sheave design for wire rope for sale

Esheaves offers the Wire Rope sheave solution to tackle any challenge you face. From strength, to availability, to like -for- like replacement, there is no heavy duty sheave application we can’t assist you with. If you need assistance selecting the best solution for your project, contact us directly to speak to a member of our knowledgeable engineering staff.

Designed for cables 1/2″ and under, eSheaves Small Cable Sheaves offers an in-stock, ready to ship solution for almost any application. Whether you select steel or stainless steel, all small cable sheaves are turned from drawn bar stock to provide strength and durability. All bearings are engineered for high load applications running at medium speed. Oil impregnation provides permanent self-lubrication. Learn more about applications and available configurations below.

Don’t see what you need? No Problem! Additional modifications are available upon request to meet your requirements. Simply complete a request for small cable sheave quotation and we will provide a price and delivery.

Precision CNC machining, turning and milling services. Capabilities include bending, waterjet cutting, routing, forming, drilling, casting, urethane molding, additive manufacturing (3D printing) and welding. Works with rubber, polyurethane, nylon, acetal, polycarbonate, acrylic, fiberglass reinforced plastics (FRP), laminates, PVC and other plastic materials. Manufacturer of custom and standard truck parts, bumpers, gaskets, seals, bushings, trays, anti-vibration or manifold grommets, caps and vibration mounts. Bearings, sheaves, pulleys, channels, nozzles, profiles, sprockets, outrigger pads, strip doors, elbows, rollers, matting, barriers, ceramic and truck liners are provided. Prototypes, short and high runs production volumes are offered. Materials are available in the form of sheets, tubes and rods. Serves agricultural, aggregate, biomass, construction, marine, port, material handling, mining, oil, gas, retail, transportation, automotive, food and beverage industries.

Sheaves facilitate the smooth and safe operation of overhead crane hoists. Damaged sheaves can wear ropes prematurely and cause other dangerous hazards, such as binding wire rope. Konecranes technicians are trained to identify and correct problems with sheaves and other parts of hoisting equipment.

Sheaves carrying ropes which can be momentarily unloaded shall be provided with close-fitting guards or other suitable devices to guide the rope back into the groove when the load is applied again.

The sheaves in the bottom block shall be equipped with close-fitting guards that will prevent ropes from becoming fouled when the block is lying on the ground with ropes loose.

In using hoisting ropes, the crane manufacturer"s recommendation shall be followed. The rated load divided by the number of parts of rope shall not exceed 20 percent of the nominal breaking strength of the rope.

Rope clips attached with U-bolts shall have the U-bolts on the dead or short end of the rope. Spacing and number of all types of clips shall be in accordance with the clip manufacturer"s recommendation. Clips shall be drop-forged steel in all sizes manufactured commercially. When a newly installed rope has been in operation for an hour, all nuts on the clip bolts shall be retightened.

Wherever exposed to temperatures, at which fiber cores would be damaged, rope having an independent wirerope or wire-strand core, or other temperature-damage resistant core shall be used.

Replacement rope shall be the same size, grade, and construction as the original rope furnished by the crane manufacturer, unless otherwise recommended by a wire rope manufacturer due to actual working condition requirements.

Konecranes wire rope inspections can help crane users extend the life of hoist ropes. Ropes, sheaves and other reeving system components are inspected for compliance with crane standards, and to determine if they have flaws that could hinder safe operation. Contact us today to schedule an assessment.

*The foregoing OSHA regulations are not intended to be a comprehensive overview of all applicable regulations pertaining to the designated topic. State laws may mandate different safety and maintenance standards. Accordingly, please consult applicable state laws as well as original equipment manufacturer specifications for further guidance. The statements and descriptions contained herein constitute the opinion/recommendation of the seller and are not intended to create any express warranties.

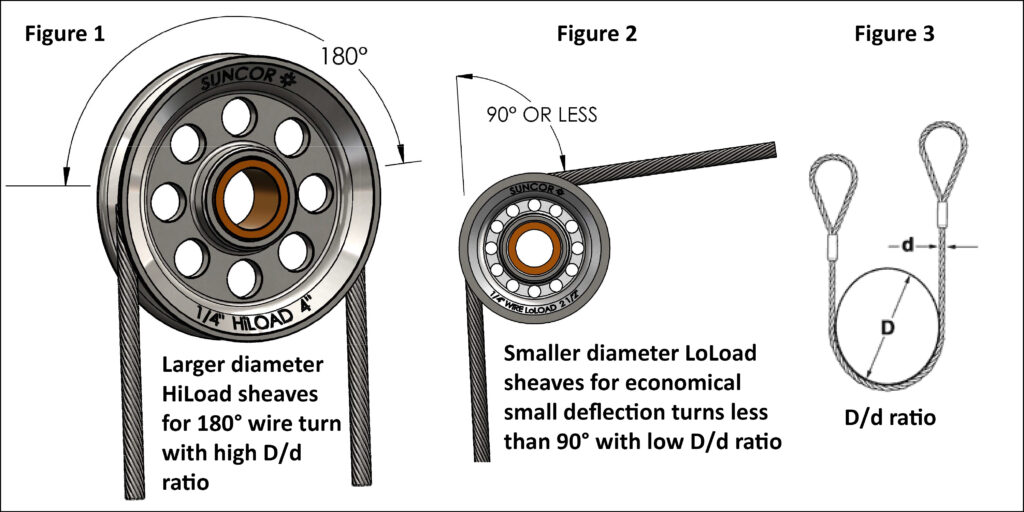

Suncor’s sheaves are comprised of high quality grade 316 stainless steel and incorporate a weight optimized design with recessed lightening holes. They are available for fibrous or wire rope and feature either stainless steel bearing or bronze bushing type hub styles. They fit rope sizes ranging from 1/4″ to 1″ and are ideal for various industrial and rigging applications.

Unique upset roll forging process provides a thicker groove section for extra strength.Stepped Hubs are precisely centered and mechanically locked in place.

5″ Sheave, industrial quality, 5/8 wide machined sheave with oil impregnated bushing grooved for 3/8 wire rope. Clear galvenized zinc; safe work load of 1850 lbs; weight 2.9 lbs. Option includes changing to 1/2″ id (internal diameter) bronze/steel oil impregnated bushing.

8613371530291

8613371530291