sand line wire rope factory

WARNING:Any warranties, expressed or implied, concerning the use of this product apply only to the nominal strength of new, unused wire rope. All equipment using this product must be properly used and maintained. Wire rope must be properly stored, handled, used and maintained. Most importantly, wire rope must be regularly inspected during use. Damage, abuse or improper maintenance can cause rope failure. Consult the AISI rope removal criteria on the use of steel sheaves. If synthetic sheaves are used, consult the sheave equipment manufacturer.WARNING!

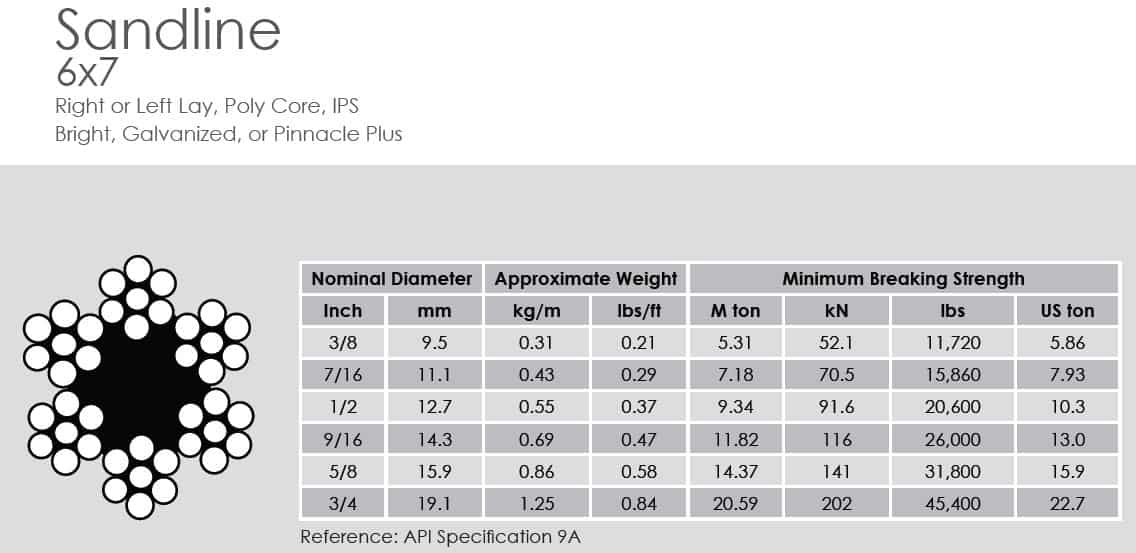

Sandline is the ideal industrial wire rope for swab and workover rigs. The wires are large and sturdy, capable of withstanding a great deal of use and wear. The fiber core on Sandline wire rope from Horizon Cable.

Call toll free 866-369-9507 today for complete information on the wide range of industrial applications for the premium quality Sandline available at reasonable prices from the industry specialists at Horizon Cable, Inc.

You can trust the Sandline wire rope from Horizon Cable for oil, water, and gas applications. Excellent spooling characteristics make Sandline wire rope resistant to wear over time. The large wire construction is sometimes referred to as “coarse laid.”

The most standard, and accepted for a wide range of applications. The direction of the individual wires is opposite to the direction of the strands. Because of this, the rope is less likely to untwist, and therefore is easier to handle than lang lay rope. This rope is also less subject to crushing.

The individual wires that form strands are most commonly available in high-carbon steel, generally supplied in an uncoated, or ""bright"" finish. Zinc coated, or ""Galvanized"" rope is available in some sizes and carries a nominal strength of 10% below that of a bright rope. On special request, wire rope can be drawn-galvanized, offering the same nominal strength as a bright rope.

Wires are laid geometrically to form strands, each composed of two or more wires. Breaking these strand configurations into several classifications is the basis for identifying wire rope.

The core is the supporting member of the rope, made of synthetic fibers. A fiber core rope offers flexibility. Note: The most popular fiber core is manufactured in polypropylene.

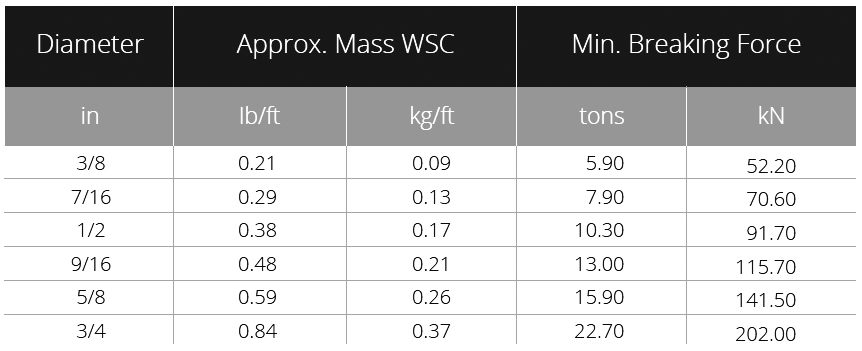

Sand Lines, Bright- Used in oil, gas and water drilling industries, this 6 x7 wire rope is also known as a sand line. It’s typically operated and stored on a winch drum and is capable of tensile forces higher than slickline. A fiber core gives this wire rope is very flexible and has an excellent resistance to fatigue from excessive bending. Spools evenly and resists kinking. Common uses: coring lines, sand lines, trawl cables, swabbing lines.

According to Federal Specification RR-W-410E and API-9A Meets the performance requirements of A.S.T.M. A1023/A1023M Wire Rope for general purposes, as applicable. Poly core, bright, heavy lube, preformed, IPS, RRL.

Regular Lay RopeThe most standard, and accepted for a wide range of applications. The direction of the individual wires is opposite to the direction of the strands. Because of this, the rope is less likely to untwist, and therefore is easier to handle than lang lay rope. This rope is also less subject to crushing.

The individual wires that form strands are most commonly available in high-carbon steel, generally supplied in an uncoated, or "bright" finish. Zinc coated, or "Galvanized" rope is available in some sizes and carries a nominal strength of 10% below that of a bright rope. On special request, wire rope can be drawn-galvanized, offering the same nominal strength as a bright rope.

Wires are laid geometrically to form strands, each composed of two or more wires. Breaking these strand configurations into several classifications is the basis for identifying wire rope.

The core is the supporting member of the rope, made of synthetic fibers. A fiber core rope offers flexibility. Note: The most popular fiber core is manufactured in polypropylene.

Regular Lay RopeThe most standard, and accepted for a wide range of applications. The direction of the individual wires is opposite to the direction of the strands. Because of this, the rope is less likely to untwist, and therefore is easier to handle than lang lay rope. This rope is also less subject to crushing.

The individual wires that form strands are most commonly available in high-carbon steel, generally supplied in an uncoated, or "bright" finish. Zinc coated, or "Galvanized" rope is available in some sizes and carries a nominal strength of 10% below that of a bright rope. On special request, wire rope can be drawn-galvanized, offering the same nominal strength as a bright rope.

Wires are laid geometrically to form strands, each composed of two or more wires. Breaking these strand configurations into several classifications is the basis for identifying wire rope.

The core is the supporting member of the rope, made of synthetic fibers. A fiber core rope offers flexibility. Note: The most popular fiber core is manufactured in polypropylene.

Crane Wire Ropes, Elevator Wire Ropes, Stainless Steel Wire Ropes, Yacht Rigging Strands, Wire Rope Assemblies & Custom Fabrications, GALV Cable & Strand- Commercial & Control Cable Grade, Structural Strands, Oil & Gas Products- Drill, Sand, & Measuring Lines

Our in stock, ready-to-ship products are available for fabricators and distributors serving the energy sector in North America. Our product offering include solutions for lifting and drilling operations, E&P activities, offshore and onshore, such as Mast Raising Lines, Drill Lines and Sandlines. Contact us today for a quote.

Weisner Steel meets your needs for wire rope, aircraft cable, cable assemblies, chain & fittings plus stainless steel, cargo control & fall protection hardware. Our solutions include general purpose wire rope & specialty ropes for sand line, drill lines, trawl cable, powered scaffolding wire rope & more.

Looking for wire rope? Trinity Sling has been known as the go-to supplier for overhead lifting supplies and rigging for decades. Since its inception, Trinity has produced rigging and lifting solutions for many different industries, like construction, manufacturing, oilfield and fracing, transportation, and architectural railing. Today, the company continues to expand its reach, supplying across North America while calling North Texas home.

Trinity Sling distributes the highest quality wire rope both from domestic and European manufacturers. Trinity’s domestic supplier, Washington Wire Rope, manufactures general purpose and oilfield ropes in the USA to industry standards. Among their products that Trinity carries are crane ropes, drill lines, sand lines and tubing lines for construction and oilfield applications. Trinity also carries Verope-branded crane ropes, European-engineered specialty ropes for all types of cranes used in construction and manufacturing.

Trinity Sling has built strong vendor relationships with Washington Wire Rope and Verope in order to be a great supplier both to our new and existing customers. Our staff understands deadlines and RFQs and works diligently to partner with our customers to provide products of high quality that they can count on.

A.B Page SR. (better known as “Blackie”) started AB Page Inc.in 1965 in the backyard of his own home. At this time “AB Page Inc” was in its infancy, unaware of its future potential and the success that is today. The young company was just a small rigging shop that only sold hand spliced slings, hardware and spooled reels of Union Wire Rope cable. Other services included long splicing of sand lines for oil field swab-trucks.

After the unfortunate passing of A.B Page, Sr. his beloved son Henry Page bought out his father’s company in 1972, where he would then change the name of the company to Page Wire Rope & Slings, Inc. Since the beginning, the company has grown impressively and exponentially over the years, from a small backyard shop to the accredited and distinguished company it is today. Page Wire Rope & Slings, Inc. has continued its dedicated service to the oil field for four generations. Four generations of Pages that include: Don Page (President), Kevin Page (Operations Manager) and Jacob Page (Inside Sales). Henry’s two daughters, Kathy Page and Laviolette (Treasurer) and Carol Page (Secretary) are also there to help continue their grandfather’s dream.

Page Wire Rope is now much larger than the original A.B. Page, Inc with additions of three new buildings to the original site. These new buildings and office renovations in Lafayette along with the two divisions, one in Shreveport, LA and one in Pleasanton, TX, added to the essential growth and the success of Page Wire Rope. Page Wire Rope has now grown the sewing of synthetic slings and the testing of wire rope slings, chain slings, and hardware. Page Wire Rope is now offering double braided and 12 strand ropes with splice capabilities.

Page Wire Rope & Slings, Inc. is based out of Lafayette, LA but has expanded operations to Shreveport, LA (Haynesville Shale) and Pleasanton, Texas (Eagle Ford Shale) as well. All sites are complete with state-of-the-art rigging that will provide customers with the highest quality of wire rope products and services. With our expanded coverage and dedicated employees, Page Wire Rope will continue to strive for quality excellence and customer satisfaction.

Page Wire Rope & Slings, Inc. shall provide products and services that continually meet or exceed customer expectations while adhering to all relevant statutory and regulatory requirements. Click here to download our policies documentation.

8613371530291

8613371530291