sand line wire rope supplier

WARNING:Any warranties, expressed or implied, concerning the use of this product apply only to the nominal strength of new, unused wire rope. All equipment using this product must be properly used and maintained. Wire rope must be properly stored, handled, used and maintained. Most importantly, wire rope must be regularly inspected during use. Damage, abuse or improper maintenance can cause rope failure. Consult the AISI rope removal criteria on the use of steel sheaves. If synthetic sheaves are used, consult the sheave equipment manufacturer.WARNING!

Sandline is the ideal industrial wire rope for swab and workover rigs. The wires are large and sturdy, capable of withstanding a great deal of use and wear. The fiber core on Sandline wire rope from Horizon Cable.

Call toll free 866-369-9507 today for complete information on the wide range of industrial applications for the premium quality Sandline available at reasonable prices from the industry specialists at Horizon Cable, Inc.

You can trust the Sandline wire rope from Horizon Cable for oil, water, and gas applications. Excellent spooling characteristics make Sandline wire rope resistant to wear over time. The large wire construction is sometimes referred to as “coarse laid.”

Sand Lines, Bright- Used in oil, gas and water drilling industries, this 6 x7 wire rope is also known as a sand line. It’s typically operated and stored on a winch drum and is capable of tensile forces higher than slickline. A fiber core gives this wire rope is very flexible and has an excellent resistance to fatigue from excessive bending. Spools evenly and resists kinking. Common uses: coring lines, sand lines, trawl cables, swabbing lines.

According to Federal Specification RR-W-410E and API-9A Meets the performance requirements of A.S.T.M. A1023/A1023M Wire Rope for general purposes, as applicable. Poly core, bright, heavy lube, preformed, IPS, RRL.

The most standard, and accepted for a wide range of applications. The direction of the individual wires is opposite to the direction of the strands. Because of this, the rope is less likely to untwist, and therefore is easier to handle than lang lay rope. This rope is also less subject to crushing.

The individual wires that form strands are most commonly available in high-carbon steel, generally supplied in an uncoated, or ""bright"" finish. Zinc coated, or ""Galvanized"" rope is available in some sizes and carries a nominal strength of 10% below that of a bright rope. On special request, wire rope can be drawn-galvanized, offering the same nominal strength as a bright rope.

Wires are laid geometrically to form strands, each composed of two or more wires. Breaking these strand configurations into several classifications is the basis for identifying wire rope.

The core is the supporting member of the rope, made of synthetic fibers. A fiber core rope offers flexibility. Note: The most popular fiber core is manufactured in polypropylene.

A 6 x 7 construction with fiber core has larger wires than many other classes of wire rope. This creates some flexibility and excellent resistance to abrasion. Resists kinking; spools evenly. Ideal for sand and swabbing lines, it"s widely used in the oil, gas, and water well driller industries.

A 6 x 7 construction with fiber core has larger wires than many other classes of wire rope. This creates some flexibility and excellent resistance to ...

A 6 x 7 construction with fiber core has larger wires than many other classes of wire rope. This creates some flexibility and excellent resistance to abrasion. Resists kinking; spools evenly. Ideal for sand and swabbing lines, it"s widely used in the oil, gas, and water well driller industries.

InterWire Products is a leading supplier of wire, cable, wire rope, and strand to the oil and gas industry. We offer a wide array of wire products specifically designed to meet the rigors of the industry.

Our wire, cable, wire rope and strand products are produced at API certified and ISO certified mills to ensure performance and withstand the harshest of conditions which are present within the industry.

Weisner Steel meets your needs for wire rope, aircraft cable, cable assemblies, chain & fittings plus stainless steel, cargo control & fall protection hardware. Our solutions include general purpose wire rope & specialty ropes for sand line, drill lines, trawl cable, powered scaffolding wire rope & more.

To accommodate for heavier weights and more heavy-duty applications, industrial wire ropes are available in different designs. Some of the most important elements to consider when purchasing wire rope for sale are:

Elite Sales offers a wide range of options for wire rope. Wire rope capacity can be adjusted based on your individual applications. Here are a few options to consider:

Industrial wire rope or cables are comprised of three key elements which all serve to support the rope’s strength and durability. It is important to understand the purpose of each of these components and the options available.

Wires: The most basic element of the wire rope are the individual wires used to form the cable. The thicker the diameter of the wire, the stronger it is, while thinner wires are more flexible.

Strands: A combination of multiple wires that are woven together form a strand. These strands are wrapped tightly together to maximize their strength and prevent uneven wear or breakage.

Fiber Core(FC) which can be made of natural or synthetic fibers that gives the wire rope some elasticity. However, it is not extremely strong nor is it optimal for high heat.

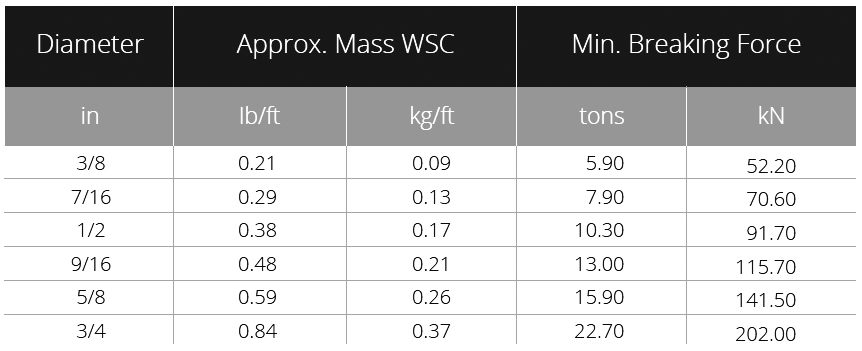

Wire Strand Core (WSC) consists of a singular wire strand which the other wires are wrapped around. This provides added stability while providing flexibility in the wire rope.

Looking for wire rope? Trinity Sling has been known as the go-to supplier for overhead lifting supplies and rigging for decades. Since its inception, Trinity has produced rigging and lifting solutions for many different industries, like construction, manufacturing, oilfield and fracing, transportation, and architectural railing. Today, the company continues to expand its reach, supplying across North America while calling North Texas home.

Trinity Sling distributes the highest quality wire rope both from domestic and European manufacturers. Trinity’s domestic supplier, Washington Wire Rope, manufactures general purpose and oilfield ropes in the USA to industry standards. Among their products that Trinity carries are crane ropes, drill lines, sand lines and tubing lines for construction and oilfield applications. Trinity also carries Verope-branded crane ropes, European-engineered specialty ropes for all types of cranes used in construction and manufacturing.

Trinity Sling has built strong vendor relationships with Washington Wire Rope and Verope in order to be a great supplier both to our new and existing customers. Our staff understands deadlines and RFQs and works diligently to partner with our customers to provide products of high quality that they can count on.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This construction of wire rope is used where ropes are dragged on the ground or over rollers, and resistance to wear and abrasion are important factors. Given the excellent spooling characteristics and ease of splicing this makes sandline the perfect choice for swab rigs and workover rigs. The wires are quite large and will stand a great deal of wear. In fact, this construction is sometimes called "coarse laid" because of the large wires. The 6x7 classification is a stiff rope and needs sheaves and drums of large size. It will not withstand bending stresses as well as ropes with smaller wires, with the resulting higher percentage of load carried by each wire, a larger factor of safety should be considered with 6x7 cables that with cables having a larger number of wires.

8613371530291

8613371530291