spiral strand wire rope for sale

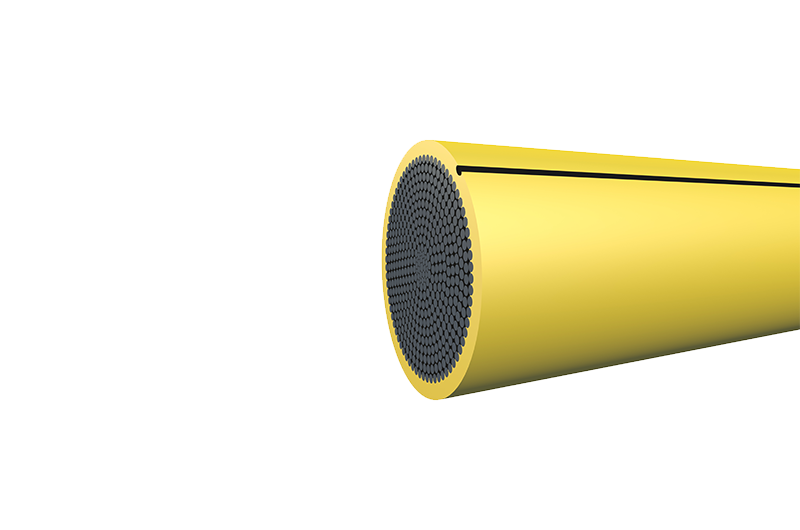

A spiral strand is a composite of multiple layers of helically twisted steel wires. Layers are spun in opposite directions providing constructional and torque stability. The use of high strength steel wires makes it a good candidate as tension member in static applications. Our proprietary Bridon-Bekaert blocking compound fills the cable on the inside, reducing the impact of steel-steel contact, and adding an additional barrier against corrosion.

Bethlehem Structural Strand is an arrangement of wires laid helically around a center wire to produce a symmetrical cross section. Structural strand is used as a load-carrying tension member where great flexibility and bending are not major requirements. For any given diameter, wire strand is the least flexible of steel cables. Structural strand provides a high strength-to-weight ratio, a high modulus of elasticity and a small diameter-per-unit strength. These are the features that permit strand to adapt so successfully to structural applications. WW manufactures Bethlehem Structural Strand to meet ASTM Specification A586, and we have the capability to manufacture strand as large as 5-1/2"diameter. Refer to Table 1 for structural strand data.

Bethlehem Structural Wire Rope consists of six strands made from zinc-coated wire with strands laid helically around a core, such as another strand or smaller wire rope. Structural wire rope provides greater flexibility when compared with coarse strand constructions and is generally the structural cable of choice where bending ability is an important requirement, such as forming flemish eye ends (drop terminals). WW manufactures Bethlehem Structural Wire Rope to meet ASTM Specification A603, and has the capability to manufacture wire rope as large as 7"diameter. Refer to Table 2 for Bethlehem Structural Wire Rope data.

Wirerope Works, Inc. offers SS-265™, a high strength structural strand designed specifically for use in tower applications. Compared with standard structural strand, SS-265 offers an increase in minimum breaking force of 15% above the values for strand manufactured to specification ASTM-A586. Using SS-265 also offers these advantages:

Reduced Structural Strand Diameter—Now that designers can utilize a smaller diameter strand for the guying system, SS-265 offers a lower cost per foot, allowing the user to cut valuable dollars from the cost of a project.

Smaller Fittings—Many fittings manufactured for standard strand may be used with the SS-265, thereby offering a lower cost per unit and adding further cost reductions.

For users who opt to use SS-265 without downsizing the diameter of the strand, other benefits apply. For example, using a 2-inch diameter as an example, the minimum breaking force increases from 245 tons to SS-265’s 282 tons. The higher strength results in an increased design factor of the guying system. SS-265 also may be used in other applications where structural strand manufactured to ASTM-A586 is utilized. Please contact your WW regional sales manager or customer service representative for further information.

To ensure quality of all Bethlehem Wire Rope and Strand products, WW utilizes Statistical Process Controls (SPC). In doing so, we are able to test and certify the following:

... state-of-the-art wire rope. Non rotating, high strength, axial and radial stiffness along with flexibility: these are the characteristics that make Flexpack the go-to wire rope for high performances. ...

... of Redaelli’s Pack wire ropes. Designed with outer compacted strands, Pack ropes are recommended for heavy applications such as hoisting, off-shore winches, risers tensioning, anchoring etc. They are ...

IPERFLEX is a non-rotating wire rope for lifting applications. Its good load capacity, good resistance to rotation and stability offer top level performance in any situation. IPERFLEX is flexible, easy to handle and has ...

19x7 is Redaelli low-torque and rotation resistant wire rope. It is suitable for any application which does not require a high breaking force, such as tower cranes. Its main characteristics are good wear resistance, good ...

Redaelli’s spiral ropes are the best option for offshore applications such as permanent mooring lines of Floating Production Storage and Offloading Units (FPSOs), drilling rigs, windmill towers in offshore fields etc. ...

Redaelli’s spiral ropes are the best option for offshore applications such as permanent mooring lines of Floating Production Storage and Offloading Units (FPSOs), drilling rigs, windmill towers in offshore fields etc. ...

... HDPE sheathing. Open spiral strands are thus useful in applications such as cable systems for tension structures, stays for pedestrian bridges, hangers for suspension ...

While some use these two terms interchangeably, technically wire rope refers to a diameter greater than 3/8”. Cable rope - also called aircraft cable - applies to all smaller variations.

Consequently, aircraft cable is only used for lighter-duty purposes, such as winch lines, fences, and railings, while wire rope can be using for lifting, towing, hoisting, etc. Both are ideal for outdoor environments because the strength and length remain constant regardless of whether they are wet or dry.

If you are looking for an option specifically designed for lifting, check out our wire rope slings. They come in a number of configurations - choices include leg count, end hardware, and more.

Generally composed of wires, strands, and a core shaped in a spiral pattern, wire rope is incredibly durable. Steel wires are aligned in a precise helix geometric pattern to form a strand in a process known as "stranding." A "closing" comes next, where the strands are laid around the core to form a wire rope.

The greater the diameter, the greater the break strength. Our selection of 1/8" stainless steel cable has a break strength of less than 2,000 lbs., while our 2-1/2" wire rope has a break strength of more than 600,000 lbs.!

Right hand and left hand designations indicate which way the strands wrap around the core of the steel rope, while regular lay and Lang lay designations specify which way the wires that make up the strand are formed in the helix pattern.

Regular lay means the wires are rotated opposite the direction of the strands around the core. Lang lay means the wires are twisted in the same direction as the strands wrapped around the wire rope core.

Our wire rope lay is right hand regular lay, with strands wrapped around the core to the right, and the wires making up the strand turned and rotated to the left.

Independent wire rope cores (IWRC) are made from steel, offer more support to the outer strands, and have a higher resistance to crushing. IWRC also offer more resistance to heat and increase the strength of the rope.

This refers to how many strands make up the rope and how many wires make up one strand. For instance, a 6x26 wire rope has 6 strands around a core with 26 wires making up each strand.

All wires consist of layer(s) arranged in a specific pattern around a center. Pattern designation is affected by the size of the wires, the number of layers, and the wires per layer. Wires can utilize either a single pattern style or a combination of them, known as a combined pattern:

Warrington - Two layers of wires. The outer layer has two diameters of wire (alternating between large and small), while the inner layer has one diameter.

Although wire rope is extremely strong, it can become damaged with improper use, making it unsafe to use. It"s important to have regular inspections for breaks, corrosion, overuse wear, and kinks.

Our rigging supplies category includes hardware and accessories for cranes, dredging, excavating, hoists & winches, logging, and marine uses. If you"re unsure what you need or have questions, call for help from our product specialists with expertise in wire rope/cable rigging supplies.

Established in 1986 in Mumbai, Maharashtra as a speciality wire ropes manufacturing company, Bharat Wire Ropes Ltd. is now a multimillion USD enterprise. The company has achieved new standards in the manufacturing of Strands, Wire Ropes and Slings for use in a varied list of application / industries such as General Engineering, Fishing, Elevators, Cranes, Material Handling, Onshore / Offshore Oil Exploration, Ports and Shipping and Mining.

Bharat Wire Ropes also has a diverse product mix which includes Mechanically Spliced Slings, Hand Spliced Slings, Earth Wires, Stay Wires, Guy Wires and Spiral Strands. Bharat Wire Ropes cater to a rich mix of clients ranging from Overseas Consumers, Private Players,the entire Indian Defense Segment and Government and Semi – Government Organizations. Providing service to a variety of clients has helped the company develop versatility which makes it better equipped to handle diverse / heterogeneous kinds of enquiries.

The company has adopted the strategy of "Partial Backward Integration" and now acquires Wire Rods from reputed companies.This change was brought in with the view of having a better control over Quality, Cost, and Inventory and to be in a position to provide Timely Service.

CERTEX specializes in lifting technology and load securing. Whatever the lifting process in industry, ports, construction sites, mining or many other industries, CERTEX offers the right products and services. With a large product range of more than 10.000 items and access to the warehouses of our worldwide suppliers, knowledge about the wire rope and all other areas of lifting technology, we can solve your problem.

8613371530291

8613371530291