ordinary lay wire rope in stock

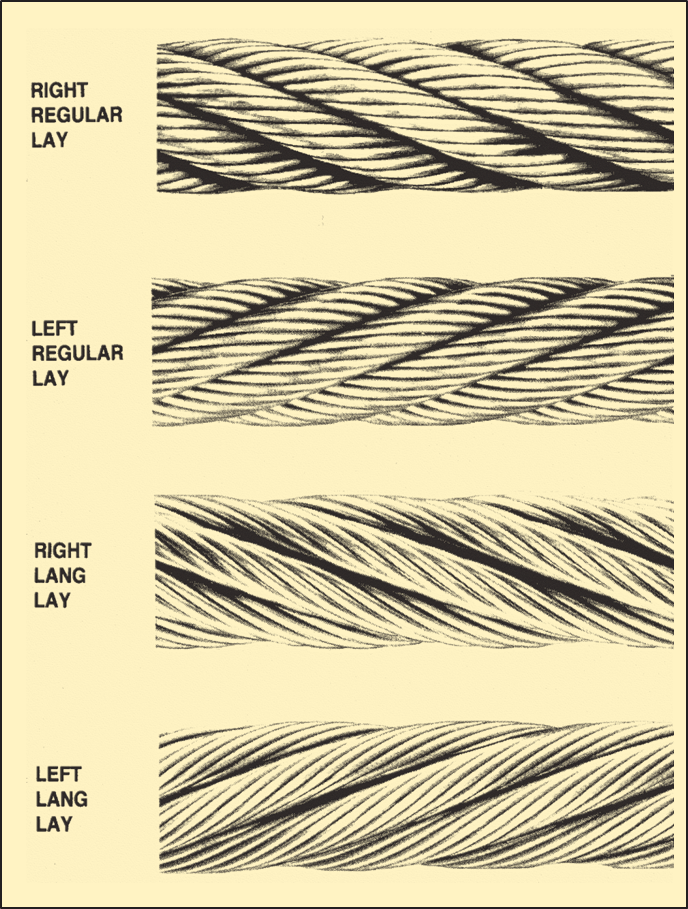

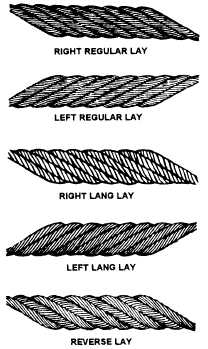

Left hand lay or right hand lay describe the manner in which the strands are laid to form the rope. To determine the lay of strands in the rope, a viewer looks at the rope as it points away from them. If the strands appear to turn in a clockwise direction, or like a right-hand thread, as the strands progress away from the viewer, the rope has a right hand lay. The picture of steel wire rope on this page shows a rope with right hand lay. If the strands appear to turn in an anti-clockwise direction, or like a left-hand thread, as the strands progress away from the viewer, the rope has a left hand lay. (The rope in the left hand lay photo shows one left hand lay rope from left to right and top to bottom, with 5 right hand lay strands, and part of a sixth in the upper left. It is not 5 right hand lay ropes adjacent to each other.)

Ordinary and Ducay"s lay describe the manner in which the wires are laid to form a strand of the wire rope. To determine which has been used, first identify if left or right hand lay has been used to make the rope. Then identify if a right or left hand lay has been used to twist the wires in each strand. (On ordinary lay, the outer wires approximately follow the alignment of the rope: with Lang"s lay they are cross at an angle of about 45�.) Lang"s laid rope is able to flex over sheaves more easily (with less damage) but it has the disadvantage of having a high torque tendency (it tends to untwist when tension load is applied) compared with ordinary laid rope. Untwisting can be dangerous with a steel-cored rope: load is shed from the strands and may cause the core to fail as it becomes higher loaded. For this reason, swivel termination units can be dangerous.

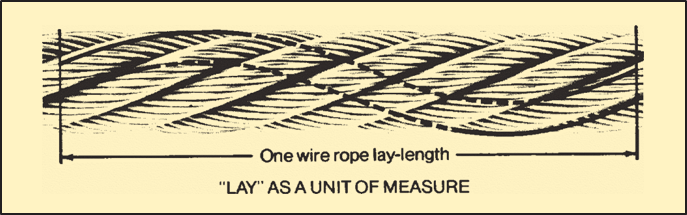

The specification of a wire rope type � including the number of wires per strand, the number of strands, and the lay of the rope � is documented using a commonly accepted coding system, consisting of a number of abbreviations.

When discussing the physical properties of wire rope, people often focus on the material, strength, and size specifications above all else. While these details are essential to understand how a product will survive in the field, they are not the only factors that drive cable performance. In fact, the lay direction of a cablehas as much impact on its functionality as any of the other aforementioned characteristics, because it determines how much a cable will rotate, twist, and kink.

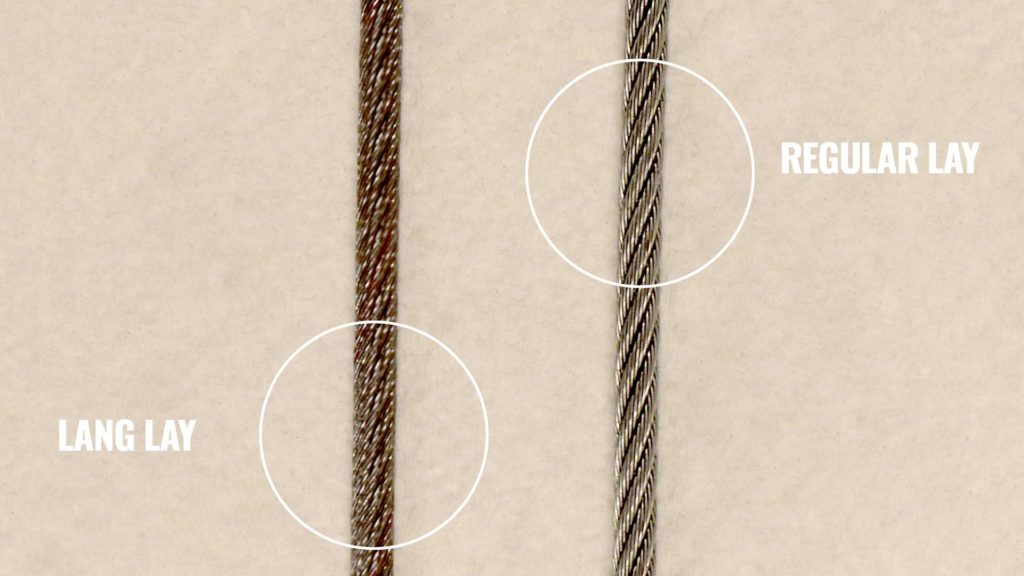

Lay direction describes the relationship between the way wires are wrapped into strands, and the way those strands are wrapped into wire ropes and cables. In general, there are two different configurations of lay directions: regular lay, and lang lay, which can rotate either to the left or to the right.

In a regular lay cable, the wires and strands are laid opposite to each other. In other words, all of the wires are laid in one direction as they are made into strands, and those strands are then laid in the opposite direction of the wires as they are combined into cable. When looking along a length of regular lay cable, the wires will appear to run parallel and straight the entire way. You can tell a cableis right regular lay because the strands will all flow to the right, or clockwise direction, compared to a regular left lay cable which flows the strands in a leftward, counterclockwise direction.

In a lang lay configuration, the wires and strands are laid in the same direction. If all the wires are laid to the right as they are made into strands, then those strands will also be laid to the right as they are combined into cable. The same applies to a left lang lay configuration, where both the wires and strands would lay to the left. When looking along a length of lang lay cable, the wires will appear to angle across the rope, following the general flow of the strands. You can tell a cable is a right lang lay cable because both the wires and strands will flow rightward, in a clockwise direction. A left lang lay cable flows both wires and strands in a leftward, counterclockwise direction.

Cable is generally manufactured with a standard right regular lay because it is useful for a variety of different applications and complies with most equipment. In general, regular lay cable is more resistant to crushing forces than lang lay cable of an identical material and size, though lang lay cable is typically more flexible. Lang lay cables are usually more susceptible to pinching and kinking than regular lay, which means they are better suited to hoisting applications where the cable only moves along one axis.

In summary, the wires and strands in regular lay cable flow in opposite directions while the wires and strands in lang lay cable flow in the same direction. Lang lay cable is great for lifting, hoisting, and push-pull applications, while regular lay cable outperforms in situations where bends are required. To learn about our range of flexible, non-rotating, and non-flexible wire rope and aircraft cable, visit https://strandcore.com/products/aircraft-cable/ or contact us at https://strandcore.com/contact/.

Equivalent Wire Rope for Stahl, Rope Length: 45 m, Diameter: 9 mm, Lay Type and Direction: Right Hand Ordinary, Minimum Breaking Load: 77.900 kN (replaces 443405240)

It is important to attach steel wire ropes at the correct locations on a smooth drum as improper winding methods will cause the spreading of terns in the first layer of steel wire ropes on the drum. Then the second layer of wire ropes may be wedged between the open coils of first layer, crushing and flattening the rope as successive layers are spooled.

Generally, steel wire ropes are wound from the top of the one reel to the top of another or from the bottom to bottom. But how to start wire ropes on a drum may puzzle lots of our customers. The following illustration will give you the best solution.

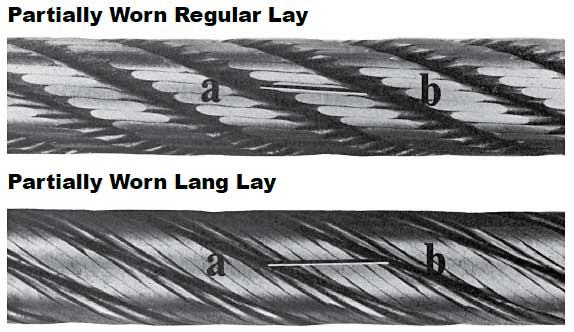

For the same size and construction (ropes having the same wire sizes and lays) lang lay ropes are somewhat more flexible than regular lay and have several times the wearing surface per wire to resist abrasion—as seen in the photos below:

Both ropes shown in the photos have been ground to the same reduction of rope diameter so as to show this comparison of the abraded areas of the wires.

The lang lay ropes, as usually made, are about 15% more flexible than the same construction of regular lay ropes. But, this value will vary depending upon the relation of the strand lay to the rope lay.

On the other hand, very small sheaves or pinching grooves in sheaves are both detrimental to lang lay ropes, the latter frequently causing “bird-caging” of the rope.

The wires of the regular lay ropes are subjected to higher unit pressure when the rope is passed over sheaves or drum, causing a somewhat heavier transverse pressure within the rope structure. Thus, the “bending” stresses are somewhat higher in the regular lay rope and it is termed “stiffer.”

The mobility of and capacity of shifting among the wires is greater in the lang lay. It is this very feature, combined with the longer exposed length of wires, that causes a misplacement of the wires in the lang lay when bent over sheaves at or near the critical tread diameter, not withstanding the somewhat greater inherent flexibility of the lang lay for normal service.

While the total area of surface wear on the rope as a whole is the same for the two types of same construction ropes for a given depth of wear, the wear on the equipment and largely the rope service rendered would favor the lang lay construction.

It is therefore not the total area of worn surface of the rope as a whole, but the nature of such wear that causes longer life to the equipment and to the rope where lang lay ropes can be economically used. To explain this “nature” of wear, we show both on the photo below—lines “a-b,” the line of contact of a moving rope with the sheave; “a-b” is parallel to the direction of rope travel, that is, to the longitudinal axis of the rope.

It will be noted that in the regular lay, the line of contact is axial with one wire; in the lang lay (for the 6 x 19 Seale construction used in this comparison), the line of contact is diagonally across three worn wires.

The shorter exposed length of the worn wires in the regular lay rope causes these wires to spring up, arching radially away from the axis of the rope as in figure below. That causes heavier individual pressure of the wires on the sheave and an earlier fatigue failure of these wires at the “neck” of wear due to local reverse bending when the contact pressure with the sheave depresses this wire. The stiffer the wire (that is, the higher the strength or grade of wire), the more pronounced this arching of the wires at the thinnest worn section or “neck.”

I’d like to pass along some insight into what makes these slings, from their construction to the maintenance and inspections that keeps them safe but, at the same time, don’t want to make your eyes bleed. That said, today, we’ll cover wire rope and we’ll cover the other sling types in future installments.

So we all know wire rope derives its strength from the strands of wire that are twisted around a core cable, right? You may ask what else is there to know about their construction beyond that. Well, frankly, a lot.

Our rental fleet has sizes of wire rope ranging from 3/4” up to 4” in diameter for single part slings and 2-1/2″ to 11″ diameter in our 9-part braided slings, but there are larger varieties available for purchase. Each wire rope sling is made up of several strands, which is then twisted in a helix around a central strand that is often the same composition as the outer strands. A wire rope strand is typically made up of anywhere between 19 and 36 wires but can reach as high as 109 wires, which are then twisted around a core wire or strand, depending on the configuration of wire rope.

Knowing the composition of the sling you’re using gives an understanding of what the rope will be able to do or, in some cases, how it will act. Various configurations exist to combat crushing, allow for greater flexibility or reduce the chances of rotation among other things. Ensuring you’ve got the correct wire for the project can be the difference between a successful job or causing damage or complete failure. As a general rule of thumb, improving one aspect will tend to reduce another. For example, a wire rope made up of smaller diameter wires provides increased flexibility, but doesn’t offer great abrasion resistance, whereas a wire rope of larger wires increases abrasion resistance while remaining more rigid.

The most common configuration of wire rope, the 6×19 class, consists of six outer strands comprised of 15-26 wires each that are twisted around a center core of smaller diameter wires in a 6×19 configuration consisting of the same number of wires as the outer strands. This configuration offers greater abrasion and crushing resistance while sacrificing a bit of flexibility and is available in sizes ranging from 3/4″ to 1-1/8” outer diameter. The next variation, for thicker outside diameters, is the 6×36 class comprised of six outer strands made up of 27-49 wires. This configuration offers increased flexibility due to the thinner wire diameters while maintaining crushing resistance but does sacrifice some of the abrasion resistance seen on the 6×19 class. LGH has 6×19 and 6×36 wire ropes from 1-1/4” to 4” outside diameter ranging from 5.6 to 130 tons safe working load (SWL) as well as 9-part braided slings that range from 59 tons to 485 tons SWL.

The next aspect of wire rope to consider is the lay of the wires that make up the strands as well as the way the strands are laid around the core. There are two main classifications of wire rope lay seen with alternating directions within each. These classifications are Regular Lay and Lang Lay.

Regular Lay wire ropes are formed with the wires that make up the strands being twisted in one direction, either left or right, and the completed strands are then laid the opposite direction, which causes the finished product to appear like the wires are running parallel to the axis of the rope. Regular lay rope is more flexible and carries better resistance to crushing forces and is easier to splice than Lang lay rope but has a shorter lifespan. Regular lay rope also tends to spool on a drum more easily and is naturally more rotation resistant.

Both regular and Lang lay can be spun clockwise (right lay) or counterclockwise (left lay) as seen in the photo above. The starting point and spooling direction of your winch drum will determine which direction is appropriate for your project.

Lang Lay wire ropes have both the wires forming the strands and the finished strands twisted the same direction, either right or left, and causes the finished product to appear with the wires running diagonally to the axis of the rope. The advantage of Lang lay rope is the increased abrasion resistance leading to a longer lifespan, but that comes at the price of flexibility.

During production, wire rope is heavily lubricated, allowing the lubricant to penetrate throughout the entire rope and into the core, which allows for slight movement of the individual wires within the rope to increase the lifespan of the rope as well as to reduce friction of the ropes as they rub against one another. From this point, maintaining proper lubrication is critical in preserving the life and structure of the wire rope and should be addressed with a combination of penetrating and coating lubricants. Penetrating lubricants reach the core and coat each strand of wire by utilizing petroleum solvent that evaporates once it reaches into the core and leaves the lubricants behind. Coating lubricants would then be used to seal the outside of the cable from moisture and reduce wear and corrosion during use.

The Discover television series “How It’s Made?” came out with an episode in 2011 showing the production of wire rope as well as crane cable and would make for an interesting view if you have five minutes available, providing further insight into the intricacies of wire rope and its composition. You can find that video here.

For more information or to rent wire rope slings and accompanying equipment, reach out to Lifting Gear Hire at www.rentlgh.com or call us at 800-878-7305.

Regular Lay ropes, Right hand Lay ropes, Lang Lay Ropes, Left hand Lay Ropes... these are the commonly-use terms in the industry for specifying the lay types of the wire ropes to be used, however have you ever look into how these common wire rope lay types look like?

The spiral of the wire ropes, which the wires are being laid into forming a strand, and thereafter the strands are being laid around the core forms the direction and the lay of the wire rope.

Understanding the basics of wire rope will help guide you on how to choose the right wire rope for your job. Application, required strength, and environmental conditions all play a factor in determining the type of wire rope that is best for you.

But when it comes to buying wire rope, the various numbers and abbreviations that describe the different types of wire rope can be confusing. EIPS wire rope, 6X19 IWRC wire rope, and lang lay wire rope are just some of the many variations available. But what does it all mean?

Displayed as inch or fractional inch measurements, the size indicates the diameter of the rope. Industry standards measure the rope at its widest point. A wide range of sizes are available from 1/8” wire rope to 2-1/2” wire rope. Thicker sized wire rope has a higher break strength. For example, our Wire Rope has a 15,100 lb. break strength while our Wire Rope has a 228,000 lb. break strength.

The numbers indicate its construction. For example: in wire rope, as shown above the first number is the number of strands (6); the second number is how many wires make up one strand (19).

When it comes to wire rope basics, regular lay also refers to right lay or ordinary lay. This indicates that the strands pass from left to right across the rope and the wires in the rope lay in opposite direction to the lay of the strands. This type of construction is the most common and offers the widest range of applications for the rope.

This term indicates that the wires twist in the same direction as the strands. These ropes are generally more flexible and have increased wearing surface per wire than right lay ropes. Because the outside wires lie at an angle to the rope’s axis, internal stress is reduced making it more resistant to fatigue from bending. This type of rope is often used in construction, excavating, and mining applications.

Independent wire rope cores offer more support to the outer strands and have a higher resistance to crushing and heat. Independent wire rope core also has less stretch and more strength.

Many of our customers use our rope and our wire rope clips to create rope assemblies. Check out of video blog on Wire Rope Clips to Wire Rope Assemblies to learn more.

For any questions on our wire rope products, call (877) 923-0349 or email customerservice@uscargocontrol.com to speak with one of our product experts.

Wire rope can be seen everywhere around us, it is made of strands or bundles of individual wires constructed around an independent core, suitable for hoisting, towing, and anchoring heavy loads.

Wire rope is specified by the number of strands in the rope, the number of wires in each strand, and the strands are then twisted to form a rope construction.

The wire rope core is in the center of the rope and provide the rope stability, it is the foundation for the wire rope. Cores can be supplied with natural or synthetic fibers and steel core. For example, the 6×19 FC wire rope means that the rope has 6 strands, and there are 19 wires in each strand, the numbers 6×19 is followed by a letter combination, it means the core of the wire rope, FC means fiber core.

IWRC is commonly manufactured from 7 strands, while the WSC is manufactured from either 7 or 9 wires. Steel cores have a higher resistance to drum crushing and where less stretch and more strength is required.

The 6×19 FC wire rope means that the rope has 6 strands, and there are 19 wires in each strand, however, 6 x 19 wire rope may not reflect the actual construction, for 6 x 21 wire rope, and 6 x 26 are designated as being in the 6 x 19 classification, despite none of their constructions contain 19 wires.

There are many different wire rope grades, the higher grade, the higher min breaking strength, commonly the grades of wire rope are available include Improved Plow Steel (IPS), Extra Improved Plow Steel (EIPS), Extra Extra Improved Plow Steel (EEIPS), and metric wire rope grades can be designated as 1770n/mm²(Improved Plow Steel), 1960n/mm²(Extra Improved Plow Steel) and 2160n/mm²(Extra Extra Improved Plow Steel).

There are main three protective coatings on the wire rope, zinc-coated (galvanized) wire rope for harsh environment, uncoated steel (bright) wire rope for most running supplied, and stainless steel wire rope for marine and architectural applications.

The type and direction of lay wire rope mean the wires are laid around the strands(regular lay or lang lay) and the direction in which the strands are laid around the core(a right or left hand).

Regular lay is also referred to as ordinary lay. The strands are twisted in one direction, either left or right across the core and the wires are laid in opposite direction to the lay of the strands, which causes the finished product to appear like the wires are running parallel to the axis of the rope.

The regular lay wire rope is more flexible and carries better resistance to crushing forces and is more naturally rotation-resistant and spool better on a drum than lang lay wire rope.

The lang lay wire rope indicates that the wire lay and strand lay around the core in the same direction, either right or left and causes the finished product to appear with the wires to form an angle with the axis of the rope. Thes lang lay ropes are generally more flexible and have increased abrasion resistance leading to a longer lifespan than regular lay ropes, which can be used in construction, excavating, and mining applications.

Wire rope is constructed of multiple strands of wire that are twisted and braided together to form a spiral design or helix. Once the separate wires are shaped into a solid form, they become a single wire with greater strength because the individual wires equalize pressure and have greater flexibility than the individual strands.

To further enhance the strength of wire ropes, they are grouped and wound together to produce cables, which adds to their usefulness as a means of support, ability to lift, and give structural stability.

A key factor in wire rope is the lay of the strands, which can be regular or lang. With regular lay, or right and ordinary lay, the strands are wound from left to right with the wires laid in the opposite direction of the lay of the strands. With lang lay, the wires are wound in the same direction.

The structure and design of wire rope produces a final product that has superior strength, excellent strength flexibility, and the ability to handle constant bending stress as well as being weather resistant.

Wire rope is one of those products that has found a place in a wide variety of industries since it can be adapted and shaped to fit several applications. It can be found as a tow cable for boats and airplanes or in the movie industry as a harness for stunt artists. The varied uses of wire rope have made it an essential part of operations that require a rope with strength, endurance, and flexibility.

In the aerospace industry, wire ropes, or Bowden cables, connect pedals and levers in the airplane cockpit to send power to aircraft systems to control the airplane. The things that are controlled by wire ropes are propeller pitch, cowl flaps, and throttle. Wire ropes on aircraft are insulated to avoid vibrations.

Wire rope is extensively used in the auto industry for a wide variety of applications due to its versatility and strength. It is used for raising windows and opening and closing sunroofs. Other uses include steering wheels, cables, exhausts, springs, sunroofs, doors, and seat components. In the manufacturing process, wire rope is used to hoist vehicles, move large body parts, and on hoists and cranes.

The construction industry has a greatest reliance on wire rope because of the need to lift and lower heavy loads. Wire rope used in construction must have extremely high strength and exceptional performance for safety reasons and efficiency. Larger versions of wire rope are used for suspension bridges and supporting concrete columns.

The main use of wire rope in food processing is for lifting, moving loads, and other heavy tasks. Finished products or raw materials require being moved in storage units and processing centers. The strength and endurance of wire rope makes it possible to move these materials. Wire rope for food processing must be able to withstand regular chemical cleaning.

As with other industries, the oil and gas industry needs strong and reliable equipment for moving heavy equipment. In ocean drilling, machinery is dropped into the ocean using wire rope to securely hold devices to be dropped to extreme depths. Wire ropes are designed to withstand the extreme pressure and stress required. A further use of wire ropes for drilling operations is to maintain stability in the drilling lines. One of the unique features of oil rig wire rope is its length, which can exceed 10,000 feet.

A very common use for wire rope is mooring and towing of sea and freshwater boats and vessels. In the shipbuilding industry, wire rope is used to secure lifeboats as well as lower them into the water. On sailboats, wire rope is used to lift and lower sails. The benefit of using wire rope is its resistance to corrosion and rust caused by salt water and ocean mist.

The skiing industry, much like heavy equipment industries, uses wire rope to hold cars, lifts, or chairs to transport skiers up the mountain. This type of wire rope comes in several varieties depending on the size of the mountain. The benefits of wire rope for skiing is its dependability, guaranteed safety, and reliability. The main challenge of wire rope for use in sports is the weather conditions it must endure.

Since the beginnings of amusement parks, wire rope has been an essential part of attraction construction. It is used to bring roller coaster cars to the top of the ride, hold swings, and pull various vehicles through attractions. One of the main concerns of public amusement parks is safety since rides are filled with powerful machinery designed to operate continuously.

Making the dangerous and exciting shots in movies requires well planned safety precautions. One of the aspects of that planning is wire rope that is designed to protect performers when they are engaged in dangerous and life threatening shots. Dependable wire ropes are ideal since they have the flexibility, strength, endurance, and versatility to be adapted to any conditions.

In architecture and design, wire rope has been used for guard rails, balustrades, and roof construction. In innovative green buildings where plants grow along the surface of the building, the plants grow along specially designed vertical wire ropes that are capable of withstanding weather conditions.

A common use of wire rope is in railings, which are safe, durable, and provide a pleasing aesthetic appeal. The use of wire rope for railings provides protection without obstructing the view from a building. This aspect of wire rope is one of the reasons that it is used for large architectural projects since it blends into the structure without interiors with the architectural design.

The types of wire rope are determined by the number of wires in each strand and how many are in the rope, which is defined by a two number system with the first number being the number of wires and the second being the number of wires in each strand. For example, a 6x19 wire rope has 6 wires in 19 strands.

There are a wide variety of products that are produced using wire rope. The demand for wire rope products is due to its strength, durability, and reliability. Since the basic purpose of wire rope is to lift and move heavy materials and items, the most common type of wire rope product is the wire rope sling.

Though the construction of wire rope slings is very similar for all types, there are certain variations applied to slings to adjust them to fit different applications. Slings are configured in various ways to fit different types of loads. These changes are referred to as hitches.

Bridle Hitch: The multiple leg or bridle hitch style has more than one wire rope sling attached to equalize the load and control balance. They reduce load damage by using fixed points on the load and offer easier rigging when hooked into fixed lifting points. .

Single Part Wire Rope Sling: The eye for a single part wire rope sling is formed by looping the wire rope back on to the rope. The end of the rope is attached by a clamp or being woven by hand or mechanically into the rope body. Single part wire rope slings use a single wire rope to produce the sling.

Braided Wire Rope Sling: A braided wire rope sling is made by braiding wire ropes to form a sling. The increased number of strands enhances the strength of the sling and its load capacity. Braiding can be done with three to nine wire ropes.

Cable Laid Wire Rope Sling: Cable laid wire rope slings are made from combining several smaller wire ropes to form a flexible, easy to handle, and kink resistant sling.

Woven Eye Wire Rope Sling: For the woven eye version of a wire rope sling, the eye is formed by weaving the wire rope into itself after forming the loop. It is designed to reduce the chance of the sling catching or being hung up when lifting.

Thimble Wire Rope Sling: To add to the strength of wire rope slings and lessen the stress on a small area of the eye, a thimble, a U shaped piece into which the wire rope fits, is placed in the eye, which helps the sling to retain its natural shape. The thimble is positioned to prevent the hook or load from coming in contact with the wire rope.

Endless Wire Rope Sling:Endless wire rope slings are adaptable slings without a set wear point. They can be manufactured in a wide range of sizes and are used in applications where headroom may be a problem. Endless wire rope slings are made by splicing the ends of a piece of wire rope together or by tucking strand ends into the body to form a core with a tucked position the opposite of the core position. They are also referred to as grommet wire rope slings.

Coiled wire rope is made from bundles of small metal wires that are twisted into a coil. It comes in many varieties and is easy to store since it does not require a spool. Coiled wire rope is produced in coils. When it is not in use, it springs back into a coil, which makes it easy to handle.

Cable wire rope is a type of high strength rope, made of several individual filaments. These filaments are twisted into strands and helically wrapped around a core. One of the most common types of wire rope cable is steel cable.

Push pull wire rope assemblies are used to send force and are used in the aircraft, exercise, medical, automotive, and office equipment industries. Unlike using a single heavy wire, push pull assemblies made with wire rope are stiffer and have a larger bend radii for smoother motion of the wire.

Wire rope assemblies include wire rope and various parts and components that have been added to the wire rope to enhance its function. The connectors for a wire rope assembly are designed to connect the assembly to hooks, equipment, or machines as well as other wire rope assemblies. The central part of a wire rope assembly is the wire rope, which determines the type and kind of work the assembly can perform.

Wire rope lanyards are a standard wire rope product that have a multitude of uses. They are produced using the same process that is used to produce wire rope with the same numbering categorizing system. Lanyards are used to hold fasteners, hardware, or components to prevent loss of an item or prevent injury.

In many ways, wire rope is a form of machine with multiple moving parts. Normally, when we think of a machine, we imagine a device with a motor, drives, and gears. Wire rope does not have any of those components but does fit the definition of being a complex mechanism. It has moving parts that work together to move heavy materials and loads.

The main function of wire rope is to do heavy lifting, which is very dependent on wire rope slings. The type of sling is determined by the quality of the wire rope used to form them and whether several ropes have been braided or wound together.

Wire is the smallest part of wire rope but makes up the various strands. The composition of the wire can be steel, iron, stainless steel, copper, or other types of metal wires and are produced in different grades. The individual wires can be coated or bright, meaning uncoated.

Strands are sets of wires that are twisted together and are placed in a helical pattern around the core. The size of the wire determines its abrasive qualities with larger wires being more abrasive and less flexible than smaller ones.

The core is the center of the wire rope and serves as a support for the strands and helps the wire rope keep its position when it is under stress or bearing a load.

Lubrication is applied during the manufacturing process to reduce friction between the wires and strands as well as protection from corrosion and rust. The tight winding of the wires enhances the ability of the wire rope to retain the lubrication which is essential to its longevity.

The purpose of applying lubricant is to limit the friction between the cables to increase the useful life of the wire rope. In certain applications, such as space travel, lubricants can be hazardous and cause equipment to malfunction. In those instances, non-lubricated wire rope is used, which is referred to as dry wire rope or cable.

Of all of the products that are made from wire rope, slings are the most common and widely used. These looped wire ropes come in different varieties and grades depending on the type of wire used. Also, to enhance wire sling performance, several wire ropes may be wound together to form a sturdier and more reliable sling.

Flemish splicing is a method for repairing a wire rope and involves breaking the wire rope in half and tying it back together. In the Flemish method, the wire rope is tied back on itself and swaged down a sleeve over the unbroken wire rope to create the new eye.

Prior to placing the wire rope into the holding device used to shape the eye, a steel compression sleeve is placed on the rope, which will be used to secure and hold the eye.

Once the proper size is achieved, the unwound strands are rewound in the reverse order of their former positioning. If the wire rope has a right hand lay, it is rewound using a left hand lay. The opposite is true if the wire rope has a left hand lay, then it is rewound using a right hand lay. By using this technique, a friction mold is formed for the splicing of the sling.

Anti-rotational wire rope resists the forces of rotation by having opposing layers of helical stands. By winding the wire rope with oppositional strands, the wire rope is guaranteed to not unwind in clockwise or counterclockwise directions. The key to anti-rotational wire rope is to ensure that the outer diameter is static.

In the manufacture of anti-rotational wire rope, counter stranded filaments have vacant spaces between them. To make the wire rope anti-rotational, it is tightly twisted in the counterclockwise direction, which tightens the spaces between the filaments. If the wire rope is turned in a counterclockwise direction, the strands tighten around each other creating a spring force.

The tails and stray wires of the wire rope have to be straightened and properly formed before applying the compression sleeve. Once the sleeve has been placed, it is carefully checked to be sure that it is accurately engaged.

Prior to placing the wire rope sling in the swaging die, the die has to be thoroughly lubricated. Once the die is set, the wire rope‘s compression sleeve and the wire rope are compressed using several hundred thousand pounds of force. The swaging process alters the dimensions of the wire rope and compression sleeve to form a tight connection for the correct diameter for the sling connection. As force is applied, the compression sleeve is turned so that pressure is evenly applied.

There are several types of metal wires that are used to produce wire rope, which include steel, stainless steel, galvanized, aluminum, nickel alloy, bronze, copper, and titanium. Carbon steel is the most common type of wire rope material.

Wire ropes are made using uncoated bright wire, which is high-carbon steel. The type of steel depends on the requirements of the wire and its tensile strength and its fatigue and wear resistance.

Galvanized wire rope is treated with zinc to prevent corrosion and can be used in harsh conditions and environments. It is a cost effective alternative to stainless steel but does not have the same corrosion resistance. Galvanized wire rope is stronger than stainless steel of the same grade and size. Vinyl coated galvanized wire rope is easy to handle and flexible.

Stainless steel wire rope is corrosion and rust resistant. It is available in types 316 and 304 with 316 having greater corrosion resistance. Stainless steel wire rope can be used for marine applications, acidic environments, and other demanding conditions. It is produced with the appropriate tolerances and composition to meet the needs of the application.

Multiple strands of copper are braided into a round hollow shape, which is pressed into the desired width and thickness. Copper wire rope has exceptional flexibility, an exceptional life span and can be used as part of electrical components.

Bronze wire rope inhibits sparking and is corrosion resistant. It is made from preformed wire to ensure that it maintains its shape and does not unravel when cut. Bronze wire rope is abrasion resistant and very flexible with a crush resistant core.

Inconel wire can be used in applications that reach temperatures as high as 2000° F and is oxidation and corrosion resistant. It is non-magnetic and has excellent resistance to chloride based corrosion cracking. Inconel wire rope can be used with nuclear generators and chemical and food processing.

Titanium wire rope comes in several grades with grade two being 99% pure. It is easily formable and weldable. Titanium wire rope is commonly used in chemical processing and marine hardware.

For wire rope to perform properly, it needs to have proper care. Wire rope is an essential tool necessary to perform a wire range of lifting and moving jobs. It is important that it be handled, treated, installed, stored, and treated correctly to prolong its life and perform to the highest standards.

Seizing should be completed on both ends of the wire rope, which will protect it from loosening. If this is done improperly, the wire rope can become distorted. Wire rope that is properly seized evenly distributes the load.

Wire rope is stored on reels or coils and has to be carefully handled when it is being removed. To ensure excellent performance, the wire rope should not be dropped during removal. If the reel or coil is dropped or damaged, it can make handling the wire rope difficult and cumbersome. As the wire rope is removed from the reel, check to see that the reel is rotating as the wire is removed.

Wire rope is depended on for heavy lifting and is trusted to keep a load and people safe. As with all heavy duty equipment, wire rope must have a regular inspection schedule and be visually assessed during use.

Broken Strands – An easy way to check for broken strands is to run a cloth over the length of the wire. Broken strands that are found in critical areas, such as parts that pass through pulleys or sections that are regularly flexed, rubbed, or constantly worked must be replaced and repaired.

Internal wear – This can be tested by flexing the wire rope, which indicates if the interior has deteriorated, experienced fatigue, or become distorted.

For wire rope to perform at the highest level, it has to be stored in a well ventilated environment that is dry, covered, and not in contact with the floor. The avoidance of high moisture or damp conditions is an absolute necessity. While the wire rope is in storage, it should be moved regularly to keep the lubricant from wearing off.

Though lubricant is applied during the manufacturing of wire rope, it wears off during use. Lubrication is the key to the performance of wire rope because it helps prevent abrasion as the wires rub against one another. Relubrication should be applied after the original lubricant has worn off.

Wire rope is a tool and must be cleaned regularly as with any form of machinery. This can be accomplished with different types of petroleum solvents and a wire brush. Mechanical methods of cleaning can include compressed air or a steam cleaner. Once the cleaning process is completed, the wire rope should be lubricated for protection.

There are several substances that can harm a wire rope. They include salt water, brine, acid, various gasses, and humidity. To avoid the intrusion of these negative effects, when a job is completed and the wire rope is to be stored, it should be cleaned, lubricated, and placed in proper storage.

When wire rope is being removed from a spool or being spooled, the operation must be performed smoothly with the spool rotating at a constant speed and rhythm. This will help prevent kinking or binding.

When a wire rope shows a reduction in diameter, has broken wires, kinks, nodes, flattened surfaces, out of place outer wires, damage from heat exposure, corrosion damage, or the formation of unexpected loops, it should be removed and replaced or be repaired.

Wire rope is regulated by the Occupational Safety and Health Administration (OSHA) as part of the regulations for cranes and derricks in construction as part of 29 CFR 1926.1413, which went into effect on November 8, 2010.

The inspection of wire ropes is on three levels: shift, monthly, and annually. Shift and monthly inspections can be completed by an approved operator, while annual inspection must be completed by certified personnel.

As with the shift and monthly inspections, the annual inspection follows the guidelines for the shift inspection. This inspection must be completed by certified personnel. The entire surface of the wire rope has to be inspected, with attention to:

Annual inspections can be excused if it is not possible due to the wire ropes setup or configuration or the location of the work site. It must be completed within six months. If any deficiencies are found, the wire rope must be repaired or removed. For some deficiencies, it is possible to keep the wire rope in use but have them regularly monitored.

Wire rope is a form of metal tool that is constructed of multiple strands of wire that are twisted and braided together to form a spiral design or helix.

To further enhance the strength of wire rope, they are grouped and wound together to produce cables, which adds to their usefulness as a means of support, ability to lift, and give structural stability.

The types of wire rope are determined by the number of wires in each strand and how many are in the rope, which is defined by a two number system with the first number being the number of wires and the second being the number of wires in each strand.

Wire rope tends to kink during uncoiling or unreeling, especially if it has been in service for a long time. In order to unreeling the wire rope is to run a steel pipe or strong rod through the center and mount the reel on drum jacks or other supports so the reel is off the ground. In this way, the reel will turn as the rope is unwound, and the rotation of the reel will help keep the rope straight.

During unreeling, pull the rope straight forward and avoid hurrying the operation. As a safeguard against kinking, never unreel wire rope from a stationary reel.

To uncoil a small coil of wire rope, simply stand the coil on edge and roll it along the ground. Never uncoil it by pulling on the end because such practice can kink or twist the rope.

The closer the position of the wire rope to the vertical, the safer it will be operated in safer conditions and with a longer lifespan, tension inside being distributed much more evenly between the strands and wires.

Non-rotating wire ropes have strands twisted around the core and the lay direction for outer strands is opposite to immediately inner strands. The outer rotational force of the rope will counteract the rotational force of the inner strands, leaving a wire rope that is resistant to rotating.

They have a long flexibility and lifespan, thanks to the winding of wires and strands in such a way that they generate low values for torsion time and tension when subjected to a load.

8613371530291

8613371530291