stahl wire rope hoist free sample

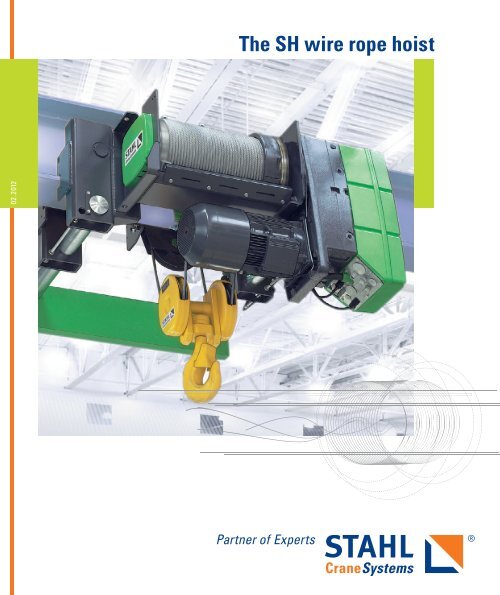

The SH wire rope hoist programme has been the embodiment of perfection in lifting and crane technology all over the world for many years. Compact, high-performing and particularly maintenance-friendly. Users, crane manufacturers and system manufacturers appreciate the modular system based on field-proven, low-maintenance components. Series manufacture of the standard components means economic advantages for you. And this combined with precise manufacture of off-standard components makes the SH wire rope hoist a widely acknowledged top quality product. The modular system permits practically...

The SH wire rope hoist The models and travel carriage variants Different types and variants of travel carriage for the SH wire rope hoist open up the most varied applications. Individually tailored to your specific requirements as stationary hoisting or towing equipment, for use with a trolley or crab, or for systems manufacture. The travel carriages are equipped as standard with two travel speeds. But in this matter too we are open to your requirements. Other speeds are available as options. Our wire rope hoists are known worldwide for their flexible and versatile use. Compact dimensions...

Cram S/stems Stationary model The SH wire rope hoist can be used as stationary hoisting or towing equipment, for example in systems manufacture. Depending on the application, the rope lead-off angle, the attachment of the hoist and the mounting position of the hoist motor can be varied. OE double rail crab The OE double rail crab is intended for use on double girder overhead travelling cranes. The extremely compact construction makes very low approach and headroom dimensions possible and the available space can thus be used to the full. The double rail crab is available with various track...

The SH wire rope hoist It’s reassuring to know what convincing technology is concealed in the SH wire rope hoist. The largely maintenance-free components of the modular wire rope hoist are optimally matched to each other. They guarantee constant performance, high efficiency and long service life. The standard safety components such as gear limit switch, motor temperature control and overload device, or even an optional additional brake, increase workplace safety. ■ Highly flexible special rope with long service life ■ Field-proven enclosed rope guide in spheroidal graphite cast iron has no...

■ Low-maintenance asbestos-free brake; needs no adjustment ■ Long service life thanks to generously dimensioned brake ■ Brake easily accessible for inspection from outside ■ Motor management ensures low wear ■ IP 65 protection ■ Special-purpose motor for hoisting applications ■ Classified according to ISO, high duty cycle and switching operation frequency ■ IP 55 protection, thermal class F ■ Motor outside rope drum, highly efficient motor cooling, maintenance-friendly ■ Temperature control by ptc thermistors ■ Optimised ratio of drum to sheave diameter ensures low wear on rope ■ Flexible...

The SH wire rope hoist There’s always room for improvement. Although it is already first-class in standard design, you have the alternative of making your SH wire rope hoist even safer, even more cost-effective, even more convenient by selecting from numerous mechanical, electrical and electronic options. As a welcome side-effect, the service life of the wire rope hoists is prolonged. The extensions to the programme increase the performance of the wire rope hoist and adapt it to your individual requirements. Here we show you some examples of the options available. If you need further...

■ Continuous load monitoring by overload cut-off even if hoist is at a standstill ■ Overload protection with ALC automatic load control ■ Load spectrum memory for load-related operating time summation ■ Operating data registration, e.g. operating hours, load spectrum, motor switching operations and load cycles ■ Data exchange with PC possible ■ Travel limit switches on trolley/crab for cross travel, optional ■ Limiting for both directions of travel ■ Switchover from "fast/slow" (predisconnect) ■ Switch contacts designed for control current ■ IP 66 protection ■ SLD four-digit 7-segment load...

The SH wire rope hoist | The options ■ The brake release device permits the hoist brake to be released manually and thus the load to be lowered during a power cut. ■ As an option, every hoist can be equipped with this supplementary equipment to the standard brake. ■ Redundant brake system provides increased safety ■ Intercept and holding brake, prevents the load falling even if the gear should break ■ Control is effected with a centrifugal switch or safety PLC Frequency control ■ Smooth starting and braking characteristics ■ Load swing greatly reduced ■ Fast, precise positioning of the...

The SH wire rope hoist Engineering means innovation and individuality. Constantly redefining the lifting and transporting of loads for complex requirements even in explosive areas is a job for our experts. Drawing on one of the widest product ranges of standard components, they regularly develop modern, individual off-standard and customised solutions. Hardly any other manufacturer of lifting and crane technology can offer you this diversity of precisely designed top quality customised solutions with maximum cost-effectiveness. The SH wire rope hoist programme forms the basis for a wide...

Example 1 TDC Twin Drive Concept The TDC Twin Drive Concept TDC is the uncompromising solution for hoists complying with DIN EN 14492-2, Annex B. Hoists in TDC design are intended for transport of molten metals and for use in high-risk applications: acids, alkalis, gases or transport over gas and acid pipelines. They are equipped as standard with two motor-gear units. Both motors are always synchronously controlled. The brakes mounted on the two motors are designed so that in an emergency each one is capable of braking or holding the load by itself. The two brakes are activated in...

2 Getting to know the wire rope hoist ..................................................................................................................................................... 7

What’s special about this: we can com- bine the individual components at will so that each of our wire rope hoists is ideally designed for your requirements. Regard- less of whether it’s a standard or an indi- vidually customised product.

The SH wire rope hoist from STAHL CraneSystems is one of the best hoists in the world. The SH Compact, powerful and particularly maintenance-friendly modular system permits practically unlimited combinations of the individual components. Five frame sizes, 26 S.W.L. variants between 500 kg and 28,000 kg: this makes the SH wire rope hoist the best hoist both for standard and off-standard solutions.

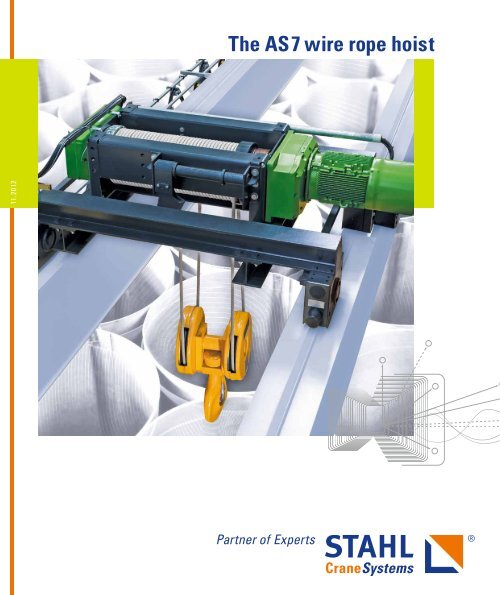

The AS 7 range supplements the SH series in the upper S.W.L. range up to 125,000 kg. Its compact construction makes it particularly suitable for systems manufacture and applications in restricted spaces. The AS 7 wire rope hoist is used either as stationary hoisting or towing equipment or mounted on crabs on double girder cranes and systems.

The combination of two AS 7 wire rope hoists as a twin hoist offers an interesting alternative to comparable hoists in a similar load class as regards technology and price. As a twin hoist, the AS 7 wire rope hoist has a higher hoisting speed than conventional hoists, considerably greater lifting heights and maximum safe working load of 125 tonnes.

STAHL winches lift heavy loads up to 160 t. Their powerful hoist motors and robust, low-maintenance design make them perfectly equipped for rugged everyday work.

In contrast to wire rope hoists, winches require only a low number of rope reevings even for heavy loads, this makes them particularly compact and cost-effective

STAHL wire rope hoists is designed from a technically mature modular system that guarantees cost- effective production at the highest level of quality.

We can combine the individual components at will so that each of our wire rope hoists is ideally designed for any of your special requirements : an individually customised product will be delivered to your specifications from standardized, field-proven components.

MANUAL RELEASE OF HOIST BRAKE:The brake release device permits the hoist brake to be released manually and thus the load to be lowered during a power cut. As an option, every hoist can be equipped with this supplementary equipment to the standard brake.

ROPE DRUM BRAKE:Redundant brake system provides increased safety. Intercept and holding brake, prevents the load falling even if the gear should break. Control is effected with a centrifugal switch or safety PLC.

FREQUENCY INVERTERS FOR “LIFTING”:Smooth starting and braking characteristics. Load swing greatly reduced. Fast, precise positioning of the load, corrective switching operations rarely necessary. The reduced dynamic load means a longer service life for hoist motor and gear and reduces stress on the whole system.. ESR function (Extended Speed Range) for higher hoisting speeds with partial load. Worldwide approvals for all frequency inverters. Certified in compliance with DIN ISO 9001.

TWIN DRIVE CONCEPT:Prevents sagging of the load even when the gearbox fails. Permanent brake, drive and load monitoring. Two synchronously controlled hoist motors and brakes. Two manually releasable brakes for emergency lowering. Robust, completely encapsulated system. Service and safety brake of identical design. Up to 60 % higher load capacities when transporting non-molten metals.

LOAD DISPLAY:SLD four-digit 7-segment load display (Stahl Load Display), large format, luminous red, available with various interfaces including CAN. Choice of 60, 100 or 150 mm digit height. No additional sensor is required as the standard load sensor is used.

SMC MULTICONTROLLER:Continuous load monitoring by overload cut-off even if hoist is at a standstill. Overload protection with ALC automatic load control. Load spectrum memory for load-related operating time summation. Monitoring of the motor temperature of the hoist motor and travel motor. Operating data registration, e.g. operating hours, load spectrum, motor switching operations and load cycles. Data exchange with PC possible.

EMERGENCY HOIST LIMIT SWITCH:In standard version, the hoist is equipped with a gear limit switch for top and bottom hook position and an operational limit switch for top hook position. As an option, up to eight switching elements can be fitted to the switch. This permits for example further stopping positions and operational limiting in bottom hook position.

Motor -Motor is located outside rope drum. The SH series has a highly efficient motor cooling, maintenance-friendly, temperature control system by ptc thermistors. IP 55 protection, thermal class F. Classified according to ISO, high duty cycle, and switching operation frequency.

Control -Robust control pendant with emergency stop palm button and control cable. All switching elements for hoist, cross, and long travel are 2-step. IP 65 protection. Additional control pendant options are available.

Wire Rope & Guide -Highly flexible, long life wire rope. Single-grooved rope drum helps guides and secures wire rope for low resistance lifts. Spheroidal graphite cast iron enclosure for wire rope and guide withstands various temperature ranges. 360° rope tensioner, helps prevent slack rope.

Overload Protection -Permanent electronic monitoring of suspended loads. Limited maximum load by load measurement at the rope anchorage for multiple reeving.

The SH Series is a heavy-duty, compact, low maintenance wire rope hoist from STAHL. Providing load capacity ranges from 1 Ton to 15 Tons. Standard dual speed motor for smooth lifts with speed options. The STAHL SH wire rope hoist can be used by itself or together with a trolley for standard cranes. Optional short headroom monorail trolley and double girder trolley available. IP 66 protection for outdoor use without a protective roof.

The SH wire rope hoist programme has been the embodiment of perfection in lifting and crane technology all over the world for many years. Compact, high-performing and particularly maintenance-friendly. Users, crane manufacturers and system manufacturers appreciate the modular system based on field-proven, low-maintenance components. Series manufacture of the standard components means economic advantages for you. And this combined with precise manufacture of off-standard components makes the SH wire rope hoist a widely acknowledged top quality product.

The modular system permits practically unlimited combinations of the sub-assemblies to produce your individual solutions. The SH series from STAHL CraneSystems is available for the load capacity range from 500 kg to 25,000 kg in five frame sizes with 26 load capacity variants. The wire rope hoists can be used as stationary models or together with a trolley or crab in standard cranes, off-standard cranes or systems manufacture. If your requirements are exceptional, the experts in our engineering department will develop customised solutions tailored to them.

Various off-standard designs are available for use in particular conditions. IP 66 protection for example is required for outdoor use without a protective roof or if the hoist is exposed to water jets. If there is a danger of the formation of condensation, or in arctic temperatures, space heaters are required. Even in explosive atmospheres you do not have to manage without the SH wire rope hoist. On request, the entire wire rope hoist programme is available in explosion-protected design for Zone 1, Zone 2, Zone 21 or Zone 22. It’s no coincidence that we are market leader for explosion-protected lifting technology and crane components.

The adaptable wire rope hoists from STAHL CraneSystems in a consistent modular system are designed for load bearing capacities from500?kg to 160,000?kg.

The SH wire rope hoist can be used as a stationary hoisting or towing device, for example, in plant construction. The rope lead-off angle, attachment of the hoist and the hoist motor end position can be varied according to the application.

Knowing the sophisticated technology behind the SH wire rope hoist is reassuring. The largely maintenance-free components of the modular chain hoist are optimised to work together. They guarantee consistent performance, high efficiency and a long service life.

There is always room for improvement. Numerous mechanical, electrical and electronic options are available to make your outstanding standard SH wire rope hoist even safer, more economical and convenient.

The service life of the wire rope hoist is also extended. Improve the performance of your wire rope hoist and adapt it to your individual needs with the options. Some examples of options are presented here.

Fundamental information You have purchased a product manufactured by STAHL CraneSystems GmbH. This wire rope hoist has been constructed in compliance with the applicable standards and regulations. Inspect hoist for damage caused in transit immediately upon delivery. Report damage caused in transit and after consulting the manufacturer/supplier repair or have repaired before installation and commissioning.

3 Installation 3.2.3 Fleet angles The rope guide must be adjusted to the fleet angle. Observe also the radial rope exit Type angle γ. γ° γ SH 3 53° SH 4 60° SH 5 53° SH 6 53° 3.2.4 Angles of installation •...

3 Installation 3.7.8 Overload cut-off Description of system • prevents an overload being lifted. If an overload has been established, the load can only be lowered. The switch is set in the factory. Corrections are only permissible in special cases, see page 57. In certain applications, wire rope hoists may also be used without an overload cut- off.

3 Installation Reeving rope (SH3 - SH6) Reeve the rope as shown in the schematic drawings and attach the end of the rope at the rope anchorage. Caution! The bottom hook block must hang horizontal (./2-1) SH3 - SH5 2/2-1 4/2-1 8/2-1 SH3 - SH5...

• Secure loose end of rope with rope clamp (3) approx. 50 mm from the end of the rope. See table for tightening torque. • Max. projection of rope wedge SH 3 - SH 4 x = 6mm ; SH 5 - 6 x = 15mm max.

3 Installation Rope anchorage (SH3 - SH5) Length L SH 3 SH 4 SH 5 SH3.. 216 241 SH4.. 265 290 SH5.. 334 366 4/2-1 SH3.. 216 241 SH4.. 265 290 SH5.. 334 366 Length L SH 3 SH 4...

3 Installation Rope anchorage(SH6) SH 6 Length L L2-L5 L2-L5 2/2-1 4/2-1 L2-L5 8/2-1 L3-L5 SH 6 Length L L2-L5 L2-L5 4/2-1 L2-L5 SH 6 Length L L2-L5 L2-L5 4/2-1 L2-L5 8/2-1 L3-L5 *1 Gear side 09.07...

6 Inspection and maintenance 6.6.5 Setting limit switch (continued) Switching point A↓ (S1) "Emergency limit switch bottom hook position" (Minimum clearance between rope guide (S) and clamping claws (K) for rope anchorage = 20 mm, see sketch) Set bottom hook position so that the bottom hook block does not touch the ground (would cause slack rope).

6 Inspection and maintenance 6.8.5 Description of optional operational hoist limit switch system An additional operational limit switch for disconnecting in top and bottom hook position during normal operation can be fitted as an option. In this case 2 cut-off ↑...

6 Inspection and maintenance 6.8.8 Setting hoist limit switch The cover of the limit switch must be removed to set the contacts. This exposes live contact connections. There is thus a danger of contact with live parts! The limit switch can be adjusted at the setscrews (S1)-(S3) or (S1)-(S4): Turning to the left: switching point is moved "downwards", Turning to the right: switching point is moved "upwards".

6 Inspection and maintenance 6.8.8 Setting hoist limit switch (continued) Combined operational and emergency hoist limit switch: ↑ 1. A (S1) ↑ 2. B (S3) ↓ 3. A (S2) ↓ 4. B (S4) ↑ Switching point A (S1) "Emergency limit switch top hook position" •...

6 Inspection and maintenance 6.1.2 Replacement of wire rope due to broken wires Twist-free wire rope Rope diameter [mm] Number of external strands Rope make-up * 18X7+SE d1315z d1315z d1315z d1315z d1318 Broken wires visible 1Bm, 1Am (FEM 9.661) 2m - 4m over a length of [mm] Broken wires visible 1Bm, 1Am (FEM 9.661)

37, 40,44, "Setting hoist limit switch". • If the new rope twists after some time in operation, untwist the rope immediately. See page 25, "Reeving rope" and "Removing rope". Type SH 3 SH 4 SH 5 SH 6 10.08...

6 Inspection and maintenance 6.11.5 Fitting rope guide • Grease thread and rope guide groove thoroughly. • Place the half-ring (1) with the short window section onto the rope drum next to the last rope winding so that the rope exits from the region of the window (x). •...

6 Inspection and maintenance 6.11.6 Inspection and maintenance of rope sheave • Check rope sheaves for wear. We recommend having them checked by personnel trained by us. They should also be checked for easy running, indicating that the ball bearings are in good condition. Wear on rope sheave Notes on limits for wear Rope sheaves...

8 Technical data 8.3.2 Pole-changing hoist motors 60Hz Hoists Motor 60 Hz Main fuse gL / gG *3 380...415 V 440...480 V 550...600 V 380... 440... 550... 415 V 480 V 600 V %DCD In [A] Ik [A] In [A] Ik [A] In [A] Ik [A]...

8 Technical data 8.3.3 Frequency-controlled hoist motors 50Hz 50 Hz cos ϕ FU Hoist motor 380-415 V 480-525 V Mains fuse 380-415 V 480-525 V In [A] I max. FU [A] In [A] I max. FU [A] 4H33 12,8 0,98 4H42 0,98 10,6...

Die Adressen von über 100 Vertriebspartnern weltweit finden Sie im Internet auf www.stahlcranes.com unter Kontakt. You will find the addresses of over 100 sales partners on the Internet at www.stahlcranes.com under Contact. STAHL CraneSystems GmbH, Daimlerstr. 6, 74653 Künzelsau, Germany Tel +49 7940 128-0, Fax +49 7940 55665, marketing@stahlcranes.com...

As a company that is routinely called out to service, inspect, and repair overhead cranes and hoists, we’ve put together this list of the five most common problems with overhead cranes so that you have a better understanding of what issues or problems you might encounter during the life of your overhead crane. And most importantly, what you can do to help prevent or mitigate them.

Damage or degradation to wire rope is one of the most common issues that you may experience with an overhead crane system. There are a number of common wire rope problems, including any of the following:The wire rope has jumped out of the reeving system

Many operating conditions can affect the life of wire rope. Bending, stresses, loading conditions, speed of load application (shock load), abrasion, corrosion, sling design, materials handled, environmental conditions (heat or chemical exposure), lubrication, and history of usage will all factor into how long wire rope can stay in service.

The best way to prevent damage to, or failure of, a wire rope is to inspect it prior to each shift. If any evidence of damage is observed, the wire rope should be properly disposed of to prevent further usage.

Also, make sure that the wire rope is properly lubricated. Proper lubrication of the wire rope has two primary benefits:Reduces friction as the individual wires move over each other

An overhead crane that is out of alignment and skewing as it travels down the runway can cause significant stresses and damages to the entire crane system. The problem with a crane that isn’t tracking properly is that over time, forces that weren’t accounted for in the design and installation of the overhead crane cause stresses to the runway beams themselves and also to the tie-backs or building support structures.

A crane that isn’t tracking properly also causes extensive wear to the wheels, wheel bearings, and wheel flanges—as well as premature wear to the motor drives and other equipment.

There are certain signs that your crane may not be aligned properly and is skewing as it moves down the runway. When your crane is in operation, be aware of the following:Loud scraping sounds

If the wheels, wheel bearings, or wheel flanges begin to wear or break down prematurely, it can be an indication that the crane is skewing and not properly tracking down the runway system. Skewing of the crane can cause excessive wear and stress on the wheels, but also on the runway beams and support structures as well.

Wheels tend to wear out faster on a crane that was installed using an existing rail system as opposed to a new installation. Unless the runway has been properly surveyed prior to installation, the runways may be misaligned or the rails may be out of tolerance.

You may also find that pendant controls can become disconnected or pulled out of the hoist. The reason that this can occur is because the operator pulls on the pendant to maneuver or position the crane—especially on jib cranes or workstation cranes. If your controls become unresponsive, you may need to check to see if the pendant became disconnected from the hoist, or have the system serviced and re-wired if any wires become loose.

Not only will regular crane inspections keep you in compliance with sanctioning bodies like OSHA, ASME, and CMAA but it will help keep the crane and hoist equipment operating at top efficiency, help to keep your employees safe, help reduce costly down time, and extend the life of the equipment.

You should receive some type of owner’s manual or maintenance interval book from your crane manufacturer. The manufacturer’s service recommendations are provided based on the duty cycle and capacity of your specific crane, so follow the manufacturer’s recommendations for crane and hoist maintenance, as well as lubrication and inspection intervals.

8613371530291

8613371530291