sheave size for wire rope supplier

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

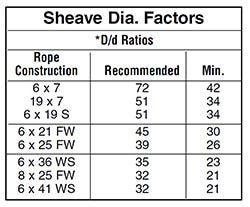

The service life of cable and wire rope can be increased if (1) it operates over the largest possible pulley or sheave diameter, and (2) it is properly supported in the pulley or sheave groove. The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. The chart below shows minimum tread diameters over which various sizes and constructions of cable should operate.

Sheaves, drums and rollers must be of a correct design if optimum service is to be obtained from both the equipment and the wire rope. Because there are many different types of equipment and many different operating conditions, it is difficult to identify the one specific size of sheave or drum most appropriate for every application.

The guideline to follow is this: the most practical design is the one that most closely accommodates the limiting factors imposed by the equipment, the operating conditions and the wire rope.

All wire ropes operating over sheaves and drums are subjected to cyclic bending stresses, thus the rope wires will eventually fatigue. The magnitude of these stresses depends—all other factors being constant—upon the ratio of the diameter of the sheave or drum to the diameter of the rope.

Frequently, fatigue from cyclic, high-magnitude bending stress is a principal reason for shortened rope service. In order for a rope to bend around a sheave, the rope’s strands and wires must move relative to one another. This movement compensates for the difference in diameter between the underside and the top side of the rope, the distance being greater along the top side than it is on the underside next to the groove.

Proper rope movement (and service) is adversely affected if the wires cannot adjust to compensate for this length differential. Also, there can be additional limitations to wire movement because of excessive pressure caused by a sheave groove diameter which is too small, or by lack of rope lubrication. Avoid changing the bending direction from one sheave to another as this reverse bending further accelerates wire fatigue.

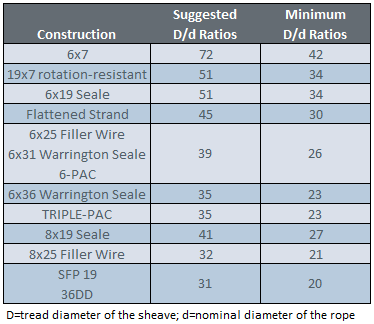

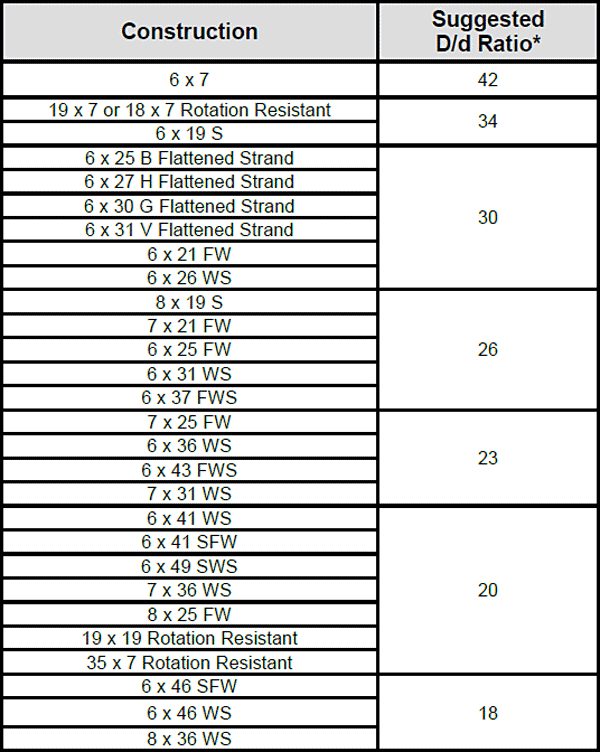

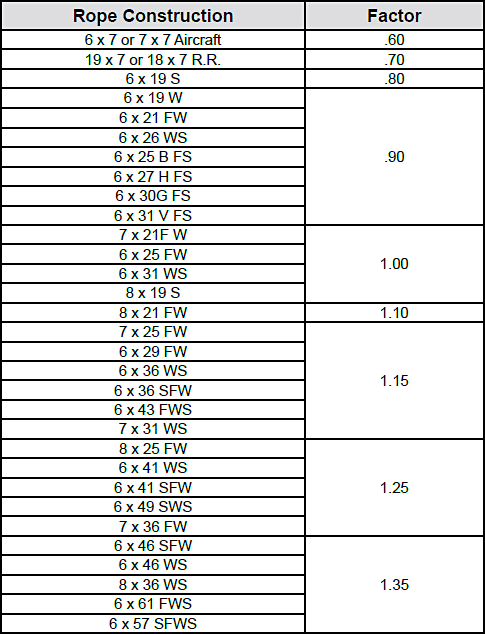

The relationship between sheave diameter and rope diameter is a critical factor that is used to estimate the rope’s fatigue resistance or relative service life. It is expressed in the D/d ratio mentioned earlier in which D is the pitch diameter of the sheave and d is the diameter of the rope. Table 1 lists suggested minimum D/d values for various rope constructions. Smaller values can affect rope life. Table 2 (on next page) shows the effect of rope construction and D/d on service life.

These D/d ratios are based on sheave and drum diameters being approximately 400 times the outer wire diameter of the rope. For rope constructions not listed, consult your Lifting Specialist.

A new wire rope requires careful installation and following all the appropriate guidelines previously noted. After the rope is installed and the ends secured in the correct manner, the equipment should be started carefully and then permitted to run through a cycle of operation at very slow speed.

During this trial operation, closely watch all working parts—sheaves, drums, rollers—to make certain that the rope runs freely, and without any possible obstructions as it makes its way through the system. If no problems appear in running the rope, the next step should include several repetitions of the normal operational cycle under increasing loads and speeds.

This procedure allows the component parts of the new rope to make a gradual adjustment to the actual operating conditions. Taking the time and effort to perform these breaking-in procedures should result in obtaining the optimum service life from the wire rope.

This service life curve only takes into account bending and tensile stresses. This curve can be utilized to predict comparative service life of a specific wire rope with varying D/d ratios.

That resultant comparison is illustrated by the following example: A rope working with a D/d ratio of 26 has a relative service life of 17. If the same rope works over a sheave that increases its D/d ratio to 35, the relative service life increases to 32.

Wire ropes are manufactured in a great variety of constructions to meet the varying demands of wire rope usage. Where abrasion is an important factor, the rope must be made of a coarse construction containing relatively large outer wires. In other cases, the great amount of bending to which the rope is subjected is more important. Here, a more flexible construction, containing many relatively small wires, is required. In either case, however, if the rope operates over inadequate size sheaves, the severe bending stresses imposed will cause the wires to break from fatigue, even though actual wear is slight. The smaller the diameter of the sheave, the sooner these fatigue breaks will occur and the shorter rope life becomes.

Another undesirable effect of small sheaves is accelerated wear of both rope and sheave groove. The pressure per unit area of rope on sheave groove for a given load is inversely proportional to the size of the sheave. In other words, the smaller the sheave the greater the rope pressure per unit area on the groove. Both sheaves and rope life can be prolonged by using the proper diameter sheave for the size and construction of rope. Sheave diameter also can influence rope strength. When a wire rope is bent around a sheave, there is a loss of effective strength due to the inability of the individual strands and wires to adjust themselves entirely to their changed position. Tests show that rope strength efficiency decreases to a marked degree as the sheave diameter is reduced with respect to the diameter of the rope.

A definite relationship exists between rope service and sheave size. As a guide to users, wire rope manufacturers have established standards for sheave sizes to be used with various rope constructions.

Precision CNC machining, turning and milling services. Capabilities include bending, waterjet cutting, routing, forming, drilling, casting, urethane molding, additive manufacturing (3D printing) and welding. Works with rubber, polyurethane, nylon, acetal, polycarbonate, acrylic, fiberglass reinforced plastics (FRP), laminates, PVC and other plastic materials. Manufacturer of custom and standard truck parts, bumpers, gaskets, seals, bushings, trays, anti-vibration or manifold grommets, caps and vibration mounts. Bearings, sheaves, pulleys, channels, nozzles, profiles, sprockets, outrigger pads, strip doors, elbows, rollers, matting, barriers, ceramic and truck liners are provided. Prototypes, short and high runs production volumes are offered. Materials are available in the form of sheets, tubes and rods. Serves agricultural, aggregate, biomass, construction, marine, port, material handling, mining, oil, gas, retail, transportation, automotive, food and beverage industries.

Wire rope and cabling is very widely used throughout industry in a variety of applications. Failures of such ropes however continue to take place, often due to misuse or lack of understanding of the constraints under which wire ropes operate. Users are referred to the appropriate suppliers who can advise them of the optimum operating conditions, but what is often abused is the size of the sheave wheel selected for a particular wire rope diameter. Many suppliers specify that the ratio of sheave diameter to rope diameter should be in the range 20 to 30 (i.e. D/d = 20 to 30). However at small rope diameters (6 to 10mm), this stringency can be relaxed to ratios closer to 10. Research studies conducted, have shown that for a 13mm diameter wire rope, simply changing a pulley diameter from the recommended 300mm to 150mm diameter led to a six fold decrease in fatigue life of the rope – a significant loss. Manufacturers’ tables should be consulted for all applications and their advice headed (they are seldom overly conservative).

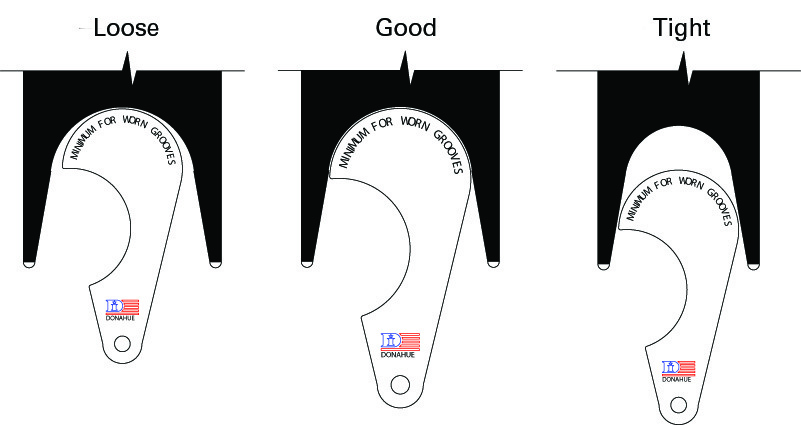

In addition, wear or incorrect machining of the grooves of the sheave is also a common problem, and worn sheaves contribute to significant wear of wire ropes and should be re-machined as soon as any wear (as measured using a suitable groove gauge) becomes apparent. Similarly inappropriate fleet angles (angle of wire running from the drum to a guide pulley/sheave) can also cause significant wear and shorten fatigue life. Fleet angles are specified at typically less than 1-2 degrees and should be adhered to for optimum fatigue life.

Multi-layer drum systems should use strand- or swage compacted Python® rope constructions having a steel core. The higher fill factor of such rope constructions will offer a greater resistance to crushing and flattening than conventional rope types. This is particularly important for boom hoist ropes on lattice boom cranes at the cross over point from one rope winding to the next.

Cranes equipped with multi-layer drum systems which require rotation-resistant or non-rotating rope are best served with Python Compac® 18 and Python Compac® 35. To further reduce drum crushing have the rope layers wound onto the drum with about 5-10% of the WLL and avoid that the first layer unspools and re-spools without tension. This would cause a ‘soft’ bottom layer which will flatten rather quickly.

Wire sheaves have been around for centuries, being very useful tools for various lifting, pulling and suspension applications. Read on for some basic use, maintenance and safety information on today’s wire rope sheaves.

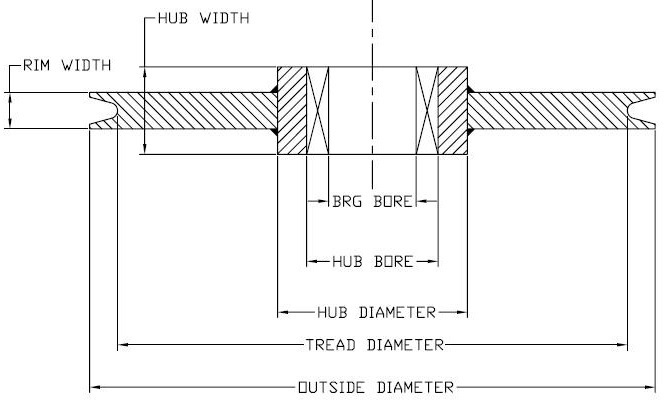

A sheave is basically a wheel with a groove or track on it which guides the wire rope over it. In its simplistic form, wire rope passes over a sheave and connects to the load. The other end of the wire is attached to a pulling device, such as a winch, to gain mechanical advantage. The threaded line over the sheave completes the device. To prevent the wire rope from leaving the groove, the minimum depth of the groove should be the thickness of the rope or cable.

Although the rope sheave has a simple construction, its function is a little bit complicated. You have to determine the exact wire rope diameter to choose the correct sheave size. The groove on a sheave should be flared and slightly larger than the nominal diameter of the rope. If the groove is too big the wire will flatten under load; if the groove is too small, the rope will be pinched.

Wire sheaves or pulleys change the direction of the force or increase the pressure to a load. The wire never lays straight in the groove of a sheave because the attached load moves from slide to slide. The movement causes the wire rope to rub against the sides of the sheave, which in turn causes wear.

Like any mechanical system, rope sheaves require maintenance. Here’s some good points to bear in mind:Always check the sheaves to avoid delay in your operations.

Pay attention to the sheave groove and the edges of the flange. Any fractures or cracks can cut the rope during operation. General wear on the surface of the sheave could result in a reduction in groove surface, creating an uneven load-bearing surface.

Centuries ago, sheaves were commonly used for sailing. Today, wire rope sheaves find usefulness in many industrial and lifting applications. And Wire Rope Australia actively participates in many of these industries as a supplier of wire rope, wire rope sheaves and a full range of wire rope fittings.

Selecting the right size for sheaves will help prevent frequent wire rope damage which in some instances occurs after just one run. Many common operational issues including the wireline getting dislodged or losing its strength are caused by improper sheave sizing and alignment problems. Our experts offer 3 valuable tips to eliminate stress failure, improve equipment safety and efficiency, as well as increase the lifespan of your sheaves and wire rope.

Pay attention to sheave groove size and diameter: When sheaves for your wire rope are too large or too small, there is greater stress on both resulting in spooling trouble and premature wear. For instance, grooves that are too large have proven to cause the wire rope to flatten and unbalance leading to the wire breaking. When properly sized, the groove provides maximum support to the rope lowering the sheave bearing pressure and increasing sheave and rope lifespan. Typically the groove diameter should exceed that of the wire rope by 5% while groove depth should be one-and-a-half times the rope diameter. A groove angle between 30° and 45° offers the best support for the wire rope. Specific dimensions and angles may vary depending on your application.

Ensure sheave groove hardness: The hardness of sheaves is a factor that is often overlooked. Since the wire rope is hard, the pressure it exerts on the groove can lead to corrugations if the sheave is not properly hardened. To avoid this, ensure your steel cable sheaves are flame hardened. (A simple way to determine if your grooves are worn out is by using a sheave gauge.) At Rockett Inc., we can provide flame hardening for wear resistance along the contact area.

Correct sheave groove alignment: Poor alignment of your sheaves wears out the wire rope and sheave flange. This is because the rope comes into constant contact with the flange creating stress on the rope, abrasion damage and fatigue breaks. Any alignment issues should be corrected immediately.

To avoid operational problems, opt for custom made steel sheaves. This way the sheaves for your wire ropes are tailored to your specific requirements instead of the other way around. As an experienced sheave manufacturer with a state-of-the-art facility in Mississippi, Rockett Inc. offers comprehensive custom solutions for diverse industrial and commercial needs.

Should you have a specific requirement, our experienced engineers can work closely with you to design and manufacture the product your application requires. Precision engineering and state-of-the-art metal fabrication equipment result in a closer tolerance fit to the wire rope to reduce fatigue and wear. Inspection at every stage of our manufacturing process ensures that the final output meets your specifications.

Need assistance with designing sheaves for wire rope? We are always happy to help. Our team can work directly from your drawings and specifications, or offer 3D CAD design and engineering support optimized for practical, cost-effective results. Over the years, we have produced the most diverse range of custom steel cable sheaves for our clients across the globe. Having the ISO 9001:2008 Certification means we take pride in quality and customer satisfaction.

Sheaves are widely used throughout the industry for a variety of pulling and lifting functions. Sheaves are available in a variety of materials including steel, plastic, or stainless steel. There are many configurations available including HiLoad sheaves, LoLoad sheaves, fibrous rope sheaves, and wire rope sheaves. You can source sheaves with bearings or bushings and some sheaves come very specialized.

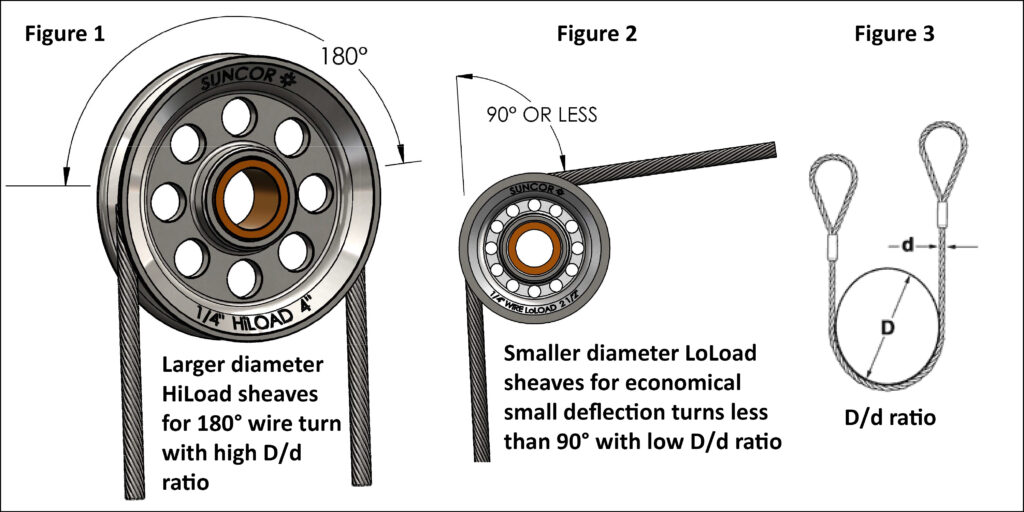

HiLOAD indicates a premium, larger diameter sheave suitable for 180° degree rope turns (see Figure 1) with a high D/d ratio, which is the ratio of the diameter around which the rope is bent, divided by the body diameter of the rope (see Figure 3). LoLOAD indicates a smaller diameter sheave designed for economical small deflection turns less than 90 degrees with a lower D/d ratio (see Figure 2).

Work load is important for both wire rope and fibrous rope sheaves, but work load limit (WLL) is critical with wire rope sheaves due to the comparative increased capacity of wire rope.

Quality sheaves should meet ASME B30.26-2610 and exceed the minimum 4:1 design factor. In most instances, the WLL for Suncor sheaves is significantly higher than comparable products and proof loads (or max WLL) are twice the WLL. Generally, twice the WLL of the wire represents the wire maximum load with a 180° wire wrap around the sheave.

A critical, and often overlooked area, is the wear exerted on the sheave during use. Throat angle, groove diameter, and sheave size are three significant factors of wear for sheaves. Sheaves are often designed with thin straight sided grooves which can cause scrubbing on the side walls and unnecessary wear on the rope and the sheave (see Figure 6). Suncor’s sheaves were designed with wide sheave grooves that provide a proper throat angle to permit slight rope lead misalignment without damaging the rope or wearing the sheave groove (see Figure 5).

The groove diameter is critical for proper wire rope support under load and has a significant effect on the overall safety and lifespan of the sheave and rope. If the sheave groove diameter has too much clearance, it will not support the rope properly leading to distortion, increased fatigue, failure, and costly repair. Conversely, if the sheave groove diameter has too little clearance the rope will not fit properly causing excessive wear and accelerated abrasion, which results in lost performance (see Figure 7).

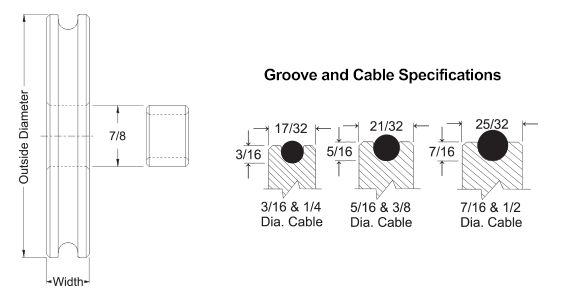

2" to 4" Wire Rope Pulleys are furnished with a 7/8" stock bore to receive a press fit on the 7/8" outside diameter powdered metal bushing sizes. Pulleys and bushings should be ordered separately by stock number.

5" to 10" Wire Rope Pulleys are furnished with a 1-1/4" stock bore to receive a press fit on the 1-1/4" outside diameter powdered metal bushing sizes. Pulleys and bushings should be ordered separately by stock number.

8613371530291

8613371530291