safety lifeline wire rope size quotation

When it comes to any at-height industry, fall protection is an important part of the job. Not to mention you will probably spend some time in situations where tying off to an appropriate anchor can be difficult. That"s why having the best lifeline is important. Our gear experts have spent years sourcing the best lifeline rope available and our hand-picked selection will help you stay safe and get the job done. We feature a range of styles, colors, lengths, and sizes of rope. You can choose a rope from 300, 600, or 1,200 foot pre-cut lengths, or if you need a custom length rope - we’ve got you covered there too. Diameters include ?, 7/16, ?, and ½ inch options and come in a variety of styles including HTP static, 3-strand, and unicore. We’ve also got a range of colors so that each lifeline can be visibly different than the others for easy identification.

The Gemtor™complete Horizontal Lifeline System is a simple, effective and economical means for achieving complete fall protection and worker mobility in a variety of elevated work sites.

Most folks think lifelines when it comes to fall protection, but if you quiz them about how these systems work or when they are good fits for an application, they come up short. So what is a cable-based fall protection system, and what are the pros and cons of lifeline systems?

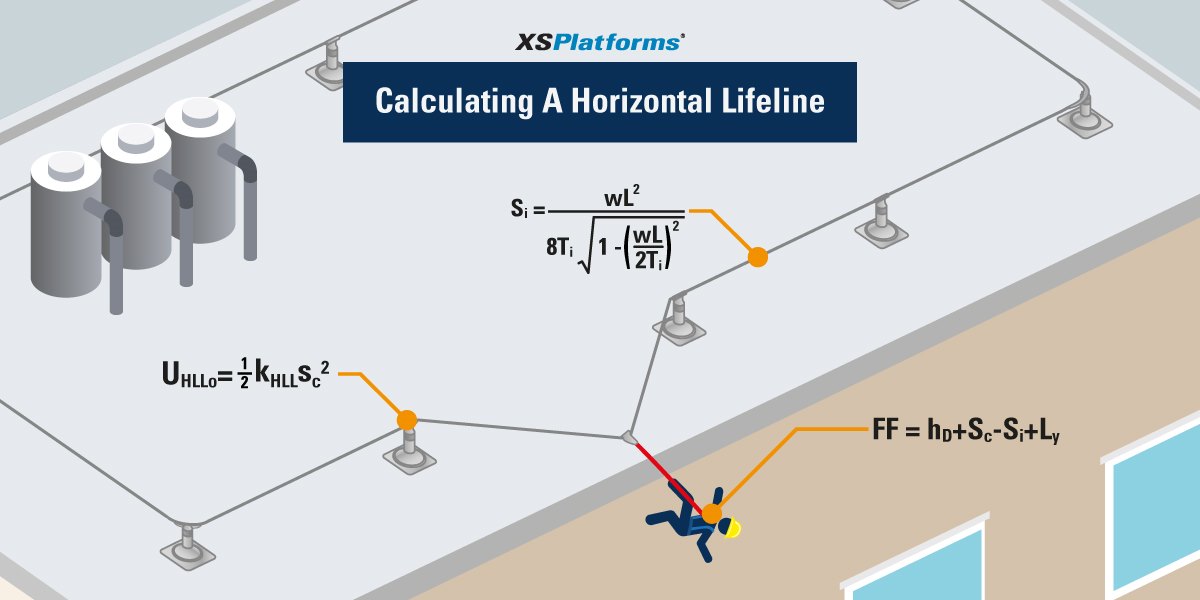

Cable fall protection systems take many names, including rat lines, HLL’s, and horizontal lifelines just to name a few. In their simplest form, cable fall protection systems consist of wire rope secured by a series of terminal and intermediate anchor points. By connecting a body harness and lanyard to a shuttle traveling the length of the line, a worker can safely move along a horizontal (or vertical) plane. Cable systems are deceptively simple in design, but done properly, they are actually highly engineered fall protection systems.

In a previous post titled “Is My Horizontal Lifeline Safe?”, we shared pictures of some home-made rat lines we have encountered in the field. Lifelines made from combinations of wire rope, wire rope clips, and turnbuckles may look safe, but these home-made solutions share little in common with the engineered lifelines we design and install at DFP.

With years of knowledge, our team can supply everything from wire rope through to individual and bespoke fittings used in these systems. Some of our main components are listed below:

M12 Thread with a swaging dimension of 12.5mm. This is smaller than the standard 16mm dimension usually associated with 8mm rope, which makes it popular among engineers swaging on site using an Electro/Hydraulic hand tool.

50 ft. (15.2m) kernmantle rope horizontal lifeline system with tensioner, energy absorber, two 6 ft. (1.8m) tie-off adapters and carrying bag.11/16″ kernmantle rope lifeline

Extremely lightweight horizontal lifeline systems which prioritize portablity- they are lightweight and easy to move from one job site to another. Sayfline cable systems are well-suited for harsh environments ir where minimal clearance exists.

The synthetic Sayfline system is lightweight, easy to use and engineered with all the 3M Fall Protection love and attention fall arrest equipment deserves. These horizontal lifeline systems are ideal where portability and flexibility is a must. Ideal for maintenance, bridgework, construction and other general industry applications.

Horizontal lifelines are more than a mere line connected between 2+ anchors, it is a secure attachment point for users working across a large horizontal surface. These systems are used to protect workers operating in the horizontal plane who may not have continuous access to suitable anchorage points.Choosing the right horizontal lifelines depends on:The attachment structure - like I-beam, rebar stub, concrete, column or roof/

Lifeline material type - Synthetic lines are extremely lightweight and compact while galvanized or stainless steel options offer added corrosion and abrasion resistance and typically require less fall clearance.

Extremely lightweight horizontal lifeline systems which prioritize portability - this system is lightweight and easy to move from one job site to another. Sayfline cable systems are well-suited for harsh environments ir where minimal clearance exists.

The synthetic Sayfline system is lightweight, easy to use and engineered with all the 3M Fall Protection love and attention fall arrest equipment deserves. These horizontal lifeline systems are ideal where portability and flexibility is a must. Ideal for maintenance, bridgework, construction and other general industry applications.

Lifelines, safety belts, and lanyards shall be used only for employee safeguarding. Any lifeline, safety belt, or lanyard actually subjected to in-service loading, as distinguished from static load testing, shall be immediately removed from service and shall not be used again for employee safeguarding.

Lifelines shall be secured above the point of operation to an anchorage or structural member capable of supporting a minimum dead weight of 5,400 pounds.

Lifelines used on rock-scaling operations, or in areas where the lifeline may be subjected to cutting or abrasion, shall be a minimum of 7⁄8 -inch wire core manila rope. For all other lifeline applications, a minimum of 3⁄4 -inch manila or equivalent, with a minimum breaking strength of 5,000 pounds, shall be used.

Safety belt lanyard shall be a minimum of 1⁄2 -inch nylon, or equivalent, with a maximum length to provide for a fall of no greater than 6 feet. The rope shall have a nominal breaking strength of 5,400 pounds.

All safety belt and lanyard hardware shall be drop forged or pressed steel, cadmium plated in accordance with type 1, Class B plating specified in Federal Specification QQ-P-416. Surface shall be smooth and free of sharp edges.

All safety belt and lanyard hardware, except rivets, shall be capable of withstanding a tensile loading of 4,000 pounds without cracking, breaking, or taking a permanent deformation.

As the name suggests, a Horizontal Lifeline system is designed to let you work high while being anchored horizontally between two anchors, rather than being stuck at one anchor point.

Horizontal Lifelines are used in many fall arrest or fall restraint systems due to their great flexibility. They can be used in areas lacking overhead anchorage points for personnel tie-off. The lifeline consists of a cable or rope that is attached to two or more anchor points on sites that poses a fall risk.

A horizontal lifeline can be used in combination with a personal fall arrest system to arrest a fall and limit the force transferred to the worker. A horizontal lifeline can also be used in combination with a body harness and lanyard to serve as a fall restraint system that limits a worker’s ability to reach a leading edge.

We carry a wide selection of Horizontal Lifelines in various sizes, lengths, and materials to cater to your specific needs. Whether for residential, commercial or any other purpose, we’ve got it. The DBI-SALA EZ Line Cable Retractable Horizontal Lifeline System is a favorite among the pros. This system is easy to install and 33% lighter than conventional systems, making it easy to transport. This unit provides hands-free horizontal mobility and continuous protection for two users per span, and up to six users per system.

Another popular option is the Miller Two Person TechLine Horizontal Lifeline System. This 60ft lifeline comes with all the bells and whistles like low-stretch fluorescent green rope for better performance, less deflection, and high visibility. It also has cross-arm anchorage straps for easy installation, plus a shock absorber to reduce fall arrest forces. A convenient adjuster allows you to accommodate your required length while keeping the lifeline secure.

Not what you need? Browse our impressive inventory of Horizontal Lifelines. Our wide selection from an extensive list of manufacturers including industry favorites like DBI-SALA, Miller by Honeywell and Guardian will accommodate all your horizontal lifeline needs. If for some reason you can’t find what you need on our site, we can get it!

Whether it is Horizontal Lifeline Systems or other valuable fall protection equipment, we have the sales team to get you what you need, whenever you need it. We have a massive selection of products, and we’re always available to help guide you through the process, so you have the most practical pieces of fall protection equipment for your needs.

When used in combination with personal protective equipment, a horizontal lifeline can arrest a fall, limiting the amount of force that is transferred both to the worker and the fall arrest system. This same combination of horizontal lifeline, body harness, and lanyard can also serve as a fall restraint system, limiting the the worker’s ability to move close enough to fall over an unprotected leading edge. The fall restraint and fall arrest properties of horizontal lifelines make the HLL an integral part of many fall protection systems.

Diversified Fall Protection a complete turnkey provider of OSHA compliant horizontal lifeline systems. Contact us for expert assistance with your fall arrest, fall restraint and fall protection requirements

Most folks think lifelines when it comes to fall protection, but if you quiz them about how these systems work or when they are good fits for an application, they come up short. So what is a cable-based fall protection system, and what are the pros and cons of lifeline systems?

Cable fall protection systems take many names, including rat lines, HLL’s, and horizontal lifelines just to name a few. In their simplest form, cable fall protection systems consist of wire rope secured by a series of terminal and intermediate anchor points. By connecting a body harness and lanyard to a shuttle traveling the length of the line, a worker can safely move along a horizontal (or vertical) plane. Cable systems are deceptively simple in design, but done properly, they are actually highly engineered fall protection systems.

In a previous post titled “Is My Horizontal Lifeline Safe?”, we shared pictures of some home-made rat lines we have encountered in the field. Lifelines made from combinations of wire rope, wire rope clips, and turnbuckles may look safe, but these home-made solutions share little in common with the engineered lifelines we design and install at DFP.

OSHA regulations say nothing about the materials required to build a lifeline, but do include specific language describing system performance in the event of a fall:

Horizontal lifelines shall be designed, installed, and used, under the supervision of a qualified person, as part of a complete personal fall arrest system, which maintains a safety factor of at least two.

If you are wondering which system (cable or rigid rail) is best, prepare for an ambiguous answer. Cable fall protection systems offer many benefits, but they aren’t suitable for every application. By working with a qualified fall protection company, you can make an informed system selection on the engineered fall protection that best meets your application needs and budget. To learn more about cable fall protection systems, contact the safety experts at Diversified Fall Protection for further assistance.

Colorado Safety Supply Company was founded in 2012 by Valerie Boyd, built on a passion for making a difference in multiple industries that have become close to her heart. What started as a business built on fall protection has evolved into a comprehensive hub for over thousands of safety items and related training and certification that’s still growing. Colorado Safety Supply Company is proud to be 100% woman-owned, with M/WBE, DBE, SBE, and WOSB certifications.

A horizontal lifeline system (HLL), such as the XSLinked system, is designed to keep workers safe, while moving around at height. Depending on the system type and the installation method the system can be used by 1 or 2 users at a time.

The lifeline consists of a steel wire-rope trajectory that is spanned between several anchor points. These anchor points are installed to sandwich panels with a steel top layer, with a minimum thickness of 0,5 mm (25 gauge), by means of the aluminum XSMD base plate. In this case installation occurs with twelve Gesipa 7,7 mm (5/16”) bulb-tite rivets.

Lifeline systems with XSConnector components have no integrated energy absorption. These systems need to be equipped with individual energy absorbers, such as the XSDynamic, when used as a fall arrest system. This will help to protect the roof structure in case a fall occurs.

All XSPlatforms fall protection systems are designed, tested and certified in accordance to the latest European standards EN 795:2012 type A/C and CEN-TS 16415:2013 type C.

8613371530291

8613371530291