spray on wire rope lubricant free sample

WIRE ROPE LUBRICANT Our wire rope lubricant is the preferred penetrating wire rope lubricant in the industry because of its ability to penetrate into a wire rope and displace water and contaminants, thus reducing wear and corrosion throughout the rope. Available in 12 oz. (12 to a case) aresol cans or 5 gallon buckets. Its important to lubricate periodically throughout the life of the rope. The surface of some ropes may become covered with dirt, rock dust or other material during their operation. This can prevent field-applied lubricants from properly penetrating into the rope, so its a good practice to clean these ropes before you lubricate them. The lubricant you apply should be light-bodied enough to penetrate to the ropes core, like ours.

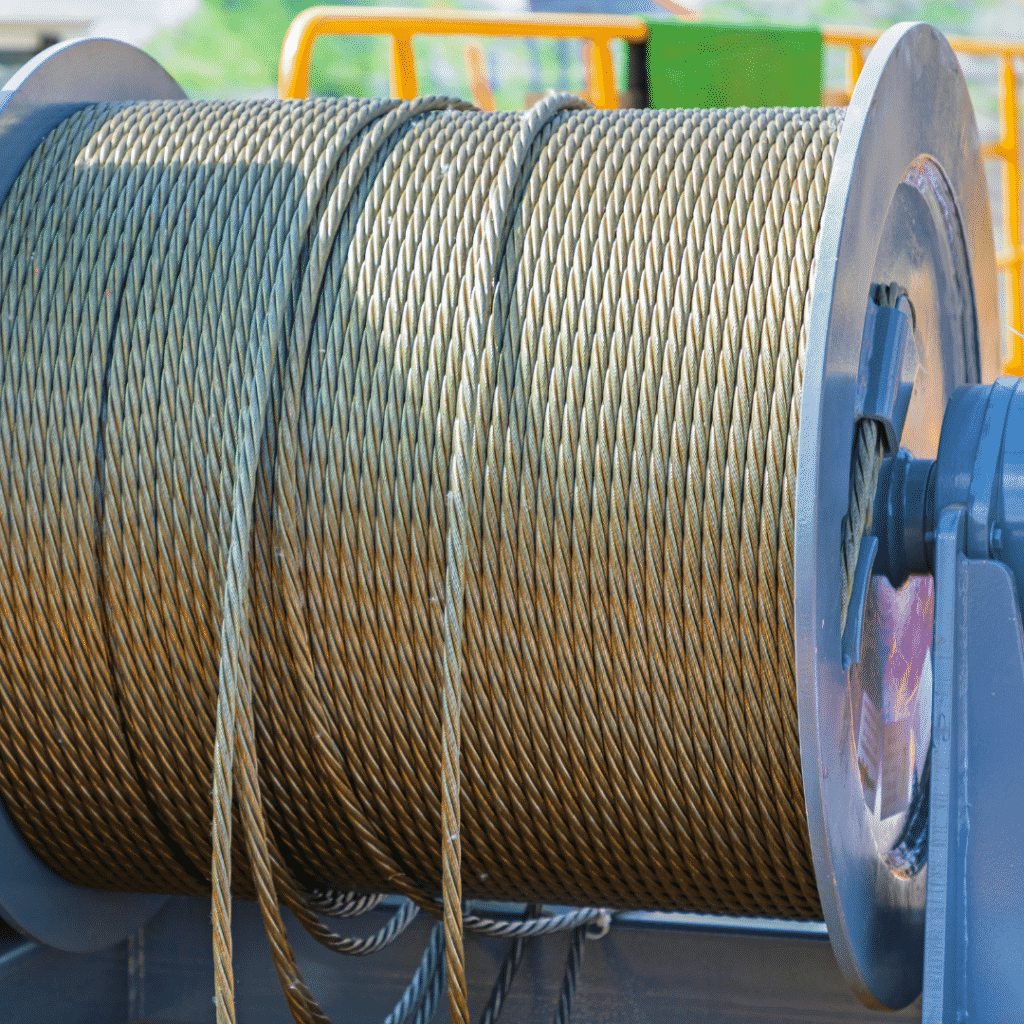

Wire rope forms an important part of many machines and structures. It is comprised of continuous wire strands wound around a central core. There are many kinds of wire rope designed for different applications. Most of them are steel wires made into strands wound with each other. The core can be made of steel, rope or even plastics.

Wire ropes (cables) are identified by several parameters including size, grade of steel used, whether or not it is preformed, by its lay, the number of strands and the number of wires in each strand.

A typical strand and wire designation is 6x19. This denotes a rope made up of six strands with 19 wires in each strand. Different strand sizes and arrangements allow for varying degrees of rope flexibility and resistance to crushing and abrasion. Small wires are better suited to being bent sharply over small sheaves (pulleys). Large outer wires are preferred when the cable will be rubbed or dragged through abrasives.

There are three types of cores. An independent wire rope core (IWRC) is normally a 6x7 wire rope with a 1x7 wire strand core resulting in a 7x7 wire rope. IWRCs have a higher tensile and bending breaking strength than a fiber core rope and a high resistance to crushing and deformation.

A wire strand core (WSC) rope has a single wire strand as its core instead of a multistrand wire rope core. WSC ropes are high strength and are mostly used as static or standing ropes.

Wire ropes also have fiber cores. Fiber core ropes were traditionally made with sisal rope, but may also use plastic materials. The fiber core ropes have less strength than steel core ropes. Fiber core ropes are quite flexible and are used in many overhead crane applications.

The lay of a wire rope is the direction that the wire strands and the strands in the cable twist. There are four common lays: right lay, left lay, regular lay and lang lay. In a right lay rope the strands twist to the right as it winds away from the observer. A left lay twists to the left. A regular lay rope has the wires in the strands twisted in the opposite direction from the strands of the cable. In a lang lay rope, the twist of the strands and the wires in the strands are both twisted the same way. Lang lay ropes are said to have better fatigue resistance due to the flatter exposure of the wires.

Wire ropes are made mostly from high carbon steel for strength, versatility, resilience and availability and for cost consideration. Wire ropes can be uncoated or galvanized. Several grades of steel are used and are described in Table 1.

Steel cable wire is stiff and springy. In nonpreformed rope construction, broken or cut wires will straighten and stick out of the rope as a burr, posing a safety hazard. A preformed cable is made of wires that are shaped so that they lie naturally in their position in the strand, preventing the wires from protruding and potentially causing injury. Preformed wire ropes also have better fatigue resistance than nonpreformed ropes and are ideal for working over small sheaves and around sharp angles.

Lubricating wire ropes is a difficult proposition, regardless of the construction and composition. Ropes with fiber cores are somewhat easier to lubricate than those made exclusively from steel materials. For this reason, it is important to carefully consider the issue of field relubrication when selecting rope for an application.

There are two types of wire rope lubricants, penetrating and coating. Penetrating lubricants contain a petroleum solvent that carries the lubricant into the core of the wire rope then evaporates, leaving behind a heavy lubricating film to protect and lubricate each strand (Figure 2). Coating lubricants penetrate slightly, sealing the outside of the cable from moisture and reducing wear and fretting corrosion from contact with external bodies.

Both types of wire rope lubricants are used. But because most wire ropes fail from the inside, it is important to make sure that the center core receives sufficient lubricant. A combination approach in which a penetrating lubricant is used to saturate the core, followed with a coating to seal and protect the outer surface, is recommended. Wire rope lubricants can be petrolatum, asphaltic, grease, petroleum oils or vegetable oil-based (Figure 3).

Petrolatum compounds, with the proper additives, provide excellent corrosion and water resistance. In addition, petrolatum compounds are translucent, allowing the technician to perform visible inspection. Petrolatum lubricants can drip off at higher temperatures but maintain their consistency well under cold temperature conditions.

Asphaltic compounds generally dry to a very dark hardened surface, which makes inspection difficult. They adhere well for extended long-term storage but will crack and become brittle in cold climates. Asphaltics are the coating type.

Various types of greases are used for wire rope lubrication. These are the coating types that penetrate partially but usually do not saturate the rope core. Common grease thickeners include sodium, lithium, lithium complex and aluminum complex soaps. Greases used for this application generally have a soft semifluid consistency. They coat and achieve partial penetration if applied with pressure lubricators.

Petroleum and vegetable oils penetrate best and are the easiest to apply because proper additive design of these penetrating types gives them excellent wear and corrosion resistance. The fluid property of oil type lubricants helps to wash the rope to remove abrasive external contaminants.

Wire ropes are lubricated during the manufacturing process. If the rope has a fiber core center, the fiber will be lubricated with a mineral oil or petrolatum type lubricant. The core will absorb the lubricant and function as a reservoir for prolonged lubrication while in service.

If the rope has a steel core, the lubricant (both oil and grease type) is pumped in a stream just ahead of the die that twists the wires into a strand. This allows complete coverage of all wires.

After the cable is put into service, relubrication is required due to loss of the original lubricant from loading, bending and stretching of the cable. The fiber core cables dry out over time due to heat from evaporation, and often absorb moisture. Field relubrication is necessary to minimize corrosion, protect and preserve the rope core and wires, and thus extend the service life of the wire rope.

If a cable is dirty or has accumulated layers of hardened lubricant or other contaminants, it must be cleaned with a wire brush and petroleum solvent, compressed air or steam cleaner before relubrication. The wire rope must then be dried and lubricated immediately to prevent rusting. Field lubricants can be applied by spray, brush, dip, drip or pressure boot. Lubricants are best applied at a drum or sheave where the rope strands have a tendency to separate slightly due to bending to facilitate maximum penetration to the core. If a pressure boot application is used, the lubricant is applied to the rope under slight tension in a straight condition. Excessive lubricant application should be avoided to prevent safety hazards.

Some key performance attributes to look for in a wire rope lubricant are wear resistance and corrosion prevention. Some useful performance benchmarks include high four-ball EP test values, such as a weld point (ASTM D2783) of above 350 kg and a load wear index of above 50. For corrosion protection, look for wire rope lubricants with salt spray (ASTM B117) resistance values above 60 hours and humidity cabinet (ASTM D1748) values of more than 60 days. Most manufacturers provide this type of data on product data sheets.

Cable life cycle and performance are influenced by several factors, including type of operation, care and environment. Cables can be damaged by worn sheaves, improper winding and splicing practices, and improper storage. High stress loading, shock loading, jerking heavy loads or rapid acceleration or deceleration (speed of the cable stopping and starting) will accelerate the wear rate.

Corrosion can cause shortened rope life due to metal loss, pitting and stress risers from pitting. If a machine is to be shut down for an extended period, the cables should be removed, cleaned, lubricated and properly stored. In service, corrosion and oxidation are caused by fumes, acids, salt brines, sulfur, gases, salt air, humidity and are accelerated by elevated temperatures. Proper and adequate lubricant application in the field can reduce corrosive attack of the cable.

Abrasive wear occurs on the inside and outside of wire ropes. Individual strands inside the rope move and rub against one another during normal operation, creating internal two-body abrasive wear. The outside of the cable accumulates dirt and contaminants from sheaves and drums. This causes three-body abrasive wear, which erodes the outer wires and strands. Abrasive wear usually reduces rope diameter and can result in core failure and internal wire breakage. Penetrating wire rope lubricants reduce abrasive wear inside the rope and also wash off the external surfaces to remove contaminants and dirt.

Many types of machines and structures use wire ropes, including draglines, cranes, elevators, shovels, drilling rigs, suspension bridges and cable-stayed towers. Each application has specific needs for the type and size of wire rope required. All wire ropes, regardless of the application, will perform at a higher level, last longer and provide greater user benefits when properly maintained.

Lubrication Engineers, Inc. has found through years of field experience, that longer wire rope life can be obtained through the use of penetrating lubricants, either alone or when used in conjunction with a coating lubricant. Practical experience at a South African mine suggests that life cycles may be doubled with this approach. At one mine site, the replacement rate for four 44-mm ropes was extended from an average 18.5 months to 43 months. At another mine, life cycles of four 43-mm x 2073 meter ropes were extended from an average 8 months to 12 months.

In another study involving 5-ton and 10-ton overhead cranes in the United States that used 3/8-inch and 5/8-inch diameter ropes, the average life of the ropes was doubled. The authors attribute this increased performance to the ability of the penetrating lubricant to displace water and contaminants while replacing them with oil, which reduces the wear and corrosion occurring throughout the rope. A good spray with penetrating wire rope lubricant effectively acts as an oil change for wire ropes.

In these examples, the savings in wire rope replacement costs (downtime, labor and capital costs) were substantial and dwarfed the cost of the lubricants. Companies who have realized the importance of proper wire rope lubrication have gained a huge advantage over those who purchase the lowest priced lubricant, or no lubricant at all, while replacing ropes on a much more frequent basis.

Wire ropes can be utilized in a number of applications. The intended application generally will dictate the initial lubrication of the wire rope by manufacturers. For example, some wire ropes are employed for the support of structures such as buildings and bridges. These ropes remain nearly static, so there is little need to relubricate them. They will not have the same internal friction and wear (although still subjected to surface corrosion) as a dynamic rope utilized in heavy equipment applications for lifting or hauling purposes.

Wire ropes used in crane services often employ a fiber core which is saturated in oil with strands of wire wrapped around it. This fiber core acts as a sponge to actively drain or release lubricant when the rope is subjected to bending or loading. Most wire ropes fail from the inside, so this fiber core can be beneficial if binding conditions occur.

Wire ropes without a fiber core are typically coated with a lubricant during the manufacturing process to lessen internal friction and to coat the surface in order to minimize corrosion due to water or the environment.

While there are standards in place for lubricants used during the manufacturing process, most are generic and only help put you on the right track in your lubricant selection. Of course, all wire rope lubricants should have corrosion control properties as well as penetrating capabilities to get as far into the core of the wire rope as possible.

There are numerous methods of applying lubricant to wire ropes. For machinery in which the rope can move, you may choose to use a drip, spray or trough method. These methods apply lubricant at a single point and utilize the movement of the rope to spread the lubricant over the entire length of the system. Some trough systems are pressurized, which can be advantageous, as they push the lubricant into the rope.

If the wire ropes are static, manual brushing or sprays usually are the easiest way to apply lubricant. In most cases, it is best to remove excess lubricant from the surface to help minimize dirt and water from sticking to the lubricant, especially in dirty environments.

Crosby’s Vitalife®products are the preferred wire rope lubricants in the industry because of their ability to penetrate into wire rope and displace water and contaminants, thus reducing wear and corrosion throughout the rope.Available in a variety of container sizes.

Whitmore’s Wire Rope Lubricant products also coat these strands to prevent friction and wear. This results in longer wire rope life, less downtime for rope changes and more production.

Whitmore’s Wire Rope Lubricant is easily pumpable at temperatures down to -25°F (-35°C). Its nondrying film remains flexible in the most extreme weather conditions, which eliminates flaking and peeling.Whitmore’s Wire Rope Lubricant can be used to lubricate all sizes of wire rope, as well as chains, leaf springs and other applications where penetrating oil is needed. It may be applied by hand or automatic lube system.

Note:The image displayed is a representation of the product. Product dimensions, finish, head type, and thread length may differ from picture. Products are guaranteed to meet the specification to which they are manufactured. Please email us with any questions.

Hazardous Material - Product can only ship within the contiguous US. Must ship ground - cannot ship Next Day or 2nd Day Air.Resists water wash-off and high-temperature sling off

3. Your data will be processed on the basis of point (a) of Article 6(1) of Regulation of the European Parliament and of the Council (EU) 2016/679 of 27 April 2016 on the protection of individuals with regard to the processing of personal data and on the free movement of such data and the repeal of Directive 95/46/EC (hereinafter referred to as: GDPR) , in order to send to the provided e-mail address, an electronic news bulletin of TME.

7. To the extent that your personal data is processed on the grounds of your consent, you have the right to withdraw that consent. Withdrawal of consent has no bearing on the legitimacy of processing that was performed prior to the withdrawal.

Although Westech Rigging Supply strives to manufacture and sell the highest quality rigging and safety gear, use of the gear is dangerous if not used correctly by competent trained professionals. Westech Rigging Supply disclaims any liability resulting from the misuse of its rigging and safety gear. Please take a moment to more thoroughly review our disclaimer.

Westech Rigging Supply rigging and safety gear is only intended to be used by competent trained professionals. Misuse of the rigging and safety gear can result in serious injury up to and including loss of life. As such, Westech Rigging Supply disclaims liability for any misuse or incorrect product selection by our customers.

Rigging and safety gear purchased from Westech Rigging Supply should be used in strict accordance with all industry and OSHA standards. At no time should rigging or safety gear be used beyond its certified load ratings (aka Working Load Limits). Normal wear and tear should be expected with use of rigging and safety gear; therefore, all gear should be thoroughly inspected before each and every use. Worn or unsafe rigging and safety gear should never be used.

Although Westech Rigging Supply strives to manufacture and sell the highest quality rigging and safety gear, use of the gear is dangerous if not used correctly by competent trained professionals. Westech Rigging Supply disclaims any liability resulting from the misuse of its rigging and safety gear. Please take a moment to more thoroughly review our disclaimer.

Westech Rigging Supply rigging and safety gear is only intended to be used by competent trained professionals. Misuse of the rigging and safety gear can result in serious injury up to and including loss of life. As such, Westech Rigging Supply disclaims liability for any misuse or incorrect product selection by our customers.

Rigging and safety gear purchased from Westech Rigging Supply should be used in strict accordance with all industry and OSHA standards. At no time should rigging or safety gear be used beyond its certified load ratings (aka Working Load Limits). Normal wear and tear should be expected with use of rigging and safety gear; therefore, all gear should be thoroughly inspected before each and every use. Worn or unsafe rigging and safety gear should never be used.

WEICON Chain and Rope Lube Spray is a synthetic, transparent adhesive lubricant for the permanent internal and external lubrication of all types of highly stressed chains and wire ropes.

Chain and Rope Lube Spray is particularly strongly adherent, has excellent creeping properties, suppresses noise, repels water and prevents elongation, friction and wear.

WEICON Chain and Rope Lube Spray can be used on all types of chains and wire ropes, gearwheels, worm gears, fast-running machine parts, joints, couplings, rollers, ball bearings and spring assemblies in many industrial applications.

Laboratory tested to withstand Salt Spray for 72 hours and Humidit y Cabinet for 60 days. Sprays as an instant foaming, deep penetrating liquid that flows inside intricate chains and cables where the greatest stress occurs. Provides a thick foam that clings to vertical surfaces. As foam breaks, lubricant penetrates into wire rope and roller chain mechanisms. Deposits a Molybdenum Disulfide based grease and provides surfaces with superior lubricating properties. Protects against high temperature and extreme pressure environments. Grease will not break down, fly off or wash away with water or steam. Retains lubricating properties under heavy shock load, acidic environments and salt spray. Protective lubricating film prevents surface oxidation and corrosion. USED BY: Industrial Facilities, Shipyards, Steel Mills, Aircraft Maintenance, Material Handling, Road Equipment, Construction, Mining, Containerized Shipping Companies. USE ON: Chains, Wire Cable, Open Gears, Sprockets, Chain Saws, Drag Lines, Power Drives, Fittings, Booms, Road and Construction Machinery, Hoists, Winches, Cranes, Material Handing Equipment, Tow Lines, Linkages and Roller Assemblies.

Proper lubrication of wire rope, or steel cable, is essential for two reasons. The first one is safety. Wire ropes that are improperly lubricated are far more prone to both interior and exterior wear, and as such are at greater risk for failing. A wire rope that breaks while being used can cause great injury or death, since they are often a critical piece in hoisting, towing, dragging, braking, or similar operations.

The second reason is simple economics. A wire rope that is well maintained and lubricated will last far longer than one that isn"t. Life of a wire rope can be extended several times if properly lubricated.

Wire rope bending around hoist drums and sheaves will wear like any other piece of metal, so you should lubricate wire rope the same as any other piece of working machinery. Wires and strands of a rope must be able to move freely in order for the rope to function correctly. Corrosion from moisture or wear due to friction shortens the service life of wire rope.

Wire rope should always be well cleaned before lubricating. Scraping, steaming, or high-pressure washing may remove most of the dirt and grit that has accumulated on used wire rope. Rust should be removed on a regular basis with a wire brush. The purpose of cleaning is to remove all foreign material and old lubricant from the valleys between the strands, as well as the spaces between the outer wires. Otherwise, new lubricant will not be able to flow into the rope.

Of the two, corrosion is more dangerous than wear because corrosion ruins the interior of a rope. This is very difficult to determine by visual inspection.

Wire rope should be inspected at regular intervals. How often these inspections take place depend on the frequency of rope use and the conditions under which it is used.

Abrasion or reverse and sharp bends cause individual wires to break and bend back. These breaks are known as fishhooks. Wire rope should be examined carefully for fishhooks, kinks, and worn and corroded spots. Breaks in individual wires will usually occur in areas where the wire runs continually over the sheaves or bend onto the drum. This is also a good place to look for problems, because the strands may separate slightly as the rope passes over, thus allowing slightly better examination.

There are two conditions that will usually reduce the diameter of a wire rope: Overloading, and failure to lubricate. Rope that is 75 percent of its original diameter should be removed from service. When pitting and corrosion of the wires are visible on the surface, you should assume that the same problem exists internally, and the rope should be removed from service.

Special care should be taken to examine the valleys and small spaces between the strands for rust and corrosion. Since corrosion is normally caused by insufficient or nonexistent lubrication, if you see external corrosion, assume that the internal wires of the rope are being damaged by extreme friction and wear at the same time. This type of internal and often invisible destruction of the wires is one of the most frequent causes of unexpected and sudden wire rope failure. To prevent this, keep the rope well lubricated, and handle and store it properly.

Wire rope should never be stored in an area where acid is or has been kept. This must be stressed to all personnel. The slightest trace of acid or acid fumes coming in contact with wire rope will damage it at the contact spot. Wire that has given way has been found many times to be acid damaged.

It is extremely important that wire rope be cleaned and lubricated properly before placing it in storage. Fortunately, corrosion of wire rope can be virtually eliminated if lubricant is applied properly and sufficient protection from the weather is provided. Remember that rust, corrosion of wires, and deterioration of the fiber core will significantly reduce the strength of wire rope.

Fin Super with MicPol: Suitable for above-water applications. A spray lubricant that goes on wet and dries to a solid film that protects from wear and moisture. Also has outstanding penetrating and creeping abilities, so it can quickly work its way throughout a wire rope and lubricate both interior and exterior.

Food Lube with MicPol: Again similar to Fin Super, but is rated NSF H1 and certified kosher and halal for use in the production of food, beverages, pharmaceuticals, cosmetics, or animal feed.

Fin Grease with MicPol: Again similar to Fin Super, except that upon application from the aerosol can, it expands to a grease instead of remaining a liquid. Suitable for applications where a more viscous solution is required.

Grease OG with MicPol: A grease with excellent metal adhesion that strongly resists washout and can withstand a temperature range of -20 C to 120 C. Ideal for use on outdoor and underwater cables, as well as heavily loaded open drive mechanisms such as turntables on cranes, bridges, locks, etc. Can be used with pneumatic lubricant spraying system. Calcium lithium complex grease with a DN factor of 60,000.

All Kirkpatrick Wire Rope Lubrication Systems are provided as an all-inclusive package. There is no itemized charge for each of the components listed in the Main System Package.

The Jumbo Systems’ maximum rated pumping capacity of 24 Pounds / 10.9 Kilograms per minute can keep up with faster Wire Rope Travel Speeds involving large Diameter Wire Ropes. These high flow capacities generate optimal pressurization inside the internal Seals for the deepest possible penetration and coating of individual Wire Strands. This also provides excellent fluid film support protection against friction wear from strand rubbing.

ITW Pro Brands strives to make its website accessible to everyone, including users with disabilities. If you are experiencing difficulty using our website or would like assistance accessing the goods and services available on the website,

please email us at customerservice@itwprobrands.com or call at 1-800-241-8334 or 1-770-243-8800 and describe the difficulty or concern. We would be happy to assist you.

Wire ropes, sometimes referred to as cables in gauges less than 3/8 in. dia., are connective elements used in static and dynamic work environments servicing industry and infrastructure needs. Common static wire-rope applications can be found in the main support systems for suspension bridges or as tensioned cable used to support tall, free-standing structures such as microwave cell towers. Popular dynamic applications include mining-cage hoists, elevator hoists, draglines, and cranes in which the wire rope moves under tension and load to lift, hoist, and transfer motion and power.

Originally developed in early 19th century Germany for the mining industry as a better alternative to existing metal chains and hemp rope—regular failure always proved catastrophic—wire rope is still manufactured in a similar manner from multiple strands of metal wire laid (wound) in a helical pattern around a center core. The center core can be made from hemp rope, plastic, fiber, or steel (specific to aircraft cable).

The multi-strand fabrication method provides tremendous tensile strength (100,000 to 350,000 psi, depending on the grade of wire steel) for lifting and hoisting while delivering flexibility of movement needed for traction and movement recovery over pulley or drum surfaces. In addition, stranded wire provides superior resistance to crushing and abrasion that can result from the extreme working conditions in which wire rope is often employed.

Wire ropes are gauged (sized) based on the number of strands surrounding the core and the number of wires used per strand. For example, an 8×19 wire rope will consist of 8 strands laid around the core, with each strand consisting of 19 wires. With 152 individual wires rubbing against each other as the rope moves over the drum or sheave pulley, friction and wear will result. That must be combatted with an effective lubrication strategy designed to maximize reliability and optimize life cycle.

In addition to load and movement, wire ropes are often subjected to weather and operating conditions that can introduce contamination and place heavy demands on the rope lubricant. Lack of a lubrication strategy can exasperate the situation and cause the wire rope to fail prematurely.

Dynamically loaded wire ropes typically fail from fatigue, wear, corrosion, and/or core shrinkage. Fatigue is a result of repetitive work cycles, subjecting the rope to constant bending, torsional twisting, and tension. These stresses eventually lead to broken wires within the strands. These same cyclic stresses also lead to high contact pressures between the wires that, in turn, set up a friction-and-wear cycle when the rope is inadequately lubricated. In addition, poorly lubricated ropes will allow solid contaminants between the wires as they open and close around the pulley. This contamination then sets up as three-body abrasion, causing accelerated wear inside the rope.

Because wire ropes are made from steel and can be subjected to outside elements such as moisture and acidic chemicals, unless a galvanized-steel rope is employed, successful corrosion abatement will rely solely on a quality lubrication program.

Core shrinkage starts to occur when the initial lubricant charge dries out, resulting in a reduced diameter and loss of support for the surrounding strands. This, in turn, can cause the strands to overlap one another, leading to nicked and cut wires.

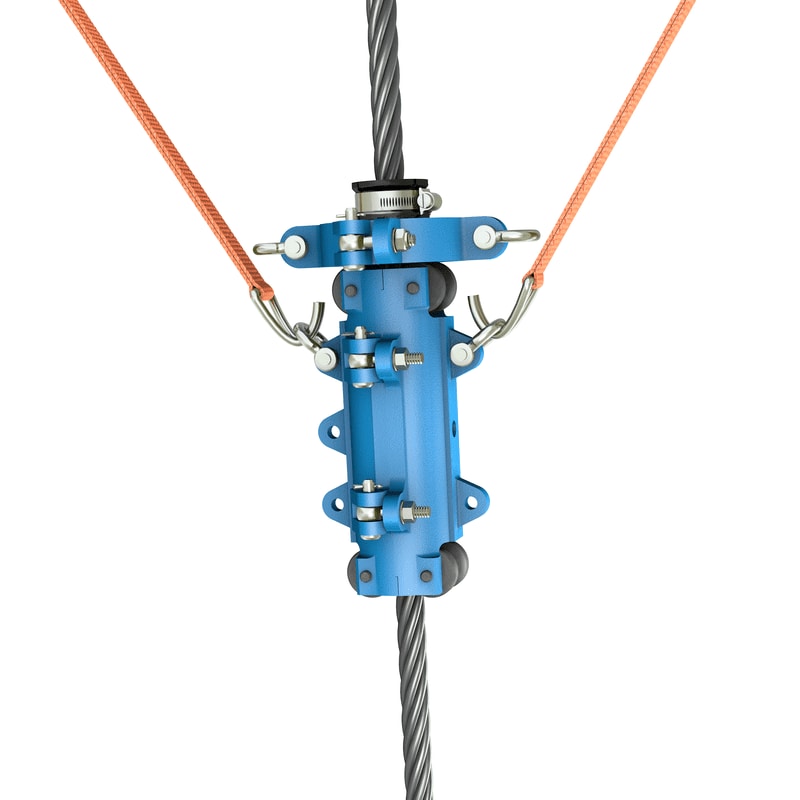

Wire-rope lubricant is automatically applied by using a pressure boot clamped on the rope in a tensioned straight section. Lubricant is gently pressured into the wire rope as it passes through the boot. Photo courtesy Lubrication Engineers Inc., Wichita, KS; lelubricants.com

New wire ropes are lubricated at the factory. The lubrication gradually depletes, once the rope is placed in service, at a rate that depends on the load and working conditions. When setting up a wire-rope lubrication program, the first rule of thumb is to ensure the field lubricant is compatible with the original lubricant charge.

Considering the four common failure modes, a good lubricant must be able to coat the outside of the wire rope and get in between the wires to provide a lubricant film between all of the moving wires. The lubricant also must provide adequate corrosion protection. Because most wire ropes fail from the inside, it is important to always use a penetrating lubricant first. Penetrating oils are petroleum-based and contain solvents that allow these lubricants to “creep” into the core and ensure the strands and core are fully coated with a heavy lubricating film. Once in place, the solvent eventually evaporates, leaving only the oil film.

In extreme operating environments, the wire rope may also require a coating oil to protect the outside surface, sealing out moisture and protecting the inner strands and core. This coating oil also protects the outer rope surface from wear and damage.

The correct choice of lubricant is based on the application, load, rope construction, and working environment, all of which will require expert assistance from your local lubricant supplier.

If a new lubricant is to perform correctly, a full wire-rope cleaning must take place prior to re-lubrication. Ropes tend to pick up dirt in service and old lubricants can harden on the rope exterior. Cleaning ranges from a wire-brush-and-solvent cleaning, if only light surface debris is present, to a full steam clean for heavily soiled wire ropes.

Wire-rope lubricant can be applied manually or automatically in the field. Most manual applications are performed with a brush, spray, or even a dip-tank process, depending on the length and size of wire rope. If the lubricant is to be manually applied, always strive to do so at a directional change point, such as a pulley sheave or drum, when the rope strands naturally open up to accommodate flexibility.

For automatic application, a device known as a pressure boot is used. It is clamped on a tensioned straight section of the rope and lubricant gently pressured into the wires as the rope passes through the boot.

Contributing editor Ken Bannister is co-author, with Heinz Bloch, of the bookPractical Lubrication for Industrial Facilities, 3rd Edition(The Fairmont Press, Lilburn, GA). As managing partner and principal consultant for Engtech Industries Inc., Innerkip, Ontario, he specializes in the implementation of lubrication-effectiveness reviews to ISO 55001 standards, asset-management systems, and training. Contact him atkbannister@engtechindustries.com, or telephone 519-469-9173.

8613371530291

8613371530291