welding wire rope together pricelist

★ Any color or thickness and sold by the foot! I think this is a web exclusive only available at WeldingSupply.com. Let us cut some cable for you! Order longer pieces for automatic bracket prices.

★ Any color or thickness and sold by the foot! I think this is a web exclusive only available at WeldingSupply.com. Let us cut some cable for you! Order longer pieces for automatic bracket prices.

Wire & Cable Your Way offers a wide selection of flexible copper welding cable at low prices with fast shipping - available by the foot with no cut charges. These cables are used by professional welders, for secondary voltage resistance welding leads and as a power supply for welding tools and applications that do not require over 600 volts AC.

At Allied Wire and Cable, we provide our customers with quality copper at bargain prices. As industry experts, we can help customers combat high or volatile copper prices. As seen in the chart below, copper prices have fluctuated throughout history. At Allied Wire and Cable, we can help you avoid sticker shock when purchasing copper.

The International Wire Group, a manufacturer of a wide range of copper wire supplied the Omega-Camden Copper Index. This index prices copper after it’s been drawn down to size, rather than in its raw form. Rod copper is pulled through a series of dies during the drawing process, which stretches the copper out into a longer, thinner strand. These strands are bunched together to form a single-stranded conductor in the end.The Omega-Camden Index is only updated twice a month.

Copper moves around the world in a variety of forms such as copper ore, raw copper, refined copper and copper wire. There are five countries that sit on roughly 65% of the world’s copper deposits, including Chile, Australia, Peru, Mexico, and the United States. Roughly 700 million metric tons of copper have been mined and an estimated 2.1 billion tons of identified deposits remain in the ground, while undiscovered deposits are estimated to be around 3.5 billion tons.

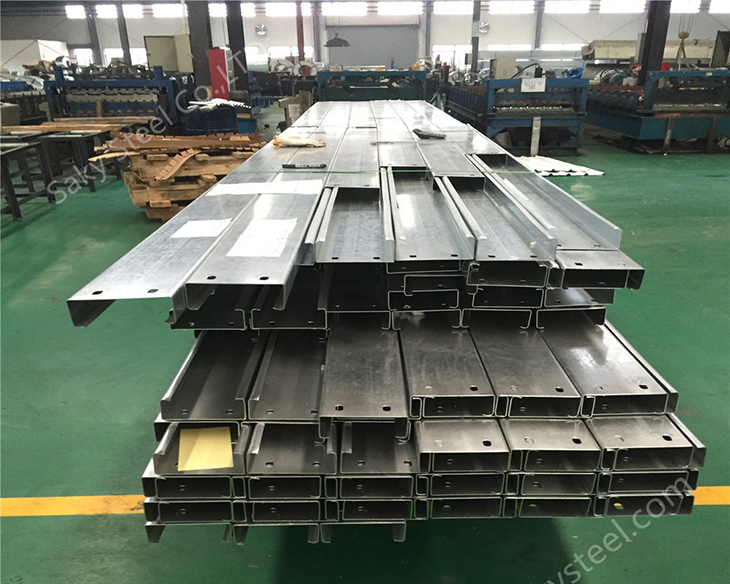

Stock up on every variety of steel wire rods at the Alibaba metalworking store. Our listings feature wholesale steel rods from a network of dependable Chinese manufacturing partners. If you need to source steel rods for construction projects, you"ll find products that are robust and durable. And if you need welding rods, they are easy to find via our search engine. Track down the steel wire rope price you need at affordable prices at Alibaba.com.

What can you do with the steel wire rods available from Alibaba"s wholesale store? One common use for steel rods is in the welding sector. Steel works well as a welding rod material thanks to its high ductility, meaning that welds are relatively strong and long-lasting. Choose a low carbon rod and you"ll be all set for successful welds in industrial settings and workshops alike. However, steel wire also has applications beyond welding. You can use it as wiring in electronic circuits and power distribution systems and it works especially well in high temperature settings as armored cabling. Find the ideal steel wire rope price for every industrial use at Alibaba.com.

Steel wire rods also have applications in everyday life. For example, you can use coils of steel wire to construct fences and barriers both inside and outside homes. It"s a common material in agricultural businesses thanks to its toughness and resistance to oxidation. Use it to create reinforcement cages, enclosures for equipment, or add it to concrete to add extra strength where it really matters. From welding to concrete reinforcement, steel wire rope price will always find a use. And whether you need small batches or huge bulk orders, our metallic materials catalog is the ideal place to look.

Copper wires and the differences can be tricky to differentiate from the various types that can be found. Insulated Cable is a common heavier copper wire that is used for heavier electrical connections like from a home or building. Usually no thicker than a finger, the Insulated Cable will have strands of copper bare bright wire inside which is gathered and covered by a single layer of insulation. The insulation can be removed to make more money on the copper wire, however we only suggest doing that if you have a large quantity of the material, otherwise you may lose too much weight by stripping the Insulated Cable.

Since 1977, Rockaway Recycling has been serving the Tri-State area for all their scrap metal needs from copper, aluminum, wire, and electronics. You will be able to find all of our current scrap prices on our website, which are updated every day during operating hours. You can also see and print our hours of operation and directions from our website. We are conveniently located in Rockaway, NJ minutes from Rt. 80 and off of Rt. 46. If you have any questions about your materials or Insulated Cable, be sure to contact us through our online forms or give us a call. We can also provide pickup services and containers for drop-offs for your insulated copper cable in the Tri-State area. If you are interested, contact us about our scrap metal pick up services. If you have any questions about the gauges or types of insulated cable you have for scrap. We can also help with the recovery rates you can expect based on the copper inside.

zw cable is a professional welding cable manufacturer in China. We can supply a competitive welding cable prices. Our unrivaled range of electrical cables include rubber welding cable, empdm welding cable, and pvc welding cable. Most of types we have in stock. All of our cables are manufactured to IEC Standards.Over the past years, we have established long-term friendly and cooperative relations with many enterprises abroad. If you are also looking for welding cable prices such as welding cable 70mm price, zw cable will be your best choice. Please leave your message, we will send our welding cable prices list to you in 12 hours.

Welding Cable is used for connection from electrode holder and clamp to arc welder, bus, welding box or transformer. May also be used in automotive applications where high flexibility and superior abrasion and chemical resistance is required.

Welding Reels are designed for electric welding cables or grounding use. They are ideal for keeping excess cable stored and accessible in a neat, safe, and efficient manner. Welding reels have positive locking ratchets and are suitable for both indoor and outdoor applications.

Copper wire is a common name for all types of Cu cable. So copper wire recycling price depends on the kind of copper scrap. You can find it the table below. Feel free to call us if you want to sell your metal but cannot determine the type of your waste. Require a scrap metal pick up service or fill in the form on the contact page.

Copper wire stripping process could be very time consuming all depending on the type of equipment you are using. Most recycling yards have professional machines that are designed to strip large quantity of wires in the shortest period of time. Unfortunately, majority of people are not equipped with this kind of machinery and resort to use knives or any other type of sharp object to get the insulation off the copper, this process could be very timely but most important dangerous. Well you decide what works for you better after this quick mathematical break down.

12-gauge wire has 75% copper recovery, so after you are done stripping your wire you end up with 75 lbs. of copper and 25% of plastic garbage that you need to figure out how to dispose of. Here is the money break down (we are going to use today’s market prices for the following calculation). For 12-gauge wire average price is a $1.30 per lb. the way it is with insulation, that would translate in to $130.00 for your 100lbs of 12-gauge wire, without stripping it. If you were to strip it, your 75lbs of copper would bring you $1.90 per pound $142.50 the difference between stripping and selling it the way it was would be $12.50. So you will net $12.50 from stripping 100lbs of 12-gauge wire, at this point it’s your decision if you should do it or not.

250mcm-750mcm wire has 90% copper recovery, so let’s use same 100 lbs. if you were to sell it the way it is in today’s market you would get average $1.50 per pound so it would get you $150.00 without doing a thing to it, just bring it to a recycling yard and sell it. If you chose to strip it, you will end up with 90 pounds of copper don’t forget 10 pounds in plastic waste and in today’s market you will get $1.90 per pound for stripped copper wire so your 90 pounds will net you $171.00 difference of $21.00 between stripping it or selling the way it is, just want to mention one thing stripping larger gauge wire is much faster and easier then stripping smaller gauge but just as dangerous. Watch your fingers and good luck with whatever you decide to do.

Copper wire that is not corroded or burned and must be shiny in its appearance. No contamination in any form. Must be thicker than a pencil lead. (10 Ga.)$3.00-$3.20/lb Request mine

Insulated Copper wire that is 14 gage or thicker (1/16 inch). If wire is stranded, each wire must be 1/16” or thicker. Must have a copper recovery of 75% or more.$2.00-$2.20/lb Request mine

Insulated Copper wire smaller than 16 gage (1/16 inch) and has a copper recovery of 55% - 79%. The copper wire may be coated by tin or nickel. All stranded wire smaller than 1/16”.$00.40-$1.60/lb Request mine

It is very important to know the applications of different types of welding methods and equipment. Welding uses high temperatures to melt and join components. On the other hand, it is important to remember that pressure can be used not only to support the process but also specifically to form welds.

The process of welding not only joins two parts together, as in the case of brazing; Rather, it causes the metal structures of the two parts to fuse and become one through the use of intense heat and sometimes the addition of other metals or gases. Soldering and soldering are two processes that are similar to welding in that they join two pieces together.

In most cases, welding additionally requires the use of a filler material or item called a consumable. It is used to provide a "filler" or bath of molten material that promotes the formation of a strong bond between base metals. As the name suggests, it is used in the process.

In metallurgy, welding has been around for thousands of years. Although forge welding, in which blacksmiths make iron and steel by heating and then forging, was for a time the only process that worked, forge welding is no longer used. Everything turned upside down in the 19th century when more sophisticated techniques were developed such as arc welding and oxy-fuel welding.

In the MIG welding process, a continuous solid wire electrode is fed from the welding torch into the weld pool, which joins the two base materials together. This type of arc welding is known as MIG welding. The weld pool is protected from contamination by shielding gas circulating through the welding torch.

Thyristor MIG welding machines are the most efficient equipment for fixing or assembling material on a suitable surface. As a rule, these are high-quality tools that will serve their owners for a very long time.

These types of welders produce only a small amount of spark, making them easy for the user to operate. These machines perform well in solid core welding and submerged arc welding. You can work with mild steel, mild steel, alloy steel, and other types of steel.

Spot welding machines are commonly used in the process of splicing components, such as Type B steel sheets. To achieve this, sheets of metal are often shielded by passing a current through them when they are sandwiched between two electrodes.

Spot welding machines have a number of significant advantages over other types of welding machines, including high productivity, excellent energy efficiency, and ease of automation. Automotive manufacturing is often the industry in which these types of machines are used the most. In addition, in most cases they are transparent.

There is a wide variety of quality welders and also welding methods and types. You might consider becoming a welder because it is a booming trade that is in high demand. However, welding is also a skill that may be put to use in the ordinary world, such as in the creation of garden art or other decorative items.

You can also utilize it to better your existing employment, which is especially helpful for those working in the agricultural or automotive industries. There is no end to the things that may be created with welding; it only depends on what kind of welding you want to learn.

There are primarily four different kinds of welding. Stick – Shielded Metal Arc Welding (SMAW), Flux-cored – Flux-cored Arc Welding (FCAW), and MIG – Gas Metal Arc Welding (GMAW). Flux-cored – Flux-cored Arc Welding (FCAW). MIG – Gas Metal Arc Welding (GMAW). TIG – Gas Tungsten Arc Welding (GTAW) (FCAW). In this section, we delve deeper into each form of welding.

In the automotive industry, MIG welding is utilized for the repair of vehicle exhausts. Additionally, this welding technique is utilized in the construction of homes and other constructions.

One of the most prevalent kinds of welding is called stick welding. One sort of arc welding is known as electrode welding, and it involves the use of a continuous wire. In addition to this, you will make use of a shielding gas that guards against contamination while traveling through the welding gun.

MIG welding and TIG welding both utilize an electric arc. Tungsten is the material that goes into the electrode that you use for TIG welding. Tungsten is one of the metals that has the highest resistance to wear.

It will not disintegrate or disappear by burning. The process of welding can be accomplished using a method known as fusion, which can be carried out with or without the addition of filler metal. TIG also makes use of an external gas source, often consisting of argon or helium.

TIG welding is utilized not just in the industrial sector but also in the aerospace and automotive industries. Welding wagon frames, fenders, and several other essential pieces of equipment is a terrific usage for this form of welding, which is another reason why it is perfect for Iowa. Farmers may use it to join together key pieces of equipment such as wagons.

The fact that stick welding equipment may be carried about easily is one of its major advantages. Stick welding is utilized in a variety of industries, including industrial fabrication, undersea pipelines, and construction and maintenance and repair.

Stick welding, also known as shielded metal art welding, is the kind of welding that you will be doing for this particular form of welding. You will make use of a disposable and shielded electrode, sometimes known as a stick.

Flux-cored arc welding is comparable to MIG welding in that both processes include the utilization of continuous wire and power supply. A continuous electrode will be combined with a metal base in this step.

The electrode is a hollow tube that is loaded with flux. This tube is then fed through the weld cannon and into the weld pool. When welding outside, a flux shield can protect the welder from the various elements of the environment. In the machining industry, as well as for welding thicker metals, this form of welding is the method of choice.

Different welding types have different applications. Beginners will find that MIG welding is one of the less complicated methods of welding to master. In reality, MIG welding is comprised of two distinct forms of welding. In the first method, bare wire is utilized, and in the second, flux core is utilized.

Thin pieces of metal can be welded together using a technique called bare wire MIG welding. Flux core The MIG welding technique does not require a flow meter or a gas supply, therefore it can be employed in open air settings.

MIG welding is typically the method of choice for do-it-yourself (DIY) enthusiasts and hobby welders who do not have the financial resources to invest in costly equipment.

Stick welding, which is also known as arc welding, is a method that is considered to be more traditional. Stick welding is a bit more difficult to grasp than MIG welding; but, if you want to try your hand at stick welding at home, you can pick up the necessary equipment for relatively little money. When performing stick welding, a stick electrode welding rod is utilized.

TIG welding requires the use of both of your hands. While using a TIG torch with one hand, the other hand is used to feed the rod. This torch is responsible for producing the heat and arc that are necessary for welding the majority of conventional metals, such as aluminum, steel, nickel alloys, copper alloys, cobalt, and titanium.

Welding steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze, and even gold is possible using a TIG welder. TIG stands for tungsten inert gas. TIG is a valuable welding technology that may be used for a variety of applications including door handles, fenders, door frames, lawn mowers, and bicycle frames.

Plasma arc welding is a precise method that is frequently utilized in the aerospace industry for applications in which the metal thickness is 0.015 of an inch.

A good illustration of this kind of use may be seen on things like air seals and engine blades. Plasma arc welding is a technology that is very similar to TIG welding in terms of its application; however, the electrode used in plasma arc welding is recessed, and the ionizing gases that are contained within the arc are employed to generate heat.

TIG welding has largely taken the place of gas welding, which is now only employed in very limited circumstances. Gas welding kits are extremely portable and require oxygen and acetylene as their primary components. They are still used on occasion to fuse together broken pieces of exhaust from automobiles.

Electron beam welding and laser welding are two examples of high-energy, extremely precise types of welding. Electron beams and lasers can be focused and aimed with the exceptional accuracy required to weld the smallest of implantable medical devices, while at the same time delivering the tremendous amounts of power required to weld large parts of spacecraft. This allows electron beams and lasers to be used for both medical and aerospace welding applications.

Electron beam and laser welding are both highly powerful and adaptable procedures that may be automated. Both are capable of producing stunning welds, both from a metallurgical and an aesthetic point of view, and both have the potential to be cost-effective.

Our solder wire is well coated and made from metals such as cast iron, steel, etc. You can contact us through authorized owners of manufacturing units and online markets to buy our best and high quality products.

Buy Unicab Welding Cable Piece 10 Meter 25sqmm online in India at wholesale rates. If you have been looking for Unicab Welding Cable Piece 10 Meter 25sqmm dealers, your search ends here as you can get the best Unicab Welding Cable Piece 10 Meter 25sqmm distributors in top cities such as Delhi NCR, Mumbai, Chennai, Bengaluru, Kolkata, Chennai, Pune, Jaipur, Hyderabad and Ahmedabad. You can purchase Unicab Welding Cable Piece 10 Meter 25sqmm of the finest quality and rest assured to get the best in terms of both durability and performance. If you are bothered about the Unicab Welding Cable Piece 10 Meter 25sqmm prices, you can be totally sure to get the best rates as Industrybuying brings you genuine Unicab Welding Cable Piece 10 Meter 25sqmm rates and quality assured products only from the best of brands with exclusive brand discounts you won’t find anywhere else. Procure Unicab Welding Cable Piece 10 Meter 25sqmm today and avail the best offers on your purchase.

8613371530291

8613371530291