sheave size for wire rope free sample

(a) Factor of Safety. All rope to be used for regular hoisting shall be wire rope providing a factor of safety not less than five to one for material hoist and ten to one for personnel hoist when new, which shall be calculated by dividing the breaking strength of the wire rope as given in the manufacturer"s published tables, by the total load to be hoisted including the total weight of the wire rope in the shaft when fully let out, plus a proper allowance for impact and acceleration.

The acceleration allowance shall be in accordance with manufacturer"s recommendations, but in all cases the factor of safety of five or more must be maintained when the load, used in determining it, is greater than the actual weight by a percentage that is numerically three times the acceleration or deceleration, whichever is greatest. For example, a deceleration or acceleration of two feet per second that increases the load would require use of an effective load 6 percent greater than the actual weight, in the calculation of a factor of safety.

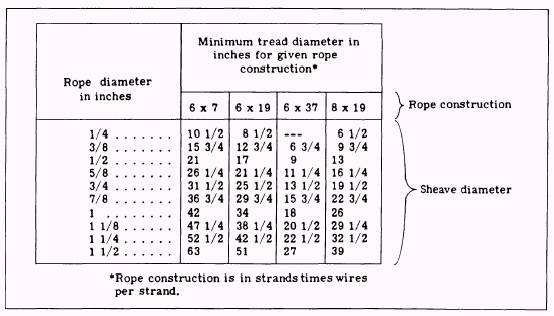

(b) Wire Rope Fastenings. Every wire rope used for hoisting shall be securely fastened at both ends and when in use shall not be fully unwound; at least three full turns shall remain on the drum so as to protect the end fastening at drum from overload. The wire rope end at the cage, skip or bucket shall be securely fastened by a properly made tapered socket joint, by an eye in the wire rope made with an oval thimble and wire rope clips, or by another method acceptable to the Division for this or similar service. If the wire rope clip method is used, the spacing and number used shall be as shown in Table - 1 for U-Bolts and in Table - 2 for Fist-Grip clips based upon using RRL or RLL wire rope, 6 x 19 or 6 x 37 Class, FC or IWRC; IPS or XIP. If Seale construction or similar large outer wire type construction in the 6 x 19 Class is to be used for sizes 1 inch and larger, add one additional clip. If a pulley (sheave) is used for turning back the wire rope, add one additional clip.

The number of clips shown also applies to rotation-resistant RRL wire rope, 8 x 19 Class, IPS, XIP, sizes 1-1/2 inch and smaller; and to rotation-resistant RRL wire rope, 19 x 7 Class, IPS, XIP (sizes 1-3/4 inch and smaller for U-Bolts and size 1-1/2 inch and smaller for Fist Grips).

(d) Splicing. Spliced wire rope shall not be used, except that the end may be attached to the load by the thimble and/or clip method, as provided in subsection (b) of this section.

(1) A safety hook, shackle or other means providing closed design protection shall form the attachment between rope and a bucket, cage, skip or load. The attachment shall be made so that the force of the hoist pull, vibration, misalignment, release of lift force, or impact will not disengage the connection. Moused or open-throat hooks with light safety latches do not meet this requirement.

(2) All wire rope fittings and connections shall be in accordance with the manufacturers" specifications and compatible with the type of wire rope used.

(g) Drum Flanges. The drum of any hoist used for hoisting shall have flanges which extend at least 2 inches radially beyond the last layer of rope when all the rope is coiled on the drum.

Good fitness equipment is key to quality exercise experience, and great fitness equipment is only achievable with the proper sheaves.Sheaves help make fitness machines run smoothly and ensure users will feel satisfied after a workout. As there are so many sheave variations, it is crucial to pick the right one for your fitness equipment. When selecting sheaves for fitness equipment, there are three features to consider: size, weight and material.

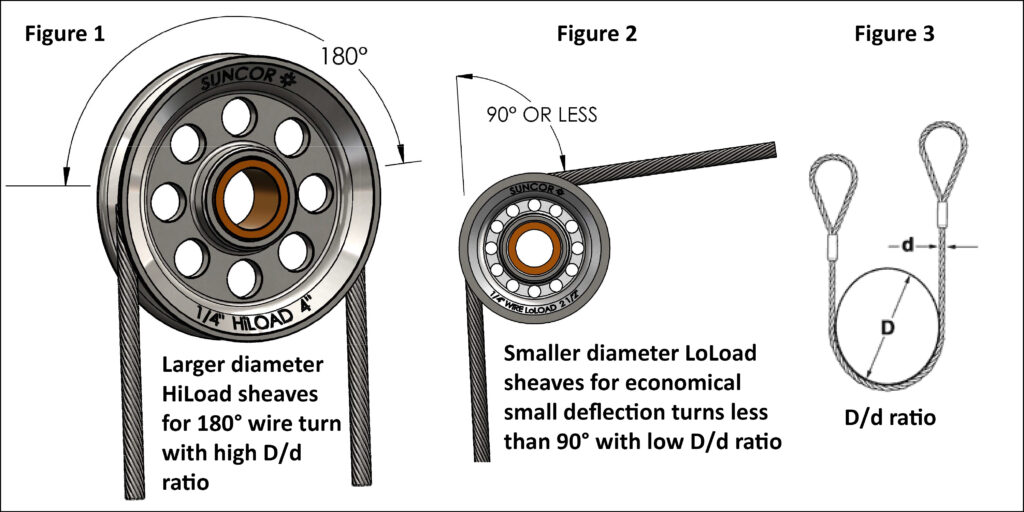

When looking for sheaves it is crucial to pick the correct size. Picking sheaves that are too big will slow down your application, and selecting ones too small will stop your machine from performing at a high level. Large cable sheaves are ideal for high-load applications that run at slow speeds. Small sheaves are best for medium load applications that run at high rates.

Choosing the correct sheave weight is significant in transforming your fitness equipment from good to great. If you want a steel or stainless steel sheave, small cable sheaves are the best option. If you choose a sheave over 6", steel or stainless steel will most likely be heavy and slow down your fitness equipment. So, if you are looking for a bigger sheave, we suggest process sheaves. These sheaves come in various materials that are lightweight, ensuring that your machine will continue to run smoothly, no matter what sheave size.

Numerous sheave materials work well for fitness equipment. Steel or Stainless Steelare excellent options when looking for a solid and durable sheave. However, if choosing these two materials, make sure you choose sheaves that provide permanent self-lubrication. If not, you will need to spend a lot of unwanted maintenance time on your sheave to ensure it operates smoothly. Aluminum, Alum-Ceramic, SX Polymer, and Cast Nylon are other options if you are looking for an alternative solution. These materials are great because they can withstand high levels of weight and pressure without damage. For example, SX Polymer process sheaves are stressed tested to 10,000lbs without failing. Non-Steel materials are also a good choice for sheaves larger than 6" as they are light and will not add unnecessary weight to your equipment.

While there are many other considerations when configuring a machine, sheaves are an integral part of fitness equipment. Choosing the right sheave for fitness equipment involves picking the right size, weight, and material. By considering these three features, you are guaranteed to get the most out of your fitness equipment.

At eSheaves, we provide a large range of sizes, weights and materials for sheaves. If you want to learn more about our Small Cable Sheaves or Process Sheaves, visit our website here. Alternatively, if you have any questions, we can help! Reach out to us by email through sales@esheaves.com, or by phone at 800-321-5667.

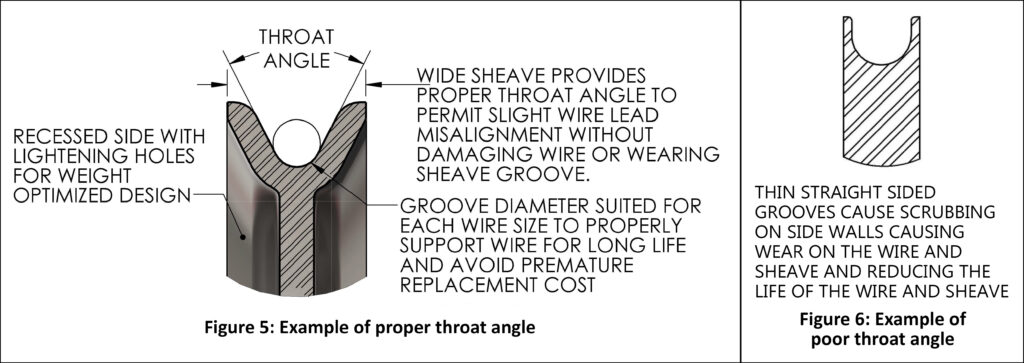

A sheave is a pulley, with a grooved wheel for holding a wire rope, belt, or rope. Wire rope sheaves are designed for holding wire ropes in place. Grooved wheels spin on a bearing or axle inside the frame of the block. This allows the wire rope to move freely, thereby minimizing wear and friction on the wire rope. Wire rope sheaves are primarily used in facilitating safe and smooth operation of overhead crane hoists. Wire ropes can wear prematurely and can cause other dangerous hazards.

Wire rope sheaves are different from standard sheaves in terms of construction and operation. They are smooth and free from defects, which may cause rope damage. The sheaves which can be momentarily unloaded has to be locked with close-fitting guards in order to guide the rope back into the groove when the load is applied again. The pockets and flanges of sheaves, which are used with hoist chains, need to be of such dimensions that the chain does not bind or catch during the operation.

Founded in 1994, Konecranes is involved in the manufacture and sale of lifting equipment. It provides overhead cranes such as standard industrial, automated cranes, overhead travelling cranes, and hoists & lifting devices. These include electric wire rope hoists, electric chain hoists, manual chain hoists, and air balancers. The company has aprroximately 17,000 employees at 600 locations in 50 countries.

Certex Norway US is manufacturer of lifting products, wire products, and mooring and marine equipment. It also provides services such as maintenance, inspections, technical support, and certifications. The company has presence in Bergen, Stavanger, Kristiansand, Oslo, Trondheim, Kristiansund, Harstad, Hammerfest, Florø, and Sandnessjøen. It is a part of Lifting Solution Group under Axinter Company, which is owned by Axel Johnson Group. Lifting Solution Group has its own distribution channel in more than 15 countries in Europe with around 40 outlets.

Expansion in infrastructure and industrial sectors across the globe is expected to drive the demand for wire ropes across the world. There exists replacement demand for wire ropes and wire rope sheaves. There is strong requirement of wire rope in oil & gas industry for meeting the needs of offshore exploration drilling rigs, offshore cranes, offshore winches, and land-based exploration drilling rigs and their servicing. Increasing demand from crane and lifting industry is anticipated to boost the demand for wire rope sheaves during the forecast period. Lifting products that use wire rope sheaves are container handling cranes, telescopic mobile cranes, mobile lattice boom cranes, overhead hoist/gantry cranes, bulk unloader cranes, ladle cranes, and piling cranes.

The wire rope sheaves market is highly susceptible to fluctuation in prices of raw materials, as almost 95% of wire rope sheaves constitute iron or steel. These prices are fluctuated on the basis of shipping costs, market maturity, energy costs, and supply demand scenario. Thus, volatility in prices of raw materials may adversely impact the purchasing decision of wire rope sheaves, since these are heavy duty products which does not easily tend to fail as these products are tested while manufacturing to almost 1.5 – 2 times its rating capacity.

Above all else, we are an engineering firm that can take your technical requirements for sheaves and translate them into cost effective solutions to meet or exceed the performance required of your application. For over fifteen years now, Sheaves Inc. has been the number one source for the wire-rope industry, designing and providing QSheaves™, alongside othercustom engineered wire rope sheavesthat meet your specific needs and rigors of your application. We also supply a large inventory of stock sheaves from thebest known brands in the industry. Contact ustoday or send a request for quotation, and our engineering team will work alongside you to find your custom pulley solution.

Want a sheave system to solve your design problem? Our expertise is based on decades of engineering and supplying leading manufacturers, from the simplest applications to the most demanding. We’ve supplied sheaves for both recreational and large commercial boat lifts, to military applications. No problem is too big for us, and no solution is too small for a consultation.

Esheaves.com offers custom solutions engineered to meet the exact requirements of your application. From the strength and durability of a nylon sheave, to the rapid shipping and stock availability of QSheaves™, we will help you meet any challenge. If our customizable options don’t measure up, we’ll engineer a complete, original solution just for you!

Need an individualized application solution?EShevaes.com is the trusted team of sheave engineers you can turn to. Find additional information about our customization options below. Ready to start a Custom Pulley Project? Visit our Custom Sheave Project page by clicking the link below

Contact us with your sheave requirements before freezing your equipment designs. We can offer a better sheave at a lower cost in many cases if we are consulting early in the design stage. Many times a modification of our QSheaves™ is the economical choice when certain design parameters preclude use of an off-the-shelf sheave. Even fully custom pulleys can be quite economical when the right decisions are made on materials and designs. Put our experience to use for your business.

Many applications, particularly in wire rope sheaves and in wire & cable processing, have design constraints that can’t be met by stock sheaves from us or other suppliers. In recent years, Process Sheaves LLC has developed over 300 custom engineered sheaves to meet critical customer parameters. We welcome the opportunity to work with you to achieve the most economical solution for your particular situation.

We pride ourselves on our quality products and excellent customer service, as well as our continual desire to look for innovative ways to meet your needs; achieved, for example, in our patented line of steel sheaves that allow us to provide an extensive range of 6” to 12” sheaves to be shipped the same day.

Engineering sheave solutions is what we do best and what we do all day, every day. We respond to our customers immediately with technical answers and practical solutions. If we, on the rare occasion cannot provide you with the solution you are looking for we will point you to who can. Why? Because our customers are OUR number one priority!

Custom sheaves expressly designed to meet you exact requirements can usually be shipped within 2 to 4 weeks after receipt of your order. Quotations are usually delivered within 24 to 48 hours after receipt of your inquiry.

The custom sheave design process is relatively simple. You tell us which are the constraining parameters – OD, bending radius, weight, temperature, shaft diameter, etc – and we will propose solutions. Refer to our order form under the ‘Request Quotation’ link. We must have maximum product size and minimum bending radius (Root Diameter).

It is generally uneconomical to purchase fewer than ten identical sheaves due to engineering and setup costs. The simplest sheaves (and most sheaves) require three distinct CNC operations and each step requires programming and setup time.

Materials are purchased to requirements. Very small orders for one or two pieces are relatively expensive. For less than ten sheaves, it may be more economical to modify a stock sheave. Prices for thirty or more identical sheaves will often be comparable to stock sheaves of a similar size.

For custom processing sheaves of 22” OD or less, we prefer Gar-Dur, the densest and most abrasion-resistant UHMW-PE available commercially. It is available in a variety of sizes and shape from stock, generally yellow in color. We have been using it for 15 years and have experienced excellent results. Other materials we use are:

Composites such as carbon fiber are our newest development in sheave manufacturing. We have a technical collaboration with a leading aerospace manufacturer that promises to yield lightweight, strong, sheaves with excellent wear characteristics. We have seen weight savings of 50% with no compromise in expected performance.

Due to tooling costs, these sheaves are economical only if the ultimate requirements will be 100 or more. However, sheaves of 30″ OD and larger may be very cost competitive even in smaller quantities. As our experience grows, we will post some case studies on our web site to give you concrete examples or weight and cost advantages.

Our products can be statically or dynamically balanced to suit your requirements. Normally balancing is not required because precision machining of homogeneous materials produces inherently balanced finished sheaves, requiring no dynamic balancing for 1500 RPM and above.

The current design uses bearings with Normal initial clearance. The interference fit on the outer ring reduces the internal clearance. We determine the operational clearance for both Normal and C3 initial clearance, to select the most appropriate bearing execution.

At least C3 clearance is required. Analysis with SKF proprietary software that considers the effects from smoothing of the mating surfaces and the probability that maximum fit reduction coincides with minimum bearing clearance provides the following values for a bearing with C3 internal clearance:

Depending on the paper machine and position of the rope sheave, the sheave may face higher operating temperatures, which will reduce the grease life. To increase grease life, the use of hybrid bearings (ceramic balls instead of steel ones) of the same size can increase the grease life by at least a factor of two.

By changing the rope sheave hub design so that the bearing’s inner ring rotates instead of the outer ring, grease life is increased. The speed factor will be ndm = 131 000 instead of nD = 176 400.

SKF has developed a rope sheave hub to take the above consideration into account. The bearings have ceramic balls, and WT grease, and their inner rings rotate (fig. 2). An enhanced design has been created using special bearings. For additional information refer to the handbook .

8613371530291

8613371530291