ordinary lay wire rope factory

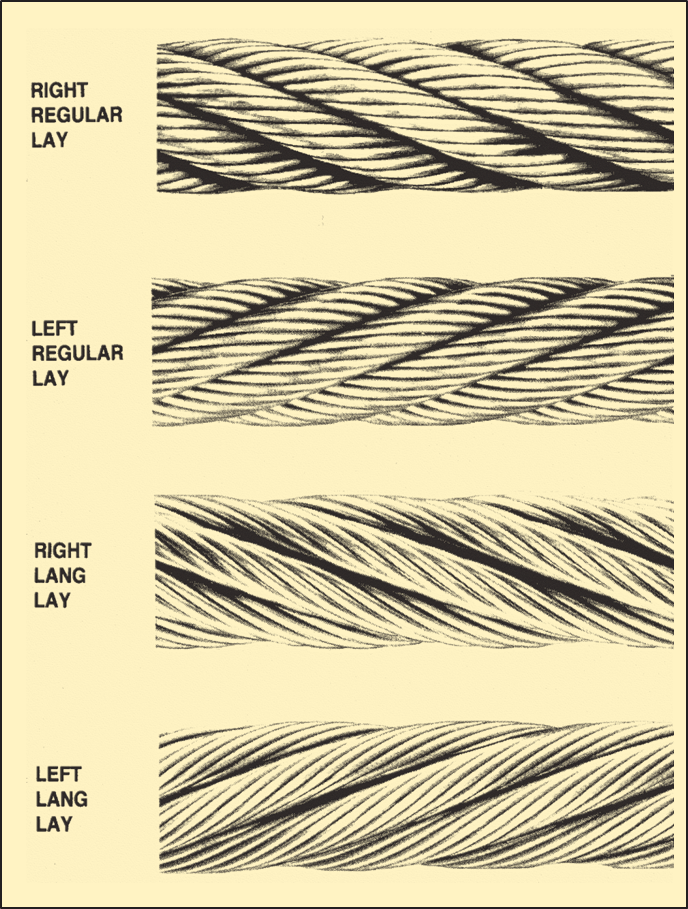

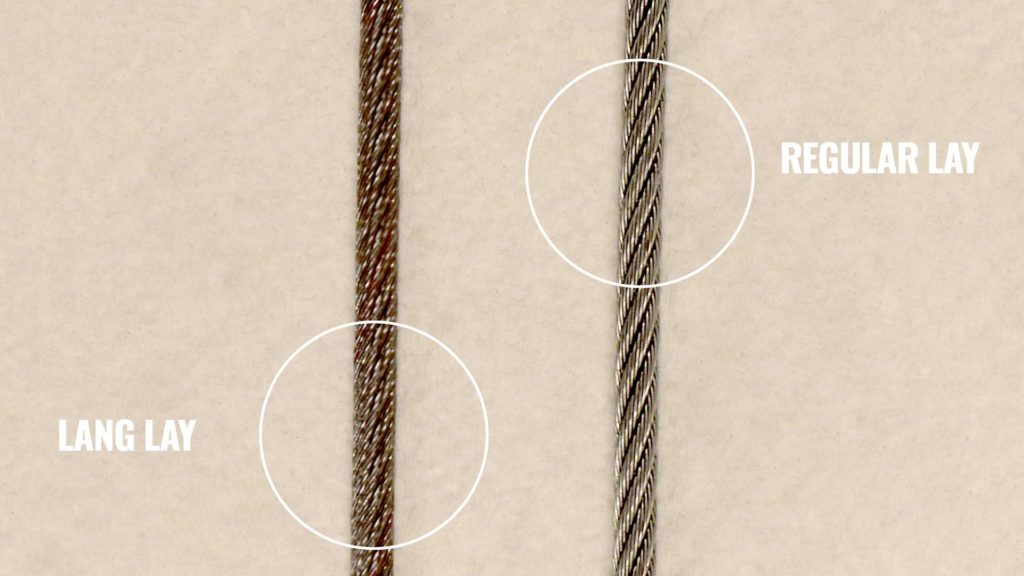

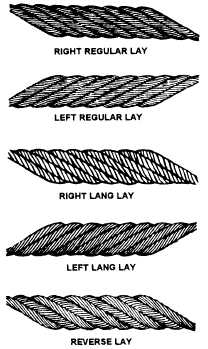

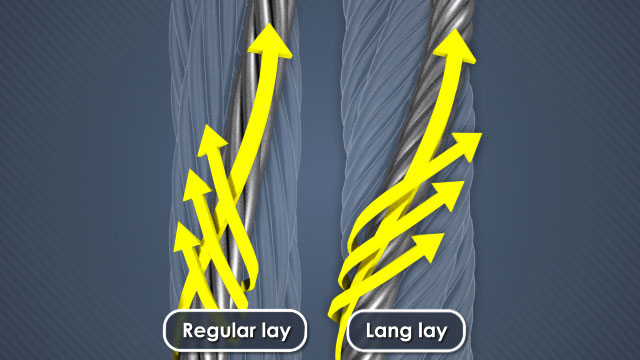

Regular laydenotes rope in which the wires are twisted in one direction, and the strands in the opposite direction to form the rope. The wires appear to run roughly parallel to the center line of the rope. Due to the difference in direction between the wires and strand, regular lay ropes are less likely to untwist or kink. Regular lay ropes are also less subject to failure from crushing and distortion because of the shorter length of exposed outer wires.

Lang layis the opposite; the wires and strands spiral in the same direction and appear to run at a diagonal to the center line of the rope. Due to the longer length of exposed outer wires, lang lay ropes have greater flexibility and abrasion resistance than do regular lay ropes. Greater care, however, must be exercised in handling and spooling lang lay ropes. These ropes are more likely to twist, kink and crush than regular lay ropes.

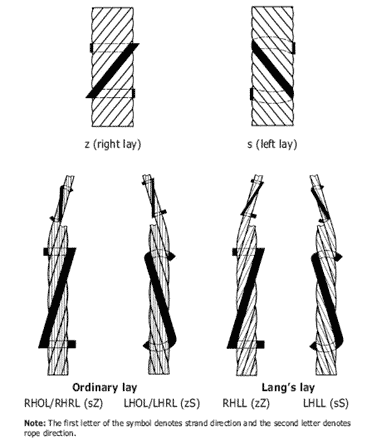

Right or left layrefers to the direction in which the strands rotate around the wire rope. If the strands rotate around the rope in a clockwise direction (as the threads do in a right hand bolt), the rope is said to be right lay. When the strands rotate in a counterclockwise direction (as the threads do in a left hand bolt), the rope is left lay.

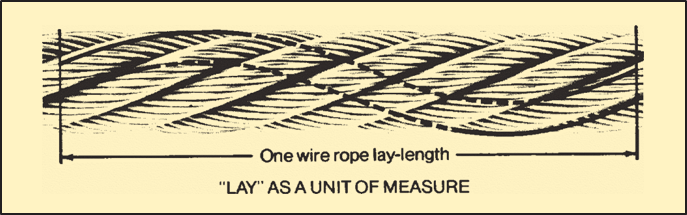

When a lay-length is used as a unit of measure, it refers to the linear distance a single strand extends in making one complete turn around the rope. Lay-length is measured in a straight line parallel to the center line of the rope, not by following the path of the strand. The appropriate time to replace a wire rope in service is frequently determined by counting the number of broken wires in the length of one rope lay.

Similar to regular lay, the right hand vs left hand is merely the way the wire rope closes with the strands in left hand lay rotating counterclockwise and right hand lay rotating clockwise. With lang lay rope, the wires in each strand lie in the same direction as the strands. When looking along a length of lang lay cable, the wires will appear to angle across the rope, following the general flow of the strands. Lang lay cables are more susceptible to pinching and kinking than regular lay, which best suits hoisting applications where the cable only moves along one axis. Lang lay is typically more flexible than regular lay. The third image down on the left is an example of right hand lang lay and the image below is left hand lang lay.

Now that you know about the differences and capabilities of each wire rope lay type, you can feel confident in purchasing the right lay for your wire rope applications! If you would like to check out our wire rope options, visit our website here. Alternatively, our team is happy to help if you have any questions! Reach out to us by email at sales@loosco.com or by phone at (860) 928-7981.

When discussing the physical properties of wire rope, people often focus on the material, strength, and size specifications above all else. While these details are essential to understand how a product will survive in the field, they are not the only factors that drive cable performance. In fact, the lay direction of a cablehas as much impact on its functionality as any of the other aforementioned characteristics, because it determines how much a cable will rotate, twist, and kink.

Lay direction describes the relationship between the way wires are wrapped into strands, and the way those strands are wrapped into wire ropes and cables. In general, there are two different configurations of lay directions: regular lay, and lang lay, which can rotate either to the left or to the right.

In a regular lay cable, the wires and strands are laid opposite to each other. In other words, all of the wires are laid in one direction as they are made into strands, and those strands are then laid in the opposite direction of the wires as they are combined into cable. When looking along a length of regular lay cable, the wires will appear to run parallel and straight the entire way. You can tell a cableis right regular lay because the strands will all flow to the right, or clockwise direction, compared to a regular left lay cable which flows the strands in a leftward, counterclockwise direction.

In a lang lay configuration, the wires and strands are laid in the same direction. If all the wires are laid to the right as they are made into strands, then those strands will also be laid to the right as they are combined into cable. The same applies to a left lang lay configuration, where both the wires and strands would lay to the left. When looking along a length of lang lay cable, the wires will appear to angle across the rope, following the general flow of the strands. You can tell a cable is a right lang lay cable because both the wires and strands will flow rightward, in a clockwise direction. A left lang lay cable flows both wires and strands in a leftward, counterclockwise direction.

Cable is generally manufactured with a standard right regular lay because it is useful for a variety of different applications and complies with most equipment. In general, regular lay cable is more resistant to crushing forces than lang lay cable of an identical material and size, though lang lay cable is typically more flexible. Lang lay cables are usually more susceptible to pinching and kinking than regular lay, which means they are better suited to hoisting applications where the cable only moves along one axis.

In summary, the wires and strands in regular lay cable flow in opposite directions while the wires and strands in lang lay cable flow in the same direction. Lang lay cable is great for lifting, hoisting, and push-pull applications, while regular lay cable outperforms in situations where bends are required. To learn about our range of flexible, non-rotating, and non-flexible wire rope and aircraft cable, visit https://strandcore.com/products/aircraft-cable/ or contact us at https://strandcore.com/contact/.

Wire rope is a machine! It is the workhorse that lifts the heavy loads on wire rope hoists. As a crane technician, there is an endless amount of information you should know about wire rope. The more you understand, the better resource you can be to your customers. Luckily, you don’t need to be the expert! There are others to help you out including, crane and hoist manufacturers, wire rope manufacturers, and other crane technicians. In this article, we will talk about how Demag designs wire rope hoists, selects the wire rope for models that you can buy today, and those you will still find in the field for inspections and repair.

In the world of wire rope, lay has many meanings and definitions. First, we will go through the directional meanings. Lay can refer to the direction in which the strands are twisted around the core of the wire rope. When left hand and right hand lay is referred to like this, it is describing whether the strands are twisted clockwise (left hand) or counter-clockwise (right hand) around the core. For a frame of reference, grab the wire rope in either hand with your thumb pointing up. When the strand appears as if going up to the left, this is a Left Hand lay rope. When it appears as though it is going up to the right, this is a Right Hand lay.

Lay can also refer to the cut of the groove corkscrew in the drum and the corkscrew can go to the left or right. The wire rope will start gathering on the left-hand side of the drum in the case of a left lay and the opposite for right lay. One way to determine this is to look at the drum from the end where the rope is clamped. The term lay can be used to describe the distance of a complete wrap of a strand once around the core. When conducting a wire rope inspection, knowing how to measure the lay is critical. It is measured by determining the distance starting on the outside wrapping the strand one complete time back to the same outside position. This measurement is used to determine the maximum number of broken wires allowed within a single lay and for the number of broken wires in the same strand in a lay. Always consult your inspection criteria bodies, like CMAA and HMI, for the most up-to-date standards.

Lay can also denote whether a rope is Regular Lay or Lang Lay. Regular lay and Lang lay rope are different types of wire rope and differ based on the wire orientation in the strand. Regular lay rope wire appears as though the outermost wire surface is aligned parallel with the centerline of the wire rope axis. Lang lay rope wires appears to be at a 45 degree angle with the wire rope centerline axis. Lang lay type of rope allows for more surface contact with the groove surface on the drum or sheave, increasing the support zone and decreasing the load by spreading it out over a larger area. It is more costly to manufacture, but it can be used in special cases where better wear life for the drum and sheaves is needed. Today, Regular Lay rope is commonly used unless there is a specific design need to use Lang Lay wire rope.

Countries and industries may have different standards or best practices for wire rope. In the USA, the wire rope industry recommends using a Right Hand (RH) lay rope on a Left Hand (LH) drum corkscrew and a Left Hand (LH) lay rope on a Right Hand (RH) drum corkscrew. This is recommended for good spooling of the rope, especially on a grooveless drum. In most cases, Demag designs their wire rope hoists in violation of this best practice, but for a major engineering reason that benefits the user and for additional safety.

Demag wire rope hoists are designed for RH rope on a RH drum and LH rope on a LH drum. This design creates straighter drops of wire rope down to the bottom block as using the same strand lay and corkscrew twists the strands tighter around the core. The straighter drop eliminates interference in a 4/1 reeving configuration as the rope crisscrosses during lifting. This becomes very apparent when the lift height is around the 70 foot range. To make sure that the hoist has positive spooling, the drum is designed with a partial groove and is equipped with a rope guide with pressure rollers or a ring that keeps the rope in the groove.

When it comes to hoists configured for 4/2 reeving with 2 attachment points for the same rope, only one side of the drum follows the best practice. Since there are 2 attachment points in 4/2 reeving, one drum corkscrew is RH and the other LH. Inherent from the reeving design, close to vertical lifting is achieved and crisscrossing interference is not a concern.

Due to wear on the drum and sheaves, we will never recommend changing the lay of the rope used on a hoist when the wire rope needs changed. The existing wire rope lay has already established wear patterns on the drum and sheave that could make changing the rope with a different lay dangerous. Being able to identify or find out what type of rope is used on a wire rope hoist is key to success when wire rope needs changed.

Wire rope is a complex machine, lifting the heaviest loads like space shuttles and precast concrete components. It does the heavy lifting when a load is being lifted by a crane and wire rope hoist. Having a good understanding of wire rope is essential for all crane technicians. Being able to understand what lay means and how to determine what kind of rope is on an existing hoist is just the beginning. Not only will this knowledge allow you to be a more effective technician for your customers, but you can promote safety in the industry.

A six strand wire rope in which three strands are ordinary lay and three strands are lang lay is known as an alternate lay wire rope and combines some of the desirable properties of both the regular lay and langs lay type of rope.

Wire rope is identified not only by its components parts, but also its construction, i.e., by the way the wires have been laid to form strands, and by the way the strands have been laid around the core.

( "a" and "c" ) shows strands as normally laid into the rope to the right - in a fashion similar to the threading in a right-hand bolt. Conversely the "left lay"rope strands (illustration "b" and "d" ) are laid in the opposite direction.

Again the first two ( "a" and "b" ) show regular lay ropes. Following ( "c" and "d" ) these are the types known as lang lay ropes. Note that the wires in regular lay ropes appear to line up with the axis of the rope; in lang lay rope the wires form an angle with the axis of the rope. This difference in appearance is a result of variations in manufacturing techniques: regular lay ropes are made so that the direction of the wire lay in the strand is opposite to the direction of the strand lay in the rope; lang lay rope are made with both strand lay and rope lay in the same direction. Finally ( "e" and "f" ) called alternate lay consists of alternating regular and lang lay strands.

Left hand lay or right hand lay describe the manner in which the strands are laid to form the rope. To determine the lay of strands in the rope, a viewer looks at the rope as it points away from them. If the strands appear to turn in a clockwise direction, or like a right-hand thread, as the strands progress away from the viewer, the rope has a right hand lay. The picture of steel wire rope on this page shows a rope with right hand lay. If the strands appear to turn in an anti-clockwise direction, or like a left-hand thread, as the strands progress away from the viewer, the rope has a left hand lay. (The rope in the left hand lay photo shows one left hand lay rope from left to right and top to bottom, with 5 right hand lay strands, and part of a sixth in the upper left. It is not 5 right hand lay ropes adjacent to each other.)

Ordinary and Ducay"s lay describe the manner in which the wires are laid to form a strand of the wire rope. To determine which has been used, first identify if left or right hand lay has been used to make the rope. Then identify if a right or left hand lay has been used to twist the wires in each strand. (On ordinary lay, the outer wires approximately follow the alignment of the rope: with Lang"s lay they are cross at an angle of about 45�.) Lang"s laid rope is able to flex over sheaves more easily (with less damage) but it has the disadvantage of having a high torque tendency (it tends to untwist when tension load is applied) compared with ordinary laid rope. Untwisting can be dangerous with a steel-cored rope: load is shed from the strands and may cause the core to fail as it becomes higher loaded. For this reason, swivel termination units can be dangerous.

The specification of a wire rope type � including the number of wires per strand, the number of strands, and the lay of the rope � is documented using a commonly accepted coding system, consisting of a number of abbreviations.

Wire rope manufacturers produce their products in order to provide a high load capacity, versatile alternative to weaker ropes like manila rope or hemp rope. Wire rope products are used for a wide variety of motion transmission applications, among them: lifting, baling, tie down, hoisting, hauling, towing, mooring, anchoring, rigging, cargo control, guidance and counterbalance. They can also be used as railing, fencing and guardrailing.

Wire rope is a must-have for many heavy duty industrial applications. From mining to forestry to marine and beyond, there’s wire rope for almost every job. Some of the many industries in which wire rope is popular include: construction, agriculture, marine, industrial manufacturing, fitness, sports and recreation (plastic coated cables for outdoor playground equipment and sports equipment), electronics, theater (black powder coated cables for stage rigging), mining, gas and oil, transportation, security, healthcare and consumer goods.

Wire rope as we know it was invented just under 200 years ago, between 1831 and 1834. At that time, the goal was to create a rope strong enough to support work in the mines of the Harz Mountains. Invented by Wilhelm Albert, a German mining engineer, this wire rope consisted on four three-stranded wires. It was much stronger than older rope varieties, such as manila rope, hemp rope and metal chain rope.

While studying at Freiburg School of Mines, a man named L.D.B. Gordon visited the mines in the Harz Mountains, where he met Albert. After he left, Gordon wrote to his friend Robert Stirling Newall, urging him to create a machine for manufacturing wire ropes. Newall, of Dundee, Scotland, did just that, designing a wire rope machine that made wire ropes with four strands, consisting of four wires each. After Gordon returned to Dundee, he and Newall, along with Charles Liddell, formed R.S. Newall and Company. In 1840, Newall received a patent for “certain improvements in wire rope and the machinery for making such rope.”

In 1841, an American manufacturer named John A. Roebling began producing wire rope for suspension bridges. Soon after, another set of Americans, Josiah White and Erskine Hazard, started incorporating wire rope into coal mining and railroad projects, forming Lehigh Coal & Navigation Company (LC&N Co.). In 1848, wire rope from their wire rope factory in Mauch Chunk, Pennsylvania provided the lift cables needed to complete the Ashley Planes Project. This project sought to improve the performance and appearance of the freight railroad that ran through Ashley, Pennsylvania, by adding lift cables. This increased tourism and increased the railroad’s coal capacity. Before, cars took almost four hours to return; after, they took less than 20 minutes.

Wire rope likewise changed the landscape (again) in Germany, in 1874, when an engineering firm called Adolf Bleichert & Co. used wire rope to build Bi-cable aerial tramways. These allowed them to mine the Ruhr Valley. Several years later, they also used wire rope to build tramways for the German Imperial Army and the Wehrmacht. These tramways were wildly successful, opening up roads in Germany and all over Europe and the USA.

Since the 1800s, manufacturers and engineers have found ways to improve wire rope, through stronger materials and material treatments, such as galvanization, and different rope configurations. Today, wire rope makes possible many heavy industrial processes. It has become a necessity of the modern world.

Strands are made by tightly twisting or braiding individual wire together. One strand could have anywhere between two and several dozen wire filaments depending on the necessary strength, flexibility, and weight capacity.

One of the most dynamic elements of wire cables is the inner core. The strands are wrapped around the core, and it can be made of different metals, fibers, or even impregnated fiber materials. For heavy applications, cores are often made of a different strand of wire called an independent wire rope core (IWRC). An IWRC has a considerable amount of flexibility and it is still very strong. In fact, at least 7.5% of the strength increase in a wire rope can be attributed to an IWRC.

While they sometimes use other metals, like aluminum, nickel, copper, titanium, and even bronze for some applications, manufacturers primarily produce wire rope from steel. This is because steel is very strong and stretchable. Among the most common types they use are: galvanized wire, bright wire, stainless steel and cold drawn steel.

Of the wire rope steels, cold drawn carbon steel wire is most popular, although stainless steel wire rope is sometimes employed as well. Stainless steel rope is most popular for its anti-corrosive properties. Bright wire rope, a type of ungalvanized steel wire rope, is also popular. For added strength and durability, galvanized steel wire rope/galvanized steel cables are a very popular choice. Galvanized aircraft cable, for example, is always a must in aerospace.

When choosing or designing a custom wire rope for your application, suppliers consider factors such as: the environment in which the rope will function, required rust resistance, required flexibility, temperature resistance, required breaking strength and wire rope diameter. To accommodate your needs, manufacturers can do special things like: make your rope rotation resistant, color code your rope, or add a corrosion resistant coating. For instance, sometimes they specially treat and coat a cable with plastic or some other compound for added protection. This is particularly important to prevent fraying if the wire rope is often in motion on a pulley.

Manufacturers and distributors identify the differences in wire cable by listing the number of strands and the amount of wires per strand so that anyone that orders understand the strength of the cable. Sometimes they are also categorized by their length or pitch. Common examples of this include: 6 x 19, 6 x 25, 19 x 7, 7 x 19, 7 x 7, 6 x 26 and 6 x 36.

More complex wire rope identification codes connote information like core type, weight limit and more. Any additional hardware like connectors, fasteners, pulleys and fittings are usually listed in the same area to show varying strengths and degrees of fray prevention.

Cable wire rope is a heavy-duty wire rope. To give it its high strength, manufacturers construct it using several individual filaments that are twisted in strands and helically wrapped around the core. A very common example of cable wire rope is steel cable.

Spiral rope is made up an assemblage of wires with round or curved strands. The assemblage features at least one outer layer cord pointed in the opposite direction of the wire. The big advantage of spiral ropes is the fact that they block moisture, water and pollutants from entering the interior of the rope.

Similarly, stranded rope steel wire is made up of an assemblage of spirally wound strands. Unlike spiral rope, though, its wire patterns have crisscrossing layers. These layers create an exceptionally strong rope. Stranded rope may have one of three core material types: wire rope, wire strand or fiber.

Wire rope chain, like all chains, is made up of a series of links. Because it is not solid, wire rope chain is quite flexible. At the same time, it is prone to mechanical failure.

Wire rope slings are made from improved plow wire steel, a strong steel wire that offers superior return loop slings and better security. The plow wire steel also shields rope at its connection points, which extends its working life. Wire rope slings, in general, provide their applications with increased safety, capacity and performance. Wire rope sling is a rope category that encompasses a wide range of sub-products, such as permaloc rope sling, permaloc bridle slings and endless slings. These and other wire rope slings may be accompanied by a wide variety of sling terminations, such as thimbles, chokers and hooks.

Wire rope offers its user many advantages. First, design of even distribution of weight among strands makes it ideal for lifting extremely heavy loads. Second, wire rope is extremely durable and, when matched properly to the application, can withstand great stress and elements like corrosion and abrasion. In addition, it is very versatile. Its many iterations and the ways in which the rope can treated means that users can get rope custom fit for virtually any application.

Depending on the type of wire rope with which you are working and your application, you may want to invest in different accessories. Among these accessories are: wire rope clips, steel carabiners, fittings, fasteners and connections.

To ensure that your wire rope quality remains high, you must regularly inspect them for wear and degradation. The right wire rope should be selected for a particular use. Watch out for performance-impacting damage like: rust, fraying and kinks. To make sure that they stay in tip-top shape, you should also clean and lubricate them as needed. Check for this need as a part of your regular inspection.

Rope care is about more than inspection. It’s also about making an effort to use and store them properly every time you use them. For example, never exceed your rope’s rated load and breaking strength. Doing so will not only cause the weakening of your cable, but it may even cause immediate breakage. In addition, always store your wire rope cable in a dry and warm area, away from those elements that could cause premature rusting or other damage. Finally, always carefully wind your wire rope when you’re done with it, so as to avoid kinks. If you follow all these tips and treat your wire rope assemblies well, they will reward you with a long and productive service life.

Always make sure that you purchase wire rope that matches your industry and regional standards. Some of the most widely referenced standards organizations for wire rope include: ISO, ASTM International and OSHA. Talk over your specifications and application with your wire rope supplier to figure out what’s best for you.

If you’re in the market for a wire rope or a wire rope assembly, the best way to know you’re getting something that will both perform well and be safe if by working with a vetted professional. Find one among the list we’ve provided on this page. Check out their profiles to get an idea of the services and products they offer. Pick out three or four to whom you’d like to speak, and reach out. Talk to them about your specifications, standard requirements and budget. Ask about lead times and delivery options. Once you’ve spoken with all of them, compare and contrast their answers. You’ll know you’ve found the one when you talk to a wire rope company that is willing to go above and beyond for your satisfaction.

PREFORMING: A manufacturing process wherein the strands and their wires are permanently formed, during fabrication, the helical shape that they will ultimately assume in the finished wire rope. Proper preforming prevents the strand and wire from unlaying during normal use. The vast majority of wire ripe sold today is preformed.

FINISH: Wire rope is either sold as “bright” (or “black”), meaning uncoated, or galvanized for better corrosion resistance. “Drawn Galvanized” wire has the same strength as bright wire, but wire, “galvanized at finished size” is usually 10% lower in strength. Plastic coated wire rope is also available, usually galvanized or stainless steel cable. The most common plastic coverings are vinyl or nylon in either clear or white, although other materials and colors are available. These coating do not add strength to the wire rope itself.

LUBRICATION: During fabrication, wire ropes receive lubrication. The kind and amount depends on the rope’s size, type a use, if known. This in-process treatment will provide the finished wire rope with ample protection for a reasonable time if it is stored under proper conditions. But, when the wire rope is put into service, the initial lubrication will normally be less than needed for the full useful life of the wire rope. Because of this, periodic applications of a suitable wire rope lubricant are necessary.

ORDERING WIRE ROPE: Construction, lay, core, finish and other factors mentioned above impart greatly differing characteristics to different wire ropes. They must be understood and considered when selecting wire rope. There is no perfect wire rope for all applications; usually some less desirable properties are traded off for other, more desirable one. Refer to the Wire Rope Users Manual by the Wire Rope Technical Board for a better understanding of wire rope properties and consult professional help when in doubt.

If a supplier receives an order for 6 x 19 wire rope he may assume this to be a class reference and is, therefore, legally identified in furnishing any construction within this category.

Working safely with wire rope, for riggingand other purposes, requires an understanding of some of the characteristics of wire rope. Characteristics you should understand include lay, classification, and construction. We"ll explain each in this article.

The second is the relationship between the direction in which the strands are wrapped around the core and the direction that the wires within the strand are wrapped. This can be regular or lay.

And the third is the linear, or straight-line, distance a strand travels while making a single revolution around the core of the wire rope. This is known as the lay length.

The different lays and lay lengths of wire rope all have a functional purpose, and wire ropes with specific lays have different advantages and disadvantages for specific applications at work.

Another way to characterize wire rope is by the number of wires in each strand and the number of strands in the rope itself. This is known as wire rope classification.

A wire rope"s classification includes two numbers (such as 6 x 19). The first number (6, in this example) represents the exact number of strands in the rope. The second number represents the number of wires in each strand, but this number identifies a class, or range and may not be an exact number of wires.For example, a 6 x 19 class wire rope always has six strands, but may have 15-26 wires in each strand.

Hope you found this brief introduction to some aspects of wire rope, including the different parts of a wire rope and the rope"s lay, classification, and construction, helpful.

Remember there"s a lot more to learn about wire rope in order to work with it properly and safely, and thankfully, we offer two online learning courses for it--our wire rope basics online course and our wire rope safety and operations online course.

We develop and manufacture strands and ropes, in the fine rope range with diameters from 0.09 to 8.0 mm, for the most diverse technical requirements, with individual specifications. This results in different requirements for the material, the rope structure and the diameter range. In our rope factory, ropes can be manufactured in different lay directions. Our standard material stainless steel 1.4401 is predominantly used for a wide variety of constructions. Depending on the requirements, we also supply ropes in special materials or process them by, for example, hammering, purifying or PU coating. We produce our ropes with fiber or steel core. We also offer conducting wire ropes of the e-rope brand. The thinnest wire processed in our rope factory for use in microtechnology has a diameter of 0.015 mm. This corresponds to 1/4 the diameter of a human hair. These wire ropes are used, for example, in medical devices. Our ropes are durable quality products and thus contribute to the sustainability of the products in which they are processed.

Here you will find everything you need to know about ropes and cables. What is the difference between a wire, strand and a rope? Which rope constructions do exist? What is meant by lay directions? What is the effect of stretching? What materials are available? What is a coated rope and what is it required for? These and other questions we, from Carl Stahl Technocables would like to answer here.

Strands are made of single high tensile wires. These are placed helically around an insert * (heart wire) in the steel cable factory. This is the basic model for the further rope prodution.

The lay direction indicates the direction in which the outer wires (outer strands) of the strand (cable) are laid around the center wire (core strand).

Furthermore, a distinction is made between ordinary/regular lay and langs in the stranding (see figure). As standard, Carl Stahl Technocables delivers the steel cables in right hand ordinary lay (sZ).

Carl Stahl Technocables uses polyamide as the standard coating material. Polyamide is an optimum cable coating, distinguished by its high wear resistance and high bending cycle capability. A further advantage of the coated cables: The coating protects the rope from dirt.

Furthermore, the coating keeps the manufacturing lubricant within the rope. This film of oil functions as a lubricant between the individual wires and strands, thereby reducing wear on the cable.

Are high temperatures or good sliding properties required of your steel wire rope? Then we use special materials for coating of the steel wire rope. For example, we recommend FEP/PTFE for temperatures of between -190°C and + 205° C.

We can also offer PA6. PA6 is stiffer than PA12 and is therefore not suitable for pulleys. However, PA6 has better sliding properties and is therefore highly suitable as a guide cable for example.

Depending on the application, the appropriate coating material is used. Don’t you know which wire rope coating is the right for your rope application? - We"re glad to help you finding the right material. Contact us directly

After the manufacturing process of the ropes and strands, small gaps remain between each wire within the strand and between each strand in the rope. When the rope is tensioned, the wires and the strand move closer to each other, and reach their optimum position. A result of this process is, that the rope elongates to a certain extent. This constructional elongation is not the same in every rope construction. It depends on lay, lay length, rope construction and other factors.

This elongation concerns the material that the single wires are made of. It occurs, when the wire is tensioned. The material elongation is proportional to the applied load. Under normal circumstances the rope will almost regain its original length as soon as the load is removed.

The diverse properties and possibilities of wire ropes and strands are attracting more and more attention when it comes to implementing mechanical applications flexibly and safely. The result is high-quality solutions for a wide range of applications, in a wide variety of industries. The possible applications of wire ropes are almost endless. Wire ropes with larger diameters up to 8.00 mm are used in mechanical engineering or in the sun protection sector. Fine wire ropes with smaller diameters from 0.09 mm are used in the medical, furniture or lighting industries, among others. Optical aspects also often play a role.

The selection of the right wire rope for the respective application is of great importance. This is done according to various criteria, which are selected on the basis of the respectivearea of application. Properties and conditions such as tensile strength, environment, corrosion resistance, form, function, surface and structureare taken into account.

Standard wire ropes and strands are made of galvanized steel, or stainless steel. Stainless steel ropes, for example, offer very high corrosion protection, are solidand have a very long service life. Wire ropes made of galvanized wire, are in many cases the most economical option and offer sufficient corrosion protection for various applications.

Carl Stahl Technocables GmbH is your competent partner from the initial consultation, through the development of technical specifications, to the manufacture of assembled ropes, Bowden cables, wire ropes and strands. We supply our products to a wide variety of industries and markets worldwide.

Ropes made of stainless steel are rustproof. They score high on durabilitydue to low abrasion, are solidand have low ductility. Stainless steel ropes offer high tensile strength for mechanical applications and are temperature resistant.

Stainless steel wire rope is the right choice for applications where the rope needs to be protected from corrosion. Applications that are likely to be used outdoors, underwater or in an area where the wire rope would be exposed to the elements. In particular, it is highly resistant to corrosion by acids and bases.

In the case of steel cables made of galvanized steel, the steel has undergone a galvanizing process called hot-dip galvanizing or HDP. HDP is the process of immersing the steel in molten zinc, which forms a coated zinc layer around the steel that protects the material from corrosion. While it is not as corrosion resistant as stainless steel cable, it is sufficient for an outdoor application in some cases.

The low cost-to-benefit ratio of galvanized steel wire rope makes this the preferred material for many mechanical applications intended for indoor use such as hanging heavy signage or suspending, lifting or balancing large objects.

The standard wires for steel wire strands and cables are made of galvanised steel or stainless steel 1.4401/ AISI 316. Galvanised wire offers sufficient corrosion protection for many areas of use. If the steel wire cables and strands are to be used in highly corrosive media, we recommend stainless steels.

Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. This structure provides strength, flexibility, and the ability to handle bending stresses. Different configurations of the material, wire, and strand structure will provide different benefits for the specific lifting application, including:Strength

However, selecting the proper wire rope for your lifting application requires some careful thought. Our goal is to help you understand the components of a wire rope, the construction of wire rope, and the different types of wire rope and what they might be used for. This will allow you to select the best performing and longest-lasting wire rope for the job at hand.

From childhood, many of us have been conditioned to think of a machine as some device with gears, shafts, belts, cams, and assorted whirring parts. Yet, by the rules of physics, an ordinary pry bar is a simple machine, even though it has only one part.

A wire rope is, in reality, a very complicated machine. A typical 6 x 25 rope has 150 wires in its outer strands, all of which move independently and together in a very complicated pattern around the core as the rope bends. Clearances between wires and strands are balanced when a rope is designed so that proper bearing clearances will exist to permit internal movement and adjustment of wires and strands when the rope has to bend. These clearances will vary as bending occurs, but are of the same range as the clearances found in automobile engine bearings.

Understanding and accepting the “machine idea” gives a rope user a greater respect for rope, and enables them to obtain better performance and longer useful life from rope applications. Anyone who uses a rope can use it more efficiently and effectively when they fully understand the machine concept.

Wires are the smallest component of wire rope and they make up the individual strands in the rope. Wires can be made from a variety of metal materials including steel, iron, stainless steel, monel, and bronze. The wires can be manufactured in a variety of grades that relate to the strength, resistance to wear, fatigue resistance, corrosion resistance, and curve of the wire rope.

Strands of wire rope consist of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the rope.

The core of a wire rope runs through the center of the rope and supports the strands and helps to maintain their relative position under loading and bending stresses. Cores can be made from a number of different materials including natural or synthetic fibers and steel.

Lubrication is applied during the manufacturing process and penetrates all the way to the core. Wire rope lubrication has two primary benefits:Reduces friction as the individual wires and strands move over each other

The number of layers of wires, the number of wires per layer, and the size of the wires per layer all affect the strand pattern type. Wire rope can be constructed using one of the following patterns, or can be constructed using two or more of the patterns below.Single Layer – The most common example is a 7 wire strand with a single-wire center and six wires of the same diameter around it.

Filler Wire – Two layers of uniform-size wire around a center with the inner layer having half the number of wires as the outer layer. Small filler wires, equal to the number in the inner layer, are laid in valleys of the inner wire.

Seale – Two layers of wires around a center with the same number of wires in each layer. All wires in each layer are the same diameter. The large outer wires rest in the valleys between the smaller inner wires.

Warrington – Two layers of wires around a center with one diameter of wire in the inner layer, and two diameters of wire alternating large and small in the outer later. The larger outer-layer wires rest in the valleys, and the smaller ones on the crowns of the inner layer.

On a preformed wire rope, the strands and wires are formed during the manufacturing process to the helical shape that they will take in a finished wire rope.

Preformed rope can be advantageous in certain applications where it needs to spool more uniformly on a drum, needs greater flexibility, or requires more fatigue-resistance when bending.

Direction and type of lay refer to the way the wires are laid to form a strand (either right or left) and how the strands are laid around the core (regular lay, lang lay, or alternate lay).Regular Lay – The wires line up with the axis of the rope. The direction of the wire lay in the strand is opposite to the direction of the strand lay. Regular lay ropes are more resistant to crushing forces, are more naturally rotation-resistant, and also spool better in a drum than lang lay ropes.

Lang Lay– The wires form an angle with the axis of the rope. The wire lay and strand lay around the core in the same direction. Lang Lay ropes have a greater fatigue-resistance and are more resistant to abrasion.

A steel core can be an independent wire rope or an individual strand. Steel cores are best suited for applications where a fiber core may not provide adequate support, or in an operating environment where temperatures could exceed 180° F.

The classifications of wire rope provide the total number of strands, as well as a nominal or exact number of wires in each strand. These are general classifications and may or may not reflect the actual construction of the strands. However, all wire ropes of the same size and wire grade in each classification will have the SAME strength and weight ratings and usually the same pricing.

Besides the general classifications of wire rope, there are other types of wire rope that are special construction and designed for special lifting applications.

Some types of wire rope, especially lang lay wire rope, are more susceptible to rotation when under load. Rotation resistant wire rope is designed to resist twisting, spinning, or rotating and can be used in a single line or multi-part system.

Special care must be taken when handling, unreeling, and installing rotation resistant wire rope. Improper handling or spooling can introduce twist into the rope which can cause uncontrolled rotation.

Compacted strand wire rope is manufactured using strands that have been compacted, reducing the outer diameter of the entire strand, by means of passing through a die or rollers. This process occurs prior to closing of the rope.

This process flattens the surface of the outer wires in the strand, but also increases the density of the strand. This results in a smoother outer surface and increases the strength compared to comparable round wire rope (comparing same diameter and classification), while also helping to extend the surface life due to increased wear resistance.

A swaged wire rope differs from a compacted strand wire rope, in that a swaged wire rope’s diameter is compacted, or reduced, by a rotary swager machine after the wire rope has been closed. A swaged wire rope can be manufactured using round or compacted strands.

The advantages of a swaged wire rope are that they are more resistant to wear, have better crushing resistance, and high strength compared to a round strand wire rope of equal diameter and classification. However, a swaged wire rope may have less bending fatigue resistance.

A plastic coating can be applied to the exterior surface of a wire rope to provide protection against abrasion, wear, and other environmental factors that may cause corrosion. However, because you can’t see the individual strands and wires underneath the plastic coating, they can be difficult to inspect.

Plastic filled wire ropes are impregnated with a matrix of plastic where the internal spaces between the strands and wires are filled. Plastic filling helps to improve bending fatigue by reducing the wear internally and externally. Plastic filled wire ropes are used for demanding lifting applications.

This type of wire rope uses an Independent Wire Rope Core (IWRC) that is either filled with plastic or coated in plastic to reduce internal wear and increase bending fatigue life.

Remember, wire rope is a complex piece of mechanical machinery. There are a number of different specifications and properties that can affect the performance and service life of wire rope. Consider the following when specifying the best type of wire rope for your lifting application:Strength

When you select a piece of rope that is resistant to one property, you will most likely have a trade-off that affects another property. For example, a fiber core rope will be more flexible, but may have less crushing resistance. A rope with larger diameter wires will be more abrasion resistant, but will offer less fatigue resistance.

At Mazzella Companies, we offer all different kinds of wire rope from all of the leading manufacturers. We sell the highest-quality domestic and non-domestic rigging products because product quality and operating safety go hand-in-hand. We have one of the largest and most complete inventories of both domestic and non-domestic rigging and lifting products to suit your lifting needs.

If you’re looking for a standard or custom specified wire rope for your lifting project, contact a Lifting Specialist at a Mazzella Companies location near you.

We stock well over 2,000,000 feet of wire rope in our various locations … ready for immediate delivery! We provide wire rope assemblies, and manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM assemblies.

An important consideration in wire rope construction is the way the wires have been laid to form strands and the way the strands have been laid around the core.

Lay is classified by both direction and type. The lay direction of the wires within a strand and of the strands within a rope is either left or right. Rope lay is further classified as either regular or lang. In a regular lay rope, the wires in the strands are laid in the opposite direction as the strands in the rope. In a lang lay rope, the wires in the strands are laid in the same direction as the strands in the rope.

Regular and lang lay ropes are easily identified by the appareance of the outer wires with respect to the rope axis as shown by the examples to the right.

Right regular and right lang are the most common types of lay in use. Each possesses unique characteristics important to proper selection. Wire rope can be manufactured with five types of lay.

Regular lay ropes are generally more stable and more resistant to crushing. Lang lay ropes are significantly superior in fatigue and abrasion resistance. However, lang lay ropes are more susceptible to crushing and require good winding conditions. They are also extremely prone to rotate under load; they must never be used unless both ends are restrained.

Alternate lay rope combines the best features of regular and lang lay ropes. It offers the advantages of both constructions while minimizing the disadvantages. This construction is ideal where high bending stresses (fatigue) are combined with high rope-to-sheave pressure (crushing); for example, as applied to boom hoist rope.

Combinations of lays are sometimes employed to achieve rotation resistant properties. In this 19 x 7 rope, (as well as in 8 x 19 IWRC Rotation Resistant rope), the extreme rotational property of lang lay rope is used in the core to counteract the tendency of the outer regular lay strands to rotate in the opposite direction.

A number of core types are available and each ahs specific properties: 1.Wire strand core(WSC)- The core is usually of the same construction as the outer strands. 2.Fibre core (FC)- These are normally sisal or polypropylene. 3.Independant wire rope core (IWRC)- a wire rope usually of 6x7(6/1) / 1x7(6/1) construction.

A fibre core, generally sisal, provides a resilient foundation for the strands in the rope structure. Fibre cores are used for ropes where flexibility in handling is required. Fibre Cores are inadequate where ropes are subjected to prolonged outdoor exposure and crushing on small drums and sheaves.

These cores are used chiefly for standing ropes(guys or rigging), and offer high tensile strength and, owing to the larger wire is the core , greater resistance to abrasion.

Independent wire rope cores are preferred for operating ropes in applications of high tensile stress, high compression loads on small drums and sheaves ( such as earth moving equipment) and high operating temperatures ( such as cranes handling molten metal). A rope with an IWRC is approximately 11% heavier and 7.5% stronger than fibre cored rope of the same size.

The term "lay" is used in three ways:To describe the direction in which the strands are laid in the rope, right or left. In a Right Hand lay strands are laid around the rope core in a clockwise direction - see illustration below. In a Left Hand lay, the strands are laid anti-clockwise - see illustration below. Steel Wire Ropes are conventionally produced Right Hand lay unless special circumstances require Left Hand lay.

To describe the direction in which the wires are stranded in relation to the direction of the strands in the completed rope, e.g. Ordinary lay or Lang"s lay. Ordinary lay means the wires in a strand are laid in a direction opposite to the direction in which the strands are laid in the final rope. Lang"s lay is the reverse of Ordinary lay. That is, the wires are laid in the same direction as the strands in the rope. Lang"s lay ropes have superior properties in resistance to wear, abrasion, fatigue and scuffing. This is illustrated below, where it can be seen that wear on an outer wire is distributed over a far greater area than in Ordinary lay.

Lay direction of strands for stranded ropes are right (z) or left (s) and correspond to the direction of lay of the outer wires in relation to the longitudinal axis of the strand. Lay direction of ropes are right (Z) or left (S)and correspond to the direction of lay of outer wires in spiral ropes, the outer strands in a stranded rope or the unit ropes in a cable-laid rope in relation to the longitudinal axis of the rope.

For example, the importance of rope lay is evident in a four-part high lift grab where rotation of the grab is prevented by the use of alternative right-hand and left-hand ropes.

Wire Drawing technology passed on from generation to generation, new equipment and stringent quality control in rod selection , wire drawing and closing ensure that our wire rope conform to Australian and international specifications.

Galvanised ropes and strand are made of zinc coated (galvanised) wire rope for protection against corrosion. With the increasing use of heavy-duty and more compact equipment( e.g. power winches on mobile cranes and mine winders) there is a gradual upward trend in the required rope wire tensile range. However, as factors other than strength influence the life of wire rope, the specific application must be kept in mind when the tensile strength of the wire is selected.

All our ropes are produced to comply with the requirements of the Australian standards. These standards require ropes to be produced to AS3569. Our ropes comply with these specifications and internationally recognised specifications. Our companies testing facilities are constantly engaged in the testing of both works production and samples received for examination. For investigation and customer service purposes, a non destructive testing unit is available. Enquiries concerning use of this instrument or advice on non-destructive testing in general are welcome. A full report of all site examinations is issued.

Note: Inspections must be carried out by competent individuals. If in your opinion, a wire rope has sufficient damage of any type that may result in an accident or injury, don’t use it, tag the wire rope “OUT OF SERVICE” and have it inspected or replaced.

In published material, wire rope strength is shown as minimum breaking force (MBF) referring to the calculated strength figures that are accepted by the wire rope industry. They are usually based on the use of wires of a nominal size and the minimum tensile strength or as in Europe these figures are based on an aggregate MBF, based on cross sectional area and tensile strength of wires only. The MBF is the figure which should be used for design of rope equipment.

The working load limit is the maximum load a rope can carry on a particular service. The WLL should be based on the MBF, not the actual breaking force, which can vary depending on construction and size. The design factor /safety factor for ropes in Australia under general conditions is 6:1. This may vary in certain circumstances such as an ‘engineered lift’, where design factor may be reduced if approved. Crane manufacturers may also choose to use higher design factors for certain ropes on certain crane models, as such if you are not sure always refer back to us or to the manufacturers specification. Due account should be taken of the number of parts and the efficiency, whenever the design factor of a system is being determined. Regulatory authorities or other Standards may require other design factors.

The following tables show rope mass in “kg per metre” and breaking force in “Kilo newtons” for the various constructions and categories of Wire Rope. Please note that the value varies from category to category since the various constructions contain different steel areas and variable losses occur in the wire stranding process. Wire quality has been nominated in 1570,1770,and 1960 grades for the majority of wire ropes, the value 1570, 1770 etc. corresponds to the minimum tensile strength of the wire expressed in mega Pascals. Marine ropes have been nominated at 1570 grade and general engineering ropes both un-galvanised and galvanised are nominated in 1770 grade. To calculate the approximate MBF equivalent in tons divide kilo newtons by 9.81.

There are many different sizes, configurations, and materials that form wire rope, and these are different types including stainless steel wire rope, galvanized wire rope, and bright wire rope.

Looking for accessories to use with wire ropes? Our rigging supplies include hardware and accessories for use with cranes, hoists & winches, and oilfield applications.

Diameter:To properly measure the diameter of steel wire ropes, measure the rope at its widest point. This is an industry standard with wire cable manufacturers and steel cable suppliers.

Grade of Steel – EIPS, EEIPS: EIPS is Extra Improved Plowed Steel and has roughly 10% more strength than IPS. EEIPS is Extra Extra Improved Plowed Steel and is approximately 10% stronger than the EIPS. We offer every variety of EIPS Wire Rope and have a one day lead time on any EEIPS ropes.

Direction of Lay: Right hand and left hand designates which way the strands wrap around the core of the steel rope. Regular lay and Lang lay specify which way the wires are formed in the helix pattern. Regular lay means the wires are rotated opposite the direction of the strands around the core. Lang lay means the wires are twisted in the same direction as the strands are wrapped around the wire rope core.

Finish – Bright Wire, Galvanized Wire, and Stainless Steel: Most wire ropes have a bright, self-colored finish hence the name. Wire ropes generally have a coating of lubricant to reduce friction and protect from corrosion. However, there are wire ropes that are galvanized, stainless steel, or coated in vinyl and other plastics.

Material of the Core: Fiber Core (FC) or Independent Wire Rope Core (IWRC) – Fiber cores are made of natural (sisal, etc.) or synthetic (polypropylene, etc.) fibers and allow for increased flexibility. IWRC offers more support to the outer strands, and have a higher resistance to crushing. IWRC also offers more resistance to heat, reduces the amount of stretch, and increases the strength of the rope.

Strands: Another variable in wire rope is how many strands make up the rope and how many wires make up one strand. For instance, a 6×26 wire rope has 6 strands around a core with 26 wires making up each strand. The 6×19 class is the most common and offers higher resistance to abrasion whereas the 6×37 class offers higher flexibility.

Although there are exceptions for special applications, the constructions in 6×36 classification are primarily designed to be the most efficient for each rope diameter. As the rope size increases, for instance, a large number of wires can be used to achieve required fatigue resistance, and still those wires will be large enough to offer adequate resistance to abrasion.

The 6×19 classification of wire ropes includes standard 6 strand, round strand ropes with 16 through 26 wires per strand. This is a good rope to withstand abrasion or crushing on the drum. Ropes with independent wire rope strands and a core (IWRC) in general, are more crush resistant than fiber core ropes.

When you purchase our 6×19 Class of wire ropes, you get more than just another rope. Manufactured in an ISO 9001 certified factory and backed by the industry’s largest staff of professional engineers, we do more than meet published specifications.

The 6×26 WS has better resistance to abrasion than a 6x25FW. It features a compact construction with solid support for the wires; therefore it has a high resistance to crushing. Its number and relative size of the inner wires add to the stability of the strand and gives it a fatigue resistance comparable to a 6×25 FW. A standard 6×26 WS construction provides the best rope for a wide range of applications. In general, we recommend the use of the 6x26WS in any application where a 6x25FW is used.

Mast Raising Lines, also called Bull Lines or Bridle Lines, are usually two pieces: each having sockets on both ends. These lines can be fabricated from either right regular lay rope or right lang lay rope. They must be fabricated from IWRC ropes.

Premium ropes may be used for specific applications. PFV cushions the strands, distributes internal stresses, keeps in wire rope lubricant and keeps out dirt and debris, extending the service life.

Flex-X® 9 features compacted strands and swaging for extra drum crushing resistance and increased stability. Its high-density strands deliver extra strength and resistance to abrasion. Flex-X® 9 is manufactured with a dual compaction process to produce a compact cross-section with minimum voids and greater surface area on outer wires that contact drums, sheaves and the rope, itself during operation. The high-density compacted strands minimize nicking at strand-to-strand contact points. Flex-X® 9 was specifically designed for boom hoist applications and tubing line applications where drum crushing is a challenge.

Flex-X® 6 users receive superior performance and increased service life in many applications compared to the ropes they had previously employed. When compared to conventional six-strand ropes, Flex-X® 6 ropes provide greater surface area and more steel per given diameter. This increases rope stability and strength. This results in a longer service life and less sheave and drum wear.

Flex-X® 19, a Category 2 rotation resistant rope, is made from 19 strands. Six strands are laid around a core strand in one direction, and then 12 strands are laid around this first operation in the opposite direction. Because of its tightly compacted smooth design, Flex-X® 19 offers more crushing resistance than standard 19×7 rope, higher strength-to-diameter, resistance to bending fatigue, exceptional stability, reduced wear to sheaves and drums, and improved handling, operating and spooling characteristics.

Wire rope is a collection of metal strands that have been twisted and wound to form the shape of a helix with the purpose of supporting and lifting heavy loads and performing tasks that are too rigorous for standard wire. On shipping docks, rigging, and load bearing equipment, wire rope is attached to swivels, shackles, or hooks to lift a load in a controlled, even, and efficient manner.

The uses for wire rope include adding support to suspension bridges, lifting elevators, and serving as additional reinforcement for towers. The design of wire rope, with its multiple strands wrapped around a stable core, provides strength, flexibility, and ease of handling for applications that have bending stress.

Individual designs of wire rope involve different materials, wire, and strand configurations as a means for supporting and assisting in the completion of lifting or supportive applications.

The term wire rope encompasses a wide range of mechanical tools that are made to perform heavy and extreme lifting jobs. Wire rope is a complicated and complex tool with multiple moving parts capable of

8613371530291

8613371530291