer ropes (MULTI, compacted 18xk7) have a larger tendency to rotate than 3-layer ones (e.g. Class 34 x 7, compacted 35WXK7). Furthermore, 2-layer spin-resistant and rotation resistant ropes will develop only about 55% to 75% of their breaking strength when one end is allowed to rotate freely. This number increases to between 95% to 100% for 3-layer (e.g. 35WXK7 compacted) non-rotating ropes.

Another important issue is that 2-layer rotation resistant and 2-layer spin-resistant rope types have shown to break up from the inside. The 8 (e.g. 8×25 spin-resistant) or 12 outer strands (19×7, 19×19, 18XK7) are not able to evenly distribute the radial forces and because of the inherent internal strand cross overs (which make the rope spin- or rotation resistant) the resultant severe notching stresses cause the rope core to break up premature (unless the core is plastic coated). Unexpected and sudden rope failures may be the result. Moreover, 2-layer spin-resistant or rotation resistant ropes satisfy only low to moderate rotational resistance demands.

3-layer rope constructions (e.g. compacted 35WXK7) have many more outer strands which can much better distribute the radial pressures onto the reverse lay inner strands. These ropes should be selected for larger mobile- and ALL tower cranes.

Non-rotating (non-rotational) wire ropes are used in various on and offshore cranes, various machinery, winches and trolleys, in the maritime and fisheries sector, on and offshore oil exploitation, civil and industrial construction, engineering and infrastructure works, underground and surface mining, timber mining and numerous other industries and applications.

8613371530291

8613371530291