sand line wire rope in stock

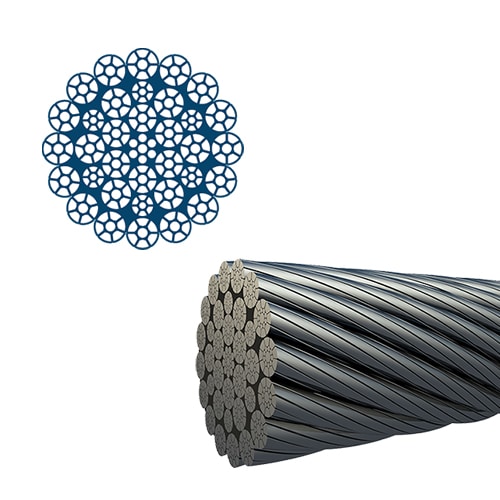

Sand Lines, Bright- Used in oil, gas and water drilling industries, this 6 x7 wire rope is also known as a sand line. It’s typically operated and stored on a winch drum and is capable of tensile forces higher than slickline. A fiber core gives this wire rope is very flexible and has an excellent resistance to fatigue from excessive bending. Spools evenly and resists kinking. Common uses: coring lines, sand lines, trawl cables, swabbing lines.

According to Federal Specification RR-W-410E and API-9A Meets the performance requirements of A.S.T.M. A1023/A1023M Wire Rope for general purposes, as applicable. Poly core, bright, heavy lube, preformed, IPS, RRL.

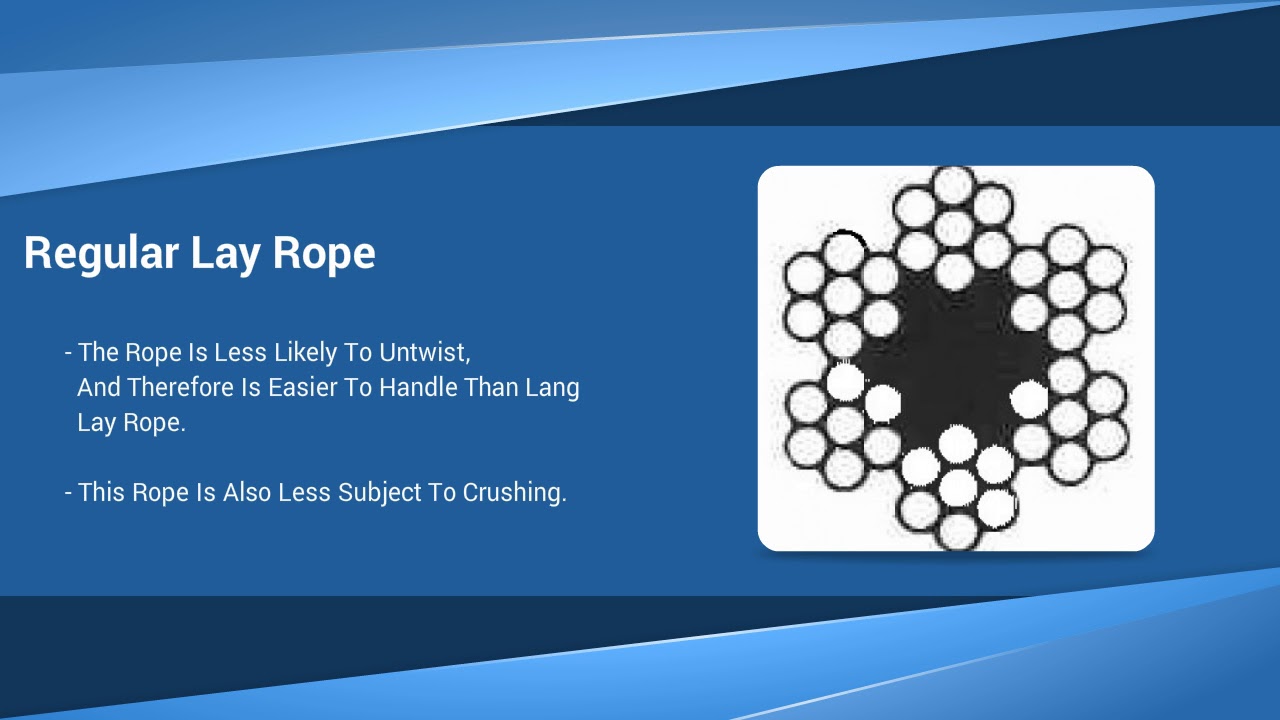

The most standard, and accepted for a wide range of applications. The direction of the individual wires is opposite to the direction of the strands. Because of this, the rope is less likely to untwist, and therefore is easier to handle than lang lay rope. This rope is also less subject to crushing.

The individual wires that form strands are most commonly available in high-carbon steel, generally supplied in an uncoated, or ""bright"" finish. Zinc coated, or ""Galvanized"" rope is available in some sizes and carries a nominal strength of 10% below that of a bright rope. On special request, wire rope can be drawn-galvanized, offering the same nominal strength as a bright rope.

Wires are laid geometrically to form strands, each composed of two or more wires. Breaking these strand configurations into several classifications is the basis for identifying wire rope.

The core is the supporting member of the rope, made of synthetic fibers. A fiber core rope offers flexibility. Note: The most popular fiber core is manufactured in polypropylene.

WARNING:Any warranties, expressed or implied, concerning the use of this product apply only to the nominal strength of new, unused wire rope. All equipment using this product must be properly used and maintained. Wire rope must be properly stored, handled, used and maintained. Most importantly, wire rope must be regularly inspected during use. Damage, abuse or improper maintenance can cause rope failure. Consult the AISI rope removal criteria on the use of steel sheaves. If synthetic sheaves are used, consult the sheave equipment manufacturer.WARNING!

Regular Lay RopeThe most standard, and accepted for a wide range of applications. The direction of the individual wires is opposite to the direction of the strands. Because of this, the rope is less likely to untwist, and therefore is easier to handle than lang lay rope. This rope is also less subject to crushing.

The individual wires that form strands are most commonly available in high-carbon steel, generally supplied in an uncoated, or "bright" finish. Zinc coated, or "Galvanized" rope is available in some sizes and carries a nominal strength of 10% below that of a bright rope. On special request, wire rope can be drawn-galvanized, offering the same nominal strength as a bright rope.

Wires are laid geometrically to form strands, each composed of two or more wires. Breaking these strand configurations into several classifications is the basis for identifying wire rope.

The core is the supporting member of the rope, made of synthetic fibers. A fiber core rope offers flexibility. Note: The most popular fiber core is manufactured in polypropylene.

With nearly 4,000 employees worldwide, WireCo WorldGroup is a great place for you to build a rewarding career. Our professionals enjoy the opportunities of a global manufacturing and distribution leader as well as a culture of open communication, professional growth, and friendly camaraderie that fosters innovation and problem solving.

1/2" wire rope is a solid choice for many rigging applications. With break strengths ranging between 10.3 tons (26,600 lbs.) and 14.6 tons (29,200 lbs.), this diameter of rope can be counted on to provide the high level of performance you require.

The spin-resistant rope has an innovative design to help keep the cable from rotating while under a load. The inner strands are spun in the opposite direction as the outer strands.

US Cargo Control offers a full line of rigging supplies so you can find the perfect solution. Our selection includes additional wire rope options (ranging in diameter from 1/8" to 2-1/2"), guy wire, wire rope fittings, and general rigging hardware.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Weisner Steel meets your needs for wire rope, aircraft cable, cable assemblies, chain & fittings plus stainless steel, cargo control & fall protection hardware. Our solutions include general purpose wire rope & specialty ropes for sand line, drill lines, trawl cable, powered scaffolding wire rope & more.

Our in stock, ready-to-ship products are available for fabricators and distributors serving the energy sector in North America. Our product offering include solutions for lifting and drilling operations, E&P activities, offshore and onshore, such as Mast Raising Lines, Drill Lines and Sandlines. Contact us today for a quote.

Fully equipped portable service for sand line, drill line, and tubing line sales, spooling, splicing, installation, string up, removal and storage or disposal. multi-phase jobs.

We stock a full line of Wirerope Works Bethlehem, American made, Oilfield servicing cables. We now feature Grade 100 chain and accessories as well as wire rope slings, nylon web slings, round endless slings and more.

8613371530291

8613371530291