ss wire rope clamps free sample

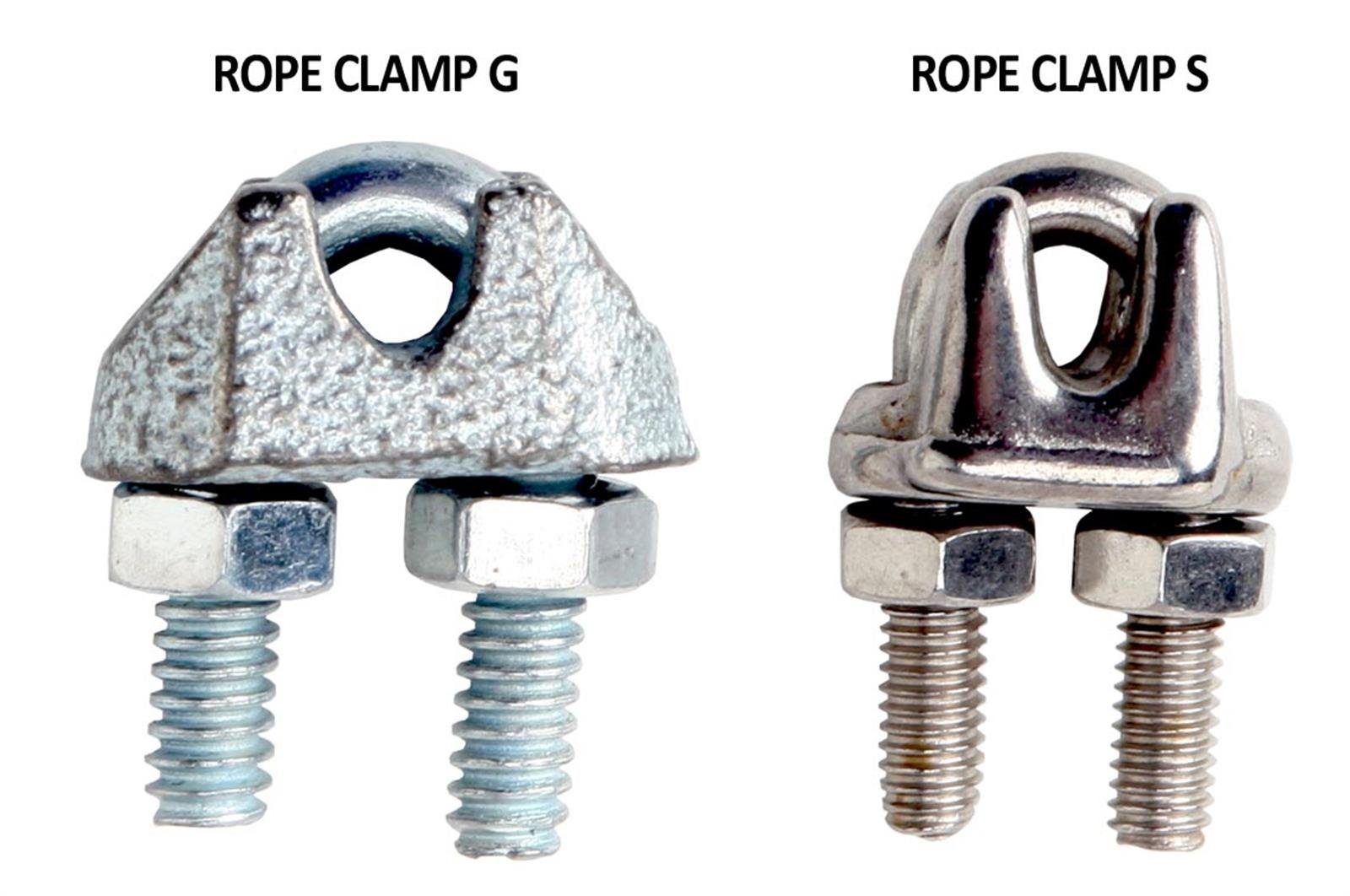

Murphy offers many sizes of wire rope clips in 4 different fabrications: zinc plated, stainless steel malleable, galvanized drop forged, and stainless steel drop forged.

You can use wire cable clips to secure the loose ends of your wire ropes. They often have nuts, u-shaped bolts, and cast saddles. You can put the wire rope in the bolt and then place the saddle over the bolt’s rope. By using the nuts, you can then secure the rope in its place.

There are a couple of ways to make the process stronger. For example, if you have a cable coated with vinyl, then you can take off the vinyl in the place where you put it in the wire rope clip.

We offer our clips in a range of materials, which gives you more options. You can use the clips for semi-permanent or permanent applications, or just temporary ones. You can use your hand tools to secure them to your stainless steel wire rope. They are also cost-effective.

You can count on our company to offer sturdy and long-lasting clips, so you can secure your loose ends well. We have good knowledge of the requirements of various industries, allowing us to offer you the best products. You can expect our wire rope clips to last for a long time.

With so many different kinds of rope clips and ropes to choose from, we know making a choice can be difficult. Luckily, Murphy Industrial Products, Inc. is here to help. Feel free to contact us today if you want to know more about our stainless steel wire rope clips and related products.

Wire rope clips, also called wire rope clamps, consist of a U-shaped bolt, a metal saddle piece, and two nuts. They are used in wire rope loop assemblies and are ideal for field installations. We offer several models to meet your specific needs.

Galvanized steel ropes in 11 different thicknesses: 1mm, 1.5mm, 2mm, 3mm, 4mm, 6mm, 8mm, 10mm, 12mm, 14mm and 16mm.Equipped with eyelets, hims, as winches, or forestry rope and set for tensioning.The steel ropes are processed in Germany after the DIN-European standard 13414.

Wire rope meter in 11 different thicknesses: 1mm, 1.5mm, 2mm, 3mm, 4mm, 6mm, 8mm, 10mm, 12mm, 14mm and 16mm.Smoothed in five different constructions: 7x7, 6x19, 7x19, 6x37 and 18x7 Available as a rotary wire rope.All offered wire ropes correspond to the DIN EN 13414-1.

galvanized wire ropes with eyelets in the strengths of 1mm to 16mm according to the specifications of the DIN-European standard 13414-2 made in Germany and optimally suitable for many applications.

Our steel cables with box galvanized steel, high quality and strict DIN specifications pressed in 2mm - 16mm strength.The cheese according to DIN6899 protects the wire rope from the inside to the load absorption point.

galvanized steel ropes tension with the help of firmly connected steel cable clamps or in set with clamps, tensionersand sleep.You will receive the sets both with smoothly cut steel rope as well as with a one-sided shew of the compression.

wire rope with hook in different versions: for light suspensions with snap hooks, as choker rope with high-strength sliding hookFor forstarts, steel cable with hooks and eyelets or as a wire rope for winches.The steel ropes are processed in Germany after the DIN-European standard 13414 and are pressed with carabiner hooks, load hooks or eyelethook of Grade 8.

Our steel cables with rope stopper " are compressed from galvanized steel in 1.5mm - 12mm strength and can be opened with an open end,to be ordered a loop or kausche.The one-sided pressed round clamp according to DIN 13411-3 fulfills the purpose of a stop terminal.

forestry ropes in seven different strengths of 5mm - 16mm.Available as choker rope with high-strength sliding hook, stop rope with hook & loop, as well as with grade 8 Load hook.The steel cables are processed in Germany after the DIN-European standard 13414 and are not highly damaged.

wire ropes for winches in eight different strengths: 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 14mm and 16mm.The wire ropes are made up to a thickness of 8mm annealed, so that fixing in the wind is very easy and easy to use.

Our Rotary wire ropes Get with the construction 18x7 in 5 different strengths. Through the,In opposite directed, strand layers, the wire ropes exert a low torque to an isolated load.The wire rope optimally serves as Hub - or Kranil to lift and depend on appropriate loads.

Labels With a compressed cheese according to DIN 6899 and a glow-separated end in 13 different lengths of 0.5m - 20m, optionally equipped with a wire cable holder and in the strengths of1.5mm - 8mm permanent & fast available.

Wire ropes for garage doors With a compressed cheese to DIN 6899 and a glow-separated end in individual length, optionally pressed with a M10x100 eye screw and in the strengths of 2mm- 5mm permanent & fast available.

Our steel rope sets are equipped with a steel cable and matching clamps, himming and wire ropes.You can choose from both different lengths, different strengths, as well as different equipment.

Our Fuse ropes for the event technique correspond to the BGV-C1 guidelines (security for events and production loads over persons) and can be optimal forLoads of 2kg - 100kg be used.

Our horizontal Rope locking system " SAVEKINGLINE?® corresponds to the DIN EN 795 type C? and serves as fall protection of personsFor the use on high-volume workplaces.The cable locking system is available in variable or defined length.

wire rope for a shoot for three different web lengths: 25m, 50m and 100m.The tension rope is one-sided melted and pressed on one side with a cheaper and equipped with a emergency element.

Welcome to buy the newest and competitive price DAWSON Stainless Steel Wire Rope Clips / Clamps U.S. Type from our factory. We"re one of the leading China manufacturers and suppliers, offering you the wholesale service and the OEM service at a discount. With CE certification, our products made in China in stock are high in quality and low in price. Please be free to get the free sample from us.

Alibaba.com offers 2,963 stainless steel wire rope clamp products. such as stainless steel, iron, and zinc. You can also choose from zinc plated, galvanized. As well as from bag, carton. And whether stainless steel wire rope clamp is silver.

Wire ropes are one of the most critical pieces of rigging and lifting hardware. You can use wire ropes for lifting, rigging, and tying loads of virtually any size, shape, and type. To make the most out of wire ropes, however, you need a few additional rigging equipment, one of which includes wire rope clamps.

Also known as wire rope clips, riggers often use this nifty little piece of hardware at the end of the length of a wire rope. You can use a wire rope clamp to:

In short, a cable clamp is what makes a wire rope one of the most versatile pieces of rigging hardware. As these clamps come in different shapes, sizes, and materials, you will need to choose one that perfectly fits your lifting and rigging application. But before we get down to that, first, you need to understand what is wire rope clamp, its types, and a few other things.

It is a simple mechanical device. A typical wire rope clip consists of a saddle, U-bolt, and two hex nuts. This simple device is suitable for less permanent rigging and lifting applications. You must never use wire rope clips to make industrial slings.

The ASME B30.9 Slings standard clearly states that riggers should not use mechanical wire rope terminations that require periodic adjustments to create slings. In other words, you need to be careful when using rope clamps. You can use a wire rope clip to create an end loop for a winching or crane cable. You can also use it to build perimeter cables or increase the length of a wire rope going through a D-shackle or eye bolt.

Based on their shape, there are two types of cable clamps, U-bolt and double saddle. They both have unique mechanical properties and hence applications.

These cable clamps consist of a U-bolt, two nuts, and a metal base called a saddle. The U-bold passes through the saddle, which you can tighten with the two nuts. They come in various sizes and types of materials, including stainless steel and galvanized steel. You can choose a U-bolt wire rope clamp depending on your rigging or lifting application.

Usually, there are three types of materials used for making rope clips. You can choose a material based on your application as each one comes with its unique strengths and weaknesses.

In this type of wire rope clip, the base or saddle is made from forged steel. The manufacturing process involves heating and hammering the clips into desired shapes. Riggers often use these cable clamps for critical and heavy-duty applications as they are very strong. You can see them in winch lines, crane cables, hoist lines, towing lines, scaffoldings, guy lines, and even tie-downs.

The base or saddle is made from cast iron. As cast iron lacks the metal properties of stainless steel, it is not that strong. So, the malleable galvanized wire rope clamps are not very strong. They can break under heavy usage. You will see them being used in small or light-duty applications like fencing, parameter cables, or guard rails.

Stainless steel wire rope clips are arguably the best ones. The base or saddle is made from high tensile strength stainless steel. They are durable and easy to use. You can find these cable clamps in temporary guard rails, flag posts, and other outdoor rigging applications.

Wire rope clamps are an essential part of the rigging hardware. You can’t do away with them. But you have to make sure to use the right ones to keep the load and the riggers safe. If a wire rope snaps because you used the wrong type of clip, it can lead to disastrous consequences.

The first step in choosing cable clamps is to buy them from a trusted and reputed rigging hardware manufacturer. The last thing you want is to use a defective or poor-quality clip. This will compromise the safety of your load and your crew.

As you can see, each wire rope clamp comes with unique properties. You need the instruction manual to understand when, where, and how to use the cable clamps. Make sure the clamps are accompanied by respective user manuals when making a purchase.

By now, you know that some cable clamps are more suited for outdoor environments, while others aren’t. As a result, carefully think about where you want to use the wire rope clips. For example, if it’s a heavy outdoor application, stainless steel wire rope clamps would be a great fit.

Taking into account how large and heavy the load is also equally important. Heavier loads will require strong cable clamps that won’t break under stress. Also, you shouldn’t use clips for any permanent rigging or lifting applications. They are suited only for temporary load applications.

Lastly, it’s always better to get an expert on board when shopping for wire rope clips. Maybe you can hire an engineer or expert with considerable field experience to help you choose the right types of clamps. An expert will help you take every detail into account before making the purchase. Remember, if you choose the right cable clamps right off the bat, you’ll save considerable time and money down the line.

Wire rope clamps are one of the essential rigging hardware. They land wire ropes more flexibility, allowing you to handle a wide range of applications with ease and safety. These are some tips that will help you choose the appropriate clamp for your need.

HHI sells different types of clamps and other rigging hardware, both online and offline. If you are looking for reasonably priced and high-quality cable clamps or other hardware, check out our online store or reach out to our experts.

While these clips are not designed to be used in an overhead lifting situation (swage sleeves should be used instead), wire rope clips are heavy-duty wire rope clips that used for sustaining overhead loads. Examples include guy lines, support lines, scaffolding, etc.

Install the first clip at the dead end side of the rope. The "U" side of the clip must always cover the dead end of the rope, and the "saddle" side of the clip on the live end of the rope. Place the nuts of the clip and tighten them using a torque wrench.

Next, apply the second clip and place it as close to the eye loop as possible. Same application for the clip. Tighten the nuts of the clip with a wrench. (If you"re planning on using more than two clips, do not tighten the nuts on the clip.)

Place more clips on the rope if you need more than two on the wire rope. Be sure to space them evenly between the end clips. Finally, tighten the end clips and apply tension to reach the recommended torque for the wire rope.

The Wire Rope Clamp can be used to join two ends of wire rope or for creating an eye end in the wire. These clips can be used in place of Nicopress sleeves, and unlike permanent sleeves, can be readjusted as needed. Made from Type 316 stainless steel, the Wire Rope Clip won’t corrode so it will stand the test of time outdoors. Designed for use with 1/8” wire. Wire Rope Clips are great for use in shade sails, tension membrane structure and architectural cable.

Please note: When using this hardware, it is your responsibility to make sure the finished structure is built in accordance with local building codes and that, given those codes, proper hardware is being used.

8613371530291

8613371530291