splice wire rope end to end manufacturer

We custom manufacture wire rope assemblies (endless loop) for conveyor lines. Our specialty is the Long splice. The Long splice is used to create a continuous or endless loop of wire rope cable frequently utilized on conveyor systems. The splice is a difficult multi-step labor intensive process in which two wire rope cable ends are joined end to end and the strands are intertwined to merge the two individual wire rope cable ropes ends.

Our proven experience can be viewed first hand in the quality of our wire rope cable splices we perform regularly for diverse clientele in the Unites States and around the world. For assistance with your unique wire rope conveyor cable splicing needs, please complete theor call us directly at

Manufacturer of aluminum swage sleeves including hour glass, oval, thin wall, combo & fiber rope sleeves. Hour glass sleeves range in rope & sleeve size from 1/32 to 1/2, width from .090 to 1.062, height from .136 to 1.625, hole width from .040 to .562, length from 1/4 to 2. Oval sleeves have a rope & sleeve size of 1/16, width of .172, height of .250, hole width of .078 & length of 3/8. Thin wall sleeves range in rope & sleeve size from 3/32 to 5/32, in width from .226 to .375, height from .372 to .562, hole width from .118 to .200 & length from 1/2 to 11/16. Combo sleeves are available with rope & sleeve size of 1/8 x 1/16, width of .343, height of .500, hole widths of .156 & .078 & length of 5/8 or sleeve size of 3/16 x 1/8, width of .430, height of .656, hole widths of .160 & .320 & length of 1. Fiber rope sleeves range in rope & sleeve size from 1/8 to 7/16, width from .250 to .855, height of .388 to 1.35, hold width from .160 to .525 & length from 1/2 to 1 1/4.

We were established in 1961 and since then Sahm-Seilklemmen has produced and distributed products complementing the mechanical splicing of wire ropes. Today we are a leading supplier for wire rope end terminations to the rigging industry and in addition to ferrules, we can supply appropriate accessories and the most diverse services.

Our product range includes ferrules made from aluminium, copper, steel and stainless steel, all manufactured exclusively by us in Germany and USA. As a system supplier, we can provide you not only with the correct ferrule for your application, but also a large range of swaging machines, test beds, cutting & annealing machines and differenttools.

Our in house machine building department ensures the highest quality standards for all our machines combined with the flexibility to react to your requirements quickly.

Since 2015 we operate under the name SAHM SPLICE GmbH. In cooperation with our affiliated firms SAHM SPLICE Ltd in Great Britain, SAHM France S.A.R.L. in France and various distribution partners we sell our products globally.

Engineering wire rope slings for your application is a highly specialized field – with exacting standards – that we gladly live by. A Union sling can meet or exceed the most exacting specifications. We apply thorough design and production controls – including an extensive ISO-controlled process. And our traceability process tracks every component through completion of the assembly and into the field.

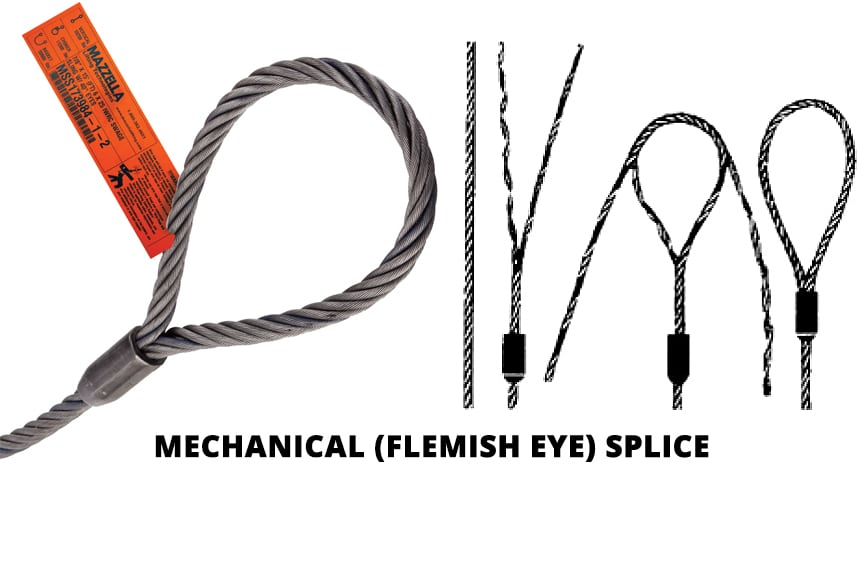

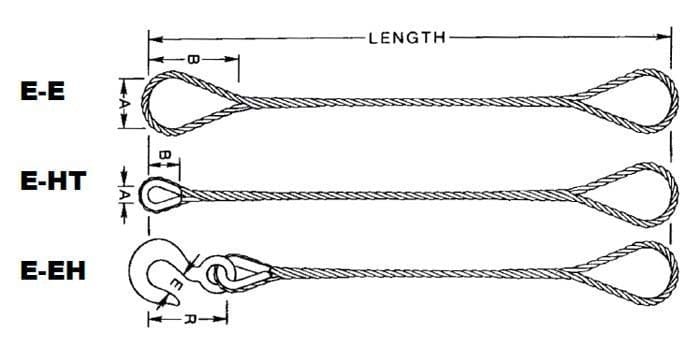

A mechanical-spliced wire rope sling is constructed when eyes are formed using the Flemish eye splice. Ends are then secured by pressing a metal sleeve over the ends of the strands of the splice. Pull is directly along the centerline of rope and eye. This splicing method gives the most efficient use of rope capacity and proves to be economical.

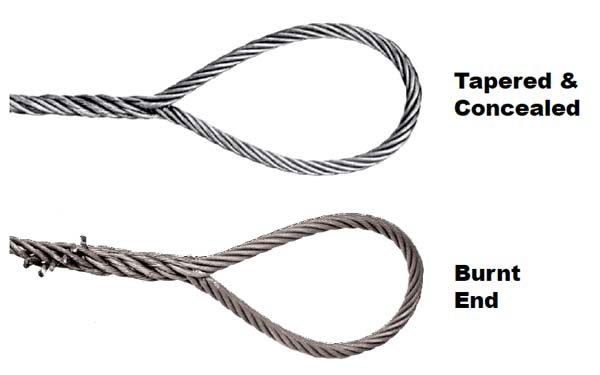

The end of a single-part hand spliced wire rope sling is bent back along the rope to form the eye, and strands are hand-tucked into the body of the rope in what is called a burnt end splice. With Burnt End splices, the ends of strands are left exposed and cut off with a torch.

Upon special request, a premium splice known as a tapered and concealed splice can be provided. Slings with rope bodies larger than 1″ diameter are made only with Burnt End splices.

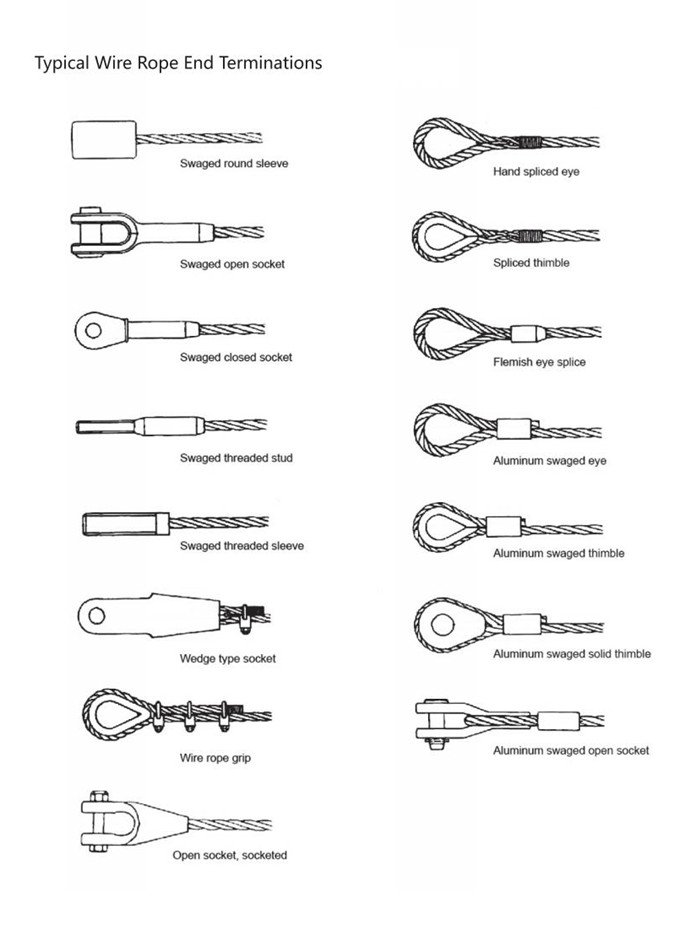

As a rigger or end-user of wire rope, it’s important to understand the types of terminations, or treatments, that can be used at the ends of a length of wire rope. These terminations are usually made by forming an eye or attaching a fitting, and are designed to be a permanent end termination on the wire rope where it connects to the load.

Wire rope is an extremely versatile mechanical device that can be used to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

In this article, we’ll explain what some of the following terms mean and how the can be used to terminate the end of a wire rope cable:Wire rope sockets—spelter sockets, swaged sockets, and wedge sockets

When you understand the construction and specifications of the wire rope you need, as well as the right type of end termination you need, you’ll be able to select the best performing and longest-lasting wire rope for the job at hand.

There are essentially two techniques that can be used to create a termination on a length of wire rope or cable:You can form an eye, or loop, in the wire rope

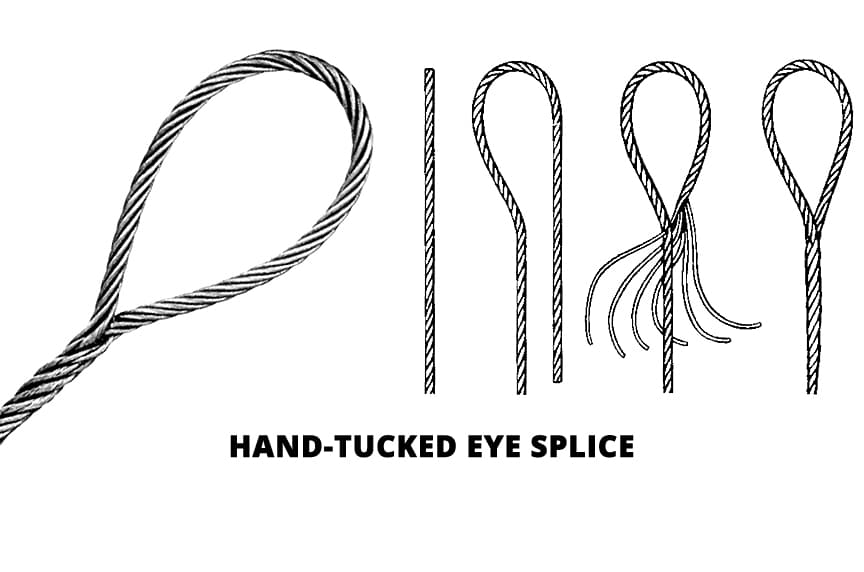

Eyes, or loops, can be created at one end of a length of wire rope by using a mechanical splice with a swaged sleeve, a hand-tucked splice, or wire rope clips.

A swaged socket is applied to the end of a wire rope cable and is then forced into place using special dies and a hydraulic machine called a swager. When properly applied with the correct sized fitting, swaged sockets have an efficiency rating of 100% of the breaking strength of the rope.

A poured socket, commonly referred to as a spelter socket, attaches a termination fitting onto the end of a wire rope cable by pouring molten zinc or resin into a socket that then hardens and holds the fitting onto the end of the cable.

Due to the rigidity of this type of termination, the wires of the rope are subject to fatigue where the wires enter the socket, if the poured socket is subject to constant vibration.

Wedge sockets secure the rope to the end attachment by passing it around a grooved, wedge-shaped piece of steel and pulling it down under load into the bowl of the fixture.

Wedge sockets are popular because they can be installed in field and adjusted in field – providing 80% efficiency of rope breaking strength. Wedge sockets are popular in applications where the wire rope may be subjected to abuse and abrasion—particularly in construction and mining applications.

Wire rope clips can be used to form a load bearing eye at the end of a cable or wire rope, or to connect two cables together with a lap splice. Wire rope clips are popular because they can be installed in the field and provide 80% efficiency of the rope breaking strength.

However, the use of wire rope clips is heavily regulated by ASME B30.26 Rigging Hardware. When using wire rope clips, the end user must account for the following:When using U-bolt wire rope clips, the saddle shall be placed on the live end of the wire rope, with the U-bolt on the dead-end side—NEVER SADDLE A DEAD HORSE!

After installation, the connection shall be loaded to at least the expected working load. After unloading, the wire rope clips shall be re-tightened to the torque specifications of the manufacturer or a Qualified Person.

This type of wire rope clip is essentially a U-bolt, two nuts, and a metal base (saddle) that can be made from forged steel or cast iron. Careful consideration and attention must be given to the way U-bolt type wire rope clips are installed.

The base of the wire rope clip is made from forged steel. Forged clips are heated and hammered into the desired shape—resulting in a consistent grain structure in the steel. Forged wire rope clips are used for critical, heavy-duty, overhead loads such as winch lines, crane hoist lines, support lines, guy lines, towing lines, tie downs, scaffolds, etc.

Malleable wire rope clips are used for making eye termination assemblies only with right regular lay wire rope and only for light duty uses with small applied loads, such as hand rails, fencing, guard rails, etc. The base of the wire rope clips is made from malleable cast iron, which may fracture under heavy use and does not have the desirable metal properties of steel, or the beneficial grain structure that a forged base has.

Double saddle wire rope clips consist of two saddles, each with a leg, and two nuts—one used on the top and one on the bottom. Double saddle wire rope clips can be used in either direction, so they take the guesswork out during installation when applying to the live end and the dead end of a piece of wire rope.

An eye splice may be used to terminate the loose end of a wire rope when forming a loop. The strands of the end of a wire rope are unwound and then the wire is bent around, and the unwrapped strands are then weaved back into the wire rope to form an eye.

A Flemish eye splice is created when the wire rope is opened, and the strands are laid out into two parts. The two strands are looped in opposite directions and then laid back together—forming an eye, or loop, at one end of the wire rope cable. The strands are then rolled back around the rope body and a metal sleeve fitting is slipped over the splice and swaged using hydraulic machinery. This splicing method provides the most efficient use of rope capacity and is highly economical.

A hand tucked splice is formed when the shorter “dead” end is tucked into the longer “live” end of the wire rope—forming an eye. These types of splices allow for easy inspection of the wire rope wires and strands.

When the end of a rope is turned back and formed into an eye, a thimble is often used to keep the shape of the eye, prevent the rope from being crushed, and keep the rope from being bent at a diameter smaller than the rope manufacturer’s recommendations.

The table below will explain the efficiencies of the different types of wire rope end terminations for both independent wire rope core (IWRC) and fiber core (FC) wire rope configurations. Rope efficiency is described as the ratio of a wire rope’s actual breaking strength and the aggregate strength of all individual wires tested separately—usually expressed as a percentage.IWRCFC

*Spelter sockets in smaller rope sizes (usually less than 7/16”) may not always develop 100% efficiency and are not recommended by some rope manufacturers.

When you need to order a replacement wire rope, understanding the right type of end termination will help to make sure you get a direct replacement rope so you can get your project back on track. We hope this article gives you a better understanding of terms related to sockets, wire rope clips, and eye splices and that you understand what type of end termination may be best for your application.

At Mazzella, we offer all different kinds of wire rope from all of the leading manufacturers. We sell the highest-quality domestic and non-domestic rigging products because product quality and operating safety go hand-in-hand. We have one of the largest and most complete inventories of both domestic and non-domestic rigging and lifting products to suit your lifting needs.

We fabricate wire rope slings and assemblies to your custom needs. We take wire rope from the manufacturer and terminate the end whether it is Flemish or hand spliced loops, thimbles solid thimbles, swage fittings (Open or Closed swage sockets, buttons, threaded studs etc), multi-leg bridles or spelter sockets.

We also fabricate chain slings and assemblies to your custom needs. We have bulk chain that we cut to length and assemble single, two, three, and four leg chain assemblies. After assembly all our chain slings are proof tested and tagged.

Yale Cordage began in 1950 with a belief in how synthetic material and high quality braiding techniques could transform the cordage industry. Our continued commitment is to remain grounded in this objective – to provide innovative end-user solutions through superior approaches to the design, manufacture, and fabrication of synthetic rope and rope systems.

We are constantly improving the safety and productivity of our products and pledge to provide exceptional customer service and products that work as hard as we do – up in space, down to the deep seafloor, and everywhere in between. A rope industry leader in expertise and innovation – Yale is passion for the pursuit of better performance.

The end of a single wire rope is bent back along the rope to form the eye, and strands are hand-tucked into the body of the rope in what is called a burnt end splice. With Burnt End splices, the ends of strands are left exposed and cut off with a torch. Upon special request, a premium splice known as a tapered and concealed splice can be provided. Slings with rope bodies larger than 1" diameter are made only with Burnt End splices. All have the same rated capacity, size for size.

The tapered and concealed splice utilizes tension in the rope body to secure strands where they are tucked back into the rope. Needs no metal sleeve to assure firm anchoring. When "tapered" and "concealed", ends of strands are tucked inward and concealed inside the rope.

Want to do your own rigging and splicing of ropes? We have made more than 30 rope splicing instruction videos. For example, how to make an eye-splice in modern ropes? Or how to make soft shackles from ropes with Dyneema® fibers? Watch our video"s! The reference numbers correspond to the chapters of "Handbook Splicing Modern Ropes".

Want to start with splicing? Check out our wide range of splicing tools. And do you already have our Rope Splicing App on your phone? All splicing instructions in your pocket and easy to use off-line!

If your rope does not hold in jammers or clutches, splice an extra cover or add an extra core. Chafing covers from Technora or Dyneema®are great to extend the life of your ropes.

Splicing modern braided ropes of super fibres is quite fun and easy to learn. Premiumropes has uploaded various splicing tutorials, such as eye-splices, soft shackles, taper sheets or make a continuous furler line. Make sure you have enough space to work and an anchoring point for your rope. If you are on board, you can use a winch in case you need extra force. Choose a fid that matches the diameter of the rope, or even one that is slightly thinner. Never use pliers to pull out a fid from the rope - you will damage it! Do you know what the construction of your rope is? Check our table what splicing technique to choose for which type of rope. The core material largely determines the type of splice, whether it is core dependend or if you need to use the cover in the eye-splice too.

A competent person must begin a visual inspection prior to each shift the equipment is used, which must be completed before or during that shift. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a)(2) of this section. Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

If a deficiency in Category I (see paragraph (a)(2)(i) of this section) is identified, an immediate determination must be made by the competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited until:

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category II (see paragraph (a)(2)(ii) of this section) is identified, operations involving use of the wire rope in question must be prohibited until:

The employer complies with the wire rope manufacturer"s established criterion for removal from service or a different criterion that the wire rope manufacturer has approved in writing for that specific wire rope (see § 1926.1417),

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope must be tagged-out, in accordance with § 1926.1417(f)(1), until the wire rope is repaired or replaced.

The inspection must include any deficiencies that the qualified person who conducts the annual inspection determines under paragraph (c)(3)(ii) of this section must be monitored.

Wire ropes on equipment must not be used until an inspection under this paragraph demonstrates that no corrective action under paragraph (a)(4) of this section is required.

At least every 12 months, wire ropes in use on equipment must be inspected by a qualified person in accordance with paragraph (a) of this section (shift inspection).

The inspection must be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under paragraph (c)(2) of this section is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections must be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

If a deficiency is identified, an immediate determination must be made by the qualified person as to whether the deficiency constitutes a safety hazard.

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the qualified person determines that, though not presently a safety hazard, the deficiency needs to be monitored, the employer must ensure that the deficiency is checked in the monthly inspections.

All documents produced under this section must be available, during the applicable document retention period, to all persons who conduct inspections under this section.

Scope. This section applies to slings used in conjunction with other material handling equipment for the movement of material by hoisting, in employments covered by this part. The types of slings covered are those made from alloy steel chain, wire rope, metal mesh, natural or synthetic fiber rope (conventional three strand construction), and synthetic web (nylon, polyester, and polypropylene).

Basket hitch is a sling configuration whereby the sling is passed under the load and has both ends, end attachments, eyes or handles on the hook or a single master link.

Cable laid endless sling-mechanical joint is a wire rope sling made endless by joining the ends of a single length of cable laid rope with one or more metallic fittings.

Cable laid grommet-hand tucked is an endless wire rope sling made from one length of rope wrapped six times around a core formed by hand tucking the ends of the rope inside the six wraps.

Cable laid rope sling-mechanical joint is a wire rope sling made from a cable laid rope with eyes fabricated by pressing or swaging one or more metal sleeves over the rope junction.

Choker hitch is a sling configuration with one end of the sling passing under the load and through an end attachment, handle or eye on the other end of the sling.

Female handle (choker) is a handle with a handle eye and a slot of such dimension as to permit passage of a male handle thereby allowing the use of a metal mesh sling in a choker hitch. (See Fig. N-184-1.)

Master coupling link is an alloy steel welded coupling link used as an intermediate link to join alloy steel chain to master links. (See Fig. N-184-3.)

Master link or gathering ring is a forged or welded steel link used to support all members (legs) of an alloy steel chain sling or wire rope sling. (See Fig. N-184-3.)

Diagam howing Two slings with indicators for sling width, overall length, bearing to bearing length, and fabric length. Further indicators point to both male handles, handle eye, female handle, and slot depth

Diagram indicates Forms of Hitch and Kind of Sling. Eye&Eye Vertical Hitch. Eye&Eye Choker Hitch. Eye&Eye Basket Hitch (Alterates have identical load rations). Endless Vertical Hitch. Endless Choker Hitch. Endless Basket Hitch (Alternateve have identical load ratings). Notes: Angles 5 deg or less from the veritcal may be considered vertical angles. For slings with legs more than 5 deg off vertical, the actual angle as shown in Figure N-184-5 must be considered. Explanation of Symbols: Minimum Diameter of Curvature. Represents a contact surface which shall have a diameter of curvature at least double the diameter of the rope from which the sling is made. Represents a contact surface which shall have a diameter of curvature at least 8 times the diameter of the rope. Represents a load in a choker hitch and illustrates the rotary force on the load and/or the slippage of the rope in contact with the load. Diameter of curvature of load surface shall be at least double the diameter of the rope.

Diagram indicates Form of Hitch and Vertical Hitch. Kind of Sling. Eye&Eye Vertical Hitch Not Applicable. Eye&Eye Choker Hitch Not Applicable. Eye&Eye Basket Hitch (Alternates have identical load ratings). Endless Vertical Hitch Not Applicable. Endless Choker Hitch Not Applicable. Endless Basket Hitch (Alternates have identical load ratings). Notes: For vertical angles of 5 deg or less, refer to Figure N-184-4 ""Basic Sling Configurations with Vertical Legs"". See Figure N-184-4 for explanation of symbols.

Proof test is a nondestructive tension test performed by the sling manufacturer or an equivalent entity to verify construction and workmanship of a sling.

Reach is the effective length of an alloy steel chain sling measured from the top bearing surface of the upper terminal component to the bottom bearing surface of the lower terminal component.

Strand laid endless sling-mechanical joint is a wire rope sling made endless from one length of rope with the ends joined by one or more metallic fittings.

Strand laid grommet-hand tucked is an endless wire rope sling made from one length of strand wrapped six times around a core formed by hand tucking the ends of the strand inside the six wraps.

Strand laid rope is a wire rope made with strands (usually six or eight) wrapped around a fiber core, wire strand core, or independent wire rope core (IWRC).

Employers must not load a sling in excess of its recommended safe working load as prescribed by the sling manufacturer on the identification markings permanently affixed to the sling.

Hooks, rings, oblong links, pear shaped links, welded or mechanical coupling links or other attachments shall have a rated capacity at least equal to that of the alloy steel chain with which they are used or the sling shall not be used in excess of the rated capacity of the weakest component.

In addition to the inspection required by paragraph (d) of this section, a thorough periodic inspection of alloy steel chain slings in use shall be made on a regular basis, to be determined on the basis of

Safe operating temperatures. Employers must permanently remove an alloy steel-chain slings from service if it is heated above 1000 degrees F. When exposed to service temperatures in excess of 600 degrees F, employers must reduce the maximum working-load limits permitted by the chain manufacturer in accordance with the chain or sling manufacturer"s recommendations.

Sling use. Employers must use only wire-rope slings that have permanently affixed and legible identification markings as prescribed by the manufacturer, and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one.

Cable laid and 6 × 19 and 6 × 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

Safe operating temperatures. Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200 °F. When nonfiber core wire rope slings of any grade are used at temperatures above 400 °F or below minus 60 °F, recommendations of the sling manufacturer regarding use at that temperature shall be followed.

All welded end attachments shall not be used unless proof tested by the manufacturer or equivalent entity at twice their rated capacity prior to initial use. The employer shall retain a certificate of the proof test, and make it available for examination.

Sling marking. Each metal mesh sling shall have permanently affixed to it a durable marking that states the rated capacity for vertical basket hitch and choker hitch loadings.

Sling testing. All new and repaired metal mesh slings, including handles, shall not be used unless proof tested by the manufacturer or equivalent entity at a minimum of 1½ times their rated capacity. Elastomer impregnated slings shall be proof tested before coating.

Safe operating temperatures. Metal mesh slings which are not impregnated with elastomers may be used in a temperature range from minus 20 °F to plus 550 °F without decreasing the working load limit. Metal mesh slings impregnated with polyvinyl chloride or neoprene may be used only in a temperature range from zero degrees to plus 200 °F. For operations outside these temperature ranges or for metal mesh slings impregnated with other materials, the sling manufacturer"s recommendations shall be followed.

Once repaired, each sling shall be permanently marked or tagged, or a written record maintained, to indicate the date and nature of the repairs and the person or organization that performed the repairs. Records of repairs shall be made available for examination.

Sling use. Employers must use natural and synthetic fiber-rope slings that have permanently affixed and legible identification markings stating the rated capacity for the type(s) of hitch(es) used and the angle upon which it is based, type of fiber material, and the number of legs if more than one.

Safe operating temperatures. Natural and synthetic fiber rope slings, except for wet frozen slings, may be used in a temperature range from minus 20 °F to plus 180 °F without decreasing the working load limit. For operations outside this temperature range and for wet frozen slings, the sling manufacturer"s recommendations shall be followed.

Splicing. Spliced fiber rope slings shall not be used unless they have been spliced in accordance with the following minimum requirements and in accordance with any additional recommendations of the manufacturer:

In manila rope, eye splices shall consist of at least three full tucks, and short splices shall consist of at least six full tucks, three on each side of the splice center line.

In synthetic fiber rope, eye splices shall consist of at least four full tucks, and short splices shall consist of at least eight full tucks, four on each side of the center line.

Strand end tails shall not be trimmed flush with the surface of the rope immediately adjacent to the full tucks. This applies to all types of fiber rope and both eye and short splices. For fiber rope under one inch in diameter, the tail shall project at least six rope diameters beyond the last full tuck. For fiber rope one inch in diameter and larger, the tail shall project at least six inches beyond the last full tuck. Where a projecting tail interferes with the use of the sling, the tail shall be tapered and spliced into the body of the rope using at least two additional tucks (which will require a tail length of approximately six rope diameters beyond the last full tuck).

For all eye splices, the eye shall be of such size to provide an included angle of not greater than 60 degrees at the splice when the eye is placed over the load or support.

Removal from service. Natural and synthetic fiber rope slings shall be immediately removed from service if any of the following conditions are present:

Attachment of end fittings to webbing and formation of eyes. Stitching shall be the only method used to attach end fittings to webbing and to form eyes. The thread shall be in an even pattern and contain a sufficient number of stitches to develop the full breaking strength of the sling.

Diagram depicting three of six types of sling constructions. Type I Triangle Choker typer. Contains Triangle Fitting, measured pull to pull when flat, choker slot, choker fitting, and fitting eye. Type II Triangle Triangle. Length Measured pull to pull when flat. Type III Eye and Eye with Flat Eyes. Length between Lap and Eye.

Diagram depicting the final three types of six of sling constructions. Type IV Eye and eye with Twisted Eyes. Length measured Eye Perpendicular to Sling Body. Type V Endless Type. Type VII Return Eye.

Each repaired sling shall be proof tested by the manufacturer or equivalent entity to twice the rated capacity prior to its return to service. The employer shall retain a certificate of the proof test and make it available for examination.

Alibaba.com has a host of modernized, personalized, and proficient wire rope eye splice hardware parts and accessories for all types of chair and sofa models. Built with sturdy quality materials and standard equipment, these products are incredibly strong with lifelong stability. Regardless of whether you want to use these wire rope eye splice for your office furniture or for your home furniture, they are equally efficient and durable. Enhanced features and damage resisting traits make these wire rope eye splice very popular among customers who are looking for quality hardware accessories for furniture.

Accessible in multiple variations and designs, these wire rope eye splice are ideal for all types of chairs and sofas, including modern and classic models. They are generally made of robust materials such as steel, aluminum, and other hardy materials to ensure optimal performance and quality over the years while being eco-friendly products. With strong features and qualities, these wire rope eye splice are ideal for commercial usages, especially in offices. Ranging from tilting equipment to footrest and height adjusting features, you can find all kinds of wire rope eye splice at the site.

Alibaba.com can surprise you with the massive selections of these incredible wire rope eye splice accessories and parts available in various designs, models, and shapes. These are manually operated hardware parts that are convenient to use and can are customizable. The wire rope eye splice collections at the site are also used in leisure clubs, movie theaters, auditoriums, among other places. The wire rope eye splice withstand heavy weights and possess anti-corrosion, anti-rust, and high-temperature resistance traits.

Do not settle for low-quality products and explore the wire rope eye splice ranges at Alibaba.com to buy them within your budget. These products are available as OEM orders against bulk purchases and come with warranty periods too. These products reduce discomforts and can considerably enhance your comfort and resting position on the chairs or sofas.

Employers must not use improved plow-steel wire rope and wire-rope slings with loads in excess of the rated capacities (i.e., working load limits) indicated on the sling by permanently affixed and legible identification markings prescribed by the manufacturer.

An eye splice made in any wire rope shall have not less than three full tucks. However, this requirement shall not operate to preclude the use of another form of splice or connection which can be shown to be as efficient and which is not otherwise prohibited.

Wire rope shall not be used if, in any length of eight diameters, the total number of visible broken wires exceeds 10 percent of the total number of wires, or if the rope shows other signs of excessive wear, corrosion, or defect.

Except for eye splices in the ends of wires and for endless rope slings, each wire rope used in hoisting or lowering, or in pulling loads, shall consist of one continuous piece without knot or splice.

Cable laid and 6 × 19 and 6 × 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200 °F (93.33 °C). When nonfiber core wire rope slings of any grade are used at temperatures above 400 °F (204.44 °C) or below minus 60 °F (15.55 °C), recommendations of the sling manufacturer regarding use at that temperature shall be followed.

All welded end attachments shall not be used unless proof tested by the manufacturer or equivalent entity at twice their rated capacity prior to initial use. The employer shall retain a certificate of the proof test, and make it available for examination.

Wire rope slings shall have permanently affixed, legible identification markings stating size, rated capacity for the type(s) of hitch(es) used and the angle upon which it is based, and the number of legs if more than one.

8613371530291

8613371530291