sand line wire rope manufacturer

WARNING:Any warranties, expressed or implied, concerning the use of this product apply only to the nominal strength of new, unused wire rope. All equipment using this product must be properly used and maintained. Wire rope must be properly stored, handled, used and maintained. Most importantly, wire rope must be regularly inspected during use. Damage, abuse or improper maintenance can cause rope failure. Consult the AISI rope removal criteria on the use of steel sheaves. If synthetic sheaves are used, consult the sheave equipment manufacturer.WARNING!

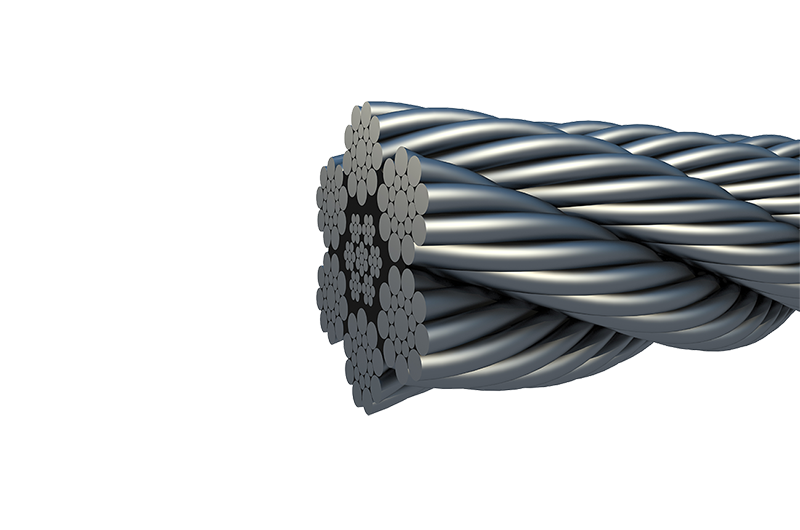

Sandline is the ideal industrial wire rope for swab and workover rigs. The wires are large and sturdy, capable of withstanding a great deal of use and wear. The fiber core on Sandline wire rope from Horizon Cable.

Call toll free 866-369-9507 today for complete information on the wide range of industrial applications for the premium quality Sandline available at reasonable prices from the industry specialists at Horizon Cable, Inc.

You can trust the Sandline wire rope from Horizon Cable for oil, water, and gas applications. Excellent spooling characteristics make Sandline wire rope resistant to wear over time. The large wire construction is sometimes referred to as “coarse laid.”

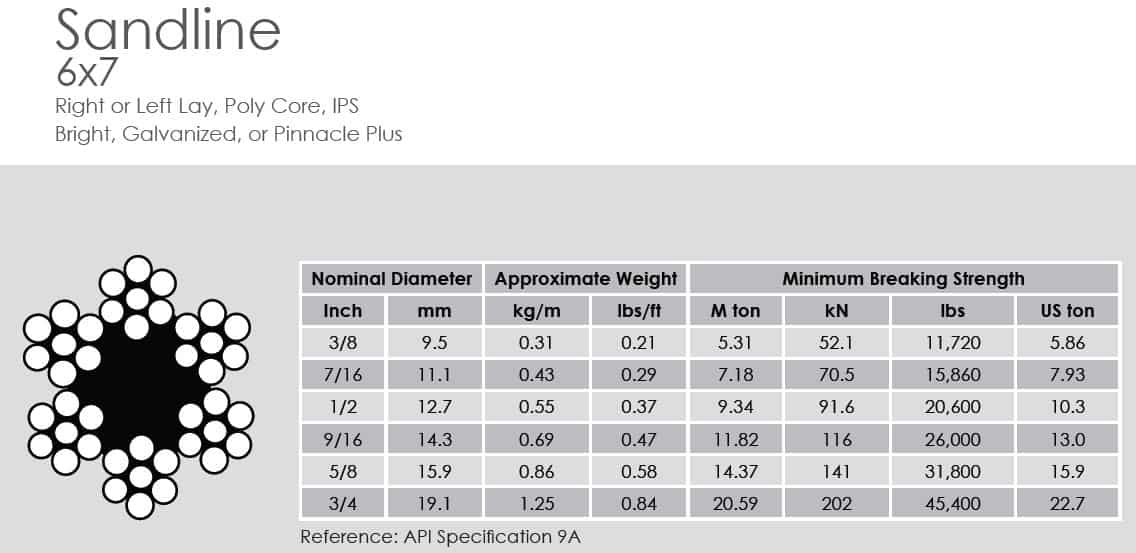

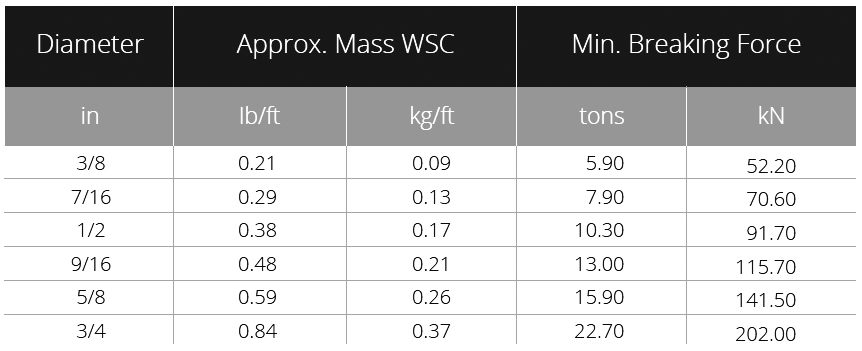

Sand Lines, Bright- Used in oil, gas and water drilling industries, this 6 x7 wire rope is also known as a sand line. It’s typically operated and stored on a winch drum and is capable of tensile forces higher than slickline. A fiber core gives this wire rope is very flexible and has an excellent resistance to fatigue from excessive bending. Spools evenly and resists kinking. Common uses: coring lines, sand lines, trawl cables, swabbing lines.

According to Federal Specification RR-W-410E and API-9A Meets the performance requirements of A.S.T.M. A1023/A1023M Wire Rope for general purposes, as applicable. Poly core, bright, heavy lube, preformed, IPS, RRL.

The most standard, and accepted for a wide range of applications. The direction of the individual wires is opposite to the direction of the strands. Because of this, the rope is less likely to untwist, and therefore is easier to handle than lang lay rope. This rope is also less subject to crushing.

The individual wires that form strands are most commonly available in high-carbon steel, generally supplied in an uncoated, or ""bright"" finish. Zinc coated, or ""Galvanized"" rope is available in some sizes and carries a nominal strength of 10% below that of a bright rope. On special request, wire rope can be drawn-galvanized, offering the same nominal strength as a bright rope.

Wires are laid geometrically to form strands, each composed of two or more wires. Breaking these strand configurations into several classifications is the basis for identifying wire rope.

The core is the supporting member of the rope, made of synthetic fibers. A fiber core rope offers flexibility. Note: The most popular fiber core is manufactured in polypropylene.

Regular Lay RopeThe most standard, and accepted for a wide range of applications. The direction of the individual wires is opposite to the direction of the strands. Because of this, the rope is less likely to untwist, and therefore is easier to handle than lang lay rope. This rope is also less subject to crushing.

The individual wires that form strands are most commonly available in high-carbon steel, generally supplied in an uncoated, or "bright" finish. Zinc coated, or "Galvanized" rope is available in some sizes and carries a nominal strength of 10% below that of a bright rope. On special request, wire rope can be drawn-galvanized, offering the same nominal strength as a bright rope.

Wires are laid geometrically to form strands, each composed of two or more wires. Breaking these strand configurations into several classifications is the basis for identifying wire rope.

The core is the supporting member of the rope, made of synthetic fibers. A fiber core rope offers flexibility. Note: The most popular fiber core is manufactured in polypropylene.

Weisner Steel meets your needs for wire rope, aircraft cable, cable assemblies, chain & fittings plus stainless steel, cargo control & fall protection hardware. Our solutions include general purpose wire rope & specialty ropes for sand line, drill lines, trawl cable, powered scaffolding wire rope & more.

Crane Wire Ropes, Elevator Wire Ropes, Stainless Steel Wire Ropes, Yacht Rigging Strands, Wire Rope Assemblies & Custom Fabrications, GALV Cable & Strand- Commercial & Control Cable Grade, Structural Strands, Oil & Gas Products- Drill, Sand, & Measuring Lines

Wirerope Works, Inc. manufactures Bethlehem Wire Rope®, the trade name under which we produce, sell and service our wire rope and strand products. The name "Bethlehem Wire Rope" represents the most complete facility and experienced personnel in North America. Our 46-acre manufacturing complex in Williamsport, Pennsylvania, with over 620,000 square feet under roof, is the single largest wire rope manufacturing facility in North America. Wirerope Works, Inc. manufactures its own wire, wire rope, structural strand, and all fabricated products such as pendants and other assemblies on the same premises.

Bethlehem brand wire rope and strand products have long been recognized worldwide for superior quality. Used for both lifting and stabilizing, Bethlehem Wire Rope products are used in a wide variety of applications ranging from crane and elevator hoist ropes to bridge suspension and anchoring offshore platforms. Wirerope Works, Inc. serves many industries including construction, logging, marine, mining, oil and gas, and steel.

There are many different types of steel wire ropes and for even more applications. At our factory you will find a large selection of steel wire ropes.

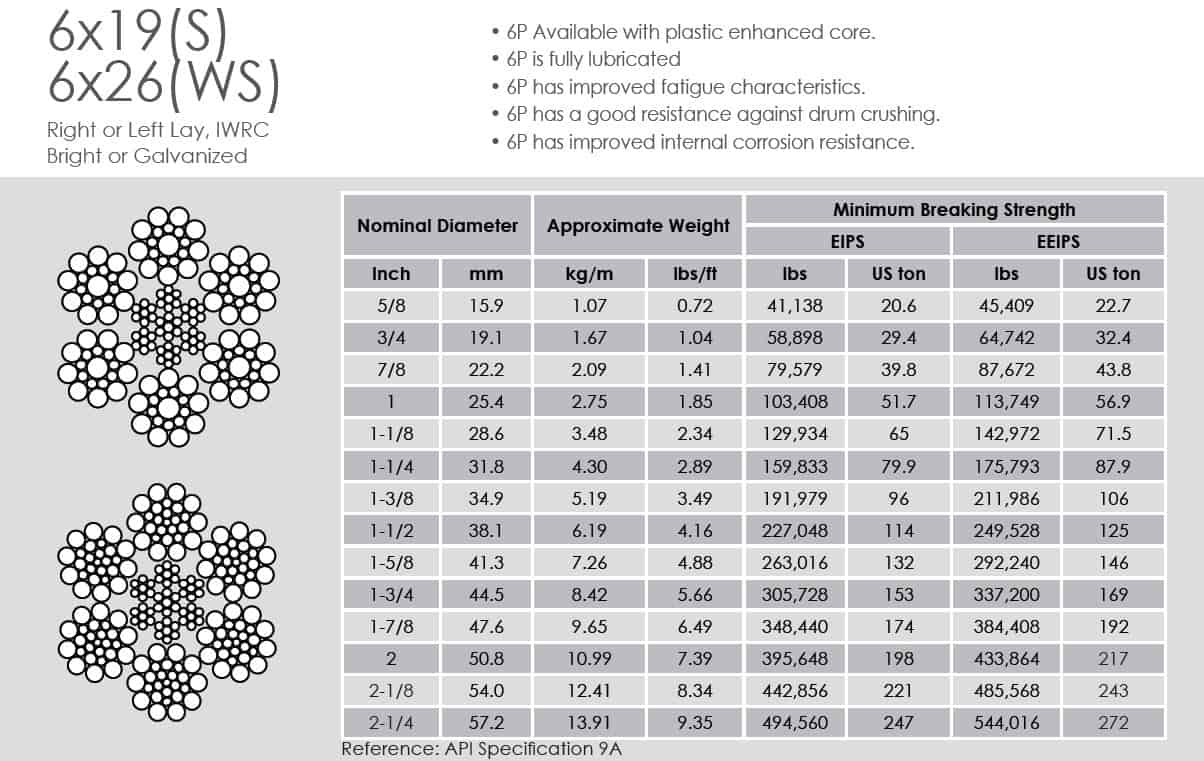

Our products of steel wire ropes cover different sizes, from the very thin up to more than 150 mm in construction like 6x19,6×36, 35×7, 7×19 etc. Our products sell well all over the world.

A few years ago, I gave the talk at Groundwater Week in Las Vegas that this series is based on. To prepare, I talked to a few manufacturers. I asked, how often do you require inspection of the wire rope on your drills? Every one of them stated they did not have change-out, rotation or inspection schedules listed in the manuals for their units. The reasoning for this was the liability of giving these recommendations. It would put the manufacturer in the hot seat if an accident occurred and the drill crew had followed manufacturer recommendations.

This lack of guidance from manufacturers puts the liability on drillers and the companies that hire them. The driller must inspect the rig and its components each day and decide if they are safe to run. The CEO or owner must question whether the company thoroughly trains crews with safety in mind. Are our crews making the right choices? Add to this the required documentation: inspections filled out, utilized and retained to develop a company change-out, replacement or rotation schedule. After all wire rope, despite its durability and strength, eventually wears out and must be removed. Regular inspection is crucial.

Visually inspect all hoisting lines at least once each day when in use, as is suggested by American Petroleum Institute (API) RP54 guidelines. Based on the amount of use and misuse, pay daily attention to the condition of all wire ropes. Wire rope is one of the most-used components of the drill rig or pump hoist, therefore is one of the most susceptible to constant wear and tear. Consider any damage or significant wear a potential problem. It is required to know the condition of the equipment before operating the rig or hoist.

The life of a wire rope is dictated by wear, abrasion, kinks, metal fatigue, corrosion and improper reeving. It should not take equipment failure or personal injury to find out your wire rope is deficient. Thoroughly inspect all hoisting lines monthly, making careful records of each month’s inspection.

Significant distortion: Wire rope structure concerns such as kinking, crushing, unstranding, birdcaging, signs of core failure or core protrusion between outer strands.

Improperly applied end connections or damaged end connections:Significantly corroded, cracked, bent, or worn end connections (such as from severe service or misuse).

If a deficiency in Category I is identified, an immediate determination must be made by a competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited. The wire rope must be replaced or, if the deficiency is localized, the problem corrected by severing the rope in two. The undamaged portion may continue to be used. Joining two or more lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have the minimum of two full wraps of wire when the load is in its lowest position.

Other than sand lines, remove wire ropes used as running ropes from service when broken wires meet any of the following Category II criteria:For six- and eight-strand constructions, replace when you see six randomly distributed broken wires within one lay length, or three broken wires in one strand within one lay length.

For rotation-resistant constructions, replace when you see two randomly distributed broken wires in six rope diameters – or four randomly distributed broken wires in 30 rope diameters.

When it comes to wire ropes used as standing ropes, such as guy lines, escape lines and pendant lines, remove from service after identifying any of the Category II deficiencies described above. Prohibit any operations involving use of the wire rope in question.

The employer complies with the wire rope manufacturer’s established criteria for removal from service, or a different criteria the wire rope manufacturer has approved in writing for that specific rope. Again, if a rope is shortened the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category III is identified, operations involving use of the wire rope in question must be prohibited until the wire rope is replaced! These type of deficiencies include:In rotation-resistant wire rope, core protrusion or other distortion indicating core failure.

Answers to these questions will lead you to your conclusion. Wire rope is an amazingly strong machine if we take care of it and use it properly. If we do not take care of it, it will be like that old car you may have had in high school. You never could be quite sure it would get you were you wanted it to. Until next month, stay safe and drill straight.

Looking for wire rope? Trinity Sling has been known as the go-to supplier for overhead lifting supplies and rigging for decades. Since its inception, Trinity has produced rigging and lifting solutions for many different industries, like construction, manufacturing, oilfield and fracing, transportation, and architectural railing. Today, the company continues to expand its reach, supplying across North America while calling North Texas home.

Trinity Sling distributes the highest quality wire rope both from domestic and European manufacturers. Trinity’s domestic supplier, Washington Wire Rope, manufactures general purpose and oilfield ropes in the USA to industry standards. Among their products that Trinity carries are crane ropes, drill lines, sand lines and tubing lines for construction and oilfield applications. Trinity also carries Verope-branded crane ropes, European-engineered specialty ropes for all types of cranes used in construction and manufacturing.

Trinity Sling has built strong vendor relationships with Washington Wire Rope and Verope in order to be a great supplier both to our new and existing customers. Our staff understands deadlines and RFQs and works diligently to partner with our customers to provide products of high quality that they can count on.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291