safe working load of wire rope sling supplier

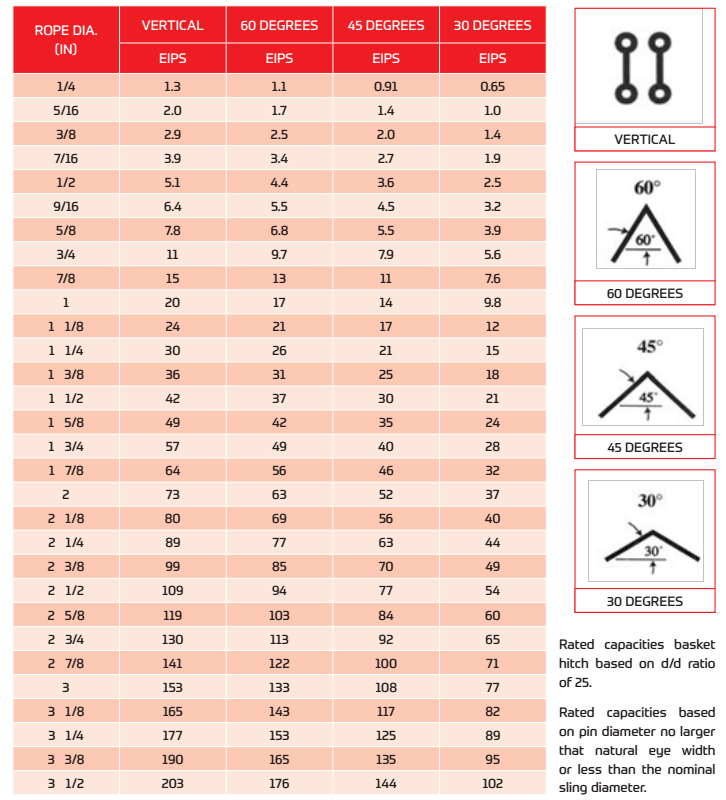

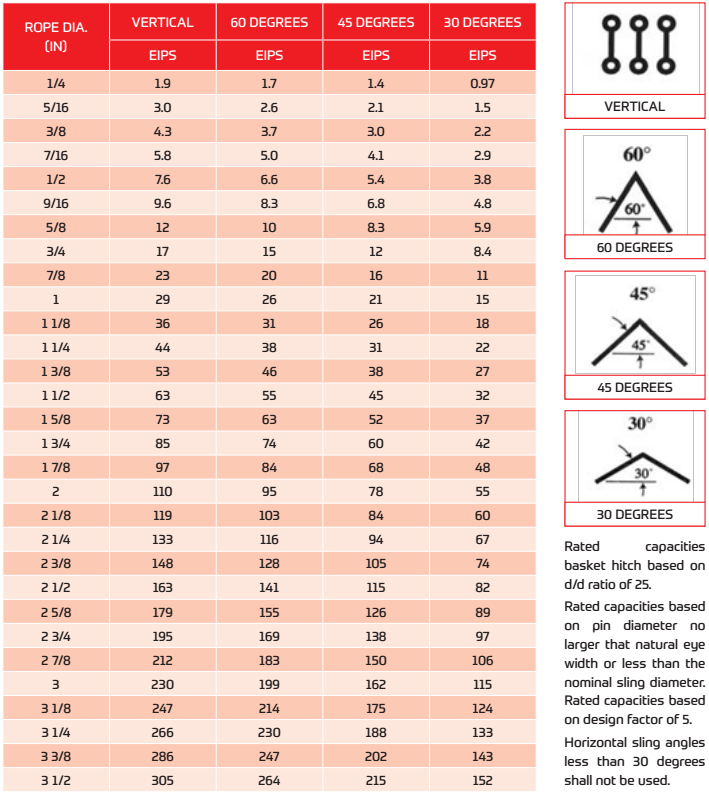

Rated load based on pin diameter no larger than one half the natural eye length or not less than the nominal sling diameter. Basket hitch capacity based on minimum D/d ratio of 25/1. For choker hitch, the angle of choke shall be 120 degrees or greater. For sling angles other than those shown, use the rated load for the next lower angle or a qualified person shall calculate the rated load. Horizontal sling angles of less than 30 degrees are not recommended. The capacity of a bridle at a 30 degree horizontal is same as single vertical leg.

Wire rope is often used in slings because of its strength, durability, abrasion resistance and ability to conform to the shape of the loads on which it is used. In addition, wire rope slings are able to lift hot materials.

Wire rope used in slings can be made of ropes with either Independent Wire Rope Core (IWRC) or a fiber-core. It should be noted that a sling manufactured with a fiber-core is usually more flexible but is less resistant to environmental damage. Conversely, a core that is made of a wire rope strand tends to have greater strength and is more resistant to heat damage.

Wire rope may be manufactured using different rope lays. The lay of a wire rope describes the direction the wires and strands are twisted during the construction of the rope. Most wire rope is right lay, regular lay. This type of rope has the widest range of applications. Wire rope slings may be made of other wire rope lays at the recommendation of the sling manufacturer or a qualified person.

Wire rope slings are made from various grades of wire rope, but the most common grades in use are Extra Improved Plow Steel (EIPS) and Extra Extra Improved Plow Steel (EEIPS). These wire ropes are manufactured and tested in accordance with ASTM guidelines. If other grades of wire rope are used, use them in accordance with the manufacturer"s recommendations and guidance.

When selecting a wire rope sling to give the best service, consider four characteristics: strength, ability to bend without distortion, ability to withstand abrasive wear, and ability to withstand abuse.

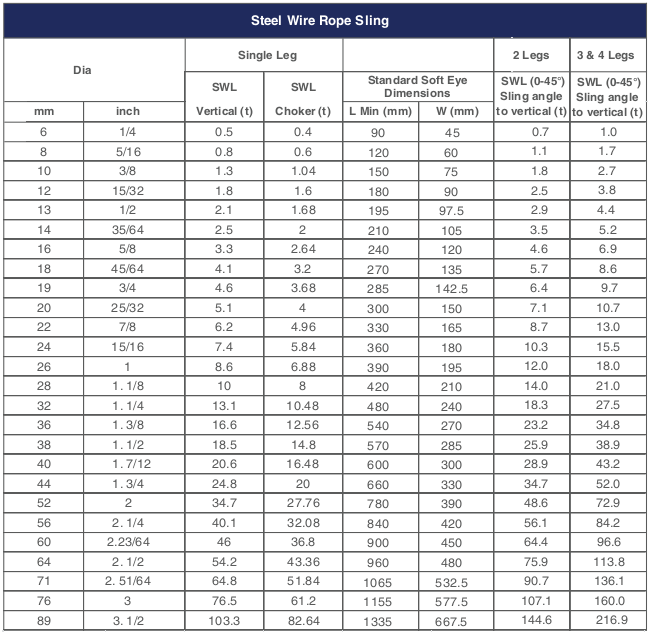

Rated loads (capacities) for single-leg vertical, choker, basket hitches, and two-, three-, and four-leg bridle slings for specific grades of wire rope slings are as shown in Tables 7 through 15.

Rated loads for a sling in a choker hitch are the values shown in Table 7, 9, 11, 13, 14, or 15, provided that the angle of the choke is 120 degrees or more (Fig. 2). Use the values in Fig. 2 or those from the sling manufacturer or a qualified person for angles of choke less than 120 degrees.

Ensure that slings made of rope with 6×19 and 6x37 classifications and cable slings have a minimum clear length of rope 10 times the component rope diameter between splices, sleeves, or end fittings unless approved by a qualified person,

Ensure that braided slings have a minimum clear length of rope 40 times the component rope diameter between the loops or end fittings unless approved by a qualified person,

Ensure that grommets and endless slings have a minimum circumferential length of 96 times the body diameter of the grommet or endless sling unless approved by a qualified person, and

Perform welding of handles or other accessories to end attachments, except covers to thimbles, before assembly of the sling. Ensure that welded end attachments are proof tested by the manufacturer or a qualified person. Retain the certificates of proof test and make them available for examination.

Do not use wire rope clips to fabricate wire rope slings, except where the application precludes the use of prefabricated slings and where the sling is designed for the specific application by a qualified person,

Although OSHA"s sling standard does not require you to make and maintain records of inspections, the ASME standard contains provisions on inspection records.[3]

Use damaged slings only after they are repaired, reconditioned, and proof tested by the sling manufacturer or a qualified person using the following criteria:

Ensure that wire rope slings have suitable characteristics for the type of load, hitch, and environment in which they will be used and that they are not used with loads in excess of the rated load capacities described in the appropriate tables. When D/d ratios (Fig. 4) are smaller than those listed in the tables, consult the sling manufacturer. Follow other safe operating practices, including:

Ensure that multiple-leg slings are selected according to Tables 7 through 15 when used at the specific angles given in the tables. Ensure that operations at other angles are limited to the rated load of the next lower angle given in the tables or calculated by a qualified person,

When D/d ratios (see Fig. 6) smaller than those cited in the tables are necessary, ensure that the rated load of the sling is decreased. Consult the sling manufacturer for specific data or refer to the WRTB (Wire Rope Technical Board) Wire Rope Sling Users Manual, and

Ensure that all portions of the human body are kept away from the areas between the sling and the load and between the sling and the crane or hoist hook,

When using a basket hitch, ensure that the legs of the sling contain or support the load from the sides, above the center of gravity, so that the load remains under control,

Ensure that the load applied to the hook is centered in the base (bowl) of the hook to prevent point loading on the hook, unless the hook is designed for point loading,

Before initial use, ensure that all new swaged-socket, poured-socket, turnback-eye, mechanical joint grommets, and endless wire rope slings are proof tested by the sling manufacturer or a qualified person.

Permanently remove from service fiber-core wire rope slings of any grade if they are exposed to temperatures in excess of 180 degrees F (82 degrees C).

Follow the recommendations of the sling manufacturer when you use metallic-core wire rope slings of any grade at temperatures above 400 degrees F (204 degrees C) or below minus 40 degrees F (minus 40 degrees C).

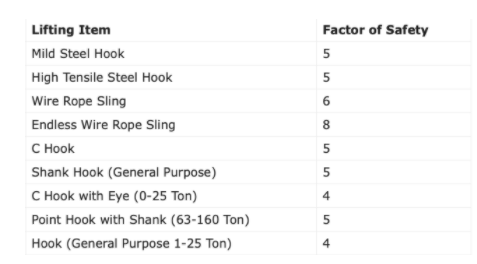

SWL, NWL, MBS — all of the acronyms can get very confusing. Don’t fret – we’re here to clear things up when it comes to safe working load limits and the terms associated with it.

Safe Working Load (SWL) sometimes stated as the Normal Working Load (NWL) is the mass or force that a piece of lifting equipment, lifting device or accessory can safely utilize to lift, suspend, or lower a mass without fear of breaking. Usually marked on the equipment by the manufacturer and is often 1/5 of the Minimum Breaking Strength (MBS) although other fractions may be used such as 1/4, 1/6 and 1/10.[1][2][3]

Other synonyms include Working Load Limit (WLL), which is the maximum working load designed by the manufacturer. This load represents a force that is much less than that required to make the lifting equipment fail or yield, also known as the Minimum Breaking Load (MBL). SWL or WLL are calculated by dividing MBL by a safety factor (SF). An example of this would be a chain that has a MBL of 2000 lbf (8.89 kN) would have a SWL or WLL of 400 lbf (1.78 kN) if a safety factor of 5 (5:1, 5 to 1, or 1/5) is used.

Here at Industrial Rope Supply, we are not only committed to providing you with a quality product, but also with all the information needed to insure safety comes first on every job. Have safety questions on a product purchased from us? Contact us today and we’ll be happy to talk you through and/or provide you with the safety materials needed.

Wire ropes are essential for safety purposes on construction sites and industrial workplaces. They are used to secure and transport extremely heavy pieces of equipment – so they must be strong enough to withstand substantial loads. This is why the wire rope safety factor is crucial.

You may have heard that it is always recommended to use wire ropes or slings with a higher breaking strength than the actual load. For instance, say that you need to move 50,000 lbs. with an overhead crane. You should generally use equipment with a working load limit that is rated for weight at least five times higher – or 250,000 lbs. in this case.

This recommendation is all thanks to the wire rope safety factor. This calculation is designed to help you determine important numbers, such as the minimum breaking strength and the working load limit of a wire rope.

The safety factor is a measurement of how strong of a force a wire rope can withstand before it breaks. It is commonly stated as a ratio, such as 5:1. This means that the wire rope can hold five times their Safe Work Load (SWL) before it will break.

So, if a 5:1 wire rope’s SWL is 10,000 lbs., the safety factor is 50,000 lbs. However, you would never want to place a load near 50,000 lbs. for wire rope safety reasons.

The safety factor rating of a wire rope is the calculation of the Minimum Break Strength (MBS) or the Minimum Breaking Load (MBL) compared to the highest absolute maximum load limit. It is crucial to use a wire rope with a high ratio to account for factors that could influence the weight of the load.

The Safe Working Load (SWL) is a measurement that is required by law to be clearly marked on all lifting devices – including hoists, lifting machines, and tackles. However, this is not visibly listed on wire ropes, so it is important to understand what this term means and how to calculate it.

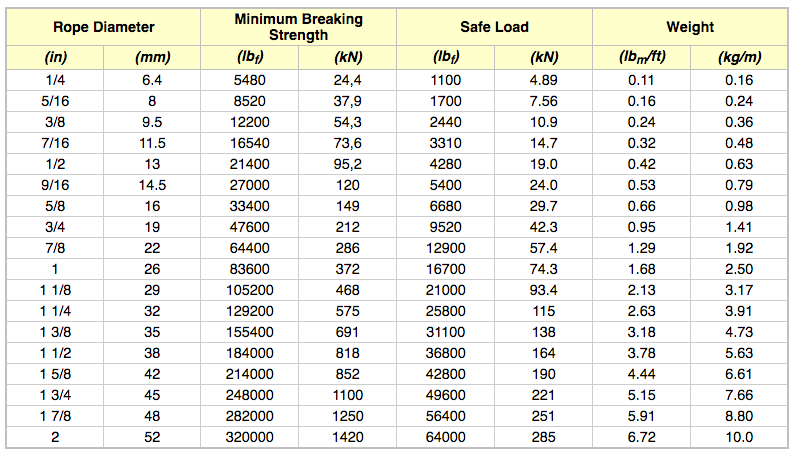

The safe working load will change depending on the diameter of the wire rope and its weight per foot. Of course, the smaller the wire rope is, the lower its SWL will be. The SWL also changes depending on the safety factor ratio.

The margin of safety for wire ropes accounts for any unexpected extra loads to ensure the utmost safety for everyone involved. Every year there aredue to overhead crane accidents. Many of these deaths occur when a heavy load is dropped because the weight load limit was not properly calculated and the wire rope broke or slipped.

The margin of safety is a hazard control calculation that essentially accounts for worst-case scenarios. For instance, what if a strong gust of wind were to blow while a crane was lifting a load? Or what if the brakes slipped and the load dropped several feet unexpectedly? This is certainly a wire rope safety factor that must be considered.

Themargin of safety(also referred to as the factor of safety) measures the ultimate load or stress divided by theallowablestress. This helps to account for the applied tensile forces and stress thatcouldbe applied to the rope, causing it to inch closer to the breaking strength limit.

A proof test must be conducted on a wire rope or any other piece of rigging equipment before it is used for the first time.that a sample of a wire rope must be tested to ensure that it can safely hold one-fifth of the breaking load limit. The proof test ensures that the wire rope is not defective and can withstand the minimum weight load limit.

First, the wire rope and other lifting accessories (such as hooks or slings) are set up as needed for the particular task. Then weight or force is slowly added until it reaches the maximum allowable working load limit.

Some wire rope distributors will conduct proof loading tests before you purchase them. Be sure to investigate the criteria of these tests before purchasing, as some testing factors may need to be changed depending on your requirements.

When purchasing wire ropes for overhead lifting or other heavy-duty applications, understanding the safety dynamics and limits is critical. These terms can get confusing, but all of thesefactors serve an important purpose.

Our company has served as a wire rope distributor and industrial hardware supplier for many years. We know all there is to know about safety factors. We will help you find the exact wire ropes that will meet your requirements, no matter what project you have in mind.

The Working Load Limit is the maximum load which should ever be applied to the product, even when the product is new and when the load is uniformly applied – straight line pull only. Avoid side loading. All catalog ratings are based upon usual environmental conditions and consideration must be given to unusual conditions such as extreme high or low temperatures, chemical solutions or vapors, prolonged immersion in salt water, etc. Never exceed the Working Load Limit.

The term “Proof Test” designates a quality control test applied to the product for the sole purpose of detecting defects in material or manufacture. The Proof Test Load (usually twice the Working Load Limit) is the load which the product withstood without deformation when new and under laboratory test conditions. A constantly increasing force is applied in direct line to the product at a uniform rate of speed on a standard pull testing machine. The Proof Test Load does not mean the Working Load Limit should ever be exceeded.

Do not use breaking strength as a criterion for service or design purposes. Refer to the Working Load Limit instead. Breaking Strength is the average force at which the product, in the condition it would leave the factory, has been found by representative testing to break, when a constantly increasing force is applied in direct line to the product at a uniform rate of speed on a standard pull testing machine. Proof testing to twice the Working Load Limit does not apply to hand-spliced slings. Remember: Breaking Strengths, when published, were obtained under controlled laboratory conditions. Listing of the Breaking Strength does not mean the Working Load Limit should ever be exceeded.

An industry term usually computed by dividing the catalog Breaking Strength by the catalog Working Load Limit and generally expressed as a ratio. For example: 5 to 1.

A load resulting from rapid change of movement, such as impacting, jerking or swinging of a static load. Sudden release of tension is another form of shock loading. Shock loads are generally significantly greater than static loads. Any shock loading must be considered when selecting the item for use in a system.

Examine slings for wear, fatigue, crushed or broken wires, kinking, ballooning or "bird-caging", heat damage, etc. Check both before and after using slings to detect any damage or defects. See Hoist wire rope for more inspection tips.

Wire rope slings can be used in many different industries such as general manufacturing, automotive, metals production and petroleum and gas. Wire rope slings are strong and flexible and can be resistant to abrasion and corrosion. Wire rope slings should be inspected by trained and qualified service personnel to minimize the risk or failure and to stay compliant with regulations.

Employers must use only wire-rope slings that have permanently affixed and legible identification markings as prescribed by the manufacturer, and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one.

Cable laid and 6 × 19 and 6 × 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200 °F. When nonfiber core wire rope slings of any grade are used at temperatures above 400 °F or below minus 60 °F, recommendations of the sling manufacturer regarding use at that temperature shall be followed.

All welded end attachments shall not be used unless proof tested by the manufacturer or equivalent entity at twice their rated capacity prior to initial use. The employer shall retain a certificate of the proof test, and make it available for examination.

Hooks that have been opened more than 15 percent of the normal throat opening measured at the narrowest point or twisted more than 10 degrees from the plane of the unbent hook.

Konecranes inspectors and technicians can inspect the slings and other rigging equipment in your facility to determine if it meets OSHA standards. The Konecranes Slings and Accessories Inspection checks non-maintainable load lifting attachments and accessories to identify deficiencies and deviations from local statutory safety and health regulations. The inspection service utilizes radio frequency identification (RFID) tags to record load lifting attachment inspection data and a smartphone app to help quickly and reliably identify attachments.

*The foregoing OSHA regulations are not intended to be a comprehensive overview of all applicable regulations pertaining to the designated topic. State laws may mandate different safety and maintenance standards. Accordingly, please consult applicable state laws as well as original equipment manufacturer specifications for further guidance. The statements and descriptions contained herein constitute the opinion/recommendation of the seller and are not intended to create any express warranties.

(1) Cable laid and 6 x 19 and 6 x 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

(c) Safe Operating Temperatures. Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200o F. When nonfiber core wire rope slings of any grade are used at temperatures above 400o F, or below minus 60o F, the sling manufacturer"s recommendations shall be followed.

(2) A prototype of each welded end attachment shall be proof tested by the manufacturer or equivalent entity to check the design and welding method at twice the rated capacity before production is started. Subsequent tests of random samples shall be made. The manufacturer or equivalent entity shall provide a certificate of such tests which the employer shall retain and make available for examination by the Division upon request.

(3) Where rope clip attachments are used, they shall be made with U-bolts on the dead or short end of the rope and the saddle on the live end. The minimum number of clips for end attachments shall be not less than indicated in manufacturer"s tables, but in no case shall be less than three for any permanent installation. Clips shall be drop-forged steel. The clips shall be spaced at a distance equal to at least six times the diameter of the rope. All clip or clamp bolts shall be kept tight after tightening while rope is under tension.

(6) Hooks that have been opened more than 15 percent of the normal throat opening measured at the narrowest point or twisted more than 10 degrees from the plane of the unbent hook.

(1) Have permanently affixed and legible identification markings as prescribed by the manufacturer, and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one; and

Have you wondered why rigging experts always suggest a sling that has a significantly higher breaking strength than the actual weight of the load you are lifting? The manufacturers know that the rigging used in overhead applications need to have room for error. This is known as the Safety Factor.

Northern Strands manufactures wire rope slings rated up to 36,000 lbs and sells round synthetic slings that are rated up to 140,000 lb capacity. This capacity is the Working Load Limit of the sling, which is the maximum amount of weight or force that the sling"s user is allowed to put on the sling. Note: These slings do not break at the working load limit. These slings are designed with a safety factor of 5:1. This means that 5 times as much force as the working load limit has to be applied to the sling before it potentially fails. This means the wire rope slings have a Breaking Strength of up to 180,000 lbs and the round synthetic slings can withhold up to 700,000 lbs.

Wear - Working load limits are based on slings in brand new condition and a safety factor can help account for normal wear and tear until it is deemed unfit for further use.

Uneven loading - Slings are made up of either wires or fibers that must all share the weight of the load evenly. If any situation arises where the sling is bent or wrapped around an object, there is potential that some of the wires or fibers will be taking on a greater share of the load than others.

Visit Northern Strands website to use the sling tension calculator. The Northern Strands Sling Calculator has been designed to assist you in selecting slings with enough load carrying capacity for your lifting applications. It is your responsibility to assure that the slings you use are appropriate for your application. http://www.northernstrands.com/sling-calculator.aspx

(1) Sling use. You must use only wire rope slings that have permanently affixed and legible identification markings as prescribed by the manufacturer, and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one.

(a) You must ensure that cable laid and 6x19 and 6x37 slings have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

(b) You must ensure that braided slings have a minimum clear length of wire rope 40 times the component rope diameter between the loops or end fittings.

(3) Safe operating temperatures. You must permanently remove fiber core wire rope slings of all grades from service if they are exposed to temperatures in excess of 200°F. When nonfiber core wire rope slings of any grade are used at temperatures above 400°F or below minus 60°F, recommendations of the sling manufacturer regarding use at that temperature must be followed.

(b) You must not use all welded end attachments unless proof tested by the manufacturer or equivalent entity at twice their rated capacity prior to initial use. You must retain a certificate of the proof test, and make it available for examination.

(f) Hooks that have been opened more than 15% of the normal throat opening measured at the narrowest point or twisted more than 10 degrees from the plane of the unbent hook.

Wire rope is a machine, and a rather complex machine. There are no precise rules to determine exactly when a wire rope sling has passed its service or expiration date. There are guidelines, though, to follow to know whether a sling is suitable for continued use or needs replacement.

Wire rope slings should be inspected prior to use to identify potential hazards or damage and to determine whether they are suitable for continued use. The Occupational Safety and Health Administration (OSHA) and ASME B30.9 standards dictate inspection intervals and procedures. They also require that inspections be executed by the sling user.

Next, the sling should be sufficiently cleaned of dirt and grease so wires and fittings are easily seen. This can usually be accompanied with a wire brush or rags.

The sling should then be given a thorough, systematic examination throughout its entire length, paying particular attention to sections showing the most wear.

Ideally, other systems for ensuring the quality of your slings should be part of your warehouse or facility inspection procedures. For example, Lifting Gear Hire is completing the final stages of adopting a new, streamlined RFID tracking system to record when equipment was inspected, who inspected it, and if and when the equipment was damaged. You can also seek out good quality training resources or learning institutes that teach courses on how to properly inspect wire rope slings—preferably ones that also provide Rigging Gear Inspector certification.

A sling’s service life can be extended substantially with good care and maintenance. Proper storage demands that slings be housed in an environment where they are not exposed to water, extreme heat, corrosives, liquids, or sprays and not stored in a kinked position, among other things.

Slings should never be left beneath loads or lying around where they can be susceptible to damage. Steel is not impervious to destruction. Slings should be housed in a rack when not in use. Custom racks can be constructed to accommodate slings of any size.

As with most machines, wire rope is lubricated at the time of manufacture. No supplementary lubrication is generally required if the sling is used under typical conditions. However, if a sling is stored outside or in any environment that could cause corrosion, additional lubrication should be applied to prevent rusting or corrosion. If the wire rope needs to be lubricated, the same type of lubrication as used during manufacture should be applied.

The storage temperature plays an important role in preserving the lifespan of a sling. Generally, steel-cored slings should not be used at temperatures above 400° F or below –40° F. Although it is not always easy to see when a sling has been damaged, a general rule of thumb is that if there are any suspicions that a sling’s integrity may have been compromised, it should be taken out of service right away or, at the very least, the manufacturer should be consulted.

Follow the sling manufacturer’s recommendations regarding use of steel-cored wire rope slings of any grade at temperatures above 400° F or below –60° F. At these temperature extremes, the internal structure of the steel may start to realign. If a sling will be or has been used in extreme temperatures, consult the manufacturer about ways to prevent degradation.

Hooks that have been opened more than 15 percent of the normal throat opening, measured at the narrowest point, or twisted more than 10 degrees from the plane of the unbent hook.

Corrosion of the rope or end attachments. Only extreme corrosion is necessary to reject a sling. Light corrosion does not substantially affect the strength of a sling.

Any evidence of eye splices that have slipped, tucked strands that have moved, or pressed sleeves that show serious damage may be sufficient cause to reject a sling.

A very common cause of damage is the kink which results from pulling through a loop while using a sling, thus causing wires and strands to be deformed and pushed out of their original position. This kink unbalances the sling, reducing its strength.

Should a sling be determined to be worn out or damaged beyond use, the inspector should immediately tag the sling as “do not use.” The sling should be destroyed as soon as possible by cutting the eye and fittings from the rope with a torch. Cutting the body of the sling is also appropriate. This method of destruction should deter another employee from mistakenly using a sling that has been retired from service. Any inspection program, however thorough, is of no value if the slings that have been rejected or retired are not disposed of properly.

According to ASME B30.9, repairs should only be conducted by the manufacturer or a qualified individual with the appropriate experience and certifications. For example, if an end fitting such as a hook becomes bent beyond guidelines, it should be sent back to the manufacturer regardless of whether the wire rope sling is intact and undamaged.

All repairs conducted on wire rope slings will require some proof of restoration. Replacement parts should be the same as those used in the original manufacturing. Following repair, a proof test of structural integrity should be conducted. With wire rope slings, the proof test is a 200-percent load test.

Should the wire rope used to craft the sling itself become damaged, it should not be repaired under any circumstances. For example, if one of the wires is damaged by weld splatter or heat damage, it is not possible to remove the one strand of wire and replace it. It is also not necessarily cost-effective to do so, as repair costs may outweigh the value of the sling.

When and how often you should inspect a wire rope sling are often the subjects of debate. The number of inspections every year should correlate with the amount of usage. At a minimum, a wire rope sling should be inspected once a year. However, if it is used frequently or in conditions that may challenge the sling’s integrity, then it should be inspected every month or quarterly, at least.

You should keep written records of when the wire rope was last inspected in case an accident or other cause for concern occurs. Keeping records also prevents someone from sending out a wire rope sling that is unsafe or has not been inspected. After all, the most important thing on a jobsite is maintaining safety.

8613371530291

8613371530291