safe working load of wire rope sling made in china

Due to the tubular design of the protective cover, the round sling is made seamless covered with a woven tubular jacket to protect the polyester fiber cores from damage of cutting, abrasions and ultraviolet degradation.

We supply a complete range of endless round slings to ASME, ANSI B30.9 and WSTDA with a safety factor of 7:1, Safety Factor of 6:1 or 5:1 is available upon customers request(for safety factor of 5:1 is commonly called disposable cargo slings, one way slings used for the loading and unloading cargoes and will be ceased and destroyed once used). The endless slings color code to show the Safe Working Load Limit, as shown in the parameter tab.

We are one of the best round sling manufacturers in China. Endless round slings are prefect for heavy loads and is made from high tenacity polyester fiber yarn continuously to provide maximum strength with minimum weight, please noted that the polyester yarn cores are not woven into a webbing then pulled through a woven tube, they are bundled by a lot of loosely twisted strands of high strength polyester fibers and blended by a specially designed machine.

The round sling protectors are also manufactured from high tenacity polyester yarn by the weaving looming machines bought from Kyang Hye, and Swiss Jakob Müller AG, then dyeing machine helps to perform two operations on polyester endless round sling, heating and cooling processes experienced by the webbing help to colour coded according to Safe Working Load Limit, Sewing step is the last and greatest important.

Raw Material High Tensile Tenacity Polyester Incoming → Yarn Matching → Raw Material Warping → Weaving → Dyeing → Measuring and Fusing → Joint Sewing and Burr Fusing (End Fitting Applying) → Multi strand wire rope → Sewing (synthetic web sling safety bulletin) → Test Inspection → Film Packing → Warehouse → Shipping

Synthetic web slings are can be configured to work as an eye and eye webbing sling, but synthetic round slings are most commonly offered as an endless grommet shape and different round sling color code to distinguish the different capacity, en 1492 2 round sling and synthetic round slings AS 4497 are the most popular endless webbing sling.

Round webbing sling is a versatile sling for general use with unlimited rigging methods, features a strong grip on loads, easy handling and storage, a tighter choke with an easier release, risk reduction of back and hand injuries and reduced cost with less total rigging weight.

They are designed for a safety factor 7:1 which is preferable for heavier loads, but with lighter loads, widely used for overhead lifting, delicate loads, for they feature more stronger, durable and relatively flexible, light weight. Besides round sling protectors sleeves can protect the potential damage from cutting, tearing, abrasion, heat and U.V. degradation than flat webbing sling. So it is very important to inspect webbing sling regularly, here are some rules you need to know:

Synthetic web slings both end can pair with rigging accessories to conjunct with a crane or some type of lifting device, such as hooks, rings or other attachments.

We offer the length of US Standard Flat Webbing Slings Eye & Eye from 1m to 12m usually but also can OEM or ODM against customers’ requests and M.B.S (lbs) from 15500 lbs to 14200 lbs.

Hilifting is the best synthetic slings manufacturer, can provide simplex, duplex, and multi-ply synthetic web slings, with a safe working load limit from 1ton to 12 tons, these slings are made of Hi-tech quality synthetic webbing, the safety factor from 5:1 to 8:1 are available.

If you have any Interested in wholesale EN 1942-1 synthetic web slings, please contact us for more information, we help you and your business grow and succeed.

End partsa large selection of end fittings, Including eye bolts, links, springs, hooks, thimble, clips, stops, ball ,ball shanks ,sleeve ,stamped eye, handles, etc.

A:Of course ,we have to know your application firstly and a number of factors have to be considered, such as work load, safety abrasion, environment ,cycle life, flexibility, , cost, When we design the steel wire cable assembly.

End partsa large selection of end fittings, Including eye bolts, links, springs, hooks, thimble, clips, stops, ball ,ball shanks ,sleeve ,stamped eye, handles, etc.

A:Of course ,we have to know your application firstly and a number of factors have to be considered, such as work load, safety abrasion, environment ,cycle life, flexibility, , cost, When we design the steel wire cable assembly.

Items: Wire Rope Slings - Domestic - Four Leg with Hooks - Capacities: 1.8 to 73 tons - Rope Diameters: 1/4 to 1 1/2 inches - Leg Lengths: 4 to 15 feet

Application: For general purpose overhead lifting using bridle hitch arrangement with quadruple pick points - Hoisting point is directly over the center of gravity of the load, the load is raised while level - Intended for crane applications, lifting, rigging, and material handling uses

Description: Bridle wire rope lifting sling with (4) four single part rope legs. Flemish loops with thimbles are formed at each leg end by mechanical splicing. Assembly incorporates an oblong master link, and leg-end standard latched sling hooks. The bridle hitch provides excellent load stability when the load is distributed equally among the wire rope legs. Quadruple leg assembly has ready-made end attachments for lift applications. Elongated master link attachment allows additional clearance at the hoisting connection.

Wire Rope Material: Made from independent wire rope core (IWRC), which offers less stretch and resistance to crushing while maintaining flexibility - Fabricated from extra improved plow steel (EIPS) - Rope with diameter of up to 1 inch has an outer rope formed of 6 strands with 25 wires per strand - Rope with diameter of 1 1/4 inches and above are formed of 6 strands with 37 wires per strand

Quality Standard: Manufactured in China - Bears a tag displaying the rated capacity - Meets or exceeds overhead lifting safety standards under ASME B30.9

The Difference: Low quality products can cause injury and damage. Look-a-like wire rope slings, often found at lower prices, are also often advertised to conform to the same safety standards, if at all. Be aware that it may refer to safety ratings in effect decades ago. So for example, under the same safety standard a decade ago, a wire rope sling may be rated to 100% without proof load testing while today it may be 300% with proof load testing. Be assured that we only sell the highest quality wire rope lifting slings, and our advertised safety standards conform to the current ASME standards.

WARNING:The use of a wire rope lifting sling requires that the cable angles be carefully determined to ensure that the legs are not overloaded - Never exceed rated capacity!

Wire rope slings adopt precast concrete construction and the main parts include wire rope, inner core, strand, center, steel wire, steel stocks and others.

We can customize various kinds of rigging according to customers’ requirement. Usually, the minimum circumference S of the sling is 50 times the wire rope diameter and the bending radius must be not less than 4 times of the wire rope diameter. The zone between the clamps can’t be bent under lifting force and the length is intended to be the dimension measured between the bearing points of the slings and the measured length of a ferrule-secured sling shall not differ from the nominal length by more than two rope diameters or 1% of the nominal length.

There are various sockets available such as open socket, closed socket and others. Also, the eye type include Flemish eye, pressed soft eye, spliced eye, thimble eye, standard eye, hard eye at both end.

①Vertical hitches are made directly from the crane hook to the load. Full rated capacity of the slings may be used but never exceeded. A tagline should be attached to prevent rotation which can damage the sling. A sling with a hand-tucked splice can’t lay and fail if the sling is allowed to rotate.

②Choker hitches reduce lifting capability of a sling, since this method of rigging affects the ability of the wire rope components to adjust during the lift, places angular loading on the body of the sling, and creates a small diameter bend in the body at the choke point.

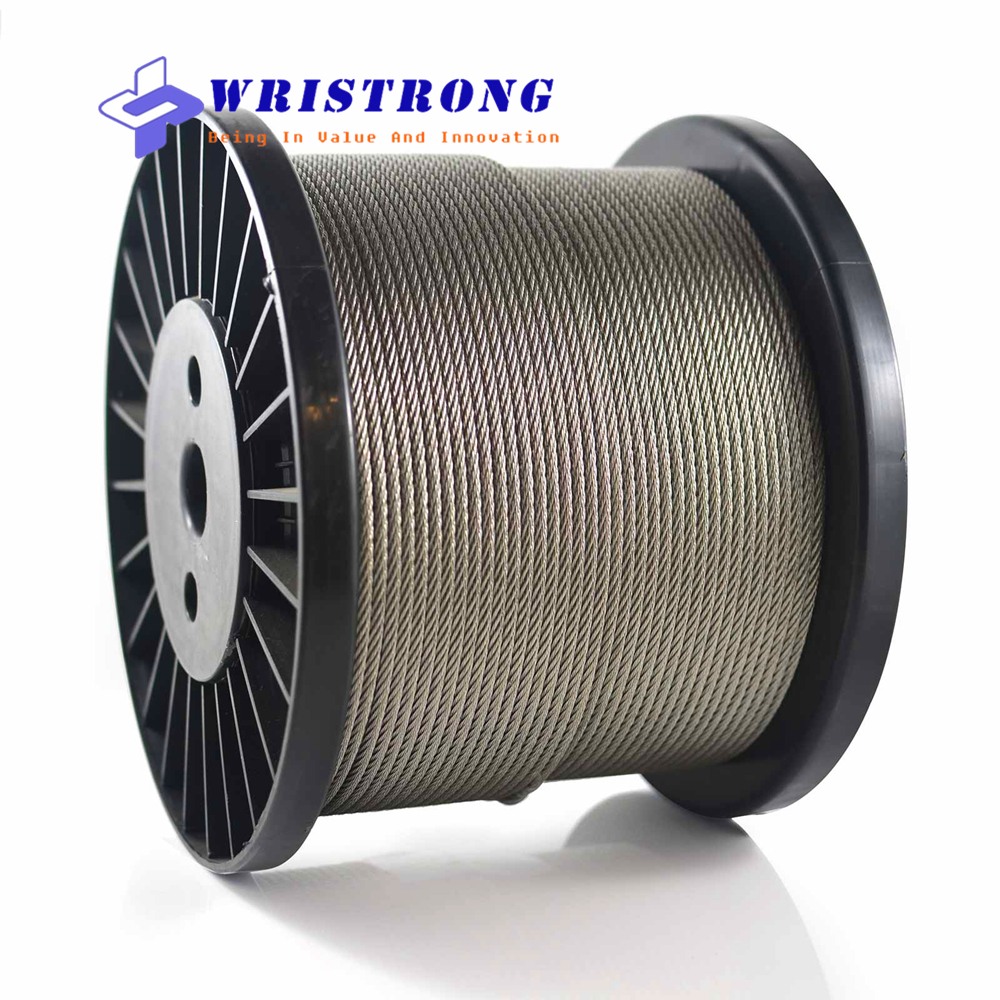

Wire rope slings are always packaged in plywood reel/plastic reel/wooden reel/coil in container, and then they will be palletized or put into a crate or a box.

There are various types of wire rope slings including slings with soft eye, hoist slings, slings with soft eye and two legs, steel ferrule secured slings, slings with Flemish eyes, ferrule secured endless slings, slings with steel-ferrule secured end stops, slings with swaged steel tie rod, slings with single hook, slings for crane, slings with sockets, slings with master link and two legs, slings with cuneiform connector, flat wire rope mesh slings, slings with master link and four legs, endless wire rope slings, container lifting slings for sea oil platform, large diameter cable laid slings, slings for lifting reinforcing steel bars, cable laid grommet slings, cable stocking, slings with spliced eye termination and others, and the main products are as following.

2-Leg bridle slings constructed of two wire rope assemblies that are attached to an oblong ring are designed for general lifting when the attachment can be made directly to the load. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object. The advantage of wire rope slings is that they are resistant to corrosion, heat, sunlight and most chemicals and they are custom built to meet your specific needs for any application.

3-Leg bridle wire rope slings constructed of three wire rope assemblies that are attached to an oblong ring are designed to handle unbalanced loads. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object. We carry a range of wire rope slings in our hire fleet with soft eye configurations at each end, available in various capacities and effective working lengths.

4-Leg bridle wire rope lifting slings constructed of four wire rope assemblies that are attached to an oblong ring are designed for balanced or unbalanced loads and for heavy lifts when the weight can easily be distributed over four points. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object.

The endless wire rope slings are orbicular, economical and adaptable slings with no fixed wear points, using special technology and the most advanced equipment and known for its softness, high tension and increased suspension points. They are suitable to lift and move tubes, pipes and long metal parts which suited in small and limited spaces and for high/large lifting loads, they are also adaptable for special bulk hoisting requirements of different conditions, such as transformers, shipbuilding and special machinery (where the warning mark locates cannot be used as lifting point)

Slings can be realized with galvanized or ungalvanized wire rope, special rope protected by strong PVC sleeve to resist against sharp edges without damaging the goods surface is also available as per your request.

7. According to the strength, wire rope slings can be divided into vertical breaking strength, chocker breaking strength, basket breaking strength, and except for standard eye size, thimble eye size, there are others of different eye hook capacity.

④Evidence of heat damage or if a wire rope sling having a fiber core is exposed to temperatures in excess of 200° F or if a wire rope sling having a steel core is used at temperatures above 400° F or below minus 60° F.

⑤Corrosion of the rope or end attachments or not laying and opening up of a tucked splice. Also, when end attachments that are cracked, deformed, or worn.

⑥Deformation—any visibly apparent bend or twist from the plane of the unbent hook. Throat opening—any distortion will cause an increase in throat opening of 5% not to exceed capacity.

⑦Avoid twists, kinks and knots before lifting, store wire rope slings where they will not be subjected to dirt, moisture, extreme heat, corrosion or mechanical damage.

⑧Protect the sling body against sharp edges and corners of loads, protrusions or abrasive surfaces. Sharp bends can distort wire rope and reduce its strength.

⑨Never "shock load" wire rope slings, the actual force caused by a sudden application of load can easily exceed rated capacities and damage slings and abruptly releasing a load can also damage the slings.

Wire rope is often used in slings because of its strength, durability, abrasion resistance and ability to conform to the shape of the loads on which it is used. In addition, wire rope slings are able to lift hot materials.

Wire rope used in slings can be made of ropes with either Independent Wire Rope Core (IWRC) or a fiber-core. It should be noted that a sling manufactured with a fiber-core is usually more flexible but is less resistant to environmental damage. Conversely, a core that is made of a wire rope strand tends to have greater strength and is more resistant to heat damage.

Wire rope may be manufactured using different rope lays. The lay of a wire rope describes the direction the wires and strands are twisted during the construction of the rope. Most wire rope is right lay, regular lay. This type of rope has the widest range of applications. Wire rope slings may be made of other wire rope lays at the recommendation of the sling manufacturer or a qualified person.

Wire rope slings are made from various grades of wire rope, but the most common grades in use are Extra Improved Plow Steel (EIPS) and Extra Extra Improved Plow Steel (EEIPS). These wire ropes are manufactured and tested in accordance with ASTM guidelines. If other grades of wire rope are used, use them in accordance with the manufacturer"s recommendations and guidance.

When selecting a wire rope sling to give the best service, consider four characteristics: strength, ability to bend without distortion, ability to withstand abrasive wear, and ability to withstand abuse.

Rated loads (capacities) for single-leg vertical, choker, basket hitches, and two-, three-, and four-leg bridle slings for specific grades of wire rope slings are as shown in Tables 7 through 15.

Rated loads for a sling in a choker hitch are the values shown in Table 7, 9, 11, 13, 14, or 15, provided that the angle of the choke is 120 degrees or more (Fig. 2). Use the values in Fig. 2 or those from the sling manufacturer or a qualified person for angles of choke less than 120 degrees.

Ensure that slings made of rope with 6×19 and 6x37 classifications and cable slings have a minimum clear length of rope 10 times the component rope diameter between splices, sleeves, or end fittings unless approved by a qualified person,

Ensure that braided slings have a minimum clear length of rope 40 times the component rope diameter between the loops or end fittings unless approved by a qualified person,

Ensure that grommets and endless slings have a minimum circumferential length of 96 times the body diameter of the grommet or endless sling unless approved by a qualified person, and

Perform welding of handles or other accessories to end attachments, except covers to thimbles, before assembly of the sling. Ensure that welded end attachments are proof tested by the manufacturer or a qualified person. Retain the certificates of proof test and make them available for examination.

Do not use wire rope clips to fabricate wire rope slings, except where the application precludes the use of prefabricated slings and where the sling is designed for the specific application by a qualified person,

Although OSHA"s sling standard does not require you to make and maintain records of inspections, the ASME standard contains provisions on inspection records.[3]

Use damaged slings only after they are repaired, reconditioned, and proof tested by the sling manufacturer or a qualified person using the following criteria:

Ensure that wire rope slings have suitable characteristics for the type of load, hitch, and environment in which they will be used and that they are not used with loads in excess of the rated load capacities described in the appropriate tables. When D/d ratios (Fig. 4) are smaller than those listed in the tables, consult the sling manufacturer. Follow other safe operating practices, including:

Ensure that multiple-leg slings are selected according to Tables 7 through 15 when used at the specific angles given in the tables. Ensure that operations at other angles are limited to the rated load of the next lower angle given in the tables or calculated by a qualified person,

When D/d ratios (see Fig. 6) smaller than those cited in the tables are necessary, ensure that the rated load of the sling is decreased. Consult the sling manufacturer for specific data or refer to the WRTB (Wire Rope Technical Board) Wire Rope Sling Users Manual, and

Ensure that all portions of the human body are kept away from the areas between the sling and the load and between the sling and the crane or hoist hook,

When using a basket hitch, ensure that the legs of the sling contain or support the load from the sides, above the center of gravity, so that the load remains under control,

Ensure that the load applied to the hook is centered in the base (bowl) of the hook to prevent point loading on the hook, unless the hook is designed for point loading,

Before initial use, ensure that all new swaged-socket, poured-socket, turnback-eye, mechanical joint grommets, and endless wire rope slings are proof tested by the sling manufacturer or a qualified person.

Permanently remove from service fiber-core wire rope slings of any grade if they are exposed to temperatures in excess of 180 degrees F (82 degrees C).

Follow the recommendations of the sling manufacturer when you use metallic-core wire rope slings of any grade at temperatures above 400 degrees F (204 degrees C) or below minus 40 degrees F (minus 40 degrees C).

Sling made with a triangle fitting on one end and a slotted triangle choker fitting on the other end. It can be used in a vertical, basket, or choker hitch.

Sling made with flat loop eye on each end with loop eye opening on same plane as sling body. This type of sling is sometimes called a flat eye-and-eye, eye-and-eye, or double-eye sling.

Sling made with both loop eyes formed as in Type III, except that the loop eyes are turned to form a loop eye which is at a right angle to the plane of the sling body. This type of sling is commonly referred to as a twisted-eye sling.

Return-eye (reversed-eye) sling is formed by using multiple widths of webbing held edge-to-edge. A wear pad is attached on one or both sides of the sling body and on one or both sides of the loop eyes to form a loop eye at each end which is at a right angle to the plane of the sling body.

(1) Cable laid and 6 x 19 and 6 x 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

(c) Safe Operating Temperatures. Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200o F. When nonfiber core wire rope slings of any grade are used at temperatures above 400o F, or below minus 60o F, the sling manufacturer"s recommendations shall be followed.

(2) A prototype of each welded end attachment shall be proof tested by the manufacturer or equivalent entity to check the design and welding method at twice the rated capacity before production is started. Subsequent tests of random samples shall be made. The manufacturer or equivalent entity shall provide a certificate of such tests which the employer shall retain and make available for examination by the Division upon request.

(3) Where rope clip attachments are used, they shall be made with U-bolts on the dead or short end of the rope and the saddle on the live end. The minimum number of clips for end attachments shall be not less than indicated in manufacturer"s tables, but in no case shall be less than three for any permanent installation. Clips shall be drop-forged steel. The clips shall be spaced at a distance equal to at least six times the diameter of the rope. All clip or clamp bolts shall be kept tight after tightening while rope is under tension.

(6) Hooks that have been opened more than 15 percent of the normal throat opening measured at the narrowest point or twisted more than 10 degrees from the plane of the unbent hook.

(1) Have permanently affixed and legible identification markings as prescribed by the manufacturer, and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one; and

Basket hitch. A method of rigging a sling in which the sling is passed around the load and both loop eyes or end fittings are attached to the lifting device.

Below-the-hook lifting device. A device used for attaching loads to a hoist. The device may contain components such as slings, hooks, rigging hardware, and lifting attachments.

Bird caging. The twisting of fiber or wire rope in an isolated area of the rope in the opposite direction of the rope lay, thereby causing it to take on the appearance of a bird cage.

Cable laid endless sling-mechanical joint. A wire rope sling made endless from one continuous length of cable laid rope with the ends joined by one or more metallic fittings.

Cable laid grommet-hand tucked. An endless wire rope sling made from one continuous length of rope formed to make a body composed of 6 ropes around a rope core. The rope ends are tucked into the body, thus forming the core. No sleeves are used.

Center of gravity. The center of gravity of any object is the point in the object around which its weight is evenly distributed. If you could put a support under that point, you could balance the object on the support.

Choker hitch. A method of rigging a sling in which the sling is passed around the load, then through one loop eye, end fitting, or other device, with the other loop eye or end fitting attached to the lifting device. This hitch can be done with a sliding choker hook or similar device.

Come-a-long. A mechanical device typically consisting of a chain or cable attached at each end that is used to facilitate movement of materials through leverage.

Competent person. One who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.

Electrical contact. When a person, object, or equipment makes contact or comes close in proximity with an energized conductor or equipment that allows the passage of current.

Fall zone. The area (including, but not limited to, the area directly beneath the load) in which it is reasonably foreseeable that partially or completely suspended materials could fall in the event of an accident.

Hoisting. The act of raising, lowering or otherwise moving a load in the air with equipment covered by this standard. As used in this standard, "hoisting" can be done by means other than wire rope/hoist drum equipment.

Hoisting equipment. A machine for lifting and lowering a load and moving it horizontally. The machine may be fixed or mobile and be driven manually, by power, or by a combination of both.

Load. The weight of the object being lifted or lowered, including the weight of the load-attaching equipment such as the load block, ropes, slings, shackles, and any other auxiliary attachment.

Qualified person. A person who, by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge, training and experience, successfully demonstrated the ability to solve/resolve problems relating to the subject matter, the work, or the project.

Rated capacity. The maximum working load permitted by the manufacturer under specified working conditions. Such working conditions typically include a specific combination of factors such as equipment configuration, radii, boom length, and other parameters of use.

Rotation resistant rope. A type of wire rope construction which reduces the tendency of a rope to rotate about its axis under load. Usually, this consists of an inner system of core strands laid in one direction covered by an outer system of strands laid in the opposite direction.

Sling. An assembly to be used for lifting when connected to a lifting mechanism. The upper portion of the sling is connected to the lifting mechanism and the lower supports the load, as described in this part.

Standing wire rope. A supporting wire rope which maintains a constant distance between the points of attachment to the two components connected by the wire rope.

Two blocking. A condition in which a component that is uppermost on the hoist line such as the load block, hook block, overhaul ball, or similar component, comes in contact with the boom tip, fixed upper block or similar component. This binds the system and continued application of power can cause failure of the hoist rope or other component.

Vertical hitch. A method of rigging a sling in which the load is attached to the loop eye or end fitting at one end of the sling and the loop eye or end fitting at the other end is attached to the lifting device. Any hitch less than 5 degrees from the vertical may be considered a vertical hitch.

Wire rope. A flexible rope constructed by laying steel wires into various patterns of multiwired strands around a core system to produce a helically wound rope.

Working load. The external load applied to the hoisting equipment, including the personnel lifting platform, its contents, and the load attaching equipment, such as lowered load block, shackles, and slings.

The Pressed Wire Rope Sling with the produce range Φ6mm-Φ120mm. And we also can make the special specifications of pressed sling according to the requirements of the customers.

Widely used in the field of machinery, metallurgy, construction, shipping, bridge project, gymnasium, oil field, fishing, drilling, colliery and ports, etc.

Some of our calculators and applications let you save application data to your local computer. These applications will - due to browser restrictions - send data between your browser and our server. We don"t save this data.

Steel wire rope slings as a basic material handling tool are most frequently used in marine line. Also they offer a strong, dependable and economical option for most lifting applications. Their popularity is enhanced by the numerous sling configurations available to support a broad range of applications. These configurations include single and multi-part slings (such as round braids, flat braids, Tri-Flex and cable laid slings), grommets, single leg slings, multiple leg bridles, and a wide variety of fittings and attachments.

Relative to other types of slings, wire rope slings are average in strength/weight ratio, average in abrasion and cut resistance, poorest in elongation and flexibility, and average for high temperatures (IWRC only).

A mechanical (or flemish) splice sling is most frequently used and is fabricated by unlaying the rope body into two parts, one having three strands, the other having the remaining three strands and core. The rope is unlayed far enough back to allow the eye to be formed by looping one part in one direction and the other part in the opposite direction and laying the rope back together.

The strands are rolled back around the rope body and a metal sleeve is slipped over the ends and pressed (or swaged) to secure the ends to the sling body. A hydraulic swaging press with special dies is used to bond the sleeve in place. Extreme pressure forces the steel sleeve to flow into the voids between the wires and strands, creating an assembly that maintains most of the wire rope"s nominal breaking strength.

As a professional manufacturer for wire rope slings and heavy lift assemblies, SOLAR has been the No.1 wire rope and sling supplier in SH area. Our customers are mostly Shipbuilding, Shipping, Offshore construction, and ship service providers. With swaging machine up to size 120mm and experienced splicing workers, we provide strongest and safest wire rope slings. Also our sales staffs are professional with lifting equipment, and could provide with customer correct wire rope and slings for their equipment or lifting requirements.

Shipyard Jib CraneDouble Girder EOT CraneHarbor Portal CraneContainer SpreaderElectromagnetic Spreader for Steel PlateHydraulic Grab Scrap GrappleCable reelDouble Flap Hydraulic GrabLifting Magnetic SpreaderCrane Hook BlockCrane Rail ClipsGB Standard Crane RailWire RopeLifting Belts SlingWire Rope SlingSingle Pole Slide Bus BarElectric Transfer CartWire Rope DrumRemote Wireless ControllerEnd CarriageSingle Girder Overhead CraneExplosion-proof CraneLadle Crane - for Molten Metal HandlingSuspended Overhead CraneGarbage Grab CraneElectromagnetic Crane for Steel SlagElectromagnetic Crane for Steel PlateC Hook Type Bridge Crane for CoilInsulation Bridge CraneHydropower Station Bridge CraneLow Clearance Overhead Crane1t~32t Gantry Crane5t~800t Gantry CraneSemi-Gantry CraneHydropower Station Gantry CraneHydraulic Gantry CraneGrab Bucket Gantry CraneFast Carrier 3t~20tFR model - RTG Crane 5-100tDB-Mobile Ganry CraneBS-Mobile Gantry CraneBH model - Side Lifting CraneCustomized RTG CraneRubber Tyre Double Beam Gantry CranePortable Gantry CraneFloor Mounted Jib CraneWall Traveling Jib CraneWall Mounted Jib CraneWire Rope Hoist - for Single Girder CraneWire Rope Hoist - for Double Girder Crane5t-41m Wire Rope HoistElectric Wire Rope HoistElectric Chain HoistFloating Dock CraneDock ArmShipbuilding Gantry CraneMobile Boat HoistBoat Jib Crane 1~12tBoat Jib Crane - with 4 HoistsRMG Crane for ContainerEL Container RTG CraneFixed Jib CraneOther

It is the goal of LKS Wire Rope to provide manufactured rigging products and hardware which are competitively priced and delivered on time with zero defects at quality and service levels that are consistent with the expectations of our customers. We fully understand that to do so is good business. The success of LKS Wire Rope depends on our commitment to associate involvement, continual improvement, and improved business performance goals.

The pressed steel wire rope sling is made of the world"s highest quality steel wire rope, which is pressed by professional wire rope deep processing equipment and advanced processing technology; it realizes the easy connection with the suspended object, which is the kind of lifting, shifting and carrying heavy objects. A safe and practical special tool for lifting.

The specifications of the wire rope are different, and the working load is different. The working load can be calculated according to the wire rope required by the user.

single leg wire rope sling is manufactured specifically for use in wire rope slings for lifting purposes. It is heat-treated for tensile strength and resistance to wear whilst also allowing for shock absorption.

Pressed steel wire rope is made of high-quality steel wire rope, which is pressed by professional steel wire deep processing equipment and advanced processing technology. It realizes easy connection with the suspended object, and is a safe, safe, Special lifting tools used. Its characteristics are high temperature resistance, wear resistance, easy to use, and large carrying capacity. It is widely used in machinery, metallurgy, shipbuilding, petroleum, fishery, forestry, drilling, coal mining, ports and other industries.

Pressed steel wire rope with diameter range: Ø6mm-Ø120mm, pressed steel wire rope with diameter of Ø90 or more, each end presses two aluminum alloy joints;

Different specifications of steel wire ropes have different working loads. The working load can be calculated according to the wire ropes required by customers;

Different wire rope structures have different working loads; the working load can be calculated according to the wire rope structure required by the customer;

Different wire rope structures have different working loads; the working load can be calculated according to the wire rope structure required by the customer;

5. Different construction rope with different working loads, we can calculate the working load. according to the steel wire rope construction which the customer required.

8613371530291

8613371530291