sheave size for wire rope in stock

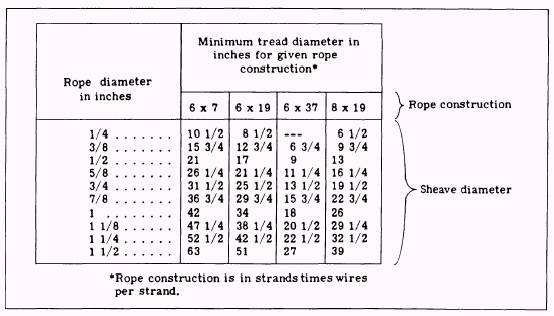

The diameter of a sheave should never be less than 20 times the diameter of the wire rope. An exception is 6 x 37 wire for which a smaller sheave can be used, because this wire rope is more flexible.

Whenever possible, drums, sheaves, and blocks used with wire rope should be placed to avoid reverse or S-shaped bends. Reverse bends cause the individual wires or strands to shift too much and increase wear and fatigue. For a reverse bend, the drums and blocks affecting the reversal should be of a larger diameter than

The makers of wire rope are careful to lay each wire in the strand and each strand in the rope under uniform tension. If the ends of the rope are not secured properly, the original balance of tension will be disturbed and maximum service cannot be obtained because some strands can carry a greater portion of the load than others. Before cutting steel wire rope, place seizing on each side of the point where the rope is to be cut (fig. 13-18).

Wind on the seizing wire uniformly, using tension on the wire. After taking the required number of turns, as shown in step 1, twist the ends of the wires counterclockwise by hand, so the twisted portion of the wires is near the middle of the seizing, as shown in step 2. Grasp the ends with end-cutting nippers and twist up slack, as shown in step 3. Do not try to tighten the seizing by twisting. Draw up on the seizing, as shown in step 4. Again twist up the slack, using nippers, as shown in step 5. Repeat steps 4 and 5 if necessary. Cut ends and pound them down on the rope, as shown in step 6. If the seizing is to be permanent or if the rope is

Wire rope can be cut successfully by a number of methods. One effective and simple method is to use a hydraulic type of wire rope cutter, as shown in figure 13-19. Remember that all wire should be seized before it is cut. For best results in using this method, place the rope in the cutter so the blade comes between the two central seizings. With the release valve closed, jack the blade against the rope at the location of the cut and continue to operate the cutter until the wire rope is cut.

Sheaves, drums and rollers must be of a correct design if optimum service is to be obtained from both the equipment and the wire rope. Because there are many different types of equipment and many different operating conditions, it is difficult to identify the one specific size of sheave or drum most appropriate for every application.

The guideline to follow is this: the most practical design is the one that most closely accommodates the limiting factors imposed by the equipment, the operating conditions and the wire rope.

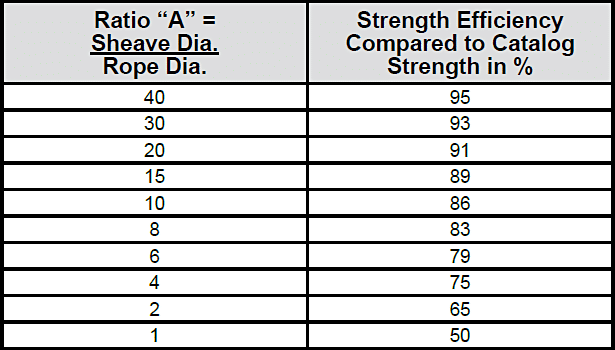

All wire ropes operating over sheaves and drums are subjected to cyclic bending stresses, thus the rope wires will eventually fatigue. The magnitude of these stresses depends—all other factors being constant—upon the ratio of the diameter of the sheave or drum to the diameter of the rope.

Frequently, fatigue from cyclic, high-magnitude bending stress is a principal reason for shortened rope service. In order for a rope to bend around a sheave, the rope’s strands and wires must move relative to one another. This movement compensates for the difference in diameter between the underside and the top side of the rope, the distance being greater along the top side than it is on the underside next to the groove.

Proper rope movement (and service) is adversely affected if the wires cannot adjust to compensate for this length differential. Also, there can be additional limitations to wire movement because of excessive pressure caused by a sheave groove diameter which is too small, or by lack of rope lubrication. Avoid changing the bending direction from one sheave to another as this reverse bending further accelerates wire fatigue.

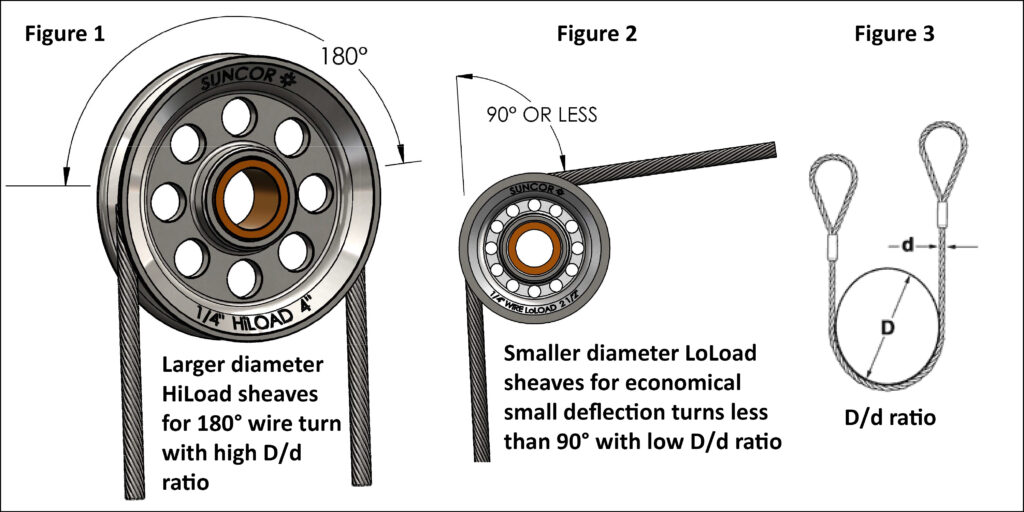

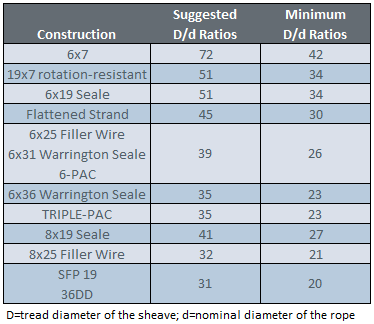

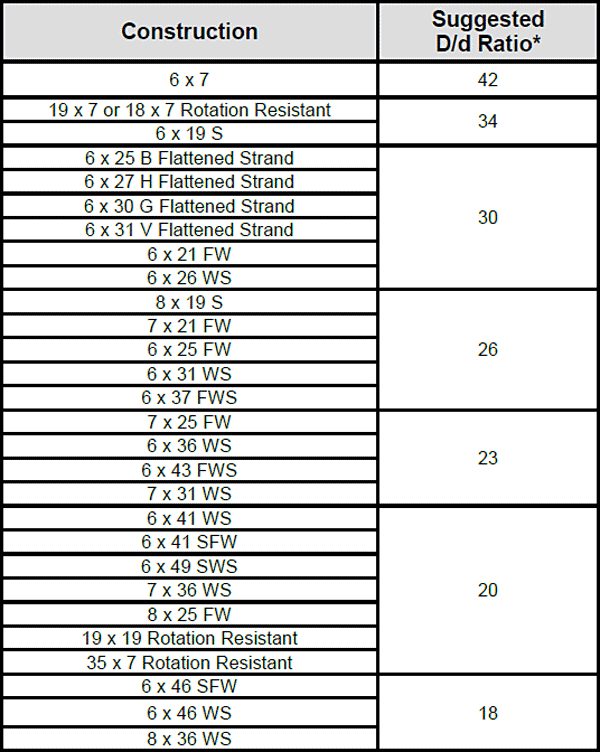

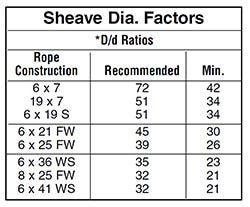

The relationship between sheave diameter and rope diameter is a critical factor that is used to estimate the rope’s fatigue resistance or relative service life. It is expressed in the D/d ratio mentioned earlier in which D is the pitch diameter of the sheave and d is the diameter of the rope. Table 1 lists suggested minimum D/d values for various rope constructions. Smaller values can affect rope life. Table 2 (on next page) shows the effect of rope construction and D/d on service life.

These D/d ratios are based on sheave and drum diameters being approximately 400 times the outer wire diameter of the rope. For rope constructions not listed, consult your Lifting Specialist.

A new wire rope requires careful installation and following all the appropriate guidelines previously noted. After the rope is installed and the ends secured in the correct manner, the equipment should be started carefully and then permitted to run through a cycle of operation at very slow speed.

During this trial operation, closely watch all working parts—sheaves, drums, rollers—to make certain that the rope runs freely, and without any possible obstructions as it makes its way through the system. If no problems appear in running the rope, the next step should include several repetitions of the normal operational cycle under increasing loads and speeds.

This procedure allows the component parts of the new rope to make a gradual adjustment to the actual operating conditions. Taking the time and effort to perform these breaking-in procedures should result in obtaining the optimum service life from the wire rope.

This service life curve only takes into account bending and tensile stresses. This curve can be utilized to predict comparative service life of a specific wire rope with varying D/d ratios.

That resultant comparison is illustrated by the following example: A rope working with a D/d ratio of 26 has a relative service life of 17. If the same rope works over a sheave that increases its D/d ratio to 35, the relative service life increases to 32.

Far too often, wire rope and cable products fail to last nearly as long as expected. While wire ropes and cables constructed from low-quality materials can sometimes contribute to premature failure, often it is because the wrong sheaves and pulleys are used in the application. Thankfully, Strand Coreprovides a radius guide to ensure you are pairing the suitable sheaves and pulleys for your wire rope and cable products. Read more to learn about the best size sheaves and pulleys for wire and cable.

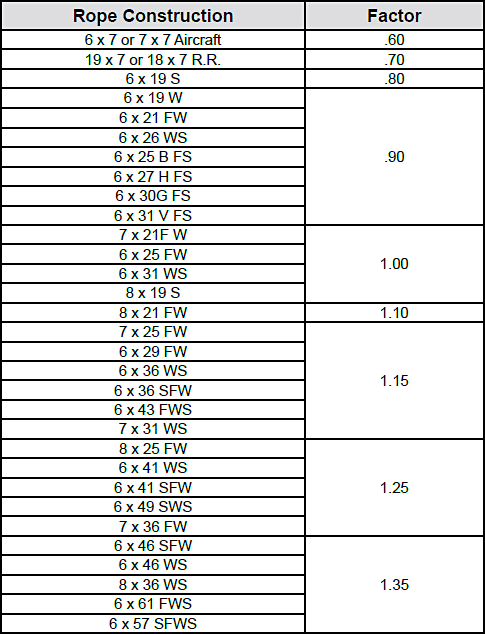

There are two considerations for sheaves and pulleys when trying to increase wire rope and cable service life. One is to make sure the cable and wire rope is operating over the largest possible sheave or pulley diameter. The reason large pulleys are recommended is because large pulleys provide a less intense angle for rope to make, putting less stress on cable, whilst choosing a small pulley means the rope will have to turn a sharp corner adding stress to your cable and wire rope, causing damage over time.The second consideration is to ensure cable and wire rope is supported correctly in the groove of the sheave or pulley. When the cable is not properly supported in the pulley groove, it becomesdented, crushed, and damaged, which severely reduces its service life.

It is important to remember that the working life of individual wire strands is significantly reduced as the pulley or sheave diameter is reduced. Strand Core provides a chart that shows minimum tread diameters over which various constructions and sizes of cable should operate.

For each cable diameter, there is a sheave and pulley desired minimum and a critical minimum. For example, cables sized 1/16”, which are typically 6x7 or 7x7 construction, have the desired minimum ratio of 4:1 and a critical minimum ratio of 28:1. Furthermore, the desired minimum pulley or sheave size for a 1/16” cable is 2/5/8”, and the critical minimum is 1-3/4”. To look at sheaves and pulleys desired and critical minimum for other cable sizes and constructions, you can check out our extensive guide here.

The key takeaway is sheaves and pulleys play a big role in wire rope and cable service life. Understanding the importance of using large pulleys and following the desired and critical minimum guide provided by Strand Core results in your wire rope and cable lasting for many years!

Why buy with us? We carry various styles and sizes of cable and rope, our products are Manufactured in USA, and we can provide a custom configuration of materials and constructions that comply with various industry specifications. If you are interested in checking out our wire rope and cable options, please visit https://strandcore.com. Alternatively, if you have any questions, our team is happy to help! Reach out to us by email through sales@strandcore.com or by phone at 800-983-9926.

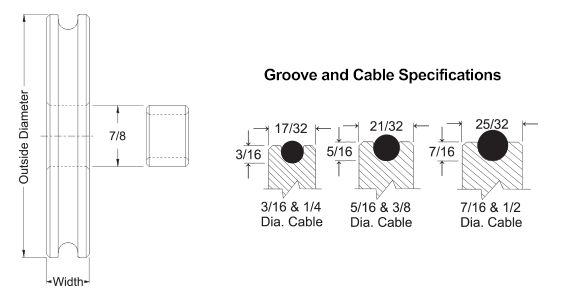

The specifications we require to custom manufacture your wire rope sheaves are: Outside Diameter, Finished Bore, Rim Width, Hub Width, Shaft Size, Groove/Tread Diameter, Hub Diameter, Rope Diameter, Pitch Diameter, Groove Depth. Other important details can be found on our Sheaves Order Form. Please call or email if you require any assistance.

Manufacturing sheaves for wire rope is our primary business. We have the capability to manufacture your sheaves to your design and specifications or you can choose your wire rope sheave from our large inventory.

Our wire rope sheaves are made from quality materials and machined to precise dimensions and tolerances in order to meet our high standards. In addition, we offer many other options to satisfy your sheave requirements, including choice of material, heat treating of the groove, case hardening, grease fittings, keyways and set screws, plating and many more. We also carry bearings and bronze bushings.

Choose from our stock sheave sizes or we can manufacture your wire rope sheaves to your design and specifications. SELECTING FROM OUR STOCK SIZES OFFERS YOU QUICKER DELIVERY AND ECONOMY, or we can stock for your ongoing requirements. Please complete this form and we will gladly quote.

Wire sheaves have been around for centuries, being very useful tools for various lifting, pulling and suspension applications. Read on for some basic use, maintenance and safety information on today’s wire rope sheaves.

A sheave is basically a wheel with a groove or track on it which guides the wire rope over it. In its simplistic form, wire rope passes over a sheave and connects to the load. The other end of the wire is attached to a pulling device, such as a winch, to gain mechanical advantage. The threaded line over the sheave completes the device. To prevent the wire rope from leaving the groove, the minimum depth of the groove should be the thickness of the rope or cable.

Although the rope sheave has a simple construction, its function is a little bit complicated. You have to determine the exact wire rope diameter to choose the correct sheave size. The groove on a sheave should be flared and slightly larger than the nominal diameter of the rope. If the groove is too big the wire will flatten under load; if the groove is too small, the rope will be pinched.

Wire sheaves or pulleys change the direction of the force or increase the pressure to a load. The wire never lays straight in the groove of a sheave because the attached load moves from slide to slide. The movement causes the wire rope to rub against the sides of the sheave, which in turn causes wear.

Like any mechanical system, rope sheaves require maintenance. Here’s some good points to bear in mind:Always check the sheaves to avoid delay in your operations.

Pay attention to the sheave groove and the edges of the flange. Any fractures or cracks can cut the rope during operation. General wear on the surface of the sheave could result in a reduction in groove surface, creating an uneven load-bearing surface.

Centuries ago, sheaves were commonly used for sailing. Today, wire rope sheaves find usefulness in many industrial and lifting applications. And Wire Rope Australia actively participates in many of these industries as a supplier of wire rope, wire rope sheaves and a full range of wire rope fittings.

2" to 4" Wire Rope Pulleys are furnished with a 7/8" stock bore to receive a press fit on the 7/8" outside diameter powdered metal bushing sizes. Pulleys and bushings should be ordered separately by stock number.

5" to 10" Wire Rope Pulleys are furnished with a 1-1/4" stock bore to receive a press fit on the 1-1/4" outside diameter powdered metal bushing sizes. Pulleys and bushings should be ordered separately by stock number.

The Right Fit Tool QSheave™ Configurator allows you to build a part number based on the specifications and performance you need in your sheave application. Review the options below and select the part number call out that fits with your needs. Build your custom part number by arranging the call outs in this specific order:

Esheaves offers the Wire Rope sheave solution to tackle any challenge you face. From strength, to availability, to like -for- like replacement, there is no heavy duty sheave application we can’t assist you with. If you need assistance selecting the best solution for your project, contact us directly to speak to a member of our knowledgeable engineering staff.

In order to ensure optimal performance of sheaves and wire rope a complete range of sheave gauges should be used. We stock gauges in the following formats:

+5% Sheave Gauges are legacy format. They should fit snugly in new or re-machined sheaves. If correctly sized wire rope is run through the sheaves there will be a minimum of friction which should extend the life of the wire rope.

The service life of cable and wire rope can be increased if (1) it operates over the largest possible pulley or sheave diameter, and (2) it is properly supported in the pulley or sheave groove. The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. The chart below shows minimum tread diameters over which various sizes and constructions of cable should operate.

8613371530291

8613371530291