rocky mountain wire rope utah free sample

“A RIGGER HAS A DEFINITE OBLIGATION TO HIS FELLOW WORKMAN, TO HIS EMPLOYER AND TO THE PUBLIC TO SEE THAT HIS EVERY ACT IS PERFORMED IN THE SAFEST POSSIBLE MANNER … A MISTAKE ON THE PART OF THE RIGGER CAN EASILY CAUSE THE LOSS OF LIFE AND THE DESTRUCTION OF PROPERTY … A CAREFUL RIGGER DOES NOT GUESS OR PLAY HUNCHES, HE HAS TO MAKE SURE HE IS RIGHT BY CHECKING HIS GEAR AND RIGGING METHODS AGAINST PROVEN AND ACCEPTED RIGGING STANDARDS.”

It"s a place that sells rope. And rigging. By the looks of things, most of their business is of the industrial/large scale/massive project variety, where I"m sure they deliver tons and tons of cable and rigging. And they probably do a good job of it.

I was recently tasked with picking up some rope for the scouts, and this was the location. They do sell to the public, so if you"re looking for rope and rigging, here"s your rope and rigging heaven. I just like saying rope and rigging. Rope and rigging. See how it rolls off the tongue? I"ve become distracted...

So that"s the story. Honestly, it"s just fine. What do you expect? They sell rope and rigging all day long. Rope and rigging. Try it... say it out loud... rope and rigging.

CLEVELAND, OH – Mazzella Lifting Technologies, a Mazzella Company, is pleased to announce the acquisition of Denver Wire Rope & Supply. This acquisition will strengthen Mazzella’s footprint west of the Mississippi River and reinforce Mazzella’s commitment to be a one-stop resource for lifting and rigging services and solutions.

Denver Wire Rope & Supply has been in business since 1983 and services a variety of industries out of their location in Denver, CO. Denver Wire Rope & Supply is a leading supplier of rigging products, crane and hoist service, below-the-hook lifting devices, and certified rigging inspection and training. Effective immediately, Denver Wire Rope & Supply will operate as Mazzella / Denver Wire Rope. Terms of the transaction are not being disclosed.

“Denver Wire Rope & Supply will complement the wide range of products and services that Mazzella Companies offers. We are dedicated to being a single-source provider for rigging products, overhead cranes, rigging inspections, and rigging training. Both companies commit to a customer-first mentality, providing the highest-quality products, and leading by example when it comes to safety and sharing our expertise with customers and the market,” says Tony Mazzella, CEO of Mazzella Companies.

“Our team and family are excited to be part of the Mazzella Companies. This acquisition strengthens our place in the market and allows our team to continue to provide excellent service and products to our valued customer base and expand our offering,” says Ken Gubanich, President of Denver Wire Rope & Supply.

“Over the years, we have had numerous companies show interest in purchasing Denver Wire Rope & Supply, none seemed to be the right fit. We are looking forward to becoming a part of an aggressive, passionate, and progressive organization. As a family business for over 36 years, it is important to us that our customers/friends, suppliers, and team members continue to be treated with first-class service, products, and employment opportunities. Again, we are very enthusiastic about our future and look forward to being a quality supplier for your crane, safety training, rigging, and hoisting needs for years to come,” says Gubanich.

“We wish Ed and Carol Gubanich all the best in their retirement. We welcome Ken and the other second and third-generation Gubanich family members, as well as the entire Denver Wire Rope Team, into the Mazzella organization,” says Mazzella.

We’ve changed our name from Denver Wire Rope to Mazzella. Aside from the new name and logo, our member experience is virtually unchanged. Here are some common questions and answers related to this change.

In 2019, Denver Wire Rope & Supply was acquired by Mazzella Companies to expand lifting and rigging products and services to the western half of the United States.

In 1954, James Mazzella founded Mazzella Wire Rope & Sling Co. in Cleveland, OH. For over 65 years, the company has grown organically by nurturing historic relationships, expanding its product offerings, and entering new markets through acquisition.

Geneva Rock Products, Inc. owns and operates the Hansen Pit, a surface sand and gravel mine for construction materials. The mine is located in Draper, Salt Lake County, Utah. Jim Golding, President, is the principal official and Ed Clayson, Production Manager, is in charge of health and safety at the mine. The mine operates five to six days a week with two, ten-hour shifts per day. Total employment is forty-eight miners.

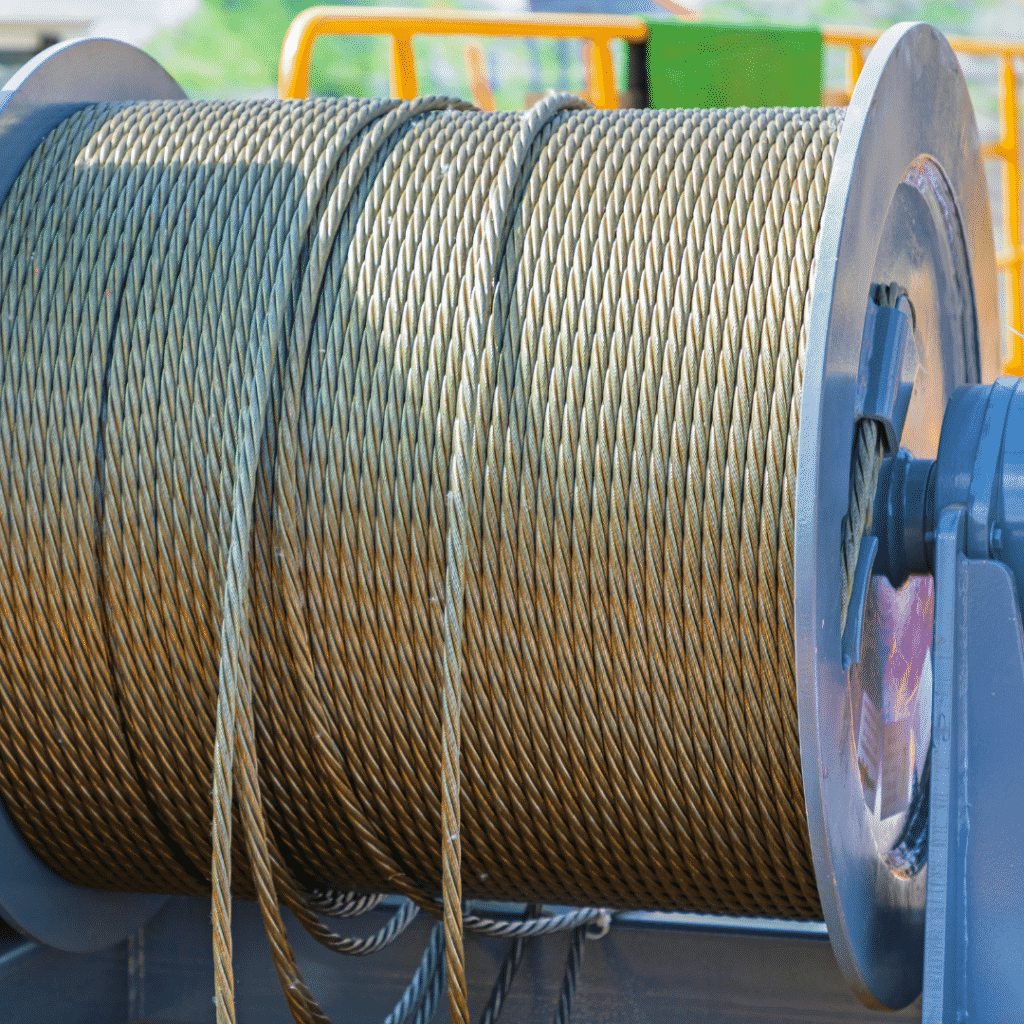

At approximately 12:30 p.m., Hardy returned to the area. Jacobson and Hardy rigged the replacement discharge chute assembly using three wire ropes ¾-inch x 10-feet long. One of the three wire ropes had a ¾-ton come-along attached between the wire rope and the lifting point to facilitate tilting the chute assembly.

Gary Hatch, Safety Director, called the Department of Labor National Contact Center (DOLNCC) at 2:19 p.m. on March 14, 2018, and notified MSHA of the accident. DOLNCC notified Peter Del Duca, Staff Assistant, in MSHA’s Rocky Mountain District. MSHA issued an order under provisions of Section 103(k) of the Mine Act to ensure the safety of the miners and began the investigation. MSHA issued a non-contributory citation for failure to comply with 30 CFR § 50.10, which requires the operator to immediately contact MSHA at once without delay and within 15 minutes once the operator knows or should know that an accident has occurred.

Miners rigged the chute assemblies for hoisting by using three ¾-inch x 10-feet long wire ropes, with two rigged to the top lifting points. Miners attached the third wire rope to a

Coffing ¾-ton Model LSB-B come-along. They attached wire ropes to the chute assemblies with 4-inch lifting hooks. Investigators detected no signs of failure in the wire ropes and determined that neither the rigging nor the come-along contributed to the accident.

It was 30 degrees in Idaho Springs, Colorado, in mid-April, and I was perched on a cliff edge in the Front Range of the Rocky Mountains, doing my best to keep moving forward despite having lost most of the feeling in my fingers. I was scrambling along the Mount Evans Via Ferrata, a set of metal cables and rungs permanently installed near the base of one of the state"s most majestic 14ers. It"s probably a good thing my phone was pinned to my body by a well-worn climbing harness. If I"d tried for a selfie hanging over the void, it probably would have wound up on the craggy rocks below.

Like a shipping pier transformed into an urban park, a via ferrata is a piece of industry reimagined. The first ones were installed in the Dolomites during World War I to help soldiers navigate the peaks more easily. In the years since, they"ve been used regularly by alpinists both serious and casual. Their cabling running up the mountain removes one of the biggest obstacles for novice climbers: the need to set anchors. (As I heard more than one guide quip, an improperly set anchor can really ruin your day.)

If you"ve heard of via ferratas, or iron paths as we would call them here, you probably associate them with Europe. But Colorado is suddenly flush with new routes. The latest and highest, coming to Arapahoe Basin this summer, will climb to 13,000 feet. They"ve been popping up at other major ski areas in the West, from Jackson Hole to Taos, and are an increasingly popular feature at remote resort properties like Camp Sarika by Amangiri in Utah and Tordrillo Mountain Lodge in Alaska.

Still, despite their growth, via ferratas remain a relatively hidden piece of the American adventure infrastructure. Almost to a person, everyone I told about the reason for my trip to Colorado—on my flight to Denver, at the car rental counter, at the adjacent picnic table at the New Terrain Brewing Company—put on a confused expression and said, “What"s that?” Which is a shame, because even more than the well-established ones in Europe, via ferratas in the U.S. offer a thrill that pretty much anyone can enjoy. Spencer Bonapace, my guide, told me he"s brought septuagenarians celebrating anniversaries, companies on team-building retreats, even tweens, to slide their clips along the steel cable that marks the route, as I was doing now. In many places where via ferratas can be found, summer activities like mountain biking and rock climbing have required technical expertise. Think of via ferratas as a new blue run on a mountain dominated by double blacks. The notion that they provide an anyone-can-do-it adventure has contributed to the growth in routes and interest. (Mount Evans is now often booked solid during the high season.) As if to emphasize how safely you"re anchored to the mountain, Bonapace showed off an exposed section he thought was a choice spot to lean back off the rocks.

This is not to say that I never got rattled along the route. “You"re gonna want to shuffle,” Bonapace told me as we reached a snow-covered platform that extended a good 15 feet over the edge of a cliff. I can have a bit of a thing about heights, so I baby-stepped my way to the slick edge, holding a rope lanyard for balance, and took several long moments to steady myself. At that point I was instructed to “just fall backwards.” As scary as this may sound, during the 50-foot free fall I clicked back into my comfort zone, knowing my equipment would catch me before I hit the ground.

The story of via ferratas in Colorado is a story about opening hard-to-reach mountain spaces to people who couldn"t access them before. As Todd Rutledge, a longtime guide, explained to me, it all started in Telluride with a colorful local climber named Chuck Kroger. “In 2007, Chuck and some friends had put in enough rungs and bolts that it was doable. He was also diagnosed with pancreatic cancer and not given long to live. He told one of his buddies to go finish that route and set it up so his wife, who was not a real climber, could do it.” It took several years, but Kroger"s wish was granted; today Telluride is home to one of the most beautiful and exposed via ferratas in the country. It"s also one of the very few that is accessible to the public without a guide. That said, if you"re at all inexperienced—with the equipment, with the heights, with the technique—you"ll want a guide to serve as your introduction to the iron paths and gateway to the mountains.

Each product construction is comprised of different fiber properties, lays and twists enhancing the performance and quality of the rope as well as expanding our abilities to provide a variety of specific applications. Always focused on excellence, we received our ISO 9001-2008 in January 2013. We pioneered the development of specialized factory equipment to meet the ever-increasing high production, quality and safety standards, while at the same time holding plant costs down. Several of our machines and processes have been patented and these unique innovations assure consistent length and strength for each strand, resulting in a balanced and safer rope product. This efficiency explains our ability to provide a valued product with superior quality and short lead times, at lower prices.

Tyler Madison has earned its position as a leading custom manufacturer of wire rope cable assemblies through its commitment to quality and customer service. We always carry an extensive inventory of stock components to meet our customers’ simpler needs. But with an extensive background in wire rope design, we welcome the opportunity to design, engineer, and manufacture wire rope solutions to perfectly match our customers’ more specific applications. Our many industrial OEM and commercial customers have learned to expect the very best with on time deliveries and the highest quality wire rope.

Our ability to design and manufacture custom wire rope products allows us to serve a wide variety of industries. We serve the aircraft, automotive, electronics, and security industries as well as many others. Among our most popular products are our wire rope lanyards and our wire rope cable assemblies. Both these wire rope products can be manufactured with galvanized steel or stainless steel and are offered with a variety of coating options. Wire rope lanyards are commonly utilized for security, hanging, anchoring, and pulling applications, while our wire rope cable assemblies are for more heavy-duty applications. A variety of aircraft grade cables are also available including military specifications-cable.

We offer a solution with DEFIANCE Wire Rope, Fiber Ropes and Hardware…quality-consitent products that meet or exceed current specifications including but not limited to RRW-410-F, API-9A. Cordage Institute Specifications, OCIMF, SOLAS, IMO etc. relating to a broad spectrum of features aimed to ensure Quality, Reliability and Satisfaction to our customer. This is what differentiates Atlantic Cordage from its competition. DEFIANCE products are precision engineered and manufactured to assure withstanding of severe marine field applications. Close control over every phase of our operations is second to none. This excellence is not only achieved by having the product available when you need it, but by also providing a knowledgeable staff fully trained in the industry we excel in.

Atlantic Cordage carries an extensive inventory of wire rope, towing hawsers, synthetic and manila rope, Embarkation/Debarkation ladders, marine and rigging hardware, chain and anchor chain and web sling products. Our main 40,000 square foot location provides a complete rigging shop to handle your every splicing need from basic wire rope slings to mooring lines. Our own fleet of trucks stand ready to deliver custom work in a matter of hours within our own delivery area. Our expediting department assures prompt service to all other parts of the country.

Located in northwest New Jersey, Jersey Strand and Cable, Inc. has been the most diversified fine diameter strand and cable manufacturer of its magnitude in the world for over 30 years. Our highly skilled and experienced staff provides our customers with the highest-quality standard and custom cable and stranded wire products available, including wire rope. Our innovative product development and unique custom cable manufacturing techniques allow us to provide micro-miniature, miniature, and small diameter wire sizes up to 1/8-inch finished product diameter.

With two state-of-the-art facilities in New Jersey that total over 100,000 square feet, Jersey Strand and Cable, Inc. is fulfilling a need in the industry for specialty cable and wire strand made to exact customer requirements. Our modern testing and development laboratory, along with other peripheral equipment and 200+ production machines, helps ensure that each customer’s product is manufactured and delivered to meet their precise specifications. Spearheaded by a former IBM systems engineer, we have developed a computerized, fully integrated management control system that controls and records all details of the manufacturing process, from RFQs to shipping and invoicing, to ensure that our products are adhering to customer and Jersey Strand and Cable, Inc. specifications. This system is efficient and streamlined and has been a huge factor in our success as the leading manufacturer of strand and cables.

Climbing ropes are typically of kernmantle construction, consisting of a core (kern) of long twisted fibres and an outer sheath (mantle) of woven coloured fibres. The core provides about 70% of the tensile strength,

Ropes used for climbing can be divided into two classes: dynamic ropes and low elongation ropes (sometimes called "static" ropes). Dynamic ropes are designed to absorb the energy of a falling climber, and are usually used as belaying ropes. When a climber falls, the rope stretches, reducing the maximum force experienced by the climber, their belayer, and equipment. Low elongation ropes stretch much less, and are usually used in anchoring systems. They are also used for abseiling (rappelling) and as fixed ropes climbed with ascenders.

Carabiners are made with many different types of gates including wire-gate, bent-gate, and straight-gate. The different gates have different strengths and uses. Most locking carabiners utilize a straight-gate. Bent-gate and wire-gate carabiners are usually found on the rope-end of quickdraws, as they facilitate easier rope clipping than straight-gate carabiners.

Quickdraws (often referred to as "draws") are used by climbers to connect ropes to bolt anchors, or to other traditional protection, allowing the rope to move through the anchoring system with minimal friction. A quickdraw consists of two non-locking carabiners connected together by a short, pre-sewn loop of webbing. Alternatively, and quite regularly, the pre-sewn webbing is replaced by a sling of the above-mentioned dyneema/nylon webbing. This is usually of a 60 cm loop and can be tripled over between the carabiners to form a 20 cm loop. Then when more length is needed the sling can be turned back into a 60 cm loop offering more versatility than a pre-sewn loop. Carabiners used for clipping into the protection generally have a straight gate, decreasing the possibility of the carabiner accidentally unclipping from the protection. The carabiner into which the rope is clipped often has a bent gate, so that clipping the rope into this carabiner can be done quickly and easily. Quickdraws are also frequently used in indoor lead climbing. The quickdraw may be pre-attached to the wall. When a climber ascends the wall, (s)he must clip the rope through the quickdraw in order to maintain safety. The safest, easiest and most effective place to clip into a quickdraw is when it is at waist height.

A harness is a system used for connecting the rope to the climber. There are two loops at the front of the harness where the climber ties into the rope at the working end using a figure-eight knot. Most harnesses used in climbing are preconstructed and are worn around the pelvis and hips, although other types are used occasionally.

Belay devices are mechanical friction brake devices used to control a rope when belaying. Their main purpose is to allow the rope to be locked off with minimal effort to arrest a climber"s fall. Multiple kinds of belay devices exist, such as tubers (for example the Black Diamond ATC) or active assisted-braking devices (for example the Petzl Grigri), some of which may additionally be used as descenders for controlled descent on a rope, as in abseiling or rappelling.

These devices are friction brakes which are designed for descending ropes. Many belay devices can be used as descenders, but there are descenders that are not practical for belaying, since it is too difficult to feed rope through them, or because they do not provide sufficient friction to hold a hard fall.

Figure eights allow fast but controlled descent on a rope. They are easy to set up and are effective in dissipating the heat caused by friction but can have a tendency to cause a rope to twist. Holding the brake hand off to the side twists the rope, whereas holding the brake hand straight down, parallel to the body, allows a controlled descent without twisting the rope. An 8 descender can wear a rope more quickly than a tube style belay/rappel device because of the many bends it puts into the rope. Many sport climbers also avoid them because of the extra bulk a Figure 8 puts on the climbing rack. However, many ice climbers prefer to use the 8, because it is much easier to thread with stiff or frozen rope. Unlike "bobbin" type descenders, figure eights can be used on doubled ropes. A major disadvantage is that they must be completely detached during fitting or removal so there is a danger of being dropped.

A rescue eight is a variation of a figure eight, with "ears" or "wings" which prevent the rope from "locking up" or creating a larks head or girth hitch, thus stranding the rappeller on the rope. Rescue eights are frequently made of steel, rather than aluminum.

Jumars perform the same functionality as friction knots but less effort is needed to use them. A Jumar employs a cam which allows the device to slide freely in one direction but tightly grip the rope when pulled on in the opposite direction. To prevent a jumar from accidentally coming off the rope, a locking carabiner is used. The Jumar is first attached to the climber"s harness by a piece of webbing or sling, and then the Jumar is clipped onto the rope and locked. Two ascenders are normally used to climb a fixed rope. For climbing a fixed rope attached to snow anchors on a steep slope, only one Jumar is used as the other hand is used for holding the ice axe.

Another type of ascender allows rope to feed in either direction, slowly, but locks up when pulled quickly. Such self-locking devices allow people to protect solo climbs because the amount of rope is automatically adjusted.

A sling or runner is an item of climbing equipment consisting of a tied or sewn loop of webbing that can be wrapped around sections of rock, hitched (tied) to other pieces of equipment or even tied directly to a tensioned line using a prusik knot, for anchor extension (to reduce rope drag and for other purposes), equalisation, or climbing the rope.

A daisy chain is a strap, several feet long and typically constructed from one-inch tubular nylon webbing of the same type used in lengthening straps between anchor-points and the main rope. The webbing is bar tacked at roughly two-inch intervals (or, in the past, tied) to create a length of small loops for attachment. Unlike the use of similar devices in backpacking, daisy chains in technical rock climbing are expected to be of sufficient strength to be "load bearing". Daisy chain pockets however are not rated to full strength, and can only take static loads.

Nuts are manufactured in many different varieties. In their simplest form, they are just a small block of metal attached to a loop of cord or wire. They are used by simply wedging them into narrowing cracks in the rock, then giving them a tug to set them. Nuts are sometimes referred to as stoppers, or by the slang term, wires.

These consist of three or four cams mounted on a common axle or two adjacent axles, in such a way that pulling on the shaft connected to the axle forces the cams to spread further apart. The SLCD is used like a syringe, by pulling the cams via a "trigger" (a small handle) which forces them closer, inserting it into a crack or pocket in the rock, and then releasing the trigger. The springs make the cams expand and grip the rock face securely. A climbing rope may then be attached to the end of the stem via a sling and carabiner. SLCDs are typically designed to maintain a constant camming angle with the rock to ensure that the normal force provided by the cam lobes against the rock face will supply enough friction to hold a cam in equilibrium with the rock. These devices are also known as "friends" for example, as they are in the UK.

They consist of a variety of different-sized pockets and edges that are designed to be hung from with various training protocols. These pockets and edges can range from large jug holds to micro crimp edges. When used effectively they can facilitate huge gains in forearm strength and lock off strength, mostly in the flexor digitorum profundus, Lumbricals of the hand and flexor digitorum superficialis muscles of the forearms. They have to be used with the proper technique and should be avoided if the user is just starting in the sport to prevent injuries, that can happen specially in the A1-4 pulleys or along sections of flexor carpi sheath linking the different FDP or FDS sections in the forearm or in the rotator cuff in the shoulders.

A series of horizontal rungs attached to an overhanging surface that may be climbed up and down without the aid of the feet. When used properly, campus boards can improve finger strength and so-called "contact strength".

The climbing helmet is a piece of safety equipment that primarily protects the skull against falling debris (such as rocks or dropped pieces of protection) and impact forces during a fall. For example, if a lead climber allows the rope to wrap behind an ankle, a fall can flip the climber over and consequently impact the back of the head. Furthermore, any effects of pendulum from a fall that have not been compensated for by the belayer may also result in head injury to the climber. The risk of head injury to a falling climber can be further significantly mitigated by falling correctly.

A belay glove is a glove constructed from either leather or a synthetic substitute, is used to protect the hands when belaying, and is especially useful if using a classic or body belay. They are also very useful for controlling the belay with single, lead ropes that are 9.5 mm or smaller.

Chalk is most frequently white, and the repeated use of holds by freshly-chalked hands leads to chalky build-up. While this isn"t a concern in an indoor gym setting, white chalk build-up on the natural rock of outdoor climbs is considered to be an eyesore at best, and many consider it a legitimate environmental/conservation concern. In the United States, the Bureau of Land Management advocates the use of chalk that matches the color of the native rock.Arches National Park in Utah, have banned white chalk, instead allowing the use of rock-colored chalk. A handful of companies make colored chalk or a chalk substitute designed to comply with these environmental conservation measures. Garden of the Gods in Colorado has gone further, banning the use of all chalk and chalk substitutes outright.

Although the USGS maps label this peak as Mount Wire, the name Big Beacon is the more commonly known name for this mountain. The name Mount Wire comes from the Salt Lake City Policeman Lester Wire, who invented the traffic light back in 1912.

Mount Wire is one of the prominent foothill peaks due east of downtown Salt Lake City. The peak was easily recognized by the two large reflector panels just south of the summit, used for transmitting telephone signals between Salt Lake and Park City, but they were removed in 2013. Atop Mount Wire is an old airway beacon, which you can climb should you desire an extra 25 feet of elevation.

While Mt. Wire is a relatively low elevation peak, it is an outstanding spring hike of over 2,000 vertical feet with incredible views in every direction, rampant wildflowers, and wildlife that includes the occasional rattlesnake or mountain lion. In most years the peak can be hiked free of snow in April, and is an excellent “tune up” for the bigger mountains.

Take I-15 4th south exit and continue east through downtown, up past the University of Utah, and turn left (east) on Wakara Avenue. Follow this up past several buildings to the end of the road. Turn right on Colorow Road and go south. There is almost immediately a trailhead that accesses the Bonneville Shoreline Trail, but the better trailhead is a little further down the road (marked with a sign), just before the Huntsman building. Park along either side of the road.

Take I-15 4th south exit and continue east through downtown, up past the University of Utah, and turn left (east) on Sunnyside Avenue. Continue past Hogle Zoo and This is the Place Heritage Park, and park at the trailhead immediately east of the Park, there is a large trail sign here, and parking for about 10-15 cars.

This is the most scenic route on the mountain. There is some route finding involved. The trail is about 2 miles each way with 2140 feet elevation gain. See the route page for details.

This is the shortest route on the mountain. It is exposed to full sun for the entire distance. This is also the route most likely to be snow free in early spring. There are a few variations, all the approximate same length. The trail is about 1.5 miles each way with 2140 feet elevation gain. See the route page for details.

Camping is allowed in the backcountry, but the routes up Mount Wire are short and there is no water unless there is still snow around. For the most part, this is a day use mountain, though at night there would be a good view of the city lights from the summit.

Weather and climate data for Parleys Summit at 7585 feet elevation is below. *SNOTEL Data 1985-2017. Expect similar conditions on the summit of Mount Wire.

8613371530291

8613371530291