sand line wire rope free sample

WARNING:Any warranties, expressed or implied, concerning the use of this product apply only to the nominal strength of new, unused wire rope. All equipment using this product must be properly used and maintained. Wire rope must be properly stored, handled, used and maintained. Most importantly, wire rope must be regularly inspected during use. Damage, abuse or improper maintenance can cause rope failure. Consult the AISI rope removal criteria on the use of steel sheaves. If synthetic sheaves are used, consult the sheave equipment manufacturer.WARNING!

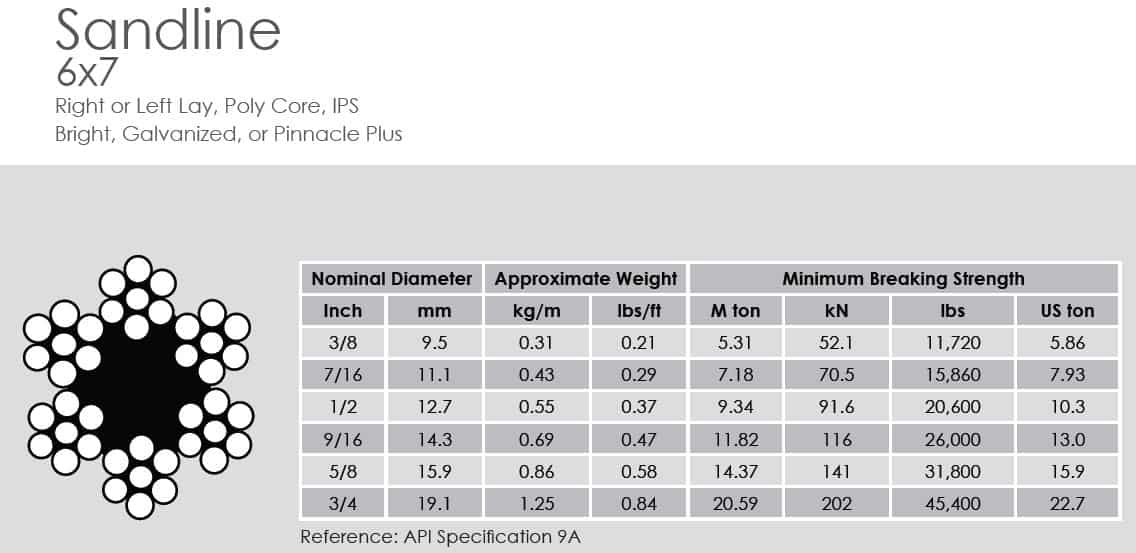

Sandline is the ideal industrial wire rope for swab and workover rigs. The wires are large and sturdy, capable of withstanding a great deal of use and wear. The fiber core on Sandline wire rope from Horizon Cable.

Call toll free 866-369-9507 today for complete information on the wide range of industrial applications for the premium quality Sandline available at reasonable prices from the industry specialists at Horizon Cable, Inc.

You can trust the Sandline wire rope from Horizon Cable for oil, water, and gas applications. Excellent spooling characteristics make Sandline wire rope resistant to wear over time. The large wire construction is sometimes referred to as “coarse laid.”

Sand Lines, Bright- Used in oil, gas and water drilling industries, this 6 x7 wire rope is also known as a sand line. It’s typically operated and stored on a winch drum and is capable of tensile forces higher than slickline. A fiber core gives this wire rope is very flexible and has an excellent resistance to fatigue from excessive bending. Spools evenly and resists kinking. Common uses: coring lines, sand lines, trawl cables, swabbing lines.

According to Federal Specification RR-W-410E and API-9A Meets the performance requirements of A.S.T.M. A1023/A1023M Wire Rope for general purposes, as applicable. Poly core, bright, heavy lube, preformed, IPS, RRL.

DNV GL (Det Norske Veritas), through its Business Assurance division, is widely recognized as a world-wide authority in the development and certification of quality standards and processes. In order to promote safe, reliable and enhanced performance in projects and operations involving the oil and gas industry, DNV has developed various standards such as 2.7.1 for Offshore Containers and 2.7.3 related to Portable Offshore Units. Equipment built to these exacting standards is readily accepted for use in markets around the globe. IntegriCert is one of a very few domestic companies certified and approved to fabricate, repair and re-certify wire rope slings or lifting sets that are in compliance with these standards.

In recent columns, we’ve gone over the wire lines of spudder rigs, namely the drilling line and the bailing line. The casing line is the third and last wire line we need to consider.

Spudders of many years ago were two-line rigs: a drill line and sand line. These rigs served well, particularly in high rock areas where not much casing gets used. In the area I have drilled, we ran casing pretty much 100% the depth of the well — not including the screen. We handled a lot of casing. If you drill a small well like a 3- or 4-inch with a spudder, and it was a two-line machine, you could handle 10 feet of casing by hand. That hand work gets pretty tough if you do a 6- or 8-inch well with the same machine. Removing the baler from the sand line and attaching a hook would make that line useable as a light duty casing line. Even the smallest spudder could probably handle one single length (21 feet) of casing with the sand line.

I once saw a rig that had two “steps” in the sand reel. The drum on which it spooled had two diameters. For about three quarters of the reel’s width, it had a normal sized drum, while the remaining quarter was much, much smaller. By switching the sand line to the small part of the reel, the driller had, in effect, a light-duty casing line. By using the large part of the reel, he still had an effective sand line. While an interesting innovation, it doesn’t replace having three dedicated lines. I have run both two-line rigs and three-line rigs, and I will tell you the latter is much, much handier. Three-line rigs come equipped with a third reel called (no kidding) the “casing” reel.

The safest, most effective way to run casing line is what we call “double.” From the reel, the casing line goes up the mast and over a sheave at the top. Then, it runs back down to the ground and through the sheave on a traveling block. It then goes back up to the top of the mast and over a second sheave there, before coming down to an anchor point somewhere on the rig frame. (Some rigs have a non-moveable support, shaped like one-half of a sheave, in place of the second sheave.) This double setup distributes the strain on the mast evenly. Another advantage is the traveling block doubles the hook load the casing reel can handle. The traveling block was usually equipped with a heavy hook to attach to elevators, chains or what-have-you.

Traveling blocks on larger rigs, like those found in the oil fields, could have two, three or even four sheaves. A casing reel with a six-part line (that is, with three sheaves on the traveling block) can lift pretty significant loads. On these rigs, a device called a casing tackle strut was attached to the mast. This acted as, in effect, a second upper section of the mast. It sat on top of the lower section and was attached near the top of the upper section. This strut had several sheaves at the top, and they were at 90 degrees to the regular casing sheaves on the main part of the mast. I don’t believe I’ve ever heard of a casing tackle strut for a small spudder like a Bucyrus-Erie 20W or 22W; a Speedstar 55, 61 or 71; or a Cyclone 36.

The wire rope that works best for casing line is quite different from what one would use for drilling and sand lines. We need to select non-rotating wire rope. This rope will have two distinct sets of small wires: a traditional 6 x 7 inner circle wire line encased in a 12 x 7 outer covering. In other words, the outer section of this rope has 12 strands of seven smaller wires. (I hope you understand. I have a little trouble with the terminology.) This non-rotating rope will be just that: relatively easy to bend with a tendency not to twist. If we set up a multi-sheave traveling block with anywhere from one to three lines and use regular wire rope, it will try to twist itself into a pretzel. Non-rotating wire rope acts something like manila hemp, as it does not tend to wrap around itself.

Our non-rotating casing line can be plow steel, since it won’t be bending like the drill line. Plow steel line will be a little stronger than mild plow steel — no kidding. The capacity charts I have list the working strength of plow steel non-rotating wire rope as anywhere from 2,700 pounds for 7/16-inch, to 5,300 pounds for ⅝-inch. One-inch rates ate 13,500 pounds. The size of the casing line depends on the rig. Oddly (or perhaps not oddly), recommendations have quite a range between Bucyrus-Erie rigs and Speedstar rigs. In resources I’ve seen, B-E recommends ⅝-inch for a 20W, and ¾-inch for a 22W or 60L. For the big 36L — not often used in water well drilling, they recommended 1-inch casing line. The 36L could handle casing loads up to 120,000 pounds with the proper derrick equipment.

Speedstar, on the other hand, recommends slightly smaller lines: 7/16-inch on the 55, ½-inch on the 61, ⅝-inch on the 71 and ¾-inch on the 72. Like the Bucyrus-Erie 36L, we don’t see many Speedstar 72s drilling water wells in Michigan.

After these recent columns, we now we have our spudder (whatever the brand or size) set up with three kinds of lines: drill, sand and casing. Each has its own purpose and needs to be cared for properly. Next time, I’ll write a few lines about proper maintenance and lubrication of wire lines and then get into selecting drilling tools, which is the heart of any spudder drilling operation.

I apologize if these topics seem over technical, maybe even a little confusing. If you have questions, contact your rig manufacturer or, if you can find them, the makers of your wire rope.

At Prem Holdings, we carry wire rope from well-known manufacturers such as Kiswire, Bridon-Bekaert and Tokyo. Our full range of wire rope and fittings enable us to meet customer demand with zero hassle. We are able to conduct proof load and breaking test up to 1000 MT with our in-house testing facility.

Wire ropes may also be named by its functions and application in various industries. Typical wire rope name in different industries includes the following:

EN12385-2 Steel wire ropes – Safety – Definitions, designation and classification provides a detailed explanation of all the terms and abbreviations used when describing a wire rope and its components. Below are a few of the most common abbreviations;

Steel wire ropes are specified in terms of a Nominal Rope Diameter and when produced have a manufacturing diameter tolerance, this tolerance can vary depending upon customer requirements and specifications and is often dictated by the diameter of grooving within sheaves and drums in which the wire rope will be expected to operate. If no diameter tolerance is specified, the general diameter tolerance is, Nominal Diameter +0% to +5% as specified within various International Rope Standards (EN12385-4, API-9A, ISO 2408). However, please note other diameter tolerances may be applied to ‘small’ diameter ropes and ropes used for specific applications/industries e.g. Mining, Aerials, Elevators, etc.

When designing any rope operated equipment, designers should consider the relevant National and/or International Standards which refer to acceptable sheave and drum diameters based upon the application, industry, etc. The diameter of sheaves and drums together with the tension, are normally associated with overall service life of the rope and in ‘simple terms’ the larger the diameter the longer the service life, although consideration should also be given to the anticipated modes of rope deterioration which will also significantly affect the service life. Typically, the diameter of sheaves and drums for crane applications are 16 to 28 times the nominal rope diameter.

Wire ropes are generally subjected to a visual examination and specifically for crane ropes these is an International Standard ISO 4309 “Cranes – Wire ropes – Care and maintenance, inspection and discard” which provides guidance on the inspection of wire ropes and provide the discard criteria. The document also includes information on the Magnetic testing of roper in service / Non-Destructive Examination and how this can assist the competent person in combination with his visual examination, determine the overall condition of the rope. All wire ropes should be inspected on a routine basis by a competent person to ensure that they remain is a good condition whilst in service and removed from service before they become dangerous. However, this standard is used for offering guidance for ropes operating in other systems where no specific discard criteria are given for that application, industry or country in which the rope is operating.

Please note, wire ropes can cause death and/or serious injury if not correctly handles, operated and maintained to good condition and care should always be taken when work with or close to wire ropes.

A new rope can easily be damaged if the pulley wheel groove is too tight, this will in effect pinch the rope probably causing a wave (spiral) deformity in your new rope.

If left unchecked in a steel pulley, parallel, linear fatigue wire breaks will be found where the contact pressures have become too high, due to a pinch affect.

The Lang’s construction, due to the wires running across the axis of the rope is the same direction as the strand, provides a greater length of wire on the exterior surface of the rope and hence since there is an increased surface area there is an increased area of steel to wear away before a broken wire occurs, therefore offering greater wear resistance. Therefore, applications where the rope is operating over larger number of support rollers and/or sheaves, the Lang’s lay rope may be of benefit.

The direction of the wires within the Lang’s lay construction also reduces the level of mechanical damage and rope interference, which takes place between adjacent wraps of rope within the crossover zones during multi-layer spooling of wire rope.

It is important to state that, single layer strand and parallel laid, rope constructions, manufactured in Lang’s lay, MUST NOT be used with one end free to rotate. Since the wires and the strands as twisted in the same direction, if the rope is free to rotate the wires and the strands will untwist tighter and seriously affect the integrity and breaking strength of the rope.

Wire ropes may be considered as machines, each with approximately 200 to 300 individual wires, which move independently to each over whenever ropes operate around sheaves or spool on or off winch drums, therefore ensuring ropes are lubricated internally will minimise the level of friction between the individual wires and optimise the ropes bend fatigue performance. Lubricant internally and externally will protect the ropes from corrosion and this applies equally to both un-galvanised/bright ropes and galvanised rope. Although the zinc on the surface of the individual wires of a galvanised rope will protect the wires from corrosion, once the zinc has sacrificed itself (oxidised) to protect the steel, the wires are then susceptible to corrosion. The longer the zinc can be protected by the lubricant the longer the zinc remains to offer protection to the steel. However there are applications where internal or external lubricant on the rope may not be advisable, anywhere the lubricant could drop off the rope and contaminate products (paper, food, etc.) in the vicinity of the rope or where the lubricant on the exterior of the rope may be contaminated with debris in the atmosphere (grit, sand, etc.). In this application, it must be accepted that ‘dry’ ropes will have a significantly reduced service life.

Ropes may be lubricated in-service with either oil or grease, both products offering slightly different benefits. Oils may be applied from a portable spray unit and although the ropes may require being re-lubricated more frequently, since it is relatively easy and cleaning to apply, operators are more likely to re-lubricate the ropes in service. The thin oil may penetrate the rope and surface coat the exterior of the rope with a thin film of lubricant, which also allows for relatively easy routine visual inspection of the rope. Alternatively, rope may be lubricated with a soft bearing type grease; the grease may be applied using a suitable pressure greasing system (Masto, Viper, etc.) to ensure uniform coating of grease along the total length of the rope passing through the greasing system, although the level and colour of grease may make visual inspection difficult. It is important that any oil or grease used to lubricate ropes in service is compatible with the lubricant applied to the rope during manufacturing and Bridon-Bekaert offer a range of wire rope lubricants specially formulated to be suitable for most environments and operations, including ECO VGP 2013 compliant (Bio-degradable, Non-toxic & Non-accumulative) products.

For ropes operating above ambient temperature consideration must be given to the effects the operating temperature may have on the wire rope. For guidance, unless otherwise stated, the maximum operating temperatures are provided in the International Standards e.g. EN 12385-3. However searches of these standards by Bridon-Bekaert indicate that the quoted temperatures within the standards have remained constant for a significant period of time, having been developed when rope constructions and usage centred around common 6-stranded rope constructions. With the introduction of more complex rope constructions incorporating higher tensile grade wires, synthetic lubricants and polymers, Bridon-Bekaert’s experiences indicate that reconsideration of the maximum operating temperatures is required. For high performance ropes incorporating synthetic lubricants and polymers Bridon-Bekaert recommend a maximum operating temperature of 100 degrees C. Excessive bleed out of lubricant from the rope may occur depending upon the rope operating temperature and the type/composition of the lubricant and frequent re-lubrication may be required.

Certain applications (Heave compensation systems, etc.) can generate high operating temperatures and for these and any application or where ropes are stored above ambient temperature, Bridon-Bekaert would be please to discuss this subject further.

Also due the smoothness of the circumference of these rope designs, they reduce wear at the cross over contact points as the rope wraps over itself as it is wound onto the drum.

An Ordinary lay rope is where the individual wires in the outer strands are spun / twisted together in the opposite direction to the direction the outer strands are twisted around the core, which results in the individual wires running along the axis of the rope. A Lang’s lay rope is where the individual wires in the outer stands are twisted in the same direction as the outer strands are twisted around the core, which results in the individual wires running across the rope in the same direction as the strands.

It is important to state that a left hand lay rope and a right hand lay rope MUST never be joined together unless the jointing mechanism is prevented from rotating, otherwise the rope will be allowed to un-twist together, which may have a significant effect on the integrity of the ropes, and could result in failure of the rope. There are two particular situations/arrangements where a left hand and/or right hand rope combination may be considered beneficial;

To prevent rotation of load – Twin rope operating systems (Overhead hoists, Grabbing systems, Container handling cranes, etc.) are generally designed to utilise one left hand rope and one right hand lay rope. When lifting a load both ropes will be subjected to an axial load and will try to un-twist, but since the ropes have been spun in different directions during manufacture one rope will trying to un-twist in one direction whilst the other rope will try to un-twist in the opposite direction, the two ropes therefore acting against each other to prevent/minimise rotation of the load.

When spooling a rope – Tension is generally applied to ropes whilst they are being spooled on to a winch drum and this tension will try to rotate / untwist the rope and therefore it is preferable to have the rope rotating up against the previous wrap of rope to minimise ‘gapping’ between the adjacent wrap of rope particularly on the bottom layer. Therefore, to achieve this, depending if the rope is anchored on the left or right hand side of the drum or the rope is being spooled under-wound or over-wound will determine if, a left or right hand lay rope should be utilised.

Rotation Resistant ropes are normally used to lift or suspend a load without the load rotating (example, hoist ropes used on Offshore, Mobile and Tower cranes, etc.) and are constructed by spinning the inner part of the rope in one direction and the outer part of the rope in the opposite direction. When an axial load is then applied to the rope the inner part will try to untwist in one direction and the outer part will try to untwist in the opposite direction, with the two parts of the rope reacting against each other. Rotation Resistant ropes are normally of a multi-strand construction and constructed of 2-layers of strands with the inner layer spun in the opposite direction to the outer layer and of 3-layers of strands with the inner two layers spun in the opposite direction to the outer layer. Three and four stranded rope constructions may also be considered as rotation resistant, but having only three or four strands, the ropes do not exhibit such a smooth exterior profile and may prove to be more difficult to spool, particularly when multi-layer spooled.

Wire rope does not have a defined shelf-live, provided the rope has been stored and maintained to ensure that the rope has not been allowed to deteriorate. To ensure that ropes remain in good condition, it is considered good practice to ensure the ropes are stored off the ground in a well-ventilated environment, protected from the sun, rain, sand/grit/dirt, chemicals or any other forms of contamination. Depending upon the environment the lubricant on the rope will tend to migrate to the bottom of the reel and dry out during storage. It is therefore good practice to rotate reels to prevent the lubricant migrating out of the rope on to the floor and to re-lubricate the ropes during storage by simple spraying a thin oil on to the surface of the rope to prevent the steel wires from corroding and/or zinc coating on the wires from oxidising (white rust). Whilst wire ropes are in storage they should be routinely inspected to ensure they have not been accidentally damaged, that all identification and certification remains in place and that the ropes remain fit for use. Rope being taken from storage on a ‘first in – first out’ basis, to minimise the length of time in storage.

Mooring ropes found onboard are of varied types with good elasticity. Generally, mooring roles supplied onboard are of nylon, polyurethane and wire ropes.

A number of precautions along with good seamanship practise can increase the life of these ropes and prevent deterioration, chaffing, cutting and internal wear.

– Ropes should preferably be stored under the deck for long voyages but if kept on deck they should be covered with tarpaulins or canvass to prevent exposure to sun and seawater or should be kept on gratings.

– A very common cause of a wire rope developing a kink is uneven turns, which are too tight or too slack where the wire gets snapped between the other turns on the drum. Thus, sharp angles or nips to be avoided with wire ropes.

– When heaving or slacking a wire, care should be taken so as to ensure that the turns on the drum are taken uniformly with sufficient tightness, avoiding any loose or extreme tight turns can cause the rope to get chaffed in between the turns and develop a kink. A good practice is to use rollers with wires to prevent unnecessary chaffing.

– Wire ropes should be regularly lubricated with recommended wire lubes, turret fluids or grease using wire rope lubricators, which helps grease reach the core of the wire and prevent corrosion. Greasing with hands may not be effective as it often lubricates the outer strands and the grease doesn’t reach the core of the wires.

– Whenever opening or uncoiling a new wire reel, follow the instructions provided for uncoiling the rope. In general, to prevent chaffing of a wire rope, rollers must be used. If wire rope is being runoff from one reel to a winch drum or another reel, run it from top to top or from bottom to bottom.

– If in any length of the 8 diameters of a wire rope the numbers of visible broken wires exceed 10% of the total number of wires in the rope, it should be discontinued from use. The more the number of wires in a strand, the more the wire is flexible. If flexibility increases the strength of the rope decreases.

– Mooring wires are provided with synthetic tail ropes at the end to secure. Tails being elastic thus provide the assembly for wire and tail to be tightened aptly while securing a vessel alongside. Tails are connected by means of tonsberg or mandal shackle. It is recommended to rig or connect the shackle in the correct manner as per the maker’s instructions to ensure proper transfer of forces and to provide flexibility.

– Avoid surging or chaffing of synthetic ropes to prevent wear and tear due to friction. Some ropes have a low melting point which can cause them to fuse permanently and get damaged. A rope should never be stowed in a wet condition to avoid rotting.

– While securing a synthetic rope on bitts the top turn should be secured against accidental springing off by means of light lashing. Synthetic ropes should be free of grease oil stains and paint marks as pose a greater danger while handling than various other shipboard activities.

– Long wires under tension can stretch enough tosnap back with a considerable force. Possibility of snapback should always be considered whilehandling ropes as often the static energy stored in a synthetic rope gets released by parting off a rope and it snapping back to its own length. Synthetic lines do not essentially provide any external warning or signs against the danger of snapback. A hazard zone can be defined as a zone of ten-degree cone around the line from any point at which it may break.

– Excessive heat can damage synthetic fibre ropes. Coils of polypropylene and polyethylene should not be stored against steam lines, bulkheads with high temperatures or under direct sunlight. Some synthetic ropes can be damaged by chemicals such as acids, alkalies, paints or thinners. When a rope becomes oily it can be scrubbed with fresh water and any other effective cleaning material.

– Being not effectively resistant to cuts and abrasions, synthetic lines should not be exposed to deterrent conditions which can damage them. While dragging them contact with sharp edges should be avoided.

– The surface of chocks and fairleads are grooved or roughened by wires which may be grinded or levelled before use with synthetic lines. Dirt, grit, sand and rust particles often cling to and penetrate into synthetic ropes causing internal abrasion. Brushing or cleaning of ropes can be a good practice before stowing them.

– Kinks formed in ropes must be removed by easing up loads first. Coiling direction of rope too play an important role in the removal of kinks. Most lines are of right-handed lay and coiled clockwise. New rope from a coil can be removed by suspending with a shaft. Winch mounted lines can be turned end to end periodically to prevent uneven wearing.

Documentation which keep a track of wear and use of wire ropes, synthetic ropes and rope tails is helpful in planning maintenance schedule. Based on that few points to be considered are as under :

All ropes, wires when received onboard should be checked for the certificate of approval or conformity. Test reports which specify manufacturer, date, minimum breaking load, lay of rope, length, thickness, number of strands, material and construction.

Rope tails or wires are required to be replaced after a certain specified period or upon deterioration or damage to the rope or as per company procedures which often is supported by a document in which the duration of their usage is recorded to provide an overview if the replacement is necessary. Wires can be turned end to end midway of their renewal date to avoid uneven wear.

Over the past decade, a handful of crane OEMs have partnered with wire and synthetic rope manufacturers to research the idea of replacing heavy wire rope with lighter fiber rope. The idea is to reduce weight without conceding strength.

“We do not see too much interest in this topic amongst our OEMs,” Balbiani said. “There is one overhead crane manufacturer who has put up a whole product line that can be equipped with fiber rope or steel wire rope.”

“The primary purpose in doing so is to reduce weight without compromising strength, increasingly a concern as lifts become higher, heavier and more complex,” said, Andreas Schmeiss, vice president of WireCo. “Synthetic ropes also tend to be easier to handle and install, reducing fatigue and the possibility of injury for those who conduct installations, inspections and change-outs. And, without any need for lubrication, fiber ropes offer environmental benefit.”

“In the industrial environment, in which ropes frequently encounter sharp edges and abrasive surfaces, steel is generally impervious, while fibers are susceptible to fraying,” he said. “Fibers are also sensitive to ultraviolet radiation and excessive heat. High temperatures can cause a condition known as ‘creep,’ in which a rope becomes pliable and stretches to a point beyond its original form.”

“Retirement criteria are also more difficult to determine with synthetic ropes, where the nondestructive testing methods used to judge the condition of a steel rope are not suitable,” he said. “Synthetic ropes tend to be more expensive than steel wire ropes. For the same application, the cost of fiber can exceed that of steel by up to three or four times.”

“Fiber rope helps reduce the required rope diameter tremendously,” Balbiani said. “In some cases, steel is the clear winner. In other cases, fiber. Advanced coatings might one day tip the balance in favor of synthetics, but, for now, it would be difficult to imagine that fiber rope would fully displace steel any time soon.”

“These include applications in which ropes are not continually wound and unwound over drums,” said Schmeiss. “WireCo, through Lankhorst Ropes, has a long history of employing synthetic ropes to moor ships, offshore energy platforms and, more recently, floating wind turbines. These ropes are transported and installed at sea, making synthetics’ reduced weight, high strength, ease-of-handling and corrosion resistance the preferred choice over steel.”

“Unlike the steel used in conventional pendants, Gladiator’s synthetic Aramid fibers act like a shock absorber during digging operations, reducing fatigue-related stresses for both the shovel equipment and those who operate it,” said Schmeiss. “This, in turn, could extend the service lives of shovels and draglines by up to three to four times over the lives typically experienced when using traditional steel technologies.”

Schmeiss said both the limited axle loads of road-approved vehicular cranes and weight limitations for crawler cranes require that ropes provide a steadily increasing breaking load at a constant diameter. To meet these requirements, synthetic alternatives must employ special fibers with tensile strengths similar to those of steel, he said.

Lankhorst Ropes’ LankoLift S does this, Schmeiss said. The yellow rope consists of 12 braided outer strands made of high-tech Dyneema and provides a breaking strength equal to that of steel rope of the same thickness. LankoLift’s core is designed to resist transverse pressures, and laboratory tests involving reversed bending cycles have yielded promising results. The rope also features a special fiber coating that reduces interior friction and increases ultraviolet resistance.

“LankoLift crane test participants have been consistently impressed with the product’s low weight, flexibility and ease of handling during installation and hook block changes,” Schmeiss said. “The rope has proven suitable for higher payloads, especially those involving higher lifting heights and longer jib lengths. The low maintenance requirements offer further advantage, since synthetic ropes of this type are corrosion-proof and require no further lubrication.”

“The bottom line is that fiber rope bears a cost disadvantage that only becomes balanced when the operations are very expensive, for example deep shaft mining, and the relatively low reduction in total weight accumulates over a long length in favor of payload, [like] increasing a skip’s capacity from 30 to 40 tons in a 3,000 meter deep shaft,” said Balbiani. “Due to economic turbulences, we have currently iced these projects and will go ahead when supply chain problems have resolved.”

WireCo offers the Casar TurboLite M, a hybrid mining rope with a plastic-coated, high-strength fiber core, surrounded by steel-wire strands. This construction provides a high strength-to-weight ratio, as well as resistance to abrasion and bending fatigue. It was designed for use in underground mining, where shafts have become progressively deeper and weight the limiting factor in hoisting capacity, Schmeiss said.

“As with other applications that favor synthetics, reduced weight is a clear benefit,” Schmeiss said. “The same is true of the added durability and reduced creep provided by hybrid ropes. In terms of downside and factors that would limit wider use, cost is likely the most significant.”

A lot of research has been conducted on hybrid ropes. The main objective has been to substitute the independent wire rope core of a conventional steel wire rope with a high performance synthetic rope that also has supportive load-bearing features.

High performance synthetic ropes are used on utility truck cranes for transmission wire and transformer applications. These ropes are being used on tower cranes, RTs and even overhead cranes. The elevator industry is also researching the use of hybrid ropes.

We are always looking for ways to decrease weight on a crane without compromising the mechanical properties for lifting. The mobile crane market demands ropes with a high break strength and non-rotating characteristics for long lifts and increased weights. Also, we must realize that end fittings – such as swage or spelter buttons, sockets and wedge sockets – have the ability to make the termination of the hybrid rope to complete the installation.

Inspection criteria of standard wire ropes have been in place for a long time. Since the introduction of high performance synthetic ropes, inspection criteria is also documented. High performance synthetic ropes have been predominantly used in the utility truck applications with much shorter lifts and very few, if any, parts of line through the block. With that said, inspection criteria for high performance synthetic ropes is very important, requiring proper education for daily inspection and third-party inspection. Inspection of these ropes has generated a lot of discussion. A critical subject is damage. If a steel wire rope jumps a sheave, the outer steel wires can withstand the abuse. But with high performance synthetic rope, very small diameter fibers can be cut between the sheave and block.

Research will undoubtedly continue. A hybrid robe gives more answers when it comes to inspection and damage assessment. And there maybe be some comfort knowing that a hybrid rope is protected by steel wire with the internal lighter fibers fulfilling the strength, flexibility and torque balance characteristics.

Tony Fastuca, Vice President of ASC Industries Python America, has been in the wire rope industry since 1979. Based in Germany, Python provides engineered ropes for customers around the world.

8613371530291

8613371530291