what is the safety factor of wire rope sling in stock

Have you wondered why rigging experts always suggest a sling that has a significantly higher breaking strength than the actual weight of the load you are lifting? The manufacturers know that the rigging used in overhead applications need to have room for error. This is known as the Safety Factor.

Northern Strands manufactures wire rope slings rated up to 36,000 lbs and sells round synthetic slings that are rated up to 140,000 lb capacity. This capacity is the Working Load Limit of the sling, which is the maximum amount of weight or force that the sling"s user is allowed to put on the sling. Note: These slings do not break at the working load limit. These slings are designed with a safety factor of 5:1. This means that 5 times as much force as the working load limit has to be applied to the sling before it potentially fails. This means the wire rope slings have a Breaking Strength of up to 180,000 lbs and the round synthetic slings can withhold up to 700,000 lbs.

Wear - Working load limits are based on slings in brand new condition and a safety factor can help account for normal wear and tear until it is deemed unfit for further use.

Uneven loading - Slings are made up of either wires or fibers that must all share the weight of the load evenly. If any situation arises where the sling is bent or wrapped around an object, there is potential that some of the wires or fibers will be taking on a greater share of the load than others.

Visit Northern Strands website to use the sling tension calculator. The Northern Strands Sling Calculator has been designed to assist you in selecting slings with enough load carrying capacity for your lifting applications. It is your responsibility to assure that the slings you use are appropriate for your application. http://www.northernstrands.com/sling-calculator.aspx

Wire ropes are essential for safety purposes on construction sites and industrial workplaces. They are used to secure and transport extremely heavy pieces of equipment – so they must be strong enough to withstand substantial loads. This is why the wire rope safety factor is crucial.

You may have heard that it is always recommended to use wire ropes or slings with a higher breaking strength than the actual load. For instance, say that you need to move 50,000 lbs. with an overhead crane. You should generally use equipment with a working load limit that is rated for weight at least five times higher – or 250,000 lbs. in this case.

This recommendation is all thanks to the wire rope safety factor. This calculation is designed to help you determine important numbers, such as the minimum breaking strength and the working load limit of a wire rope.

The safety factor is a measurement of how strong of a force a wire rope can withstand before it breaks. It is commonly stated as a ratio, such as 5:1. This means that the wire rope can hold five times their Safe Work Load (SWL) before it will break.

So, if a 5:1 wire rope’s SWL is 10,000 lbs., the safety factor is 50,000 lbs. However, you would never want to place a load near 50,000 lbs. for wire rope safety reasons.

The safety factor rating of a wire rope is the calculation of the Minimum Break Strength (MBS) or the Minimum Breaking Load (MBL) compared to the highest absolute maximum load limit. It is crucial to use a wire rope with a high ratio to account for factors that could influence the weight of the load.

The Safe Working Load (SWL) is a measurement that is required by law to be clearly marked on all lifting devices – including hoists, lifting machines, and tackles. However, this is not visibly listed on wire ropes, so it is important to understand what this term means and how to calculate it.

The safe working load will change depending on the diameter of the wire rope and its weight per foot. Of course, the smaller the wire rope is, the lower its SWL will be. The SWL also changes depending on the safety factor ratio.

The margin of safety for wire ropes accounts for any unexpected extra loads to ensure the utmost safety for everyone involved. Every year there aredue to overhead crane accidents. Many of these deaths occur when a heavy load is dropped because the weight load limit was not properly calculated and the wire rope broke or slipped.

The margin of safety is a hazard control calculation that essentially accounts for worst-case scenarios. For instance, what if a strong gust of wind were to blow while a crane was lifting a load? Or what if the brakes slipped and the load dropped several feet unexpectedly? This is certainly a wire rope safety factor that must be considered.

Themargin of safety(also referred to as the factor of safety) measures the ultimate load or stress divided by theallowablestress. This helps to account for the applied tensile forces and stress thatcouldbe applied to the rope, causing it to inch closer to the breaking strength limit.

A proof test must be conducted on a wire rope or any other piece of rigging equipment before it is used for the first time.that a sample of a wire rope must be tested to ensure that it can safely hold one-fifth of the breaking load limit. The proof test ensures that the wire rope is not defective and can withstand the minimum weight load limit.

First, the wire rope and other lifting accessories (such as hooks or slings) are set up as needed for the particular task. Then weight or force is slowly added until it reaches the maximum allowable working load limit.

Some wire rope distributors will conduct proof loading tests before you purchase them. Be sure to investigate the criteria of these tests before purchasing, as some testing factors may need to be changed depending on your requirements.

When purchasing wire ropes for overhead lifting or other heavy-duty applications, understanding the safety dynamics and limits is critical. These terms can get confusing, but all of thesefactors serve an important purpose.

Our company has served as a wire rope distributor and industrial hardware supplier for many years. We know all there is to know about safety factors. We will help you find the exact wire ropes that will meet your requirements, no matter what project you have in mind.

Wire rope is often used in slings because of its strength, durability, abrasion resistance and ability to conform to the shape of the loads on which it is used. In addition, wire rope slings are able to lift hot materials.

Wire rope used in slings can be made of ropes with either Independent Wire Rope Core (IWRC) or a fiber-core. It should be noted that a sling manufactured with a fiber-core is usually more flexible but is less resistant to environmental damage. Conversely, a core that is made of a wire rope strand tends to have greater strength and is more resistant to heat damage.

Wire rope may be manufactured using different rope lays. The lay of a wire rope describes the direction the wires and strands are twisted during the construction of the rope. Most wire rope is right lay, regular lay. This type of rope has the widest range of applications. Wire rope slings may be made of other wire rope lays at the recommendation of the sling manufacturer or a qualified person.

Wire rope slings are made from various grades of wire rope, but the most common grades in use are Extra Improved Plow Steel (EIPS) and Extra Extra Improved Plow Steel (EEIPS). These wire ropes are manufactured and tested in accordance with ASTM guidelines. If other grades of wire rope are used, use them in accordance with the manufacturer"s recommendations and guidance.

When selecting a wire rope sling to give the best service, consider four characteristics: strength, ability to bend without distortion, ability to withstand abrasive wear, and ability to withstand abuse.

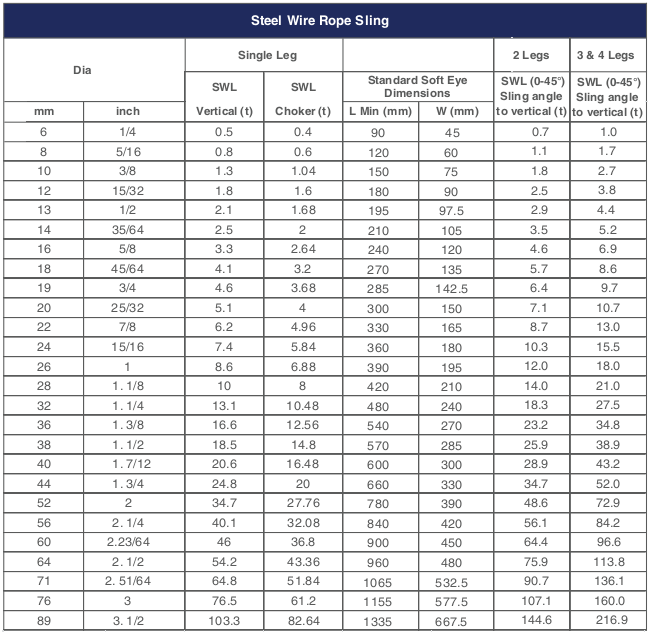

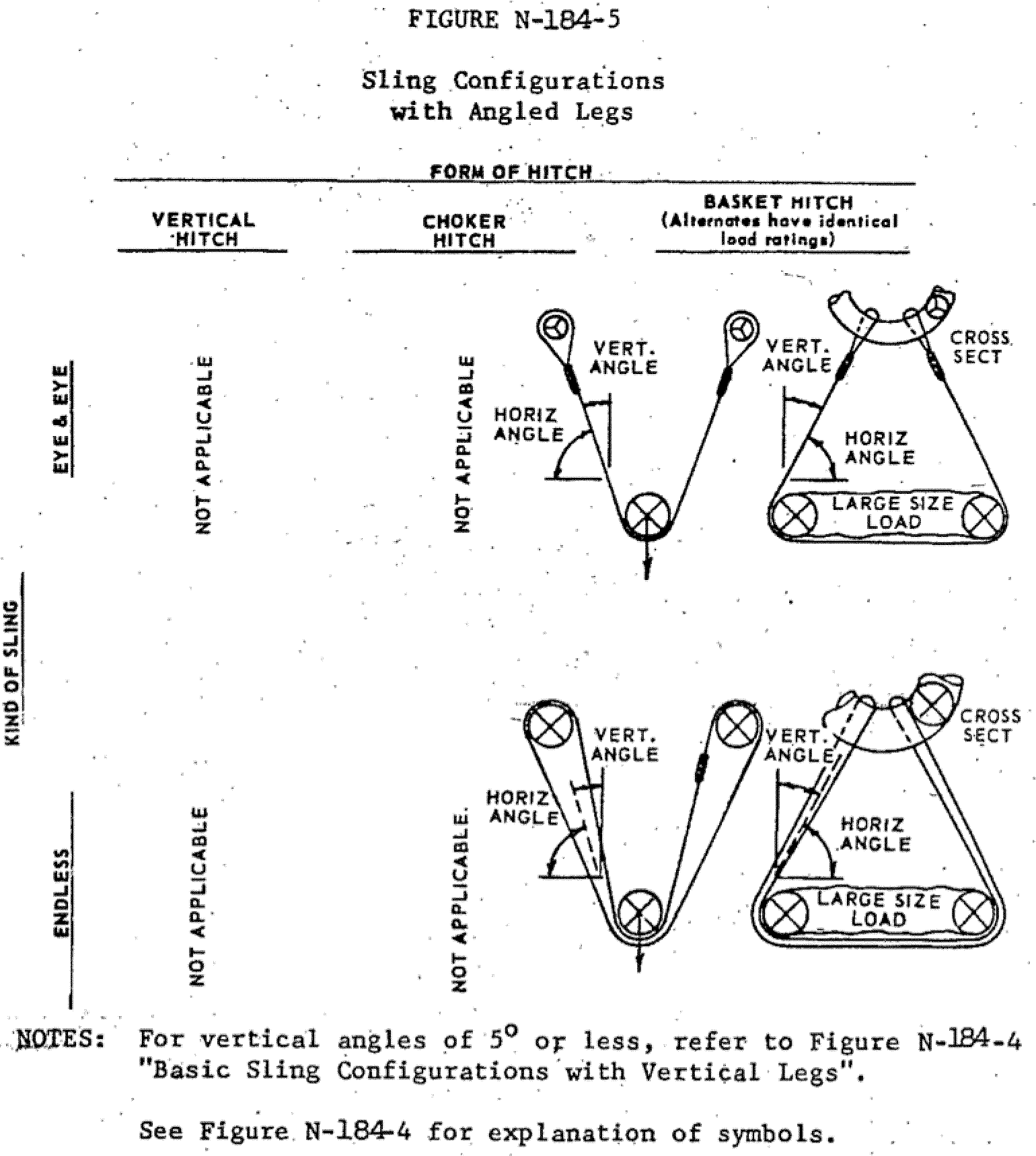

Rated loads (capacities) for single-leg vertical, choker, basket hitches, and two-, three-, and four-leg bridle slings for specific grades of wire rope slings are as shown in Tables 7 through 15.

Rated loads for a sling in a choker hitch are the values shown in Table 7, 9, 11, 13, 14, or 15, provided that the angle of the choke is 120 degrees or more (Fig. 2). Use the values in Fig. 2 or those from the sling manufacturer or a qualified person for angles of choke less than 120 degrees.

Ensure that slings made of rope with 6×19 and 6x37 classifications and cable slings have a minimum clear length of rope 10 times the component rope diameter between splices, sleeves, or end fittings unless approved by a qualified person,

Ensure that braided slings have a minimum clear length of rope 40 times the component rope diameter between the loops or end fittings unless approved by a qualified person,

Ensure that grommets and endless slings have a minimum circumferential length of 96 times the body diameter of the grommet or endless sling unless approved by a qualified person, and

Perform welding of handles or other accessories to end attachments, except covers to thimbles, before assembly of the sling. Ensure that welded end attachments are proof tested by the manufacturer or a qualified person. Retain the certificates of proof test and make them available for examination.

Do not use wire rope clips to fabricate wire rope slings, except where the application precludes the use of prefabricated slings and where the sling is designed for the specific application by a qualified person,

Although OSHA"s sling standard does not require you to make and maintain records of inspections, the ASME standard contains provisions on inspection records.[3]

Use damaged slings only after they are repaired, reconditioned, and proof tested by the sling manufacturer or a qualified person using the following criteria:

Ensure that wire rope slings have suitable characteristics for the type of load, hitch, and environment in which they will be used and that they are not used with loads in excess of the rated load capacities described in the appropriate tables. When D/d ratios (Fig. 4) are smaller than those listed in the tables, consult the sling manufacturer. Follow other safe operating practices, including:

Ensure that multiple-leg slings are selected according to Tables 7 through 15 when used at the specific angles given in the tables. Ensure that operations at other angles are limited to the rated load of the next lower angle given in the tables or calculated by a qualified person,

When D/d ratios (see Fig. 6) smaller than those cited in the tables are necessary, ensure that the rated load of the sling is decreased. Consult the sling manufacturer for specific data or refer to the WRTB (Wire Rope Technical Board) Wire Rope Sling Users Manual, and

Ensure that all portions of the human body are kept away from the areas between the sling and the load and between the sling and the crane or hoist hook,

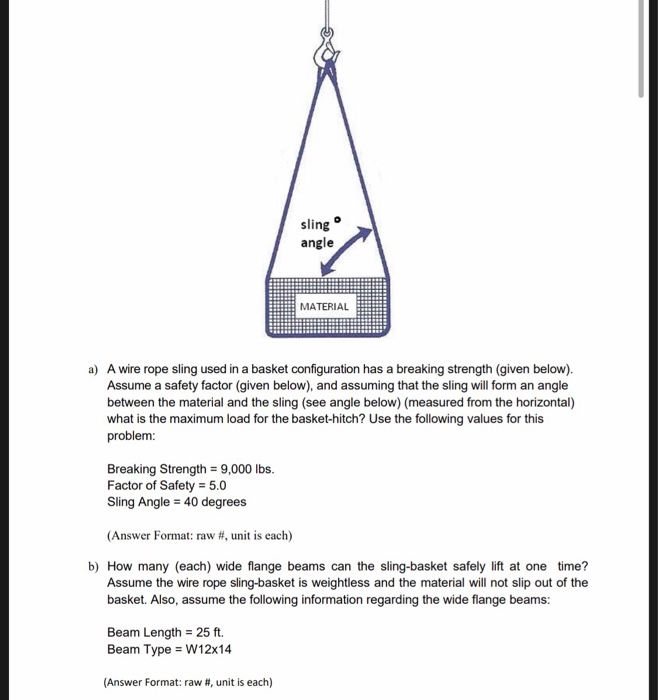

When using a basket hitch, ensure that the legs of the sling contain or support the load from the sides, above the center of gravity, so that the load remains under control,

Ensure that the load applied to the hook is centered in the base (bowl) of the hook to prevent point loading on the hook, unless the hook is designed for point loading,

Before initial use, ensure that all new swaged-socket, poured-socket, turnback-eye, mechanical joint grommets, and endless wire rope slings are proof tested by the sling manufacturer or a qualified person.

Permanently remove from service fiber-core wire rope slings of any grade if they are exposed to temperatures in excess of 180 degrees F (82 degrees C).

Follow the recommendations of the sling manufacturer when you use metallic-core wire rope slings of any grade at temperatures above 400 degrees F (204 degrees C) or below minus 40 degrees F (minus 40 degrees C).

Safe Working Load (SWL) is the limiting safety factor to lift and carry any load safely. It must be clearly marked on any lifting device (hoist, lifts, lifting machines, and lifting tackles).

“No lifting machine and no chain, rope or lifting tackle shall, except for the purpose of the test, be loaded beyond the safe working load which shall be plainly marked and duly entered in the prescribed register, and where this is not practicable, a table showing the safe working loads of every kind and size of lifting machine or chain, rope or lifting tackle in use shall be displayed in prominent positions on the premises”

Where the safe working load may be varied by the raising or lowering of the jib, a table indicating the SWL at the corresponding indication of the jib or corresponding radii of the load shall be attached with the jib-crane.

A table showing the SWL (Safe Working Load) of every kind and size of chain, rope, or lifting tackle in use, and in case of multiple slings, the SWLat different angles of the legs, shall be posted in the storeroom.

Lifting equipment should have a tally plate indicating the Safe Working Load. The tally plate also indicates the identification number which can be mentioned in the test certificate held by the user. It should also indicate the date of the last inspection.

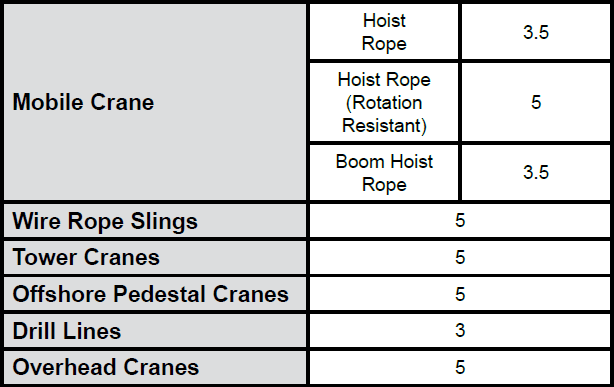

Safe Working Load (SWL) of any mobile crane depends on the operator’s skill, condition of the ground, boom length, the radius of rotation while lifting the load, the inclination of the boom to the vertical and outrigger blocked or free.

Safe Working Load is generally tabulated in the load chart of the crane. Sometimes, it is de-rated(decreased) due to defect in welding, bend in angle, bracing, etc., and condition of clutch, brake, etc. Modern cranes give a digital display of SWL, angle indicator, boom limit switch, and alarm for exceeding load.

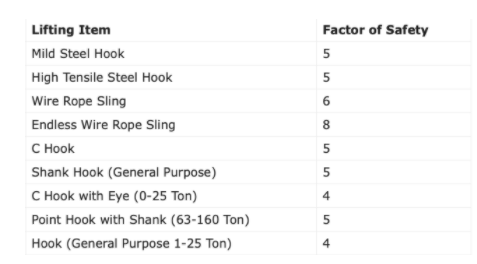

The factor of the safety (Safety Factor) of fiber ropes varies from 6 to 12 mm depending on the conditions of use. fiber rope less than 12 mm dia should not be used for a sling or apart of a lifting appliance. Their factor of safety (FS) varies with diameter. The factor of Safety for the hook, wire rope sling, chain, fiber rope, and belt are given in the table below:

Proof testing is the application of a load greater than the SWL (Safe Working Load) to detect defective workmanship, faulty weld or other inherent weaknesses. It is not a means to assess the SWLwhich should only be done by calculations and checked where necessary by suitable tests on samples.

The proof test is required as a part of ‘thorough examination’ u/r 60(1) of GFRand no lifting machine or tackle should be used for the first time without this proof test.

In general, the proof load applied to chains, rings, hooks, shackles, and similar gear is twice the SWL. It should be just under the yield stress for the material.

Chain, ring, hook, shackles, swivel, sling, individual components of the hoist, wire rope, chain, pulleys, hooks, eye bolts, pins, axles, bearings, turnbuckles & ringing screws.2 SWL

After the above proof test, the parts are to be examined thoroughly by a competent person for signs of cracks, fatigue, deformation, permanent stretch, etc.

Fiber rope and wire rope are widely used across the groundwater industry. Fiber rope is more commonly used in manual hoisting, such as raising up or lowering down tools. Wire rope is commonly used for mechanical hoisting operations.

The improper use of fiber rope or wire rope can result in serious incidents involving property damage, injuries, and death. Using the ropes as intended within their safe working load and maintaining them in good condition are critical in preventing rope failures.

Both types of rope include a combination of characteristics that give them certain performance traits depending on design, materials, and composition.

Wire rope is made of steel wires laid together to form a strand. These strands are laid together to form a rope, usually around a central core of either fiber or wire.

The number of strands, number of wires per strand, type of material, and nature of the core depend on the intended purpose of the wire rope. Wire rope that has many smaller wires and strands is more flexible than rope with larger-diameter wires and fewer strands. Wire rope used with sheaves and drums should have many strands to be flexible enough to bend around the sheaves and drums.

Wire ropes are classified by grouping the strands according to the number of wires per strand. The number of wires and the pattern defines the rope’s characteristics.

For example, a 6 × 7 rope indicates the rope is comprised of six strands and each individual strand is comprised of seven wires. This particular rope has large wires and is not very flexible but has good abrasion-resistant qualities. Whereas, a 6 × 19 rope has 19 wires per strand and thus is more flexible.

The more wires in a strand, the more flexible the wire rope. Likewise, the more strands in the rope, the more flexible the rope. However, the more strands in a rope and more wires in a strand, the less abrasion resistant.

Other important requirements to consider when selecting a wire rope are the breaking strength and “safe working load.” These values can be found with the use of a chart.

Most hoisting jobs use a safe working load based on a 5:1 safety factor of the wire rope’s breaking strength. However, this safety factor should be even higher if there is a possibility of injury or death from the rope breaking. For example, elevators are based on a 20:1 safety factor. Critical lifts with a danger to personnel should be calculated on a 10:1 safety factor.

Wire rope inspections are important checks on any type of rigging equipment. Wear, metal fatigue, abrasion, corrosion, kinks, and improper reeving are more important in dictating the life of a wire rope—more so than its breaking strength when new. Therefore, wire rope should be regularly inspected in accordance with OSHA and industry standards.

The frequency of inspections depends on the service conditions. Slings should be inspected each day before being used. Wire rope in continuous service or severe conditions should be inspected at least weekly and also observed during normal operation. For most other applications, wire rope should be inspected at least monthly.

Broken wires: Removing a wire rope from service due to broken wires depends on how the particular rope is being used. Finding one broken wire (or several widely spread) is usually not a problem. Regular breaks are a cause for concern and require a closer inspection. General guidelines for rope replacement due to broken wires are as follows:

Running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

Pendants or standing wire ropes: More than two broken wires in one rope lay located in the rope beyond end connections or more than one broken wire in a rope lay located at an end connection. Slings: Ten randomly distributed broken wires in one rope lay or five broken wires in one strand in one rope lay.

Rotation-resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters. Valley breaks:Wire ropes with any wire breaks in between two adjoining strands should be removed from service.

Abrasion:Wire rope winding over drums or through sheaves will wear. The rope should be replaced if the outer wire exceeds one-third of the original diameter.

Crushed strands: This condition is a result of too many layers of rope wrapped around a drum. There should be no more than two layers of wire rope on the drum, especially if the rope is a type with many small wires (such as 6 × 37). Crushing also occurs by cross winding, which is a result of poor winding procedures when the rope is wound in a pile in the middle of a drum.

Corrosion: This problem is difficult to evaluate and is also much more serious than normal wear. Corrosion will often start inside the rope before it shows on the outside. A lack of lubrication is usually the cause. Wire pitting or severe rusting should be cause for immediate replacement.

Kinks: Kinks are permanent distortions. After a wire rope is kinked, it is impossible to straighten the rope enough to return it to its original strength. If a rope cannot be unkinked by hand, it should be removed from service.

Electric arc:Wire rope that has been inadvertently (or purposely) used as a ground in welding or has been in contact with a live power line will have fused or annealed wires, and must be removed from service.

Metal fatigue: This is usually caused by bending stress from repeated passes over sheaves, or from vibration such as crane pendants. Fatigue fractures can be external or internal. A larger sheave or drum size, or using a more flexible rope, may increase the rope life.

Diameter reduction: Any noticeable reduction in diameter is a serious deterioration problem. A wire rope is measured across its diameter at its widest point. Diameter reduction could be caused by one fault or a combination of faults. Wire ropes should be replaced when the reduction in diameter is more than 5% from the nominal diameter.

Wire rope stretch: Any new wire rope will stretch when the initial load is applied. After the initial stretch and a slight stretching over time during normal wear, the rope will begin to stretch at a quicker rate, which means it is approaching time for replacement.

Bird caging: This is a torsional imbalance, which is a result of mistreatment such as pulling rope through tight sheaves, being wound on too small a drum, or sudden stops.

A wire rope is lubricated during the manufacturing process. This provides the rope with protection for a reasonable time if stored under proper conditions. When the wire rope is in service, the initial lubrication will not be enough to last the lifetime of the rope. Therefore, it is usually necessary to apply a lubricant to a wire rope under working conditions. A light mineral oil can be used for lubrication. Never use old crankcase oil.

Fiber ropes are preferred for some rigging applications because they are more pliant. However, they should be used only on light loads and must not be used on objects that have sharp edges capable of cutting the rope. Fiber ropes should also not be used where they will be exposed to high temperatures, severe abrasion, or acids.

The choice of rope depends on its application. Manila is a natural fiber and has relatively high elasticity, strength, and resistance to wear and deterioration. Manila rope is generally the most common natural fiber rope used because of its quality and relative strength.

The principal synthetic fiber used for rope is nylon, which has a tensile strength nearly three times that of manila. The advantages of nylon rope are it is waterproof and has the ability to stretch, absorb shocks, and resume its normal length. Nylon also has better resistance against abrasion, rot, decay, and fungus growth as compared to natural fibers.

Avoid dragging rope through sand or dirt or pulling over sharp edges. Sand or grit between the fibers of the rope cuts the fibers and reduces its strength.

The outside appearance of fiber rope is not a good indication of its internal condition. The rope softens with use. Dampness, heavy strain, fraying and breaking of strands, and chafing on rough edges all weaken the rope considerably.

Overloading a rope may cause it to break. For this reason, fiber ropes should be inspected at regular intervals to determine their condition. Untwist the strands slightly to open the rope so the inside can be examined.

Mildewed rope has a musty odor and the inner fibers of the strands have a dark, stained appearance. Broken strands or broken yarns ordinarily are easy to identify. Dirt and sawdustlike material inside the rope, caused by chafing, indicate damage. In rope having a central core, the core should not break away in small pieces upon examination. If this happens, it indicates the rope has been overstrained.

To prevent rope failures and minimize deterioration and damage: select the right rope for the job, inspect regularly, use as intended, and properly store and maintain.

To help meet your professional needs, this article covers skills and competencies found in DACUM charts for drillers and pump installers. DO refers to the drilling chart. The letter and number immediately following is the skill on the chart covered by the article. This article covers:

Examine slings for wear, fatigue, crushed or broken wires, kinking, ballooning or "bird-caging", heat damage, etc. Check both before and after using slings to detect any damage or defects. See Hoist wire rope for more inspection tips.

Alloy Steel-chain slings differ from wire-rope slings in that components using wire are replaced by link chain. Other sling components are similar. Chain slings are more rugged and flexible, but less shock resistant than wire-rope or braided slings. This size is measured by the link stock.

However, as with ANY wire rope sling, when using a chain link sling in ANY Marine related construction activity…Safety is of the upmost of importance.

When exposed to service temperatures more than 600 degrees F (315 degrees C), one should reduce the working load limits in accordance with the chain manufacturer’s recommendations.

Lastly, extremely low temperatures (less than 0 degrees F) may cause brittle fractures. Under these conditions, sudden loading should be avoided, and the load should be lifted a very short distance while the chains are carefully inspected.

Chains should be stored in racks or in designated locations when not in use. Chains should never be stored in damp or dirty places, nor in places exposed to the weather. For long-term storage, they should receive a coating of oil. Should one have any empty chains, the “Ends” should be hooked onto the hoist hook or bull ring.

Chains should not be lubricated when in use because this might make them dangerous to handle. Chains should be cleaned periodically to remove abrasive grit and to facilitate inspection.

The total load that can be lifted safely with steel-chain slings depends on how the slings are attached to the load. If all legs of a steel-chain sling are hooked back into the master link, the safe-load capacity of the whole sling may be increased by 100 percent if the capacity of the master link is not exceeded.

The safe-load level of any chain sling is a function of three basic factors: size and number of legs, condition of chain and other components. Let alone the sling angle between legs and horizontal. One should note the dramatic drop in load capacity when a “Double Chain Link Sling” is positioned in an extremely low hook height and wide leg spreads.

One should keep in mind that hooks, rings, oblong links, pear shaped links, welded or mechanical coupling links and other attachments should always have a rated capacity at least equal to that of the alloy steel chain with which they are used or the sling should NOT be used in excess of the rated capacity of the weakest component.

In ending, upon the return to the shop ANY chain link slings coming off of ANY Project no matter how short the job was, one should always do the following, at a MINIMUM, prior to storing…said Slings.

SWL, NWL, MBS — all of the acronyms can get very confusing. Don’t fret – we’re here to clear things up when it comes to safe working load limits and the terms associated with it.

Safe Working Load (SWL) sometimes stated as the Normal Working Load (NWL) is the mass or force that a piece of lifting equipment, lifting device or accessory can safely utilize to lift, suspend, or lower a mass without fear of breaking. Usually marked on the equipment by the manufacturer and is often 1/5 of the Minimum Breaking Strength (MBS) although other fractions may be used such as 1/4, 1/6 and 1/10.[1][2][3]

Other synonyms include Working Load Limit (WLL), which is the maximum working load designed by the manufacturer. This load represents a force that is much less than that required to make the lifting equipment fail or yield, also known as the Minimum Breaking Load (MBL). SWL or WLL are calculated by dividing MBL by a safety factor (SF). An example of this would be a chain that has a MBL of 2000 lbf (8.89 kN) would have a SWL or WLL of 400 lbf (1.78 kN) if a safety factor of 5 (5:1, 5 to 1, or 1/5) is used.

Here at Industrial Rope Supply, we are not only committed to providing you with a quality product, but also with all the information needed to insure safety comes first on every job. Have safety questions on a product purchased from us? Contact us today and we’ll be happy to talk you through and/or provide you with the safety materials needed.

A lifting sling has a purpose, which is to move bulky, large, and heavy loads. Slings are used because lifting without them can be difficult and sometimes not even possible. Lifting slings makes a direct connection between the load and the lifting equipment being used. Although these slings are used to make lifting more accessible, they can make lifting more dangerous if the straps are misused. Anytime a sling is used for lifting, it is essential that users take concrete steps and precautions.

A lifting sling should be inspected before every use (including the first time). A damaged sling can break while lifting loads. Dropping loads can harm people, products, and the environment.

Different sling styles and sizes exist, and so not all can be used interchangeably. When it comes to lifting tools, you need the right sling for the job. Webbing slings have a full surface, which can help to protect larger loads.

Never exceed the working limit for a load. All lifting devices, like cranes and hoists, are rated for the weight they can carry. Lifting slings are calculated similarly. If you are lifting an object that is roughly 18 tonnes, you will want to acquire slings that have a WLL (working load limit) of 20 tonnes.

Workers involved in hoisting and rigging must exercise care when selecting and using slings. The selection of slings should be based upon the size and type of the load, and the environmental conditions of the workplace. Slings should be visually inspected before each use to ensure their effectiveness. Improper use of hoisting equipment, including slings, may result in overloading, excessive speed (e.g., taking up slack with a sudden jerk, shock loading), or sudden acceleration or deceleration of equipment.

Factors to consider when choosing the best sling for the job include size, weight, shape, temperature, and sensitivity of the material being moved, and the environmental conditions under which the sling will be used. The following guide may be useful in selecting the appropriate sling:

Alloy steel chains are strong and able to adapt to the shape of the load. Care should be taken when using chain slings because sudden shocks will damage them. This may result in sling failure and possible injury to workers or damage to the load.

Chain slings must be visually inspected prior to use. During the inspection, pay particular attention to any stretching, nicks, gouges, and wear in excess of the allowances made by the manufacturer. These signs indicate that the sling may be unsafe and must be removed from service immediately.

Wire rope is composed of individual wires that have been twisted to form strands. Strands are then twisted to form a wire rope. When wire rope has a fiber core, it is usually more flexible but less resistant to environmental damage. Conversely, wire rope with a core that is made of a wire rope strand tends to have greater strength and is more resistant to heat damage.

When selecting a wire rope sling to give the best service, there are four characteristics to consider: strength, ability to withstand fatigue (e.g., to bend without distortion), ability to withstand abrasive wear, and ability to withstand abuse.

Strength – Strength of wire rope is a function of its size (e.g., diameter of the rope), grade, and construction, and must be sufficient to accommodate the maximum applied load.

Fatigue (Bending without Failure) – Fatigue failure of wire rope is caused by the development of small cracks during small radius bends. The best means for preventing fatigue failure of wire rope slings is to use blocking or padding to increase the bend radius.

Abrasive Wear – The ability of wire rope to withstand abrasion is determined by the size and number of the individual wires used to make up the rope. Smaller wires bend more readily and offer greater flexibility, but are less able to withstand abrasion. Larger wires are less flexible, but withstand abrasion better.

Abuse – Misuse or abuse of wire rope slings will result in their failure long before any other factor. Abuse can lead to serious structural damage, resulting in kinks or bird caging. (In bird caging, the wire rope strands are forcibly untwisted and become spread outwards.) To prevent injuries to workers and prolong the life of the sling, strictly adhered to safe and proper use of wire rope slings.

Wire rope slings must be visually inspected before use. Slings with excessive broken wires, severe corrosion, localized wear, damage to end-fittings (e.g., hooks, rings, links, or collars), or damage to the rope structure (e.g., kinks, bird caging, distortion) must be removed from service and discarded.

Fiber rope and synthetic web slings are used primarily for temporary work, such as construction or painting, and are the best choice for use on expensive loads, highly finished or fragile parts, and delicate equipment.

Fiber rope slings deteriorate on contact with acids and caustics and, therefore, must not be used around these substances. Fiber rope slings that exhibit cuts, gouges, worn surface areas, brittle or discolored fibers, melting, or charring must be discarded. A buildup of powder-like sawdust on the inside of a fiber rope indicates excessive internal wear and that the sling is unsafe. Finally, if the rope fibers separate easily when scratched with a fingernail, it indicates that the sling has suffered some kind of chemical damage and should be discarded.

Shock Absorbency - Regardless of the construction material, shock loading (e.g., excessive speed, rapid acceleration or deceleration) of slings should be minimized. However, it should be noted that synthetic web slings can absorb heavy shocks without damage.

Economy and Long Life – Synthetic web slings have a low initial cost and a long service life. They are unaffected by mildew, rot, or bacteria, resist some chemical action, and have excellent abrasion resistance.

Synthetic web slings must be inspected before use and should be removed from service if found to have acid or caustic burns, melting or charring of any part of the surface, snags, tears, or cuts, broken stitches, distorted fittings, or wear or elongation beyond the manufacturer’s specifications.

Editor’s note: NATE’sTowerTimesran an article in this month’s issue they have invitedInside Towersto share with our readers. The author is Caleb Messer with help from the members of the PAN Advisory Group: Craig Snyder, Jeremy Buckles, John Erichsen, Ken Hill, Michelle Kang, Marianna Kramarikova, and Scott Kisting. Due to the length and detail of the article, we will present it in two parts.(part two will continue in tomorrow’s issue)

At the time of writing, there are multiple rope and rigging subcommittees that are currently working to improve training and communications, refine standards and best practices, and consult equipment manufacturers for product innovations. These committees are made up entirely of volunteers that are investing their time and talent to ensure the workforce has access to the knowledge that, when applied, will ensure that the industry becomes a safer place.

This article is intended to continue this momentum, and complements the recent document about the basics of rope selection, characteristics, and usage. Improved familiarity with existing regulations, standards, and best practices for rigging with synthetic rope should serve as a good starting point in the development of training, sound operating procedures, and equipment selection. This document will address the most common pieces of equipment used as part of a rigging system in telecommunications work: capstan hoists, synthetic rope, blocks, shackles, and synthetic slings.

Please note, this article is not intended to be an all-inclusive list and does not attempt to cover all equipment, jobsite-safety, or rigging fundamentals.

For means and methods, the ANSI/ASSP A10.48 Standard should be consulted along with other standards and regulations that may apply to the specific work environment.

A chain is only as strong as its weakest link. The same is true for a rigging system. The ANSI/ASSP A10.48 and ASME B30 Standards do an excellent job of requiring and clarifying the Working Load Limit (WLL) of the system components. Information about the WLL requirements of each component and the source of those requirements is below. Industry best practices are to ensure the WLL of each of the components below exceeds the maximum rated capacity of the hoist/ winch which will be used in a lift.

It should be noted that establishing the WLL for synthetic rope used in our industry for hoisting applications is specifically addressed in the ANSI/ASSP A10.48 due to the simple fact synthetic ropes are not currently addressed within other recognized consensus standards for this particular application. It is therefore essential for those working with synthetic ropes to be trained and knowledgeable on the requirements for properly determining the applicable WLL using a minimum gross 10:1 safety factor applied to the rope manufacturer’s published minimum breaking strength (MBS) which builds in efficiency losses up to 50% for typical knot terminations and wrap efficiencies thus netting an effective safety factor no less than 5:1.

Synthetic slings require a minimum 5:1 safety factor in accordance with the ASME B30.9 with the rated WLL based upon the type of sling hitch. Shackles Standard shackles used in our industry require a minimum 5:1 safety factor in accordance with the ASME B30.26. Blocks Rigging blocks require a minimum 4:1 safety factor in accordance with the ASME B30.26.

The establishment of minimum safety factors for each of the rigging components is only beneficial if those in the field fully understand the loading demands and are able to clearly discern the rated capacity for each component within the system. As a result, the standards which dictate the safety factors have also generated labeling requirements which are intended to eliminate accidental overloads. Below are the labeling requirements for each of the components. One additional note – the labels must be legible throughout the service life of the product. If a label becomes illegible or is removed from the product, it must be removed from service.

The ANSI/ASSP A10.48 doesn’t specify labeling requirements for rope, but does require that “Synthetic rope shall not be used unless there is documentation available verifying its minimum breaking strength (MBS).” The commonly accepted best practice at this point is that the rope is tagged with the MBS, production date, original length, and diameter.

ASME B30.9 requires that synthetic slings be marked with the manufacturer’s name or trademark, material composition of the sling, manufacturer’s code or stock number, and the rated WLL in at least one hitch type; although, standard practice is to clearly label the WLL for vertical, choked, and basket hitch configurations.

ASME B30.26 mandates that the shackle body be durably marked with the name or trademark of the manufacturer, the rated WLL, and the size. Additionally, the shackle pin must be labeled with the name or trademark of the manufacturer, and the grade, material type, rigging blocks used in our industry with labeled compatible rope sizes of ½” and an inner sheave diameter slightly below 3” still meet the minimum 6:1 ratio when used with double-braid and kernmantle ropes.

With regards to the sheave groove profile, the ANSI/ASSP A10.48 states, “The size of the synthetic rope shall be compatible with the sheave groove in the rooster head and rigging blocks. Groove widths shall be greater than or equal to 1.10 times the rope diameter.” This requirement is one of the primary reasons why blocks may be categorized as either wire rope or synthetic rope blocks.

The narrower groove on the sheave of wire rope blocks introduces significant risk of rope milking or binding as it passes over the block. The wider groove enables the rope to spread over the sheave as it passes over the block enabling a smooth transition.

8613371530291

8613371530291