steel wire rope thimble free sample

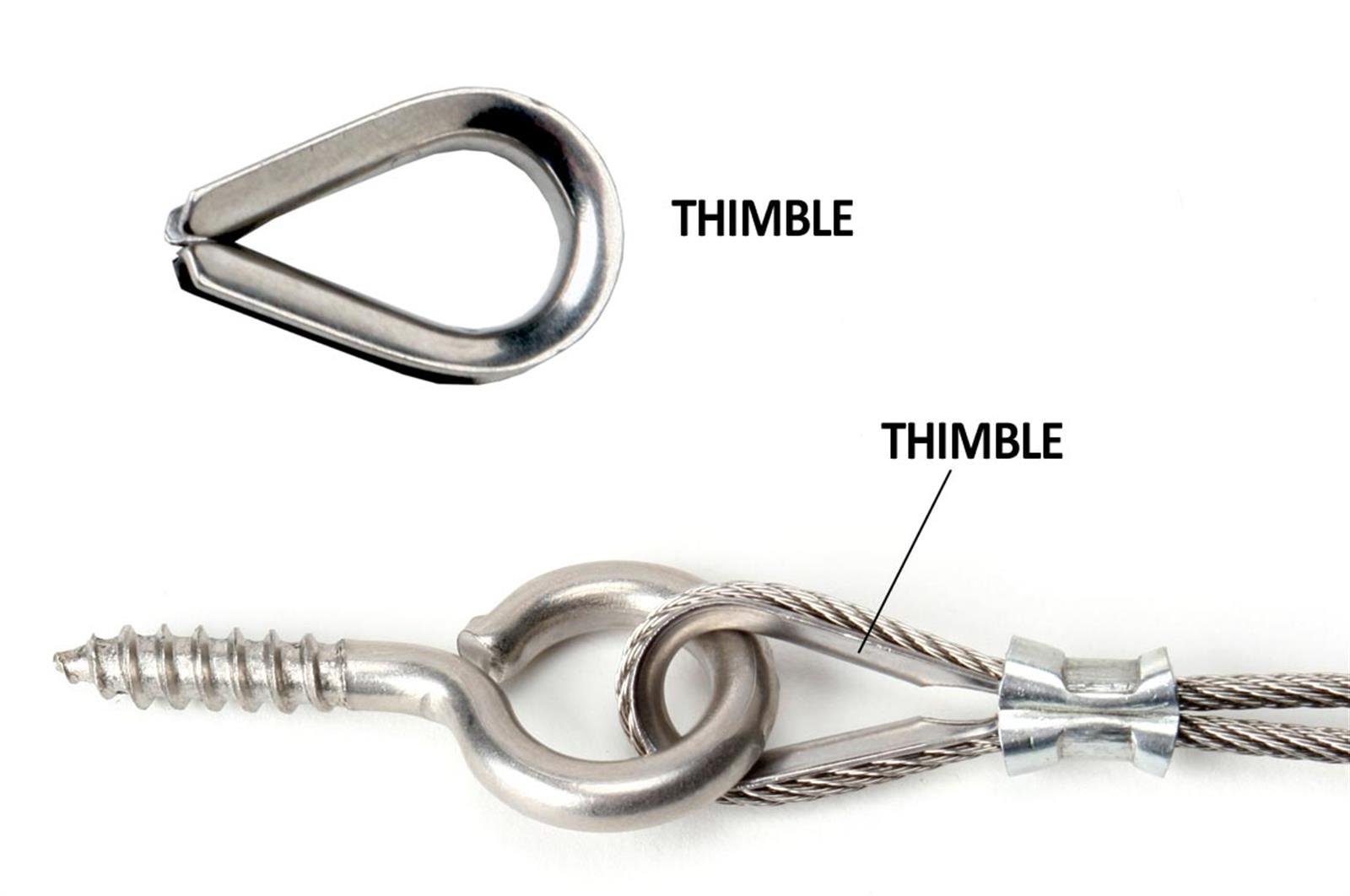

Wire rope thimbles also known as cable thimbles, are used for making reinforce loop(eyelet) with grips, clips or clamps by preventing fraying caused by friction at the bearing anchor point to protect and extend the service life of the wire rope or sling. They are just one of the many types of wire rope fittings (ferrules, wire rope clips, terminals, etc.).

Wire rope thimbles are available in a variety of strengths and materials(carbon steel and stainless steel, see our post on Surface Finish: 4 Common Types You Should Know) but mainly they come in two different duty grades.

If you use it in high moisture or corrosive environments, recommend our stainless steel wire rope thimbles which can offer resistance to corrosion on the surface, particularly in marine applications.

Simply wrap the end of the wire rope around the outer groove of the thimble, lace the dead end of the wire rope past the U-bolt of the wire rope grips or a wire rope ferrule crimp to hold onto the bearing anchor point at the end of the thimble to prevent fraying caused by friction.

Once in place, put another wire rope clip as near the loop you just wrapped over the thimble. Turn nuts firmly but do not yet tighten to the proper torque, we recommend using a crimping/swaging tool to compress the ferrule firmly onto the rope to hold your thimble loop securely.

Alternatively, you can use a wire rope ferrule crimp to secure your thimble in place. this method is quick and easy to install. For further information on installation using a wire rope ferrule please – click here

Wire rope thimbles are used in conjunction with cable and rope to protect the eyes and will allow for smooth rope guiding around natural curves. So that the most important thing is to make sure the thimble eye securely fastened. Here are some tips for correctly using wire rope thimble:

Make sure that the cable thimbles size properly and securely fastened in the eye of the loop, not too loose or too tighten, so they can create an extra layer of support to connect with other properly sized rigging fittings.

While you are using a vinyl coated cable, you should multiply the actual size of the cable, usually use a larger size thimble than normal, for the actual diameter is the thickness of the vinyl coating plus the inside wire rope diameter. For example, if you are using a 5/16″ vinyl coated cable that is coated to 3/8″ diameter, you’d want to use a 3/8″ wire rope thimble.

G411 is a standard duty wire rope thimble with electric galvanized surface treatment. This thimble provides a hard eye in a wire rope lifting sling. The galvanized surface increases the corrosion resistance. It is recommended for light duty applications.

G414 wire rope thimble is a heavy-duty wire thimble that provide a hard eye in a wire rope sling, it made according to federal specification FF-T-276b. It is the most selling wire rope thimble for heavy duty service.

We"re well-known as one of the leading wire rope thimbles manufacturers and suppliers in China. Welcome to buy high quality wire rope thimbles at competitive price from our factory. Also, free sample is available for quality checking. Galvanized fishing wire ropes, European ordinary wire rope thimble, Stainless steel snap hooks

Thimbles are designed to extend the longevity of wire rope loops by preventing fraying that can occur due to friction at the bearing point. Thimbles must be used in conjunction with either sleeves or wire rope clips in several specifications.

In stricter senses, the term wire rope refers to a diameter larger than 9.5 mm (3⁄8 in), with smaller gauges designated cable or cords.wrought iron wires were used, but today steel is the main material used for wire ropes.

Historically, wire rope evolved from wrought iron chains, which had a record of mechanical failure. While flaws in chain links or solid steel bars can lead to catastrophic failure, flaws in the wires making up a steel cable are less critical as the other wires easily take up the load. While friction between the individual wires and strands causes wear over the life of the rope, it also helps to compensate for minor failures in the short run.

Wire ropes were developed starting with mining hoist applications in the 1830s. Wire ropes are used dynamically for lifting and hoisting in cranes and elevators, and for transmission of mechanical power. Wire rope is also used to transmit force in mechanisms, such as a Bowden cable or the control surfaces of an airplane connected to levers and pedals in the cockpit. Only aircraft cables have WSC (wire strand core). Also, aircraft cables are available in smaller diameters than wire rope. For example, aircraft cables are available in 1.2 mm (3⁄64 in) diameter while most wire ropes begin at a 6.4 mm (1⁄4 in) diameter.suspension bridges or as guy wires to support towers. An aerial tramway relies on wire rope to support and move cargo overhead.

Modern wire rope was invented by the German mining engineer Wilhelm Albert in the years between 1831 and 1834 for use in mining in the Harz Mountains in Clausthal, Lower Saxony, Germany.chains, such as had been used before.

Wilhelm Albert"s first ropes consisted of three strands consisting of four wires each. In 1840, Scotsman Robert Stirling Newall improved the process further.John A. Roebling, starting in 1841suspension bridge building. Roebling introduced a number of innovations in the design, materials and manufacture of wire rope. Ever with an ear to technology developments in mining and railroading, Josiah White and Erskine Hazard, principal ownersLehigh Coal & Navigation Company (LC&N Co.) — as they had with the first blast furnaces in the Lehigh Valley — built a Wire Rope factory in Mauch Chunk,Pennsylvania in 1848, which provided lift cables for the Ashley Planes project, then the back track planes of the Summit Hill & Mauch Chunk Railroad, improving its attractiveness as a premier tourism destination, and vastly improving the throughput of the coal capacity since return of cars dropped from nearly four hours to less than 20 minutes. The decades were witness to a burgeoning increase in deep shaft mining in both Europe and North America as surface mineral deposits were exhausted and miners had to chase layers along inclined layers. The era was early in railroad development and steam engines lacked sufficient tractive effort to climb steep slopes, so incline plane railways were common. This pushed development of cable hoists rapidly in the United States as surface deposits in the Anthracite Coal Region north and south dove deeper every year, and even the rich deposits in the Panther Creek Valley required LC&N Co. to drive their first shafts into lower slopes beginning Lansford and its Schuylkill County twin-town Coaldale.

The German engineering firm of Adolf Bleichert & Co. was founded in 1874 and began to build bicable aerial tramways for mining in the Ruhr Valley. With important patents, and dozens of working systems in Europe, Bleichert dominated the global industry, later licensing its designs and manufacturing techniques to Trenton Iron Works, New Jersey, USA which built systems across America. Adolf Bleichert & Co. went on to build hundreds of aerial tramways around the world: from Alaska to Argentina, Australia and Spitsbergen. The Bleichert company also built hundreds of aerial tramways for both the Imperial German Army and the Wehrmacht.

In the last half of the 19th century, wire rope systems were used as a means of transmitting mechanical powercable cars. Wire rope systems cost one-tenth as much and had lower friction losses than line shafts. Because of these advantages, wire rope systems were used to transmit power for a distance of a few miles or kilometers.

Steel wires for wire ropes are normally made of non-alloy carbon steel with a carbon content of 0.4 to 0.95%. The very high strength of the rope wires enables wire ropes to support large tensile forces and to run over sheaves with relatively small diameters.

In the mostly used parallel lay strands, the lay length of all the wire layers is equal and the wires of any two superimposed layers are parallel, resulting in linear contact. The wire of the outer layer is supported by two wires of the inner layer. These wires are neighbors along the whole length of the strand. Parallel lay strands are made in one operation. The endurance of wire ropes with this kind of strand is always much greater than of those (seldom used) with cross lay strands. Parallel lay strands with two wire layers have the construction Filler, Seale or Warrington.

In principle, spiral ropes are round strands as they have an assembly of layers of wires laid helically over a centre with at least one layer of wires being laid in the opposite direction to that of the outer layer. Spiral ropes can be dimensioned in such a way that they are non-rotating which means that under tension the rope torque is nearly zero. The open spiral rope consists only of round wires. The half-locked coil rope and the full-locked coil rope always have a centre made of round wires. The locked coil ropes have one or more outer layers of profile wires. They have the advantage that their construction prevents the penetration of dirt and water to a greater extent and it also protects them from loss of lubricant. In addition, they have one further very important advantage as the ends of a broken outer wire cannot leave the rope if it has the proper dimensions.

Stranded ropes are an assembly of several strands laid helically in one or more layers around a core. This core can be one of three types. The first is a fiber core, made up of synthetic material or natural fibers like sisal. Synthetic fibers are stronger and more uniform but cannot absorb much lubricant. Natural fibers can absorb up to 15% of their weight in lubricant and so protect the inner wires much better from corrosion than synthetic fibers do. Fiber cores are the most flexible and elastic, but have the downside of getting crushed easily. The second type, wire strand core, is made up of one additional strand of wire, and is typically used for suspension. The third type is independent wire rope core (IWRC), which is the most durable in all types of environments.ordinary lay rope if the lay direction of the wires in the outer strands is in the opposite direction to the lay of the outer strands themselves. If both the wires in the outer strands and the outer strands themselves have the same lay direction, the rope is called a lang lay rope (from Dutch langslag contrary to kruisslag,Regular lay means the individual wires were wrapped around the centers in one direction and the strands were wrapped around the core in the opposite direction.

Multi-strand ropes are all more or less resistant to rotation and have at least two layers of strands laid helically around a centre. The direction of the outer strands is opposite to that of the underlying strand layers. Ropes with three strand layers can be nearly non-rotating. Ropes with two strand layers are mostly only low-rotating.

Stationary ropes, stay ropes (spiral ropes, mostly full-locked) have to carry tensile forces and are therefore mainly loaded by static and fluctuating tensile stresses. Ropes used for suspension are often called cables.

Track ropes (full locked ropes) have to act as rails for the rollers of cabins or other loads in aerial ropeways and cable cranes. In contrast to running ropes, track ropes do not take on the curvature of the rollers. Under the roller force, a so-called free bending radius of the rope occurs. This radius increases (and the bending stresses decrease) with the tensile force and decreases with the roller force.

Wire rope slings (stranded ropes) are used to harness various kinds of goods. These slings are stressed by the tensile forces but first of all by bending stresses when bent over the more or less sharp edges of the goods.

Technical regulations apply to the design of rope drives for cranes, elevators, rope ways and mining installations. Factors that are considered in design include:

Donandt force (yielding tensile force for a given bending diameter ratio D/d) - strict limit. The nominal rope tensile force S must be smaller than the Donandt force SD1.

The wire ropes are stressed by fluctuating forces, by wear, by corrosion and in seldom cases by extreme forces. The rope life is finite and the safety is only ensured by inspection for the detection of wire breaks on a reference rope length, of cross-section loss, as well as other failures so that the wire rope can be replaced before a dangerous situation occurs. Installations should be designed to facilitate the inspection of the wire ropes.

Lifting installations for passenger transportation require that a combination of several methods should be used to prevent a car from plunging downwards. Elevators must have redundant bearing ropes and a safety gear. Ropeways and mine hoistings must be permanently supervised by a responsible manager and the rope must be inspected by a magnetic method capable of detecting inner wire breaks.

The end of a wire rope tends to fray readily, and cannot be easily connected to plant and equipment. There are different ways of securing the ends of wire ropes to prevent fraying. The common and useful type of end fitting for a wire rope is to turn the end back to form a loop. The loose end is then fixed back on the wire rope. Termination efficiencies vary from about 70% for a Flemish eye alone; to nearly 90% for a Flemish eye and splice; to 100% for potted ends and swagings.

When the wire rope is terminated with a loop, there is a risk that it will bend too tightly, especially when the loop is connected to a device that concentrates the load on a relatively small area. A thimble can be installed inside the loop to preserve the natural shape of the loop, and protect the cable from pinching and abrading on the inside of the loop. The use of thimbles in loops is industry best practice. The thimble prevents the load from coming into direct contact with the wires.

A wire rope clip, sometimes called a clamp, is used to fix the loose end of the loop back to the wire rope. It usually consists of a U-bolt, a forged saddle, and two nuts. The two layers of wire rope are placed in the U-bolt. The saddle is then fitted to the bolt over the ropes (the saddle includes two holes to fit to the U-bolt). The nuts secure the arrangement in place. Two or more clips are usually used to terminate a wire rope depending on the diameter. As many as eight may be needed for a 2 in (50.8 mm) diameter rope.

The mnemonic "never saddle a dead horse" means that when installing clips, the saddle portion of the assembly is placed on the load-bearing or "live" side, not on the non-load-bearing or "dead" side of the cable. This is to protect the live or stress-bearing end of the rope against crushing and abuse. The flat bearing seat and extended prongs of the body are designed to protect the rope and are always placed against the live end.

An eye splice may be used to terminate the loose end of a wire rope when forming a loop. The strands of the end of a wire rope are unwound a certain distance, then bent around so that the end of the unwrapped length forms an eye. The unwrapped strands are then plaited back into the wire rope, forming the loop, or an eye, called an eye splice.

A Flemish eye, or Dutch Splice, involves unwrapping three strands (the strands need to be next to each other, not alternates) of the wire and keeping them off to one side. The remaining strands are bent around, until the end of the wire meets the "V" where the unwrapping finished, to form the eye. The strands kept to one side are now re-wrapped by wrapping from the end of the wire back to the "V" of the eye. These strands are effectively rewrapped along the wire in the opposite direction to their original lay. When this type of rope splice is used specifically on wire rope, it is called a "Molly Hogan", and, by some, a "Dutch" eye instead of a "Flemish" eye.

Swaging is a method of wire rope termination that refers to the installation technique. The purpose of swaging wire rope fittings is to connect two wire rope ends together, or to otherwise terminate one end of wire rope to something else. A mechanical or hydraulic swager is used to compress and deform the fitting, creating a permanent connection. Threaded studs, ferrules, sockets, and sleeves are examples of different swaged terminations.

A wedge socket termination is useful when the fitting needs to be replaced frequently. For example, if the end of a wire rope is in a high-wear region, the rope may be periodically trimmed, requiring the termination hardware to be removed and reapplied. An example of this is on the ends of the drag ropes on a dragline. The end loop of the wire rope enters a tapered opening in the socket, wrapped around a separate component called the wedge. The arrangement is knocked in place, and load gradually eased onto the rope. As the load increases on the wire rope, the wedge become more secure, gripping the rope tighter.

Poured sockets are used to make a high strength, permanent termination; they are created by inserting the wire rope into the narrow end of a conical cavity which is oriented in-line with the intended direction of strain. The individual wires are splayed out inside the cone or "capel", and the cone is then filled with molten lead-antimony-tin (Pb80Sb15Sn5) solder or "white metal capping",zincpolyester resin compound.

Donald Sayenga. "Modern History of Wire Rope". History of the Atlantic Cable & Submarine Telegraphy (atlantic-cable.com). Archived from the original on 3 February 2014. Retrieved 9 April 2014.

Kevlar fiber braided round rope has high stability in temperature performance. It can not only be used continuously in the temperature range of -196℃ to 204℃ without obvious change or loss, but also has insolubility and non-dissolution. Combustion (fire resistance), carbonization will only start at 427°C, and even at a low temperature of -196°C, there will be no brittleness and performance loss, and excellent heat resistance that can withstand short-term contact at temperatures up to 538°C.

Compared with ordinary braided rope, aramid rope also has excellent special properties. It has high tensile strength, ultra-high tensile force, ultra-low elongation, high modulus, high breaking strength, high temperature resistance, flame retardant, chemical resistance, High stability, low thermal expansion coefficient, insulation, etc.

The rope braided by para-aramid fiber can be used for parachuting protection, fire rescue, glass hoisting belt, high-altitude operation, film and television shooting rope, downhill, hoisting traction, cable protection, army training, escape rescue and other fields.

Galvanized steel ropes in 11 different thicknesses: 1mm, 1.5mm, 2mm, 3mm, 4mm, 6mm, 8mm, 10mm, 12mm, 14mm and 16mm.Equipped with eyelets, hims, as winches, or forestry rope and set for tensioning.The steel ropes are processed in Germany after the DIN-European standard 13414.

Wire rope meter in 11 different thicknesses: 1mm, 1.5mm, 2mm, 3mm, 4mm, 6mm, 8mm, 10mm, 12mm, 14mm and 16mm.Smoothed in five different constructions: 7x7, 6x19, 7x19, 6x37 and 18x7 Available as a rotary wire rope.All offered wire ropes correspond to the DIN EN 13414-1.

galvanized wire ropes with eyelets in the strengths of 1mm to 16mm according to the specifications of the DIN-European standard 13414-2 made in Germany and optimally suitable for many applications.

Our steel cables with box galvanized steel, high quality and strict DIN specifications pressed in 2mm - 16mm strength.The cheese according to DIN6899 protects the wire rope from the inside to the load absorption point.

galvanized steel ropes tension with the help of firmly connected steel cable clamps or in set with clamps, tensionersand sleep.You will receive the sets both with smoothly cut steel rope as well as with a one-sided shew of the compression.

wire rope with hook in different versions: for light suspensions with snap hooks, as choker rope with high-strength sliding hookFor forstarts, steel cable with hooks and eyelets or as a wire rope for winches.The steel ropes are processed in Germany after the DIN-European standard 13414 and are pressed with carabiner hooks, load hooks or eyelethook of Grade 8.

Our steel cables with rope stopper " are compressed from galvanized steel in 1.5mm - 12mm strength and can be opened with an open end,to be ordered a loop or kausche.The one-sided pressed round clamp according to DIN 13411-3 fulfills the purpose of a stop terminal.

forestry ropes in seven different strengths of 5mm - 16mm.Available as choker rope with high-strength sliding hook, stop rope with hook & loop, as well as with grade 8 Load hook.The steel cables are processed in Germany after the DIN-European standard 13414 and are not highly damaged.

wire ropes for winches in eight different strengths: 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 14mm and 16mm.The wire ropes are made up to a thickness of 8mm annealed, so that fixing in the wind is very easy and easy to use.

Our Rotary wire ropes Get with the construction 18x7 in 5 different strengths. Through the,In opposite directed, strand layers, the wire ropes exert a low torque to an isolated load.The wire rope optimally serves as Hub - or Kranil to lift and depend on appropriate loads.

Labels With a compressed cheese according to DIN 6899 and a glow-separated end in 13 different lengths of 0.5m - 20m, optionally equipped with a wire cable holder and in the strengths of1.5mm - 8mm permanent & fast available.

Wire ropes for garage doors With a compressed cheese to DIN 6899 and a glow-separated end in individual length, optionally pressed with a M10x100 eye screw and in the strengths of 2mm- 5mm permanent & fast available.

Our steel rope sets are equipped with a steel cable and matching clamps, himming and wire ropes.You can choose from both different lengths, different strengths, as well as different equipment.

Our Fuse ropes for the event technique correspond to the BGV-C1 guidelines (security for events and production loads over persons) and can be optimal forLoads of 2kg - 100kg be used.

Our horizontal Rope locking system " SAVEKINGLINE?® corresponds to the DIN EN 795 type C? and serves as fall protection of personsFor the use on high-volume workplaces.The cable locking system is available in variable or defined length.

wire rope for a shoot for three different web lengths: 25m, 50m and 100m.The tension rope is one-sided melted and pressed on one side with a cheaper and equipped with a emergency element.

Meets specification FF-T-276b, Type lll. Insure proper number of clips used with thimbles per industry specifications. Stainless Steel dimension may be slightly smaller than galvanized products.B - OD Width

Meets specification FF-T-276b, Type lll. Insure proper number of clips used with thimbles per industry specifications. Stainless Steel dimension may be slightly smaller than galvanized products.B - OD Width

20mm nominal diameter x 5tonne Working Load Limit (Vertical) 6X36 IWRC Grade EIPS (Tensile Strength 1960N/mm2) Galvanized Steel Wire Rope Sling Both End Mechanical Spliced with Aluminium Ferrule DIN3093 Standard Length.

Jiangsu Rongstar Industry Co., Ltd. is a professional company focusing on the development and production of high-end metal cables. The R & D and operation of the company"s products started from Taizhou headquarters, with its marketing center in Shanghai, and a production base in the city Binhai and Jiangyin. In these places, the engineers, designers and manufacturing experts of Rongstar industry have been working hard. Through continuous exploration and technical practice, they have created products that can truly solve the quality and cost advantages of metal ropes, and adhere to intelligent manufacturing to create greater value for customers.

We often think about why we can"t provide good quality with low cost products for industrial customers. That’s good but expensive or the low-cost with poor quality products have been consuming the courage of the experimenters has eroded the patience of the industry customers. What"s terrible is that we can"t continue to make progress. Rongstar has been committed to making industrial products with high quality and good price. We always pay attention to the production system Cost of manufacturing link, focusing on intelligent production mode of metal rope!

8613371530291

8613371530291