seizing wire rope ends supplier

applies on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there

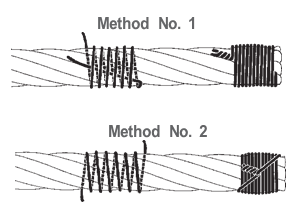

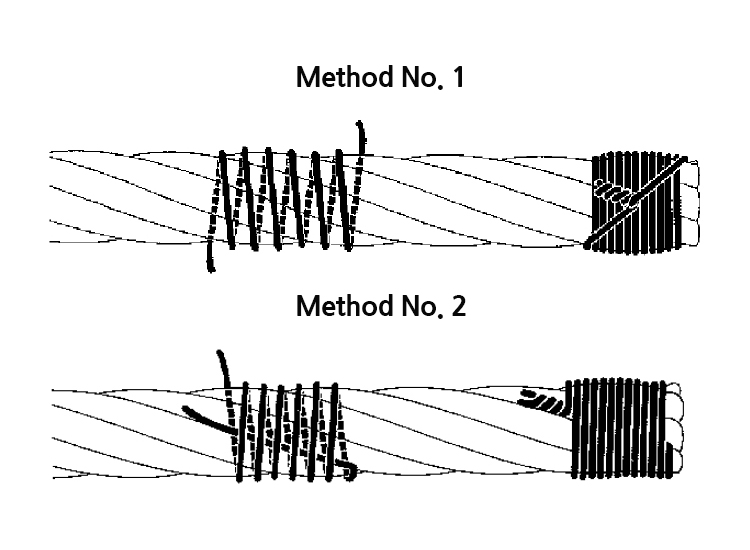

The two widely accepted methods of applying seizing are illustrated in Figures 25A and 25B. The seizing itself should be soft, or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. But the length of the seizing should never be less than the diameter of the rope being seized. Normally, for preformed ropes, one seizing on each side of the cut is sufficient. But for ropes that are not preformed or rotation resistant ropes, a minimum of two seizings on each side is recommended; and these should be spaced six rope diameters apart (Fig. 26).

Proper seizing and cutting operations are not difficult to perform, and they ensure that the wire rope will meet the user’s performance expectations. Proper seizings must be applied on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there may be an uneven distribution of loads to the strands; a condition that will significantly shorten the life of the rope.

Either of the following seizing methods is acceptable. Method No. 1 is usually used on wire ropes over one inch in diameter. Method No. 2 applies to ropes one inch and under.

Method No. 1: Place one end of the seizing wire in the valley between two strands. Then turn its long end at right angles to the rope and closely and tightly wind the wire back over itself and the rope until the proper length of seizing has been applied. Twist the two ends of the wire together, and by alternately pulling and twisting, draw the seizing tight.

The Seizing Wire. The seizing wire should be soft or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. The length of the seizing should never be less than the diameter of the rope being seized.

Proper end seizing while cutting and installing, particularly on rotation-resistant ropes, is critical. Failure to adhere to simple precautionary measures may cause core slippage and loose strands, resulting in serious rope damage. Refer to the table below ("Suggested Seizing Wire Diameters") for established guidelines. If core protrusion occurs beyond the outer strands, or core retraction within the outer strands, cut the rope flush to allow for proper seizing of both the core and outer strands.

Interested in becoming a distributor for Miami Cordage/Florida Wire & Rigging Works? Whether you have a brick-and-mortar store or are an on-line retailer, we offer substantial discounts to our loyal distributors. Click here to find out more information.

applies on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there

The two widely accepted methods of applying seizing are illustrated in Figures 25A and 25B. The seizing itself should be soft, or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. But the length of the seizing should never be less than the diameter of the rope being seized. Normally, for preformed ropes, one seizing on each side of the cut is sufficient. But for ropes that are not preformed or rotation resistant ropes, a minimum of two seizings on each side is recommended; and these should be spaced six rope diameters apart (Fig. 26).

Loos & Co., Inc. has long been a manufacturer of high-quality wire rope fittings and accessories for a variety of industries. Our most successful wire rope products are our wire rope terminals. Our domestically manufactured wire rope terminals come in many milspec (MS) and commercial hardware styles for a range of applications. And are Made in the USA at our Naples, Florida facility. By buying our Made in the USA terminals, you are ensured a high-quality product from our craftsmen, with each purchase directly supporting the American workforce and the America manufacturing sector. If you would like to speak with one of our experts of wire rope terminals, or learn more about our other domestically manufactured products, please contact us via one of the methods below, and we will reach out to you directly.

After cutting the rope (see below) it is good practice to braze PYTHON®, 19×7, and 34×7 rope ends to ensure that they don’t unravel. Leave the seizings on the rope for added holding strength. Be careful not to damage the seizing while brazing.

We found that blade cutting a rope gives the best results. Be sure to use a cutting blade suitable for the job (We use cutting blades made by ‘PFERD-HORSE’ type ELASTIC # 80 EHT 230-2 A 24 SG INOX.) Follow the safety precautions for free hand cutting.

Rope diameter is specified by the user and is generally given in the equipment manufacturer’s instruction manual accompanying the machine on which the rope is to be used.

Rope diameters are determined by measuring the circle that just touches the extreme outer limits of the strands - that is, the greatest dimension that can be measured with a pair of parallel-jawed calipers or machinist’s caliper square. A mistake could be made by measuring the smaller dimension.

The Right Way To Unreel. To unreel wire rope from a heavy reel, place a shaft through the center and jack up the reel far enough to clear the floor and revolve easily. One person holds the end of the rope and walks a straight line away from the reel, taking the wire rope off the top of the reel. A second person regulates the speed of the turning reel by holding a wood block against the flange as a brake, taking care to keep slack from developing on the reel, as this can easily cause a kink in the rope. Lightweight reels can be properly unreeled using a vertical shaft; the same care should be taken to keep the rope taut.

The Wrong Way To Unreel. If a reel of wire rope is laid on its flange with its axis vertical to the floor and the rope unreeled by throwing off the turns, spirals will occur and kinks are likely to form in the rope. Wire rope always should be handled in a way that neither twists nor unlays it. If handled in a careless manner, reverse bends and kinks can easily occur.

The Right Way To Uncoil. There is only one correct way to uncoil wire rope. One person must hold the end of the rope while a second person rolls the coil along the floor, backing away. The rope is allowed to uncoil naturally with the lay, without spiraling or twisting. Always uncoil wire rope as shown.

The Wrong Way To Uncoil. If a coil of wire rope is laid flat on the floor and uncoiled by pulling it straight off, spirals will occur and kinking is likely. Torsions are put into the rope by every loop that is pulled off, and the rope becomes twisted and unmanageable. Also, wire rope cannot be uncoiled like hemp rope. Pulling one end through the middle of the coil will only result in kinking.

Kinks. Great stress has been placed on the care that should be taken to avoid kinks in wire rope. Kinks are places where the rope has been unintentionally bent to a permanent set. This happens where loops are pulled through by tension on the rope until the diameter of the loop is only a few inches. They are also caused by bending a rope around a sheave having too severe a radius. Wires in the strands at the kink are permanently damaged and will not give normal service, even after apparent "restraightening."

When wire rope is wound onto a sheave or drum, it should bend in the manner in which it was originally wound. This will avoid causing a reverse bend in the rope. Always wind wire rope from the top of the one reel onto the top of the other. Also acceptable, but less so, is re-reeling from the bottom of one reel to the bottom of another. Re-reeling may also be done with reels having their shafts vertical, but extreme care must be taken to ensure that the rope always remains taut. It should never be allowed to drop below the lower flange of the reel. A reel resting on the floor with its axis horizontal may also be rolled along the floor to unreel the rope.

Wire rope should be attached at the correct location on a flat or smooth-faced drum, so that the rope will spool evenly, with the turns lying snugly against each other in even layers. If wire rope is wound on a smooth-face drum in the wrong direction, the turns in the first layer of rope will tend to spread apart on the drum. This results in the second layer of rope wedging between the open coils, crushing and flattening the rope as successive layers are spooled.

A simple method of determining how a wire rope should be started on a drum is shown above. The observer stands behind the drum, with the rope coming towards him. Using the right hand for right-lay wire rope, and the left hand for left lay wire rope, the clenched fist denotes the drum, the extended index finger the oncoming rope.

Clips are usually spaced about six wire rope diameters apart to give adequate holding power. They should be tightened before the rope is placed under tension. After the load is placed on the rope, tighten the clips again to take care of any lessening in rope diameter caused by tension of the load. A wire rope thimble should be used in the eye of the loop to prevent kinking.

U-bolt Clips. There is only one correct method for attaching U-bolt clips to wire rope ends, as shown in the "Correct Way". The base of the clip bears on the live end of the rope; the "U" of the bolt bears on the dead end.

Compare this with the incorrect methods. Five of the six clips shown are incorrectly attached - only the center clip in the top view is correct. When the "U" of the clip bears on the live end of the rope, there is a possibility of the rope’s being cut or kinked, with subsequent failure.

Proper seizing and cutting operations are not difficult to perform, and they ensure that the wire rope will meet the user’s performance expectations. Proper seizings must be applied on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there may be an uneven distribution of loads to the strands; a condition that will significantly shorten the life of the rope.

Either of the following seizing methods is acceptable. Method No. 1 is usually used on wire ropes over one inch in diameter. Method No. 2 applies to ropes one inch and under.

Place one end of the seizing wire in the valley between two strands. Then turn its long end at right angles to the rope and closely and tightly wind the wire back over itself and the rope until the proper length of seizing has been applied. Twist the two ends of the wire together, and by alternately pulling and twisting, draw the seizing tight.

The seizing wire should be soft or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. The length of the seizing should never be less than the diameter of the rope being seized.

Proper end seizing while cutting and installing, particularly on rotation-resistant ropes, is critical. Failure to adhere to simple precautionary measures may cause core slippage and loose strands, resulting in serious rope damage. Refer to the table for established guidelines. If core protrusion occurs beyond the outer strands, or core retraction within the outer strands, cut the rope flush to allow for proper seizing of both the core and outer strands.

Rigging equipment has a tough job lifting and moving heavy loads for hours and hours a day. In order for that equipment to be able to be its job, we have to take proper care of it. We expect longevity and endurance from equipment like wire rope, but that can easily turn if not properly treated. Equipment that is properly treated, handled, installed, inspected and stored will reward us with a prolonged life of service, better job performance and peace of mind in knowing it won’t fail.

Riggers don’t have the luxury of simple equipment slip-ups. If your rigging equipment fails you, it can cause damage to product, property and worst-case scenario, an extreme safety hazard resulting in injury or loss of life. Since wire rope is a material of choice in heavier lifts, extreme safety hazards can be a real possibility if you’re using rope that’s in an unsafe condition.

Seizing and cutting operations are not difficult to perform, but are crucial in the performance of wire rope. Proper seizing must be applied to both rope ends to protect the wire ropes from loosening – Carelessly or inadequately seized ends may cause distortion or flattening of the rope. If you use wire rope that is not properly seized it will cause uneven distribution of the load over the strands causing the life of the wire rope to be drastically shortened.

Normally, one of two methods are used to do this. Typically method one is suitable for wire ropes with a diameter over one inch, and method two is those with a diameter one inch and under.

If you’re dealing with loading or unloading wire rope in a reel or coil, it’s important to know that that is not a protected storage method and if you drop the reel during this process, it can lead to serious damage to your wire rope. Because of this, it is important to handle reels of wire rope with care and focus not to drop or damage the reel. Damage to the reel can also make it incredibly difficult to remove the wire rope from the reel, so it’s not only an important safety precaution but will also save you time and frustration in the future.

It’s also important to take care when removing wire rope from the reels or coils. When doing this, ensure the reel or coil is rotating as the wire rope unwinds. Below you will see some of the rights vs. wrongs for unwinding rope.

In the rigging field, it’s very important that workers be properly trained in any and all tasks they are performing because many lifts can become extremely dangerous if even one aspect is done incorrectly. So the most important thing to take away from this tip is to seek out proper training from certified professionals before taking on tasks like installing wire rope!

Once you have that training you will know how important it is to take into account the design factor of any equipment being used with wire rope, being sure to take note of the nominal diameter of wire rope to use with the equipment, as specified by the manufacturer. Installing an incorrect size will result in a failed rope or shorter service life as the rope can get pinched into a smaller space compromising its integrity.

Wire rope diameter is determined by measuring the outer circle of the strands, which is the greatest dimension that can be measured with a pair of parallel-jawed calipers or machinist’s caliper square. You can easily make a mistake if not taking care in measuring the largest dimension, as shown below:

Keeping up with the required inspections is something that must be prioritized for all rigging equipment. Wire rope is often used for heavy lifting, which means they are being used in situations where they are trusted to keep not just your load safe, but the people and the environment around it. That means that you have to be confident that your wire rope is up to the task – And how do you do that? Inspections!

Based on manufacturer/organization recommendations, ensure your wire rope is being inspected by a certified professional where the rope can be dismantled and tested through visual assessment and non-destructive testing. Hercules SLR can make this a worry-free part of your business – Our experience and LEEA certified team can take this completely off your hands, on-site or in our fell service rigging shops!

On top of these professional inspections, wire rope should also be visually assessed by trained and experienced workers at the start of every shift or when resuming stalled work. Thorough visual assessments should also be carried out after reattaching or refitting the wire rope on the same or different equipment. Machine operators should be trained to visually assess the entire wire rope, with emphasis on points of attachment.

Things to look for when visually assessing a wire rope: Broken Strands– One of the easiest ways to do this is to run a cotton cloth over the length of the wire (if possible), checking for any places where the material get’s snagged. Any cable that has a single broken wire strand located around critical fatigue areas (where the cable runs around a pulley, sleeve or through a fair-lead; or any section where the cable is flexed, rubbed, or worked) must be replaced. Generally, SOME broken wires in non-critical areas are okay, but always consult your service/maintenance manual.

https://gfycat.com/naturalsilverhawk-skycatcher-stationair-inspection-propeller Internal Ware and Tare – It is recommended to remove the cable whenever possible and flex them to ensure that all cables on the inside of the wire rope haven’t worn down due to environmental deterioration, distortion or fatigue. If you haven’t been keeping up with regular inspections, this is particularly necessary as it is possible for wire rope to look completely sound from the outside, but as soon as you move it around, it completely fails.

Wire rope needs to be stored in a well-ventilated, dry, and covered area and should not come in contact with the floor. If it is necessary to store it outside, they must be covered so that moisture cannot get inside and cause corrosion. You should also make sure that they are protected from dust, water, steam, salt, chemical fumes or adverse climatic conditions.

Turning the reel occasionally is a good practice to get in the habit of. This will prevent the wire rope’s lubricant from wearing off. If ropes are stored for a long time, it is advised for you to get them examined periodically and apply a coat of lubricant to them.

Whatever cutting methods your applied, certain precaution - seizing both rope ends must be employed to protect the steel wire ropes from loosening. But carelessly or inadequately seized ends may cause distortion and flattening of the rope. If these loose ropes are applied to works, uneven distribution of loads to the strands may shorten the life of ropes badly. So it is important to seize the wire ropes in the optimal way.

Normally, two methods are widely accepted by our customer. The method one is suitable for wire ropes with diameter over one inch, while the method two is for those with diameter one inch and under.

The diameter and length of seizing wires may different as the diameter of the wire rope. Make sure that the seizing length is no less than the diameter of the steel wire rope.

Generally, one seizing on each side of the cut is sufficient for preformed ropes. But for rotation resistant or non-preformed ropes, no less than two seizing parts are needed with the distance about six rope diameters.

8613371530291

8613371530291