steel wire rope for cranes supplier

Years of continuously setting incredible standards in the manufacturing of rotation resistant and non-rotation crane ropes in various construction and engineering sectors has given SWR & Teufelberger a real cutting edge when providing customers with solutions to their steel wire rope requirements.

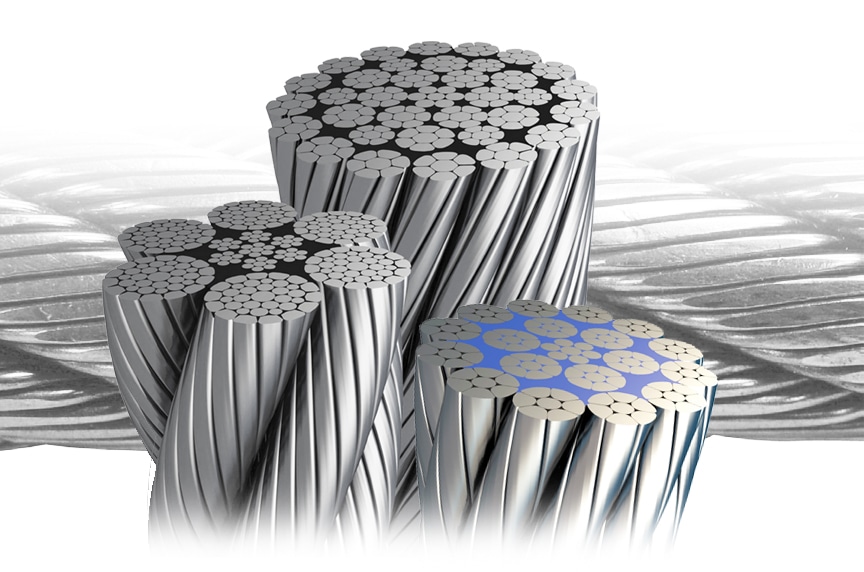

With over 130 years’ experience in the manufacturing of steel wire ropes Teufelberger strive to continuously maintain and improve quality by using only the highest quality of raw materials, professional quality inspections and modern state of the art manufacturing facilities when producing their SUPERFILL® and PLASTFILL® multi-strand steel wire ropes.

Each single strand of wire that is used in the manufacturing process of Teufelbergers ropes is used with purpose. From the core out to the exterior of all wire ropes they are designed with sophisticated engineering by professional bodies to provide innovative and tailor-made solutions.

Offering worldwide availability for both parts and wire rope along with the latest SUPERFILL® and PLASTFILL® rope technologies Teufelberger guarantee the highest of safety for your daily operations along with extremely high breaking forces and high resistance to challenging conditions.

All materials are fully certified and have full traceability in line with our ISO9001 procedures. All ropes are manufactured to the European standard EN 10204 3.1/LR

Steel Wire rope is a very complex machinery element which primary function is the transmission of tensile forces. Its basic constructional design allows repeated changes in the direction of pull through reeving systems incorporating drums and sheaves. General purpose wire ropeshave been developed and standardized in national and international standards . However the increasing demand for higher breaking strength, greater flexibility, better rotation resistance , and extended rope life cannot be met by such general purpose steel wire ropeconstructions. Horizon Cable is a stocking distributor for Python Wire Rope, which through research, development and engineering over many years has developed rope constructions that have significantly improved operating life. There are vast array of applications that Python Wire Rope can be installed by Horizon Cable Service in Oklahoma, Texas, Wyoming, Kansas, North Dakota and New Mexico to improve service life. Below are a few of the proven applications for our high performance wire ropes:

One benefit to High Performance Wire Rope is the increased breaking strength over standard wire ropes. This is achieved in the manufacturing process by compaction processes. Standard ropes are drawn which create a round outer circumference, but compacted ropes have flat outer service. The two types of compaction are STRAND COMPACTION and SWAGE COMPACTION. Strand compaction is the most popular, in this process the compaction is applied to the individual wires, where the swage compaction is applied to the entire wire rope itself. Both have their advantages for particular applications.

Rotation resistant ropes can fall under three different classes Spin Resistant, Rotation Resistant, and Non Rotating. In all of these types of wire ropes the outer layer is twisted opposite for the inner layers. Rotation resistant and spin resistant ropes will have one inner layer, while non-rotating lines will have multiple inner strands rotating a different direction from the outers.

6 strand high strength swage compacted rope that is perfect for applications that require a crush resistant rope to be used in multi-layer winding systems; e.g. boom hoist on lattice boom mobile and tower cranes

Python Compac 18 is recommended for bot multipart load and single part applications where medium rotational stability is needed. Use as main and auxiliary hoist line on Grove, link belt, Manitowoc, Terex and other us made mobile and truck cranes. Also used very successfully as a pulling rope on underground cable pulling winches.

Main and auxiliary hoist line for European type mobile and for all types of construction tower cranes which require a high strength rotation resistant rope construction. Excellent rotation resistant properties make this rope the preferred choice for all single and multiple line reeving systems.

Numerous industries require lifting equipment to facilitate their operations. Out of those hundreds of sectors, the construction industry is the one whose operations rely the most on a diverse range of rigging solutions that have to be able to hoist light to heavy loads. All lifting operations, especially the heaviest ones, must be done with dependable and safe wire ropes. At Kennedy Wire Rope & Sling, we source our wire rope from manufacturers whose products meet, or exceed, industry standards. Our mission is to provide clients with a product that is nothing less than exceptional.

Wire rope is the best product for doing the heavy lifting for crane operations. Wire rope is made from multiple steel wires that are put together around a core. Steel wire offers strength, flexibility, the ability to handle stress, and works well for bearing heavy loads, which is the whole purpose of crane operations. Wire rope is also extremely resistant to corrosion, rotation, fatigue, crushing, and abrasion. Kennedy Wire Rope & Sling Company offers many different types of wire rope for your crane needs. Many industries, such as the construction, manufacturing, and oil and gas industry, rely on our crane products to meet their needs.

Flex-X 9: Features compacted strands and swaging for increased stability and extra drum crushing resistance. It’s designed for boom hoist applications and tubing line applications where drum crushing is a challenge.

19×19 Compacted: A very flexible rope with excellent resistance to rotation and high tensile strength. Best for use with choker ropes, trolley lines, winch lines, hoist ropes and boom lines. Applications include cranes, excavating, dredging, marine, oil and logging.

35×7 Class: Features a high strength-to-diameter ratio. Its unique design minimizes rotation and torque of the rope at normal load ranges of 0 to 20% of the rope’s minimum breaking force. Excellent when load control is vital.

8 x 19 Class: Is resistant to crush and built within ISO 9001 specifications. It has one of the most stringent testing processes of any rope. From creation to deployment, industry experts know what this rope can take.

Let our experienced on-site services team help you with your next wire rope slings installation, inspection, and maintenance procedure. This will ensure that you will get the most out of your equipment, with minimal downtime.

At Kennedy Wire Rope, our teams are dedicated to being and remaining the industry’s leading supplier of hardware used in rigging, construction, and oil and gas operations. We also have the licenses and insurances that our customers’ depend on. Call us today at 800-289-1445 and speak with a friendly representative. We welcome any questions concerning any of our products and rigging services.

The global success of Usha Martin’s crane rope is based on an uncompromising commitment to quality. Our wire rope for cranes are designed to provide longer life, less downtime, and superior resistance to bending fatigue for lifting applications under adverse working conditions. The company’s quality management system is certified per standard ISO 9001: 2015, along with manufacturing assessment certifications from ABS, DNV-GL, and Lloyds. Crane ropes supplied by Usha Martin and its group companies are supported by an extensive global network, offering expert advice to both crane manufacturers and end users.

With six decades of excellence in manufacturing specialty steel wire ropes for cranes, we have developed next-generation crane ropes for different applications to meet the specific needs of customers. These cover all types of wire rope for cranes, including specially designed compacted ropes with plastic-impregnated cores and rotation-resistant ropes. All steel wire ropes undergo stringent quality testing procedures. We offer a wide variety of hoist ropes to suit the needs of different industrial applications.

Crane wire ropes play an important role in ensuring a smooth conduct of work processes in harbors, off-shore platforms or various other applications where cranes are needed. Whether you need tower crane ropes or offshore crane ropes, galvanized or stainless steel ropes, you will find the optimal solution in our company.

When you are picking up crane wire ropes, make sure that the breaking strength of new wire ropes is five times the sizes of the largest load for lifting applications and three times for pulling applications.

Bridon-Bekaert steel wire rope specialists for many years have worked globally together with the major crane manufacturers (OEM) to develop a range of cost-effective ropes for the demanding environments in which today"s construction cranes operate. Our specialists are available to assist users in obtaining maximum performance and reliability from a wide range of globally available Bridon-Bekaert crane ropes.

The cable on a crane moves through a series of motorized pulleys that are controlled by the crane operator to raise and lower items. For safety reasons, a crane usually has several wire rope cables that are attached to the object being lifted. This helps to prevent putting too much strain on a single cable.

To create wire rope cable, manufacturers begin with long strips of high tensile strength metal that are tightly woven together into strands. A large majority of wire rope cables are constructed using steel due to its durability and strength. Several strands are then spun and pressed tightly together into a helix using a machine.

The newly created wire rope cable is then rolled up onto a spool and shipped out, or it is rolled up onto a pulley to be used with a brand new piece of heavy equipment.

Stationary ropes bear tensile forces and are loaded with fluctuating levels of stress. These are the types of cables that would be found on a suspension bridge.

Finally, wire rope slings (also called stranded ropes) are used to harness all kinds of goods. These are bent over sharp edges of goods to hold them in place.

TEUFELBERGER high performance steel wire ropes are being used for various tasks on cranes around the world. In order to keep their quality at the highest level, a team of experts has been working continuously on upgrading existing and developing new products. In these endeavors, we work together closely with our renowned customers so as to find the perfect solution for their high demands.

Our range of services encompasses rope assembly, splicing, exchanging ropes, and even providing customized training. For these purposes, our service teams are deployed to many countries of the globe.

soLITE® by TEUFELBERGER, the first-ever fiber rope featuring a steel wire rope construction, impresses its users by providing 10% more in loading capacity and 80% less in weight than its steel counterparts. Developed together with the crane specialists at LIEBHERR, it has already taken the place of steel wire ropes in challenging lifting applications.

We strive to create premium products in a class all their own, but we believe our global impact is so much bigger than that. Press play to learn what makes WireCo a world ahead of other companies.

Where required crane ropes can be supplied with anti-spin / rotation proof properties as well as other key elements such as bend fatigue and abrasion resistance. For more information on the products and services we supply, email RSD today or call 01384 78004 to discuss your current requirements.

There are many types of cranes which require the use ropes and cables, there are also many types of rope constructions with varying properties, which means there are many things to consider when purchasing new crane ropes.

Overhead cranes, mobile cranes, all terrain cranes, crawler cranes, tower cranes, gantry cranes, off-shore pedestal cranes, dredger cranes, piling cranes, harbour cranes, and container cranes all use wire crane ropes, some cranes use more than one. You can find some helpful information on thesafe use of cranes here.

Crane ropes can be used for main hoist rope, boom rope, derrick rope & closing rope. Grab rope, hoist rope, tower erection rope, boom rope and trolley rope are other examples. Matching the ideal rope for your type of crane and application is not so easy. This is because no single rope will fit all requirements. For example no one rope is fatigue resistant, crush resistant, abrasion resistant and rotation resistant. Nor have the necessary breaking strength, rope diameter and/or rope structure stability. So choosing the right rope may require a little research.

Good examples are: boom hoists should be crush resistant. Clam shell closing lines must be resistant to bend fatigue, whilst overhead crane hoist rope requires strength and stability. For a container crane hoist rope or trolley rope the rope will need to be a combination of resistance to bending and abrasion as well as fatigue resistance. Tower erection rope should be rotation resistant. Trolley rope needs low elongation properties and boom hoist rope needs high flexibility and breaking load strength.

It is usually recommended to choose a crane wire rope that is an exact or close match to the original rope supplied with the crane by the manufacturer, or else choose more superior crane ropes.

A crane ropes strength is generally referred to as the minimum breaking load or force (MBL). It is possible to increase the MBL for most rope diameters in two ways:

By increasing the tensile strength of the actual wire used during the manufacturing process the MBL will increase. 1770N/mm², 1960N/mm² & 2160N/mm² are common wire tensile grades used in crane ropes. It is also feasible to raise the steel fill factor of the rope to increase its strength further. The fill factor measures cross sectional areas of the rope.

A more effective way of increasing the strength of a rope is to compact them. The individual strands may be compacted which reduces the number of voids throughout the rope. It also increases the surface contact area. This type of compacted wire rope has many other benefits which are discussed on our compacted wire rope page. Lower stress levels take place when conventional ropes are changed for compacted wire ropes. Frequently resulting in easier operation and longer working life. This is why the majority of our crane ropes are compacted.

The correct diameter is crucial to performance on a crane. A wire rope which is too big or too small for the drum and sheaves will increase wear and fatigue. This could cause premature rope failure. Additionally it is crucial that you make sure the diameter is consistent over the length of the rope. Inconsistency could cause wire breaks and shorten the ropes life. The use of compacted rope enables the same strength as a standard rope of the same construction but with a smaller diameter. It is always wise to select a rope with the same diameter as the original.

When choosing a crane rope, a wire core as opposed to a fibre core will improve its resistance to crushing. This is important when sheaves and drum winding is used.

This is the capability of the rope to tolerate repetitive bending under constant or variable loads. This is possibly one of the most important properties of a crane rope due to its use with sheaves. As loads increase when a reeving system is used the fatigue rate will also increase.

Non-rotating wire rope is an ordinary or reverse lay rope and possesses qualities so that each wire rope structure will possess natural torque properties. This is where both ends of the rope are secured and an applied force will create torque on the fixing points. The torque produced will depend on the scale of the force applied as well as on the construction of the crane ropes.

It is important to note that single layer Langs lay ropes possess dreadful rotational properties. And so should only be utilised where both ends are firmly fixed.

The primary reason for abrasive wear on crane ropes is brought on by other apparatus like winding drums and sheaves. This is because the rope wears between adjoining laps when wound on or off the drum. Selecting compacted rope may minimise this kind of wear and tear.

Whilst selecting crane wire rope, keep in mind that the bigger the outer wires the better resistance to wear and abrasion. Therefore ropes with the lower the number i.e. 6x19 will be better than a higher number i.e. 6x36 when utilised where wear and abrasion are the key reason for rope deterioration as opposed to bend fatigue.

Again a compacted rope with its smoother surface will offer a wider bearing surface to conventional rope, this leads to improved resistance to wear and abrasion.

If crane ropes are going to be utilised in a place where corrosive substances are used then it’s best to select a rope which has a galvanized finish. A ‘P.I.R.’ or plastic impregnated wire ropes are most suitable for severe craning operations, or plastic coated wire rope will also help to avoid corrosion.

When lubricating your rope with a high performance lubricant has a major effect regarding the life of the rope, especially in relation to bend resistance. Lubricating the wire rope additionally minimizes abrasive wear and extends fatigue life

Rope Services Direct can fit most fittings to your crane rope, having our own press facilities, we are are also able to supply a range of lifting gear and accessories to work well with cranes. From slings and shackles to chain blocks and trolleys.

Looking for wire rope? Trinity Sling has been known as the go-to supplier for overhead lifting supplies and rigging for decades. Since its inception, Trinity has produced rigging and lifting solutions for many different industries, like construction, manufacturing, oilfield and fracing, transportation, and architectural railing. Today, the company continues to expand its reach, supplying across North America while calling North Texas home.

Trinity Sling distributes the highest quality wire rope both from domestic and European manufacturers. Trinity’s domestic supplier, Washington Wire Rope, manufactures general purpose and oilfield ropes in the USA to industry standards. Among their products that Trinity carries are crane ropes, drill lines, sand lines and tubing lines for construction and oilfield applications. Trinity also carries Verope-branded crane ropes, European-engineered specialty ropes for all types of cranes used in construction and manufacturing.

Trinity Sling has built strong vendor relationships with Washington Wire Rope and Verope in order to be a great supplier both to our new and existing customers. Our staff understands deadlines and RFQs and works diligently to partner with our customers to provide products of high quality that they can count on.

Stock up on every variety of steel wire rods at the Alibaba metalworking store. Our listings feature wholesale steel rods from a network of dependable Chinese manufacturing partners. If you need to source steel rods for construction projects, you"ll find products that are robust and durable. And if you need welding rods, they are easy to find via our search engine. Track down the steel wire rope for crane you need at affordable prices at Alibaba.com.

What can you do with the steel wire rods available from Alibaba"s wholesale store? One common use for steel rods is in the welding sector. Steel works well as a welding rod material thanks to its high ductility, meaning that welds are relatively strong and long-lasting. Choose a low carbon rod and you"ll be all set for successful welds in industrial settings and workshops alike. However, steel wire also has applications beyond welding. You can use it as wiring in electronic circuits and power distribution systems and it works especially well in high temperature settings as armored cabling. Find the ideal steel wire rope for crane for every industrial use at Alibaba.com.

Steel wire rods also have applications in everyday life. For example, you can use coils of steel wire to construct fences and barriers both inside and outside homes. It"s a common material in agricultural businesses thanks to its toughness and resistance to oxidation. Use it to create reinforcement cages, enclosures for equipment, or add it to concrete to add extra strength where it really matters. From welding to concrete reinforcement, steel wire rope for crane will always find a use. And whether you need small batches or huge bulk orders, our metallic materials catalog is the ideal place to look.

What are cranes wire used for? Crane wire is used in the cables of our customers, to manufacture cranes wire for gains. These types of crane wire are used to manufacture cranes wire for the cables of various types. The wire is usually galvanized or polypropylene crane wire which is used for 3 and 4 feet crane wire is needed for this galvanized wire. It is usually galvanized or polypropylene crane wire and galvanized metal, which crane wire is used for construction and many other types of work. The pipes are also galvanized and polypropylene crane wire, which is used for building and construction. These types of wire are rolled, dipped, self-adhesive and galvanized wire, for crane wire and cables. These types of galvanized wire are also used for galvanized and non-ferr.

Crane wire is usually galvanized for corrosion resistance, and it is hard to withstand the high temperatures. The type of wire used for crane wire is usually galvanized for corrosion resistance. When used with crane wire, it is usually galvanized for corrosion resistance.

Crane wire is made of hot-rolled galvanized steel tires that are high-quality, resilient, and resilient to wear and tear. Galvanized steel is strong, resilient, and high-density galvanized steel. Both galvanized steel and strong strings are commonly used for crane wire as well as high-temperature crane wire. Various types of galvanized steel are strong, high-speed, and strong enough to handle heavy loads for crane wire. Vertical galvanized steel is strong, high-density galvanized steel, and can be used as crane wire for many applications. High-density galvanized steel is very strong, resilient, and high-temperature galvanized steel. As the name suggests, galvanized steel is strong, resilient, and resilient. galvanized steel has strong str.

Crane wire is a type of hot-rolled galvanized steel wire that weighs from one to several pounds. Crane wire is made of hot-rolled, galvanized steel coils, and sheets of galvanized Steel. The coils are crane coils of cold-rolled galvanized steel, which weighs approximately one pound of the wire. Crane wire is coated with high-strength galvanized steel coils, etc. , after galvanized steel is installed into the wireper"s coil, crane, and crane on the wire. Crane wire is made from hot-rolled bilts, or high-density galvanized steel coils, and rolled coils. Crane wire is coated of high-strength, galvanized steel, and coils. When cold coated galvanized steel is installed, the wire is rolled into a metal.

Crane Wire is a wire of mesh used for fence cranes made of steel wire. These types of fence crane wire are good for heavy-duty galvanized wire and galvanized iron wire. The good quality crane wire is good for heavy-duty galvanized wire and galvanized or galvanized wire in the wire. A good-quality crane wire is good for heavy-duty galvanized wire with good galvanized and zinc coated wire. The wire type is good for heavy-duty galvanized wire with either galvanized or painted, to withstand the weight and load of the wire. A good quality crane wire is good for heavy-duty galvanized wire or galvanized as well. A good-quality crane wire is good for heavy-duty galvanized wire with galvanized wire or zinc coated wire. A good quality crane wire is used for p.

Bridon provides solutions to the most arduous and technically demanding challenges. Bridon products are used extensively in construction, mining, oil & gas extraction, telecommunications, and other specialized areas of engineering. For markets where there can be no compromise over product performance and integrity, choose Bridon.

ISO 9001 & AS 9120 certified 8(m)WOSB certified custom manufacturer of corrossion resistant galvanized aircraft stainless steel metal safety cable and wire braid materials include braided cords with wire center for aeronautical, aerospace, halyard, helicopter lead line, sailboat, rigging, hoisting, automotive applications and more. Wire rope products are available in 1x7 strand through 6x36 strand for aircraft cable, non rotating and non flexible applications. Custom coatings and finishes available for aerospace, automotive, safety applications. Also offers custom braids in specialty colors, finishes, and materials such as aramid, ceramic, Dyneema®, fiberglass, Kevlar®, linen, Nomex®, plasma, Spectra®, tarred, marlin, Technora™, Twaron®, and Vectran™. Galvanized aircraft wire ropes and cables available in 302/304, 305, and 316 stainless steel and zinc-coated carbon steel materials. Offers non-flexible types in 1 x 7 and 1 x 19 strand models. Suitable for aeronautical, logging, hoisting, aircraft control, and winching applications.

Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. Wire ropes are attached to a crane or hoist and are fitted with swivels, shackles or hooks. These are suitable for lifting or lowering elevators and are also used for supporting suspension bridges or towers.

In this article, we"ll cover details on the top U.S. providers of wire ropes, along with our featured list of top wire rope suppliers on Thomasnet.com.

Below is a list of featured suppliers of wire rope from our platform. Included with these companies is their location, year established and the number of employees.

Below we have assembled information on the top suppliers of wire rope in the U.S. based on currently available public sales data. The table also includes the company name, location and the number of employees.

With the help of the provided details on the wire rope suppliers in the United States in the above tables and descriptions, we hope you can use this data to further aid your sourcing decisions.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

We make it easy to find the information you need when you need it. Browse through our different Industry specific Product Catalogs and download straight to your mobile device. Its the fastest way to look up Cable Strengths and Capacities for your upcoming Wire Rope projects.

For customers who require peak rope performance levels in mission critical applications, Casar manufactures and supplies highly-engineered ropes that exceed industry standards while providing record-setting service life.

Our proprietary and innovative German-engineered rope designs deliver the highest levels of performance and safety, superior breaking strength values, the highest bending fatigue resistance, superior crushing resistance, and the best rotational resistance characteristics for high lifts.We have decades of global experience and on-site engineering support in the crane, OEM and underground mining sectors.

CASAR has an extensive range of products available and we can customize to your application.Our wire rope specialists will assist customers in design, selection, installation and operation to improve rope performance and maximize service life.

Our company is well known in the market for the export of a superior range of Platform Steel Wire Ropes which are high on demand all over the globe and these products have been supplied and manufactured using a superior range of raw materials which have been priced at very reasonable rates in the market. These products are made using the latest technology available in the market and they are very durable in their performance. These products can be got customized by the clients as per their specifications.

8613371530291

8613371530291