seizing wire rope ends made in china

Whatever cutting methods your applied, certain precaution - seizing both rope ends must be employed to protect the steel wire ropes from loosening. But carelessly or inadequately seized ends may cause distortion and flattening of the rope. If these loose ropes are applied to works, uneven distribution of loads to the strands may shorten the life of ropes badly. So it is important to seize the wire ropes in the optimal way.

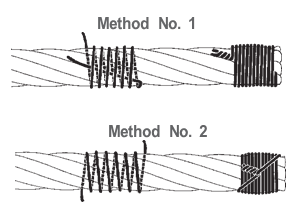

Normally, two methods are widely accepted by our customer. The method one is suitable for wire ropes with diameter over one inch, while the method two is for those with diameter one inch and under.

The diameter and length of seizing wires may different as the diameter of the wire rope. Make sure that the seizing length is no less than the diameter of the steel wire rope.

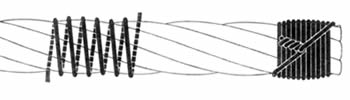

Generally, one seizing on each side of the cut is sufficient for preformed ropes. But for rotation resistant or non-preformed ropes, no less than two seizing parts are needed with the distance about six rope diameters.

applies on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there

The two widely accepted methods of applying seizing are illustrated in Figures 25A and 25B. The seizing itself should be soft, or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. But the length of the seizing should never be less than the diameter of the rope being seized. Normally, for preformed ropes, one seizing on each side of the cut is sufficient. But for ropes that are not preformed or rotation resistant ropes, a minimum of two seizings on each side is recommended; and these should be spaced six rope diameters apart (Fig. 26).

Proper seizing and cutting operations are not difficult to perform, and they ensure that the wire rope will meet the user’s performance expectations. Proper seizings must be applied on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there may be an uneven distribution of loads to the strands; a condition that will significantly shorten the life of the rope.

Either of the following seizing methods is acceptable. Method No. 1 is usually used on wire ropes over one inch in diameter. Method No. 2 applies to ropes one inch and under.

Method No. 1: Place one end of the seizing wire in the valley between two strands. Then turn its long end at right angles to the rope and closely and tightly wind the wire back over itself and the rope until the proper length of seizing has been applied. Twist the two ends of the wire together, and by alternately pulling and twisting, draw the seizing tight.

The Seizing Wire. The seizing wire should be soft or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. The length of the seizing should never be less than the diameter of the rope being seized.

Proper end seizing while cutting and installing, particularly on rotation-resistant ropes, is critical. Failure to adhere to simple precautionary measures may cause core slippage and loose strands, resulting in serious rope damage. Refer to the table below ("Suggested Seizing Wire Diameters") for established guidelines. If core protrusion occurs beyond the outer strands, or core retraction within the outer strands, cut the rope flush to allow for proper seizing of both the core and outer strands.

Loos & Co., Inc. has long been a manufacturer of high-quality wire rope fittings and accessories for a variety of industries. Our most successful wire rope products are our wire rope terminals. Our domestically manufactured wire rope terminals come in many milspec (MS) and commercial hardware styles for a range of applications. And are Made in the USA at our Naples, Florida facility. By buying our Made in the USA terminals, you are ensured a high-quality product from our craftsmen, with each purchase directly supporting the American workforce and the America manufacturing sector. If you would like to speak with one of our experts of wire rope terminals, or learn more about our other domestically manufactured products, please contact us via one of the methods below, and we will reach out to you directly.

LSG Snake Grips, as overhead pulling grips, are used to pull a new cable or wire rope with the existing cable or wire rope that is being replaced. The Lewis Snake Grips expand or contract to grip different or identical cable and/or rope sizes as per the customer’s needs.

Snake grips (aka wire grip or cable grip) are part of Lewis Pulling Grips line of products and typically are used on Oil Rigs, Drilling Rigs & Platform.

As shown in Figure 1, the utility model comprises main haulage cable 2, wherein the guiding seizing wire 3 of an end and the slick and sly steel toe 1 that is connected the steel wire rope two ends constitute to be welded in main haulage cable 2, on the slick and sly steel toe 1 through wires hole 11 is set, the diameter of guiding seizing wire 3 is less than main haulage cable 2, the diameter of guiding seizing wire 3 is 1.5MM, be that its suppleness diameter of phi is 0.0357MM, the length of guiding seizing wire is 0.5CM.

As shown in Figure 1, the utility model comprises main haulage cable 2, wherein the guiding seizing wire 3 of an end and the slick and sly steel toe 1 that is connected the steel wire rope two ends constitute to be welded in main haulage cable 2, on the slick and sly steel toe 1 through wires hole 11 is set, the diameter of guiding seizing wire 3 is less than main haulage cable 2, the diameter of guiding seizing wire 3 is 2MM, be that its suppleness diameter of phi is 0.0476MM, the length of guiding seizing wire is 150CM.

As shown in Figure 1, the utility model comprises main haulage cable 2, wherein the guiding seizing wire 3 that forms of an end drawing-down and the slick and sly steel toe 1 that is connected the steel wire rope two ends constitute with main haulage cable 2 by drawing process, on the slick and sly steel toe 1 through wires hole 11 is set, the diameter of guiding seizing wire 3 is less than main haulage cable 2, the diameter of guiding seizing wire 3 is 2.5MM, be that its suppleness diameter of phi is 0.0595MM, the length of guiding seizing wire is 250CM.

Because the utility model is provided with one section guiding seizing wire 3 on main haulage cable 2, then in use threading apparatus runs into crooked tube wall and will become curved and walk over along tube wall, thereby is more prone to walk the pipeline of pre-buried various band bent angles.

applies on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there

The two widely accepted methods of applying seizing are illustrated in Figures 25A and 25B. The seizing itself should be soft, or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. But the length of the seizing should never be less than the diameter of the rope being seized. Normally, for preformed ropes, one seizing on each side of the cut is sufficient. But for ropes that are not preformed or rotation resistant ropes, a minimum of two seizings on each side is recommended; and these should be spaced six rope diameters apart (Fig. 26).

Master link- Forged or welded steel link used to support all members (legs) of an alloy-steel chain or wire rope sling (includes bull ring, pear link, oblong link, and weldless sling link). Also called bull- ring.

Milking- The progressive movement of strands along the axis of the rope, resulting from the ropes movement through a restricted passage such as a tight sheave.

Mousing - A method of bridging the throat opening of a hook to prevent the release of load lines and slings, under service or slack conditions, by wrapping with soft wire, rope, heavy tape, or similar materials.

Nominal strength, wire rope - Nominal wire rope strengths as calculated by a standardized industry- accepted procedure. Minimum acceptance strength is 22% lower than nominal strength. (Re: Wire Rope Users Manual.)

Pitch diameter- The distance, measured through the center of a drum or sheave, from center to center of a rope passed about the periphery of the drum or sheave.

Pig tail - A short, standard eye-eye wire rope sling, often used to connect between a crane hook and another wire rope sling or bridle; also known as a "messenger sling."

Preformed strand - Strand in which the wires are permanently shaped, before fabrication in the strands, to the helical form they assume in the strand.

Preformed wire rope- Wire rope in which the strands are permanently shaped, before fabrication into the rope, to the helical form they assume in the wire rope.

Reeved blocks - Passing rope through a set of blocks, as opposed to laced blocks, and in such a manner that there are no lines crossed or rubbing each other.

Repetitive pickup point- When operating on a short cycle operation, the rope being used on single layer and being spooled repetitively over a short portion of the drum.

Right-lay - (a) Strand in which the cover wires are laid in a helix having a right-hand pitch, similar to a right-hand screw; (b) Rope in which the strands are laid in a helix having a right-hand pitch, similar to a right-hand screw.

Rotation-resistant rope - A wire rope consisting of an inner layer of strands laid in one direction, covered by a layer of strands laid in the opposite direction. This has the effect of counteracting torque by reducing the tendency of the finished rope to rotate.

Seale- A strand construction having one size of cover wires with the same number of one size of wires in the inner layer and each layer having the same length and direction of lay. Most common construction is one center wire, nine inner wires, and nine cover wires.

Slings, endless and grommet wire rope - A wire rope made endless from one continuous length of cable-laid rope with the ends joined by one or more metallic fittings.

Snatch block - A single- or double-sheave block arranged so one or both cheek plates can be opened, permitting the block to be reeved without having to use a free rope end; also called gate block.

Splicing - Interweaving of two ends of ropes to make a continuous or endless length without appreciably increasing the diameter. Also, making a loop or eye in the end or a rope by tucking the ends of the strands.

Spreader bar - A frame, forming part of the boom suspension, supporting sheaves for the live suspension ropes and attached to the fixed suspension ropes (pendants); also called bridle, spreader, live spreader, or flating harness.

Standing line - A fixed-length line that supports loads without being spooled on or off a drum; a line of which both ends are dead; also called stay rope or pendant.

Standing rope (pendant)- A supporting rope that maintains a constant distance between the points of attachment to the two components connected by the rope.

Strand laid endless sling-mechanical joint - a wire rope sling made endless from one length of rope with the ends joined by one or more metallic fittings.

Strand laid grommet-hand tucked - an endless wire rope sling made from one length of strand wrapped six times around a core formed by hand tucking the ends of the strand inside the six wraps.

Strand laid rope - a wire rope made with strands (usually six or eight) wrapped around a fiber core, wire strand core, or independent wire rope core (IWRC).

Thimble - Grooved-metal fitting designed to prevent crushing or over-stressing wire rope at the terminal end which is used to protect the eye of a wire rope or sling.

Trolley - A unit that travels on the bridge rails consisting of frame, end Trucks, drive supporting the hoisting mechanism, rope, and load block that supports the load, or a unit that travels on the lower flange of a beam or monorail system supporting a hoist.

Turnbuckle - Device attached to wire rope chain or rods for making limited adjustments in length, which consists of a barrel and right-hand and left-hand threaded bolts.

Winch head (gypsy head) - A rotatable cylindrical drum with curved end flanges, used for load handling by means of fiber rope coiled about its barrel with hand tension applied to the non-load end. Also called a capstan.

Interesting that Stevenson used the wrong word. Although he came from a family of lighthouse engineers and went with his father to visit some of his father"s projects he was not a sailor. A seizing has never meant a wrapping to prevent a rope"s end from fraying. As the OED definition quoted makes clear, a seizing always involves binding two parts together. As Hans in Texas points out, the normal usage is to "whip" the end of a rope. However, although that is current usage, it is not modern. It"s recorded as far back as the 15th century.

8613371530291

8613371530291