seizing wire rope ends manufacturer

Proper seizing and cutting operations are not difficult to perform, and they ensure that the wire rope will meet the user’s performance expectations. Proper seizings must be applied on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there may be an uneven distribution of loads to the strands; a condition that will significantly shorten the life of the rope.

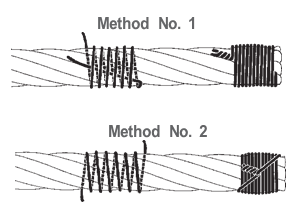

Either of the following seizing methods is acceptable. Method No. 1 is usually used on wire ropes over one inch in diameter. Method No. 2 applies to ropes one inch and under.

Method No. 1: Place one end of the seizing wire in the valley between two strands. Then turn its long end at right angles to the rope and closely and tightly wind the wire back over itself and the rope until the proper length of seizing has been applied. Twist the two ends of the wire together, and by alternately pulling and twisting, draw the seizing tight.

The Seizing Wire. The seizing wire should be soft or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. The length of the seizing should never be less than the diameter of the rope being seized.

Proper end seizing while cutting and installing, particularly on rotation-resistant ropes, is critical. Failure to adhere to simple precautionary measures may cause core slippage and loose strands, resulting in serious rope damage. Refer to the table below ("Suggested Seizing Wire Diameters") for established guidelines. If core protrusion occurs beyond the outer strands, or core retraction within the outer strands, cut the rope flush to allow for proper seizing of both the core and outer strands.

applies on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there

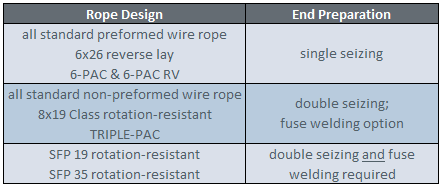

The two widely accepted methods of applying seizing are illustrated in Figures 25A and 25B. The seizing itself should be soft, or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. But the length of the seizing should never be less than the diameter of the rope being seized. Normally, for preformed ropes, one seizing on each side of the cut is sufficient. But for ropes that are not preformed or rotation resistant ropes, a minimum of two seizings on each side is recommended; and these should be spaced six rope diameters apart (Fig. 26).

applies on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there

The two widely accepted methods of applying seizing are illustrated in Figures 25A and 25B. The seizing itself should be soft, or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. But the length of the seizing should never be less than the diameter of the rope being seized. Normally, for preformed ropes, one seizing on each side of the cut is sufficient. But for ropes that are not preformed or rotation resistant ropes, a minimum of two seizings on each side is recommended; and these should be spaced six rope diameters apart (Fig. 26).

As specialist for manufacturing quality steel wire ropes over 20 years, our company can supply strong, durable and reliable ropes that capable to minimize your downtime and maximize cost effectiveness. Decades of experience we owned make us know clearly the work you do and capable to provide professional guidance.

We select the best steel or stainless steel as raw material for wire rope manufacturing. Our products are manufactured under strict quality managements and test before they leave the factory.

Our engineers can provide professional advice about picking up optimal steel wire ropes for their application, installation guidance to ensure maximum return in their wire rope system.

If you are going to pick up steel wire ropes that suit your project perfectly, you must have an ideal about the construction about them. Our company can supply bright wire rope, galvanized wire rope, stainless steel wire rope, compacted wire rope, rotation resistant wire ropes, mining wire rope, elevator wire rope, crane wire rope and gas & oilfield wire ropes. Here are some details to solve the problem that may puzzle you whether you are browsing the web or picking up steel wire ropes.

Bright steel wire ropes mean no surface treatment is applied to the rope. Therefore, they have the lower price among these three wire ropes. Generally, they are fully lubricated to protect the rope from rust and corrosion.

Galvanized steel wire ropes feature compressed zinc coating for providing excellent corrosion resistance. With higher break strength yet lower price than stainless steel, galvanized steel wire ropes are widely used in general engineering applications such as winches and security ropes.

Stainless steel wire ropes, made of quality 304, 305, 316 steels, are the most corrosive type for marine environments and other places subjected to salt water spray. Meanwhile, bright and shiny appearance can be maintained for years rather than dull as galvanized steel wire ropes.

Steel wire ropes are composed of multiple strands of individual wires that surrounding a wire or fiber center to form a combination with excellent fatigue and abrasion resistance. These wires and strands are wound in different directions to from different lay types as follows:

Beside above lay types, alternative lay ropes which combine regular lay and lang lay together and ideal for boom hoist and winch lines, can also be supplied as your request.

Two main methods about seizing steel wire ropes in conjunction with soft or annealing wire or strands to protect cut ends of the ropes form loosening.

Whatever cutting methods your applied, certain precaution - seizing both rope ends must be employed to protect the steel wire ropes from loosening. But carelessly or inadequately seized ends may cause distortion and flattening of the rope. If these loose ropes are applied to works, uneven distribution of loads to the strands may shorten the life of ropes badly. So it is important to seize the wire ropes in the optimal way.

Normally, two methods are widely accepted by our customer. The method one is suitable for wire ropes with diameter over one inch, while the method two is for those with diameter one inch and under.

The diameter and length of seizing wires may different as the diameter of the wire rope. Make sure that the seizing length is no less than the diameter of the steel wire rope.

Generally, one seizing on each side of the cut is sufficient for preformed ropes. But for rotation resistant or non-preformed ropes, no less than two seizing parts are needed with the distance about six rope diameters.

After cutting the rope (see below) it is good practice to braze PYTHON®, 19×7, and 34×7 rope ends to ensure that they don’t unravel. Leave the seizings on the rope for added holding strength. Be careful not to damage the seizing while brazing.

We found that blade cutting a rope gives the best results. Be sure to use a cutting blade suitable for the job (We use cutting blades made by ‘PFERD-HORSE’ type ELASTIC # 80 EHT 230-2 A 24 SG INOX.) Follow the safety precautions for free hand cutting.

8613371530291

8613371530291