safe working load of wire rope sling factory

SWL, NWL, MBS — all of the acronyms can get very confusing. Don’t fret – we’re here to clear things up when it comes to safe working load limits and the terms associated with it.

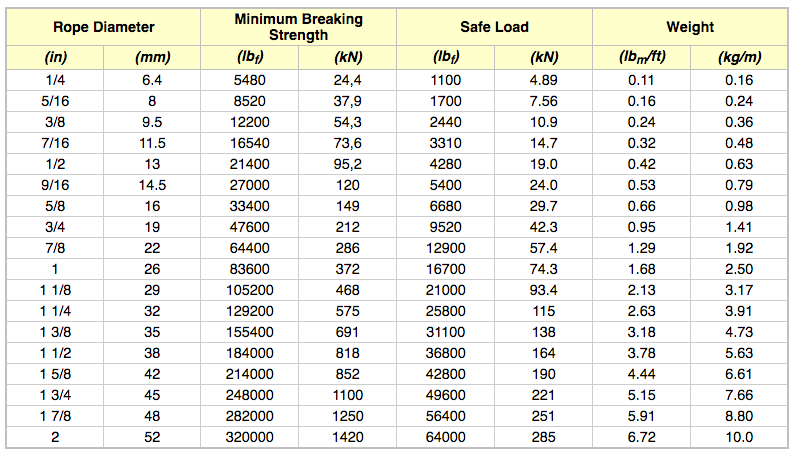

Safe Working Load (SWL) sometimes stated as the Normal Working Load (NWL) is the mass or force that a piece of lifting equipment, lifting device or accessory can safely utilize to lift, suspend, or lower a mass without fear of breaking. Usually marked on the equipment by the manufacturer and is often 1/5 of the Minimum Breaking Strength (MBS) although other fractions may be used such as 1/4, 1/6 and 1/10.[1][2][3]

Other synonyms include Working Load Limit (WLL), which is the maximum working load designed by the manufacturer. This load represents a force that is much less than that required to make the lifting equipment fail or yield, also known as the Minimum Breaking Load (MBL). SWL or WLL are calculated by dividing MBL by a safety factor (SF). An example of this would be a chain that has a MBL of 2000 lbf (8.89 kN) would have a SWL or WLL of 400 lbf (1.78 kN) if a safety factor of 5 (5:1, 5 to 1, or 1/5) is used.

Here at Industrial Rope Supply, we are not only committed to providing you with a quality product, but also with all the information needed to insure safety comes first on every job. Have safety questions on a product purchased from us? Contact us today and we’ll be happy to talk you through and/or provide you with the safety materials needed.

Safe Working Load (SWL) is the limiting safety factor to lift and carry any load safely. It must be clearly marked on any lifting device (hoist, lifts, lifting machines, and lifting tackles).

“No lifting machine and no chain, rope or lifting tackle shall, except for the purpose of the test, be loaded beyond the safe working load which shall be plainly marked and duly entered in the prescribed register, and where this is not practicable, a table showing the safe working loads of every kind and size of lifting machine or chain, rope or lifting tackle in use shall be displayed in prominent positions on the premises”

Where the safe working load may be varied by the raising or lowering of the jib, a table indicating the SWL at the corresponding indication of the jib or corresponding radii of the load shall be attached with the jib-crane.

A table showing the SWL (Safe Working Load) of every kind and size of chain, rope, or lifting tackle in use, and in case of multiple slings, the SWLat different angles of the legs, shall be posted in the storeroom.

Lifting equipment should have a tally plate indicating the Safe Working Load. The tally plate also indicates the identification number which can be mentioned in the test certificate held by the user. It should also indicate the date of the last inspection.

Safe Working Load (SWL) of any mobile crane depends on the operator’s skill, condition of the ground, boom length, the radius of rotation while lifting the load, the inclination of the boom to the vertical and outrigger blocked or free.

Safe Working Load is generally tabulated in the load chart of the crane. Sometimes, it is de-rated(decreased) due to defect in welding, bend in angle, bracing, etc., and condition of clutch, brake, etc. Modern cranes give a digital display of SWL, angle indicator, boom limit switch, and alarm for exceeding load.

The factor of the safety (Safety Factor) of fiber ropes varies from 6 to 12 mm depending on the conditions of use. fiber rope less than 12 mm dia should not be used for a sling or apart of a lifting appliance. Their factor of safety (FS) varies with diameter. The factor of Safety for the hook, wire rope sling, chain, fiber rope, and belt are given in the table below:

Proof testing is the application of a load greater than the SWL (Safe Working Load) to detect defective workmanship, faulty weld or other inherent weaknesses. It is not a means to assess the SWLwhich should only be done by calculations and checked where necessary by suitable tests on samples.

The proof test is required as a part of ‘thorough examination’ u/r 60(1) of GFRand no lifting machine or tackle should be used for the first time without this proof test.

In general, the proof load applied to chains, rings, hooks, shackles, and similar gear is twice the SWL. It should be just under the yield stress for the material.

Chain, ring, hook, shackles, swivel, sling, individual components of the hoist, wire rope, chain, pulleys, hooks, eye bolts, pins, axles, bearings, turnbuckles & ringing screws.2 SWL

After the above proof test, the parts are to be examined thoroughly by a competent person for signs of cracks, fatigue, deformation, permanent stretch, etc.

Wire ropes are essential for safety purposes on construction sites and industrial workplaces. They are used to secure and transport extremely heavy pieces of equipment – so they must be strong enough to withstand substantial loads. This is why the wire rope safety factor is crucial.

You may have heard that it is always recommended to use wire ropes or slings with a higher breaking strength than the actual load. For instance, say that you need to move 50,000 lbs. with an overhead crane. You should generally use equipment with a working load limit that is rated for weight at least five times higher – or 250,000 lbs. in this case.

This recommendation is all thanks to the wire rope safety factor. This calculation is designed to help you determine important numbers, such as the minimum breaking strength and the working load limit of a wire rope.

The safety factor is a measurement of how strong of a force a wire rope can withstand before it breaks. It is commonly stated as a ratio, such as 5:1. This means that the wire rope can hold five times their Safe Work Load (SWL) before it will break.

So, if a 5:1 wire rope’s SWL is 10,000 lbs., the safety factor is 50,000 lbs. However, you would never want to place a load near 50,000 lbs. for wire rope safety reasons.

The safety factor rating of a wire rope is the calculation of the Minimum Break Strength (MBS) or the Minimum Breaking Load (MBL) compared to the highest absolute maximum load limit. It is crucial to use a wire rope with a high ratio to account for factors that could influence the weight of the load.

The Safe Working Load (SWL) is a measurement that is required by law to be clearly marked on all lifting devices – including hoists, lifting machines, and tackles. However, this is not visibly listed on wire ropes, so it is important to understand what this term means and how to calculate it.

The safe working load will change depending on the diameter of the wire rope and its weight per foot. Of course, the smaller the wire rope is, the lower its SWL will be. The SWL also changes depending on the safety factor ratio.

The margin of safety for wire ropes accounts for any unexpected extra loads to ensure the utmost safety for everyone involved. Every year there aredue to overhead crane accidents. Many of these deaths occur when a heavy load is dropped because the weight load limit was not properly calculated and the wire rope broke or slipped.

The margin of safety is a hazard control calculation that essentially accounts for worst-case scenarios. For instance, what if a strong gust of wind were to blow while a crane was lifting a load? Or what if the brakes slipped and the load dropped several feet unexpectedly? This is certainly a wire rope safety factor that must be considered.

Themargin of safety(also referred to as the factor of safety) measures the ultimate load or stress divided by theallowablestress. This helps to account for the applied tensile forces and stress thatcouldbe applied to the rope, causing it to inch closer to the breaking strength limit.

A proof test must be conducted on a wire rope or any other piece of rigging equipment before it is used for the first time.that a sample of a wire rope must be tested to ensure that it can safely hold one-fifth of the breaking load limit. The proof test ensures that the wire rope is not defective and can withstand the minimum weight load limit.

First, the wire rope and other lifting accessories (such as hooks or slings) are set up as needed for the particular task. Then weight or force is slowly added until it reaches the maximum allowable working load limit.

Some wire rope distributors will conduct proof loading tests before you purchase them. Be sure to investigate the criteria of these tests before purchasing, as some testing factors may need to be changed depending on your requirements.

When purchasing wire ropes for overhead lifting or other heavy-duty applications, understanding the safety dynamics and limits is critical. These terms can get confusing, but all of thesefactors serve an important purpose.

Our company has served as a wire rope distributor and industrial hardware supplier for many years. We know all there is to know about safety factors. We will help you find the exact wire ropes that will meet your requirements, no matter what project you have in mind.

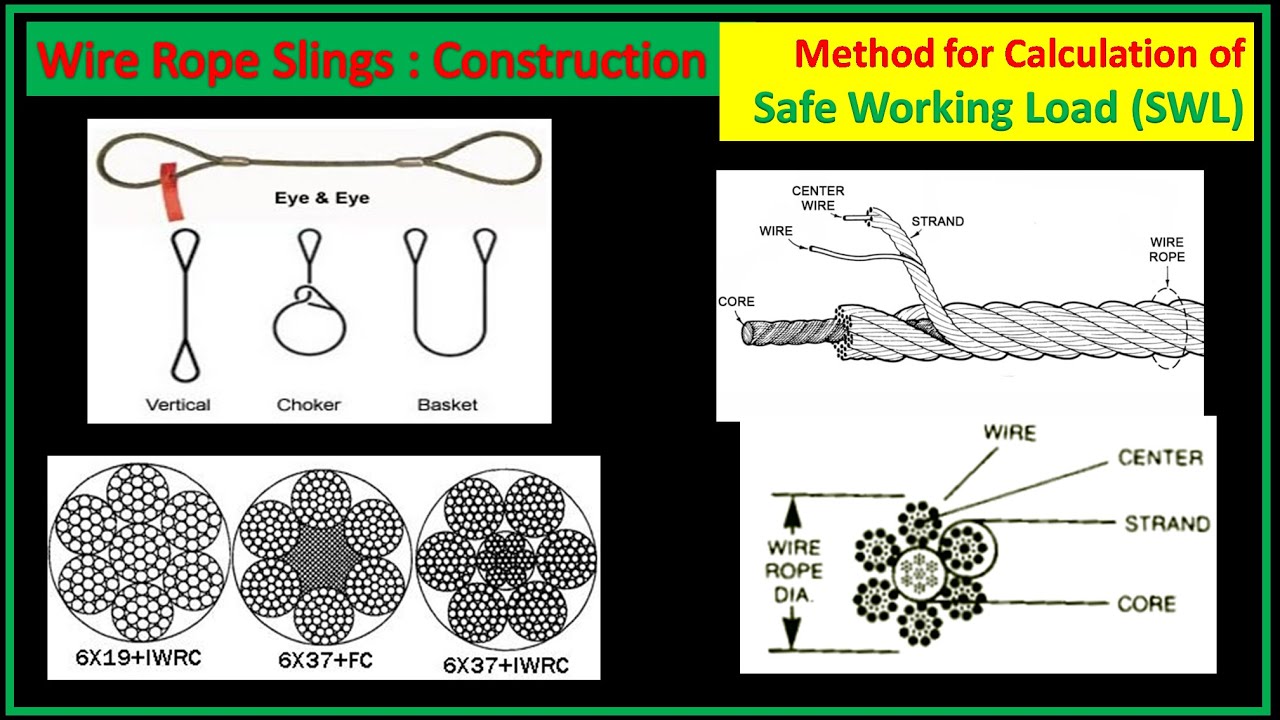

Wire rope is often used in slings because of its strength, durability, abrasion resistance and ability to conform to the shape of the loads on which it is used. In addition, wire rope slings are able to lift hot materials.

Wire rope used in slings can be made of ropes with either Independent Wire Rope Core (IWRC) or a fiber-core. It should be noted that a sling manufactured with a fiber-core is usually more flexible but is less resistant to environmental damage. Conversely, a core that is made of a wire rope strand tends to have greater strength and is more resistant to heat damage.

Wire rope may be manufactured using different rope lays. The lay of a wire rope describes the direction the wires and strands are twisted during the construction of the rope. Most wire rope is right lay, regular lay. This type of rope has the widest range of applications. Wire rope slings may be made of other wire rope lays at the recommendation of the sling manufacturer or a qualified person.

Wire rope slings are made from various grades of wire rope, but the most common grades in use are Extra Improved Plow Steel (EIPS) and Extra Extra Improved Plow Steel (EEIPS). These wire ropes are manufactured and tested in accordance with ASTM guidelines. If other grades of wire rope are used, use them in accordance with the manufacturer"s recommendations and guidance.

When selecting a wire rope sling to give the best service, consider four characteristics: strength, ability to bend without distortion, ability to withstand abrasive wear, and ability to withstand abuse.

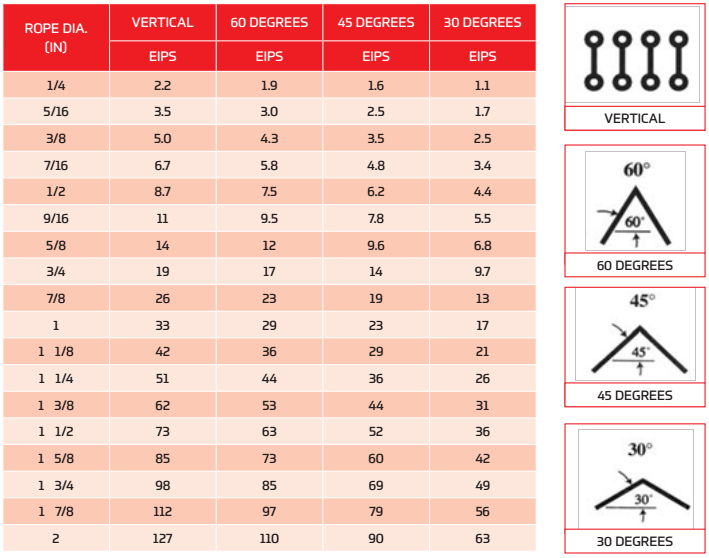

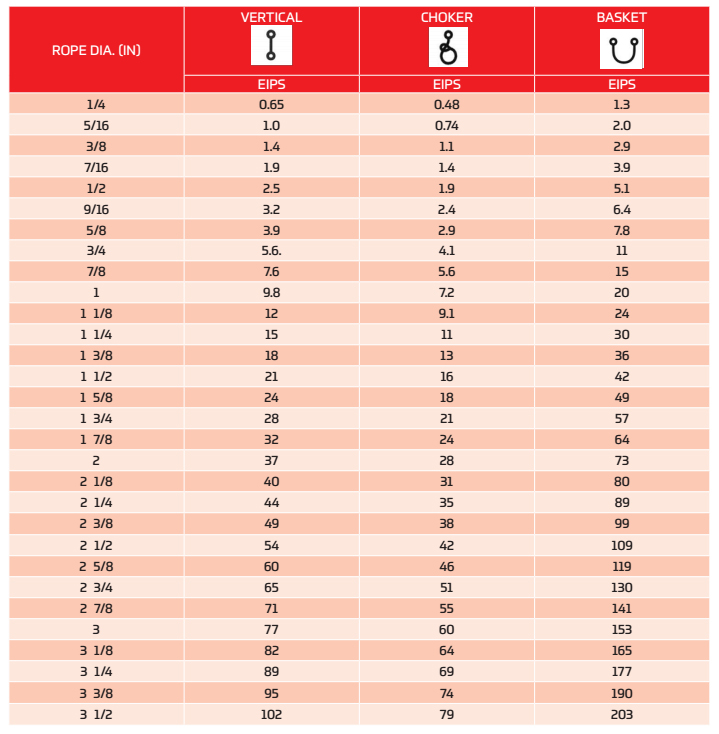

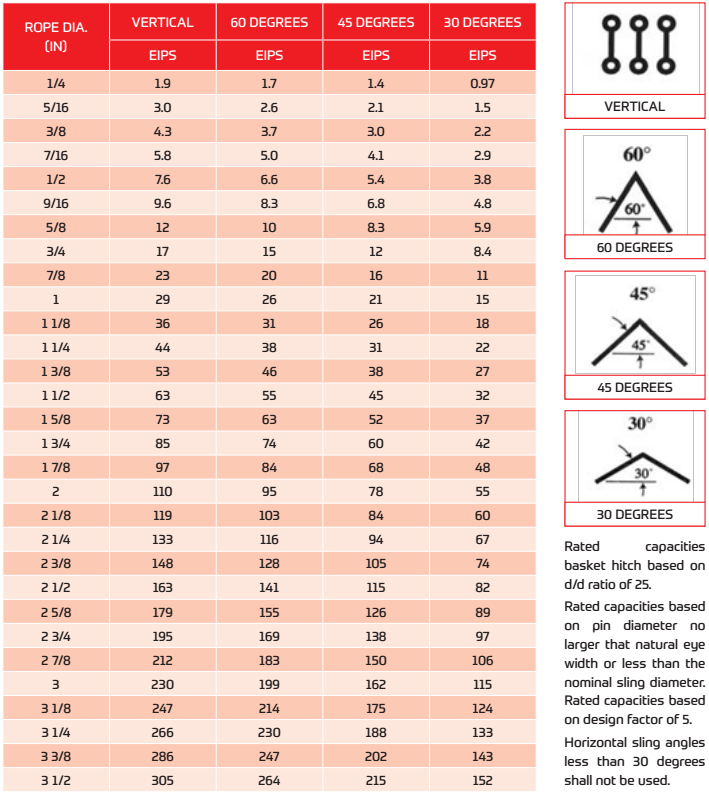

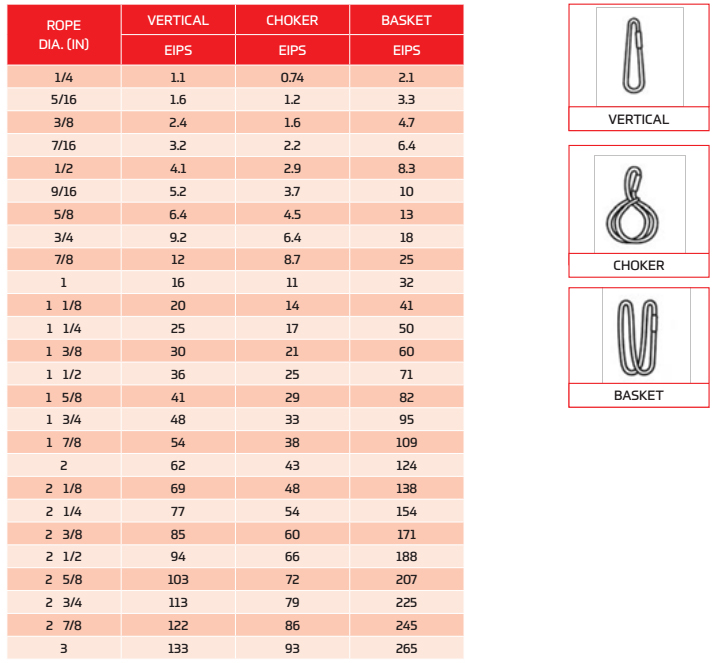

Rated loads (capacities) for single-leg vertical, choker, basket hitches, and two-, three-, and four-leg bridle slings for specific grades of wire rope slings are as shown in Tables 7 through 15.

Rated loads for a sling in a choker hitch are the values shown in Table 7, 9, 11, 13, 14, or 15, provided that the angle of the choke is 120 degrees or more (Fig. 2). Use the values in Fig. 2 or those from the sling manufacturer or a qualified person for angles of choke less than 120 degrees.

Ensure that slings made of rope with 6×19 and 6x37 classifications and cable slings have a minimum clear length of rope 10 times the component rope diameter between splices, sleeves, or end fittings unless approved by a qualified person,

Ensure that braided slings have a minimum clear length of rope 40 times the component rope diameter between the loops or end fittings unless approved by a qualified person,

Ensure that grommets and endless slings have a minimum circumferential length of 96 times the body diameter of the grommet or endless sling unless approved by a qualified person, and

Perform welding of handles or other accessories to end attachments, except covers to thimbles, before assembly of the sling. Ensure that welded end attachments are proof tested by the manufacturer or a qualified person. Retain the certificates of proof test and make them available for examination.

Do not use wire rope clips to fabricate wire rope slings, except where the application precludes the use of prefabricated slings and where the sling is designed for the specific application by a qualified person,

Although OSHA"s sling standard does not require you to make and maintain records of inspections, the ASME standard contains provisions on inspection records.[3]

Use damaged slings only after they are repaired, reconditioned, and proof tested by the sling manufacturer or a qualified person using the following criteria:

Ensure that wire rope slings have suitable characteristics for the type of load, hitch, and environment in which they will be used and that they are not used with loads in excess of the rated load capacities described in the appropriate tables. When D/d ratios (Fig. 4) are smaller than those listed in the tables, consult the sling manufacturer. Follow other safe operating practices, including:

Ensure that multiple-leg slings are selected according to Tables 7 through 15 when used at the specific angles given in the tables. Ensure that operations at other angles are limited to the rated load of the next lower angle given in the tables or calculated by a qualified person,

When D/d ratios (see Fig. 6) smaller than those cited in the tables are necessary, ensure that the rated load of the sling is decreased. Consult the sling manufacturer for specific data or refer to the WRTB (Wire Rope Technical Board) Wire Rope Sling Users Manual, and

Ensure that all portions of the human body are kept away from the areas between the sling and the load and between the sling and the crane or hoist hook,

When using a basket hitch, ensure that the legs of the sling contain or support the load from the sides, above the center of gravity, so that the load remains under control,

Ensure that the load applied to the hook is centered in the base (bowl) of the hook to prevent point loading on the hook, unless the hook is designed for point loading,

Before initial use, ensure that all new swaged-socket, poured-socket, turnback-eye, mechanical joint grommets, and endless wire rope slings are proof tested by the sling manufacturer or a qualified person.

Permanently remove from service fiber-core wire rope slings of any grade if they are exposed to temperatures in excess of 180 degrees F (82 degrees C).

Follow the recommendations of the sling manufacturer when you use metallic-core wire rope slings of any grade at temperatures above 400 degrees F (204 degrees C) or below minus 40 degrees F (minus 40 degrees C).

Lifting slings usually consist of chain, rope, or webbing used in alliance with a crane for lifting purposes. It facilitates moving heavy materials from one place to another while also keeping the balance of the load.

Workers practising rigging must exercise extreme cautiousness when involved in lifting processes that include using slings. Operators should receive training before participating in the lifting procedures, and you must monitor the splints frequently to avoid hazards.

Here is a brief guide to the main types of slings you can choose from as per your need. Alloy Chain Slings:Chain slings lift very hefty and enormous loads daily. However, when it comes to durability and endurance, they are the perfect fit. They can withstand high temperatures and adversities almost up to 1000°F. Once damaged, the chains are repairable and ready for use after the load testing. They are not affected by grease or oil and are tolerant to corrosion and UV rays. Wire Rope Slings:You can configure the Synthetic Web Slings:Synthetic web slings are preferable for lifting delicate and high-polished loads because it protects them from scratches, unlike other slings. Usually made from woven polyester or nylon, they make a good choice as it is cost-effective. Despite being made from soft materials, they are capable of lifting expensive and heavy loads. However, you can"t use it in conditions exceeding 194°F.

While choosing a sling, there are a few things to keep in mind. Here, is everything you must know before selecting the ideal sling:- The weight of the load:

It is crucial to determine the weight of the load before lifting it. It helps to ensure the safety of the workers present at the site from any possible mishaps. One of the ways to measure the weight of the load is to manually calculate it.

Another way can be following a load chart. A load chart helps in estimating the need for extensive calculations. It is also important to recalculate this since the lift range can keep varying. The Working Load Limit of the sling in use:

While choosing the ideal sling, it is important to keep its Working Load Limit (WLL) in consideration. It is extremely vital because the sling in use should handle the size and weight of the load.

For example, chain slings help lift bulky loads as compared to synthetic slings. However, if you end up opting for the wrong sling, it would have a risky possibility of the load getting dropped. The Environmental Factors:

Environmental factors play a major role in choosing the right sling. You need to be conscious about the details like temperature and the presence of corrosive substances.

Every sling is different and uses discrete materials. Keeping the material of the sling in mind assists in observing what goes best as per your requirement. The fragility of the materials depicts the distinct use of each. For example, chain slings are compatible with repetitive use because of their longevity. However, synthetic web slings are used for the flexibility they provide.

The working load limit (WLL) or previously known as safe working load (SWL) indicates the ultimate working load designated by the manufacturer. Exceeding the maximum limit can be threatening to the worker"s safety. Be mindful of the working load limit always being 1/3 of the breaking limit.

Some factors determining workload limit are:- Design Factor:For example, the design factor of chain slings is 4:1 whereas for wire rope sling it is 5:1.

Loading Angle:Sling to load angle can be described as the angle between the sling leg and the horizontal surface. Therefore, as the sling to load angle decreases, so does the given capacity of a sling.

So, these are the important points and factors that you have to perceive. It will give you an idea of the functionality of the slings. In the future, if you want to establish a business that involves slings, these pieces of information will help you.

The end point in a wire rope sling’s useful service life is prior to the failure of the sling. It must be removed from service when normal wear or accidental damage weakens the sling to the degree that an adequate factor of safety no longer exists.

The term “Breaking Strength” is never used with reference to slings. Slings have a “Rated Capacity” that is determined by the manufacturer. A sling should never be used to lift a load that is greater than the published “Rated Capacity” for the particular sling and for the type of hitch being used. The design factor used in the calculation of a sling’s Rated Capacity compensates for normal dynamic loading and builds useful life into the sling.

Selection of a sling to lift a load is based on selecting a sling with a Rated Capacity at least equal to the weight of the load. The sling must also be proper to allow the user to select a hitch that will conform to the shape of the load and keep it under control during the lift, The use of multiple leg slings is not recommended when the angle between any leg and the vertical is greater than 450• In any case when lifting headroom is restricted and a larger leg angle is necessary, care must be exercised in selecting a sling with a proper Rated Capacity at the leg angle which will be used. A visual inspection of the sling must be conducted before each lift to make sure the sling is in new or near new condition. A manufacturer’s Rated Capacity applies only to an undamaged sling.

Slings used in selected industries are presently covered by specific codes seffing standards for the removal of a sling from service. However, many industries are presently without standards. Safety is the prime consideration on all jobs and the user must inspect a sling before each lift, and must remove the sling from service upon observation of any of the following conditions:

Our responsibility is limited to the sling as purchased new; and the responsibility for safe operation, maintenance and use rest with the purchaser.Whenever a sling is being rigged, tensioned or used to lift a load, a potentially hazardous condition exists and extreme caution should be used by riggers and personnel in the area. In all cases, safe rigging practices must be employed.

Have you wondered why rigging experts always suggest a sling that has a significantly higher breaking strength than the actual weight of the load you are lifting? The manufacturers know that the rigging used in overhead applications need to have room for error. This is known as the Safety Factor.

Northern Strands manufactures wire rope slings rated up to 36,000 lbs and sells round synthetic slings that are rated up to 140,000 lb capacity. This capacity is the Working Load Limit of the sling, which is the maximum amount of weight or force that the sling"s user is allowed to put on the sling. Note: These slings do not break at the working load limit. These slings are designed with a safety factor of 5:1. This means that 5 times as much force as the working load limit has to be applied to the sling before it potentially fails. This means the wire rope slings have a Breaking Strength of up to 180,000 lbs and the round synthetic slings can withhold up to 700,000 lbs.

Wear - Working load limits are based on slings in brand new condition and a safety factor can help account for normal wear and tear until it is deemed unfit for further use.

Uneven loading - Slings are made up of either wires or fibers that must all share the weight of the load evenly. If any situation arises where the sling is bent or wrapped around an object, there is potential that some of the wires or fibers will be taking on a greater share of the load than others.

Visit Northern Strands website to use the sling tension calculator. The Northern Strands Sling Calculator has been designed to assist you in selecting slings with enough load carrying capacity for your lifting applications. It is your responsibility to assure that the slings you use are appropriate for your application. http://www.northernstrands.com/sling-calculator.aspx

(1) Cable laid and 6 x 19 and 6 x 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

(c) Safe Operating Temperatures. Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200o F. When nonfiber core wire rope slings of any grade are used at temperatures above 400o F, or below minus 60o F, the sling manufacturer"s recommendations shall be followed.

(2) A prototype of each welded end attachment shall be proof tested by the manufacturer or equivalent entity to check the design and welding method at twice the rated capacity before production is started. Subsequent tests of random samples shall be made. The manufacturer or equivalent entity shall provide a certificate of such tests which the employer shall retain and make available for examination by the Division upon request.

(3) Where rope clip attachments are used, they shall be made with U-bolts on the dead or short end of the rope and the saddle on the live end. The minimum number of clips for end attachments shall be not less than indicated in manufacturer"s tables, but in no case shall be less than three for any permanent installation. Clips shall be drop-forged steel. The clips shall be spaced at a distance equal to at least six times the diameter of the rope. All clip or clamp bolts shall be kept tight after tightening while rope is under tension.

(6) Hooks that have been opened more than 15 percent of the normal throat opening measured at the narrowest point or twisted more than 10 degrees from the plane of the unbent hook.

(1) Have permanently affixed and legible identification markings as prescribed by the manufacturer, and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one; and

Workers involved in hoisting and rigging must exercise care when selecting and using slings. The selection of slings should be based upon the size and type of the load, and the environmental conditions of the workplace. Slings should be visually inspected before each use to ensure their effectiveness. Improper use of hoisting equipment, including slings, may result in overloading, excessive speed (e.g., taking up slack with a sudden jerk, shock loading), or sudden acceleration or deceleration of equipment.

Factors to consider when choosing the best sling for the job include size, weight, shape, temperature, and sensitivity of the material being moved, and the environmental conditions under which the sling will be used. The following guide may be useful in selecting the appropriate sling:

Alloy steel chains are strong and able to adapt to the shape of the load. Care should be taken when using chain slings because sudden shocks will damage them. This may result in sling failure and possible injury to workers or damage to the load.

Chain slings must be visually inspected prior to use. During the inspection, pay particular attention to any stretching, nicks, gouges, and wear in excess of the allowances made by the manufacturer. These signs indicate that the sling may be unsafe and must be removed from service immediately.

Wire rope is composed of individual wires that have been twisted to form strands. Strands are then twisted to form a wire rope. When wire rope has a fiber core, it is usually more flexible but less resistant to environmental damage. Conversely, wire rope with a core that is made of a wire rope strand tends to have greater strength and is more resistant to heat damage.

When selecting a wire rope sling to give the best service, there are four characteristics to consider: strength, ability to withstand fatigue (e.g., to bend without distortion), ability to withstand abrasive wear, and ability to withstand abuse.

Strength – Strength of wire rope is a function of its size (e.g., diameter of the rope), grade, and construction, and must be sufficient to accommodate the maximum applied load.

Fatigue (Bending without Failure) – Fatigue failure of wire rope is caused by the development of small cracks during small radius bends. The best means for preventing fatigue failure of wire rope slings is to use blocking or padding to increase the bend radius.

Abrasive Wear – The ability of wire rope to withstand abrasion is determined by the size and number of the individual wires used to make up the rope. Smaller wires bend more readily and offer greater flexibility, but are less able to withstand abrasion. Larger wires are less flexible, but withstand abrasion better.

Abuse – Misuse or abuse of wire rope slings will result in their failure long before any other factor. Abuse can lead to serious structural damage, resulting in kinks or bird caging. (In bird caging, the wire rope strands are forcibly untwisted and become spread outwards.) To prevent injuries to workers and prolong the life of the sling, strictly adhered to safe and proper use of wire rope slings.

Wire rope slings must be visually inspected before use. Slings with excessive broken wires, severe corrosion, localized wear, damage to end-fittings (e.g., hooks, rings, links, or collars), or damage to the rope structure (e.g., kinks, bird caging, distortion) must be removed from service and discarded.

Fiber rope and synthetic web slings are used primarily for temporary work, such as construction or painting, and are the best choice for use on expensive loads, highly finished or fragile parts, and delicate equipment.

Fiber rope slings deteriorate on contact with acids and caustics and, therefore, must not be used around these substances. Fiber rope slings that exhibit cuts, gouges, worn surface areas, brittle or discolored fibers, melting, or charring must be discarded. A buildup of powder-like sawdust on the inside of a fiber rope indicates excessive internal wear and that the sling is unsafe. Finally, if the rope fibers separate easily when scratched with a fingernail, it indicates that the sling has suffered some kind of chemical damage and should be discarded.

Shock Absorbency - Regardless of the construction material, shock loading (e.g., excessive speed, rapid acceleration or deceleration) of slings should be minimized. However, it should be noted that synthetic web slings can absorb heavy shocks without damage.

Economy and Long Life – Synthetic web slings have a low initial cost and a long service life. They are unaffected by mildew, rot, or bacteria, resist some chemical action, and have excellent abrasion resistance.

Synthetic web slings must be inspected before use and should be removed from service if found to have acid or caustic burns, melting or charring of any part of the surface, snags, tears, or cuts, broken stitches, distorted fittings, or wear or elongation beyond the manufacturer’s specifications.

Being able to move heavy and bulky materials is a vital segment of many businesses. Without specialized tools for lifting, business, in many cases, would not be possible. Considering material handling is such an essential part of many industries, it is important to remember safety protocols when using material handling equipment. Mishandling equipment and parts will waste time and money. It is imperative to understand that this heavy machinery can potentially be deadly if misused. According to OSHA.gov, the single most common cause of injury and damage in the workplace is related to human error or mishandling.

Hoists, cranes, and derricks rely on slings to suspend loads, and so slings are widely considered the most common material for handling apparatuses. Understanding safe sling operations and OSHA regulations will significantly reduce risks to workers, products, and property.

The first line of defense for safe crane usage is a well-trained crane operator. At all times, an operator must demonstrate intelligence, common sense, and care. For instance, different lifting slings serve various functions, and it is crucial for operators to choose tools based on the specifics of the job. The operator must select the type, size, and conditions of the workplace. The worker must inspect slings visually before each use, to ensure effectiveness.

Not only can a good crane operator save lives and money, but they can also substantially extend the working life of the machine. Frequently, devices come to early retirement because they were misused and overworked. Well trained operators know how to circumvent the hazardous effects of lifting. Another mark of a good operator is their continued dedication to safety while not lifting or moving loads. The crane operator should be a leader in carrying-out safety measures throughout the facility.

Slings come in different types so that different jobs can be done safely and efficiently. Knowing when to use appropriate slings will help keep workers safe and working. Slings can be broken down into one of six categories:

The above slings are generally, because of use and inspection procedures, divided into three groups that include: chain, fiber rope web, and wire rope/mesh. Each above type has its characteristics, which comes with advantages and disadvantages. Many influences should be well-thought-out when choosing an appropriate sling for your specific job. Factors to consider include:

Chains are commonly employed because they boast high strengths relative to other options. They are also easily able to conform to the shape of specific loads. Of course, all types have their drawbacks. For chains, it is essential to be careful regarding sudden shocks, which will cause damage. Misusing the chain sling will more than likely lead to damage to the sling (resulting in failure).

If the load you are lifting has a high temperature, then chains are perfect. They can be heated to temperatures around 1,000 degrees Fahrenheit (or 538 degrees Celsius). Just because high heats can be reached that does not mean they should be sustained for prolonged periods of time. Any chain sling that has a consistent service temperature of 600 degrees Fahrenheitmust have its working load limit reduced to the recommendations of the manufacturer.

Steel chain slings must be inspected before use to ensure safety. Look for stretching, nicks, gouges, and wear in excess. All the above signs are clear indicators that the sling is in a compromised state. It may still work when lifting, but it should be no surprise if things do go poorly.

Wire ropes are another commonly used type of sling. Wire rope consists of many individual wires that are wrapped and twisted to form strong strands. Different cores are built into the rope to enhance specific characteristics. For instance, when wire rope has a fiber core, it is generally more flexible but less resistant to environmental corrosion. Cores that consist of wire rope strands are strong and can withstand higher heats.

The lay of the rope also helps to define the final product. Lay refers to the direction of twisting wires and strands during the construction process. The most common direction is right-lay because it offers users the widest range of applications. Lang lay and left lay are also options.

Fiber ropes and synthetic webs are mostly used for temporary work. Typical jobs frequently include construction, marine operations, and painting jobs. They also work well for expensive loads that have highly finished parts, delicate equipment, or fragile parts. Do not use fiber ropes near caustics or acids because the material will deteriorate. Each synthetic material has unique characteristics, and so they should always be used with the manufacturer’s recommendations and instructions in mind.

When it comes to safety and material handling, picking the right rigging supplies is the first step to keeping employees, materials, and facilities out of harm"s way. Regardless of using wire rope or nylon slings, make sure safety is the most crucial part of production and operation.

8613371530291

8613371530291